Patents

Literature

56 results about "Diagonal Axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The shape of a diagonal mirror is an ellipse (oval), the shape a circle becomes when it is tilted back at an angle. Ellipses have a major (long) and minor (short) axis, which is the longest and shortest diameters of the ellipse. By convention, 45° mirror diagonals are specified by their minor axis size.

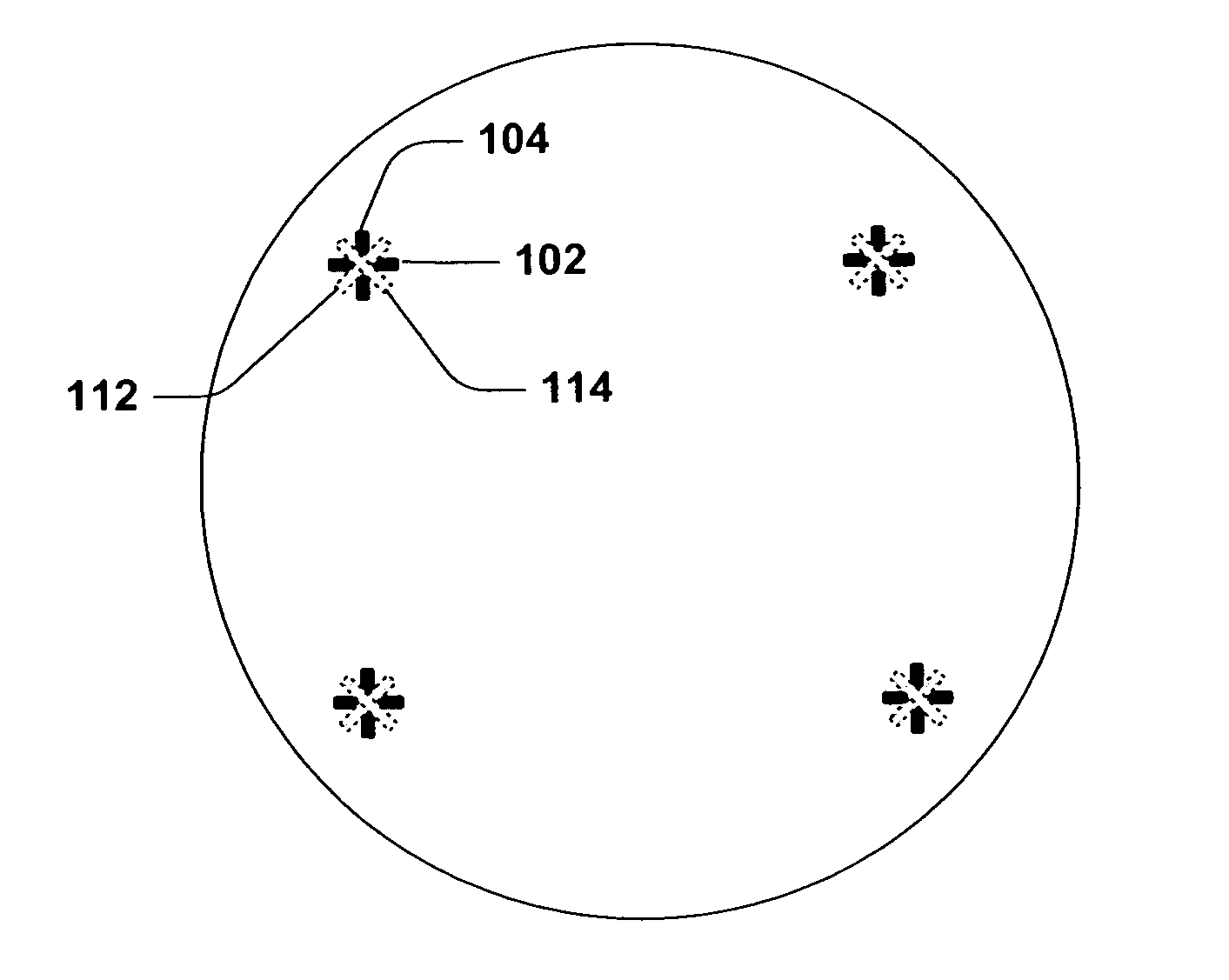

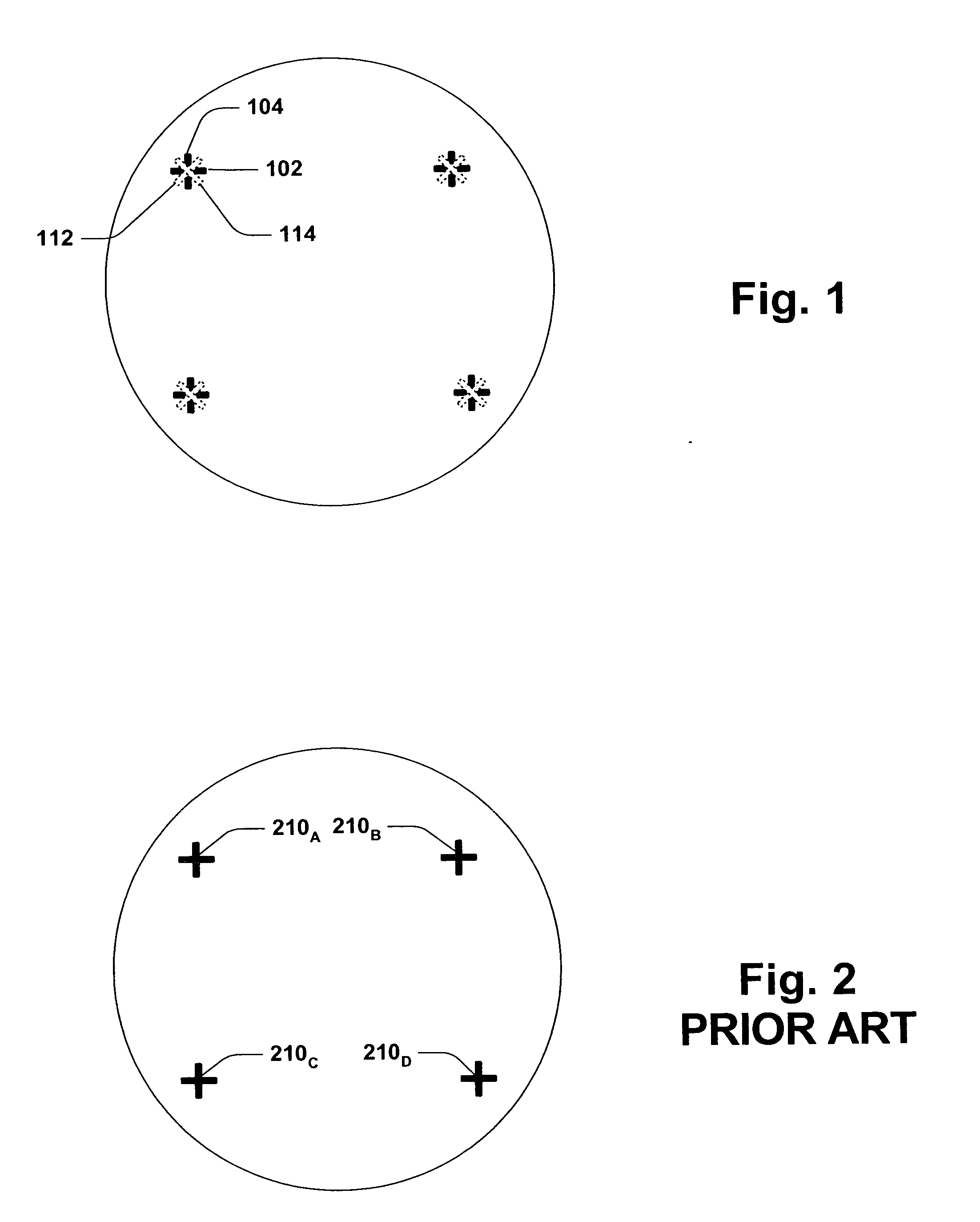

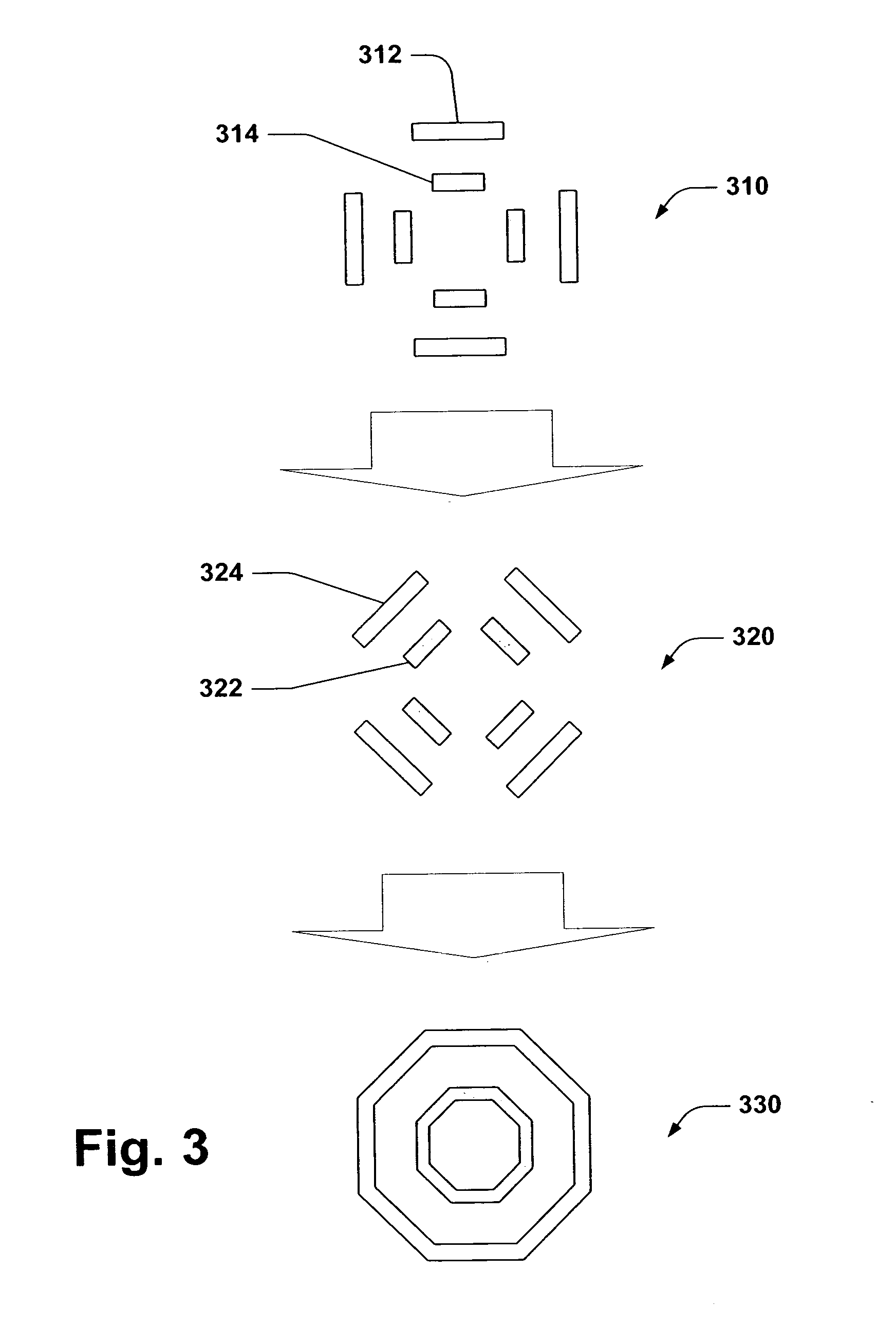

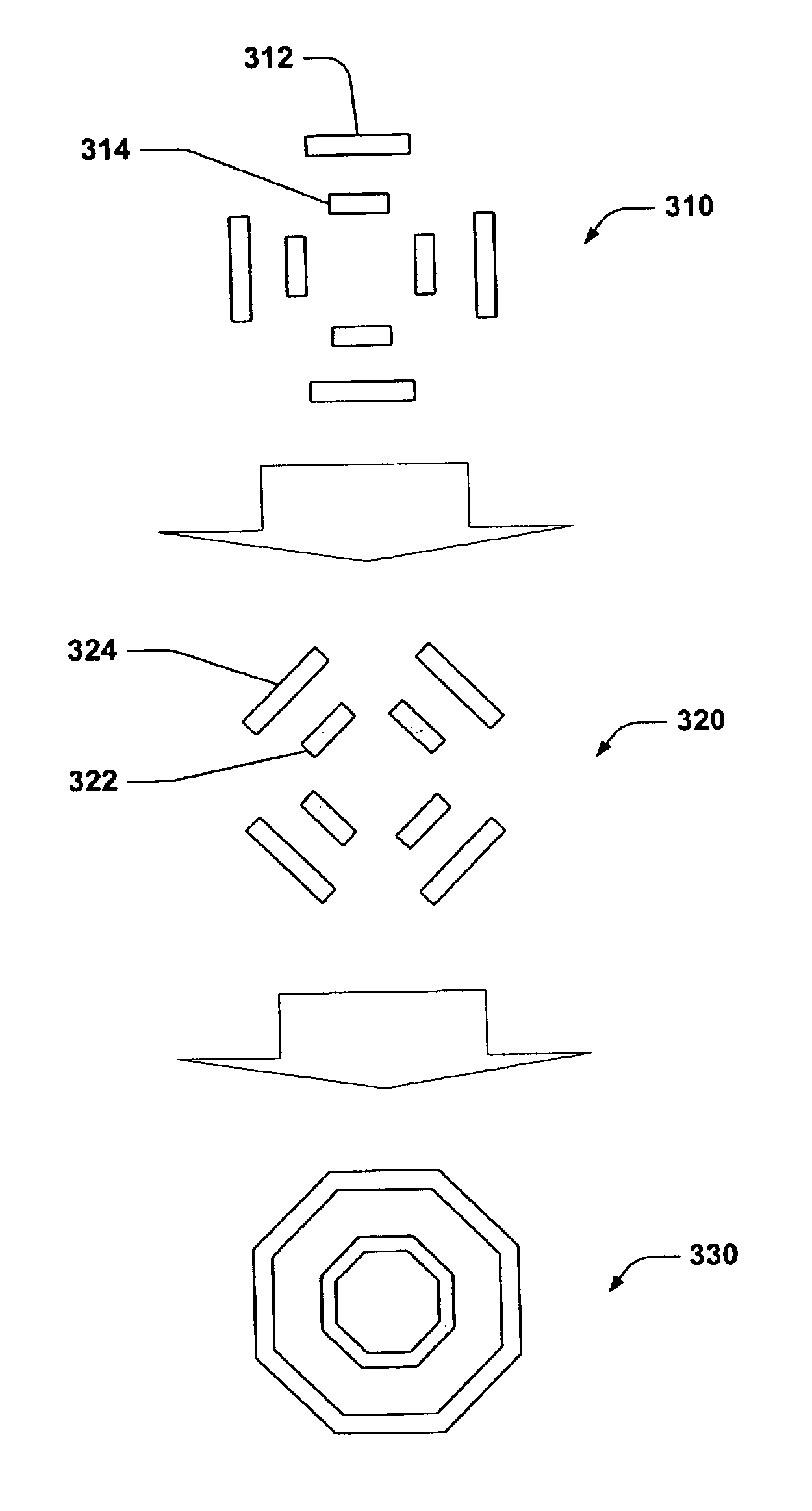

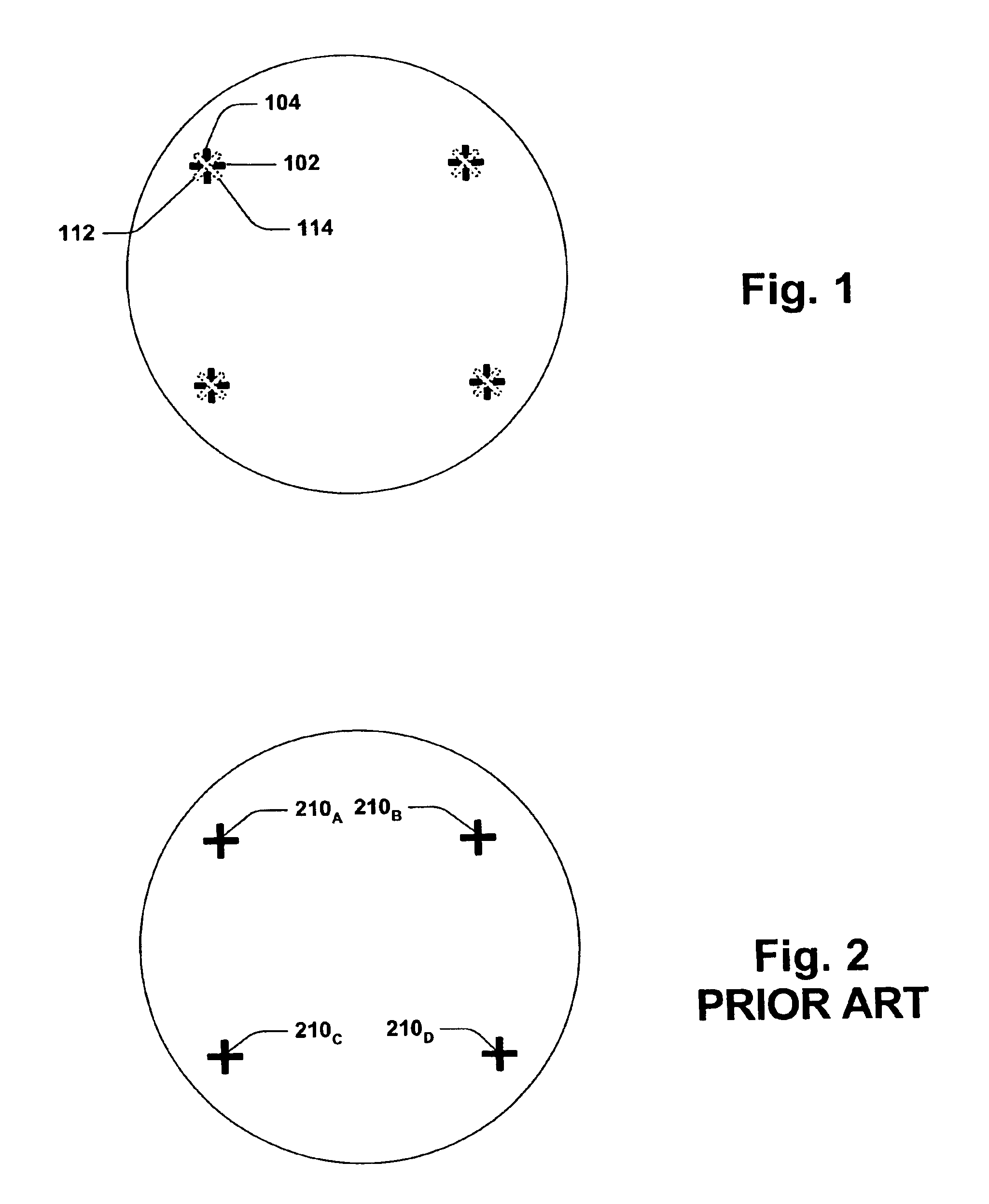

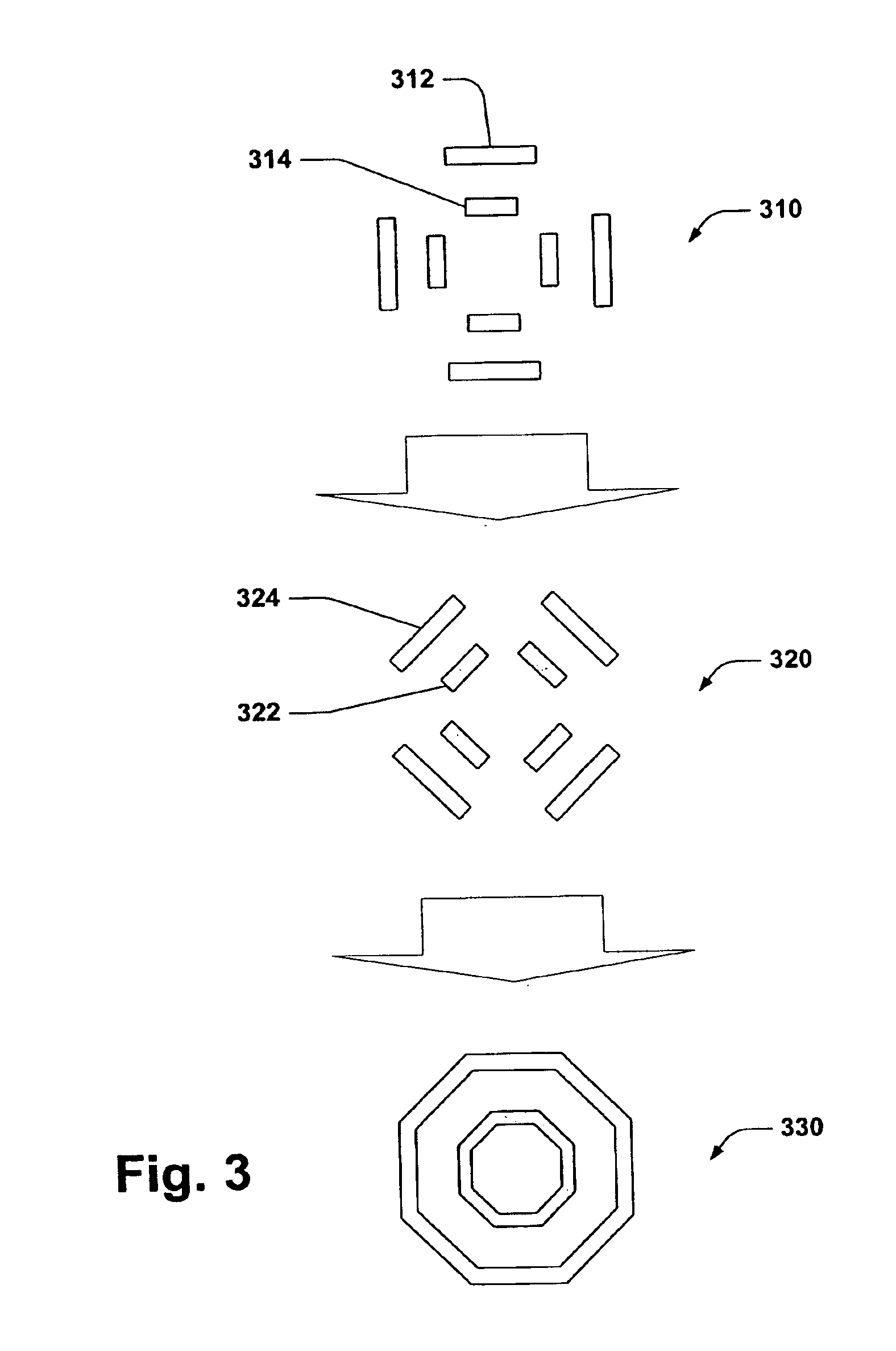

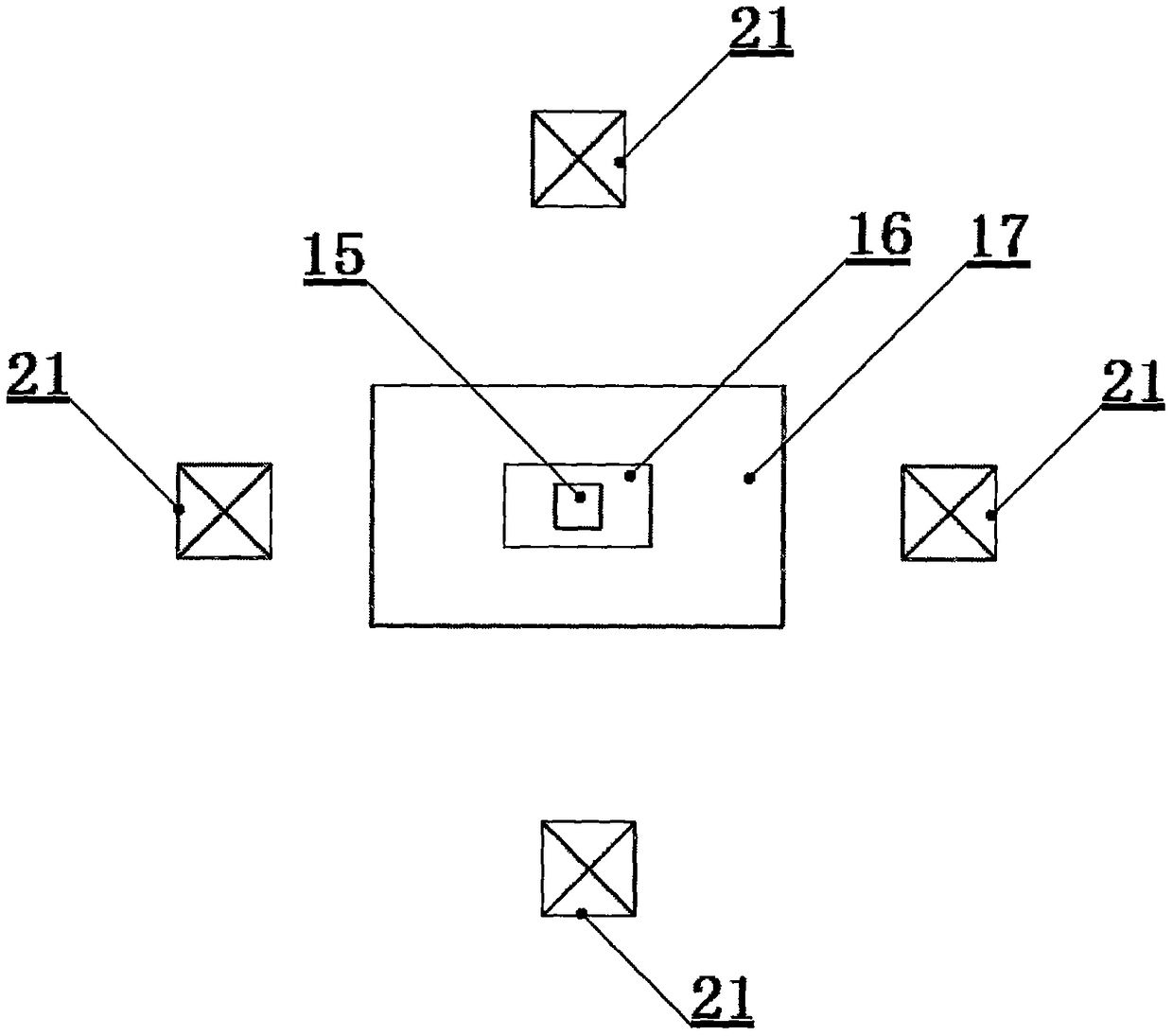

Pattern recognition and metrology structure for an x-initiative layout design

InactiveUS20050048741A1Easy to checkImprove accuracyNavigation by terrestrial meansSemiconductor/solid-state device manufacturingMetrologyDiagonal

The present invention relates to inspection methods and systems utilized to provide a best means for inspection of a wafer. The methods and systems include wafer-to-reticle alignment, layer-to-layer alignment and wafer surface feature inspection. The wafer-to-reticle alignment is improved by the addition of diagonal lines to existing alignment marks to decrease the intersection size and corresponding area that a desired point can reside. Layer-to-layer alignment is improved in a similar manner by the addition of oblique and / or non-linear line segments to existing overlay targets. Also, providing for wafer surface inspection in a multitude of desired diagonal axes allows for more accurate feature measurement.

Owner:GLOBALFOUNDRIES INC

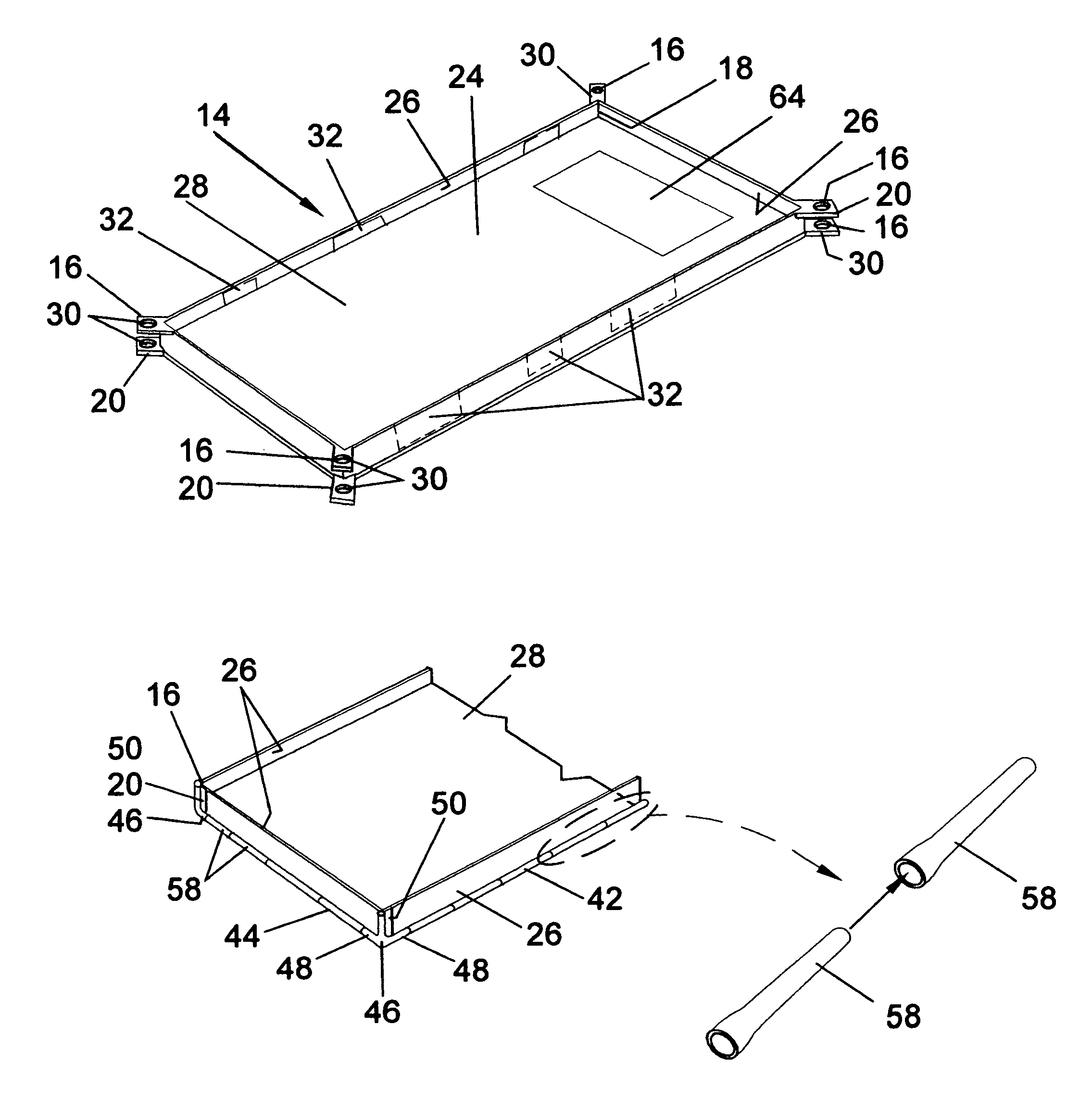

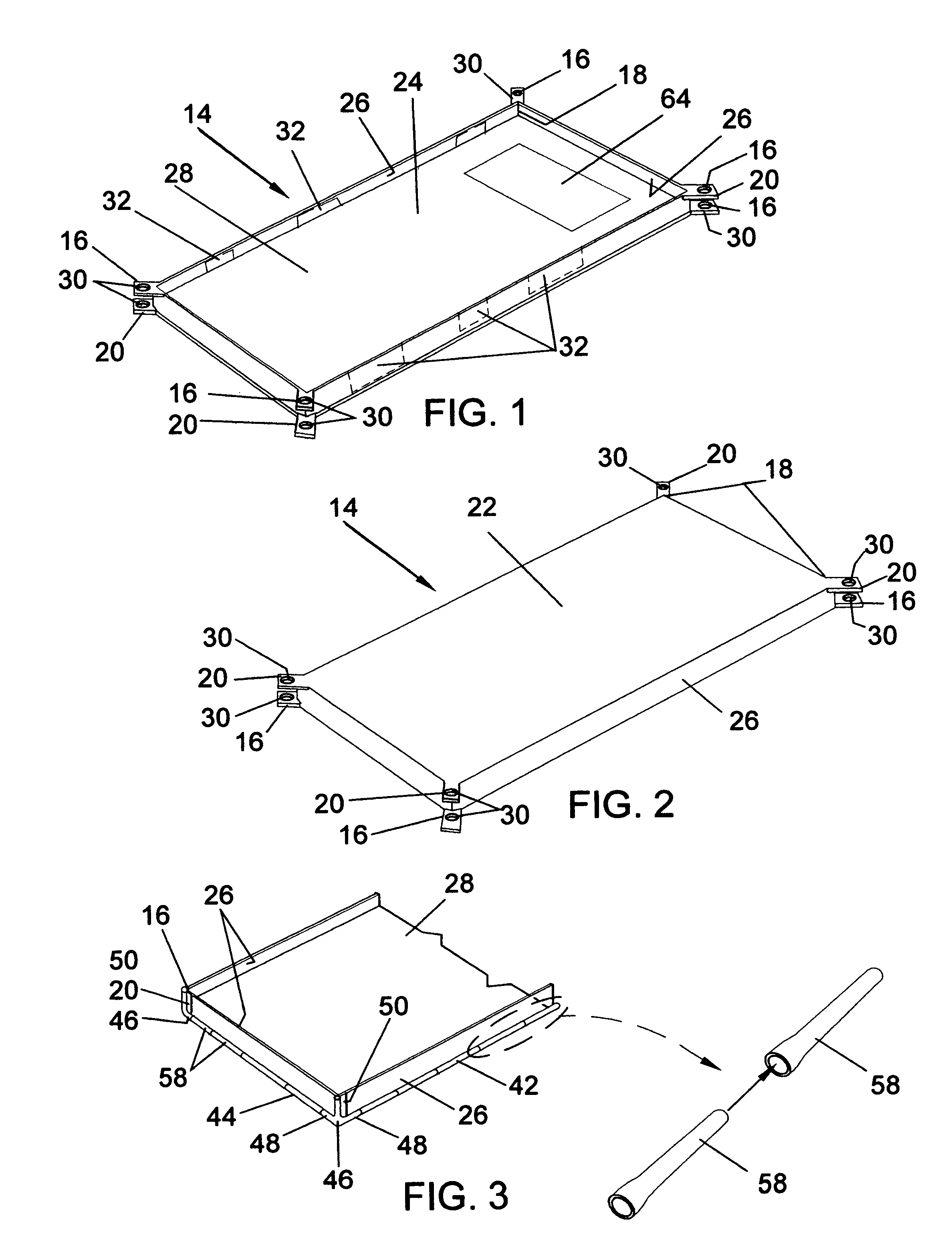

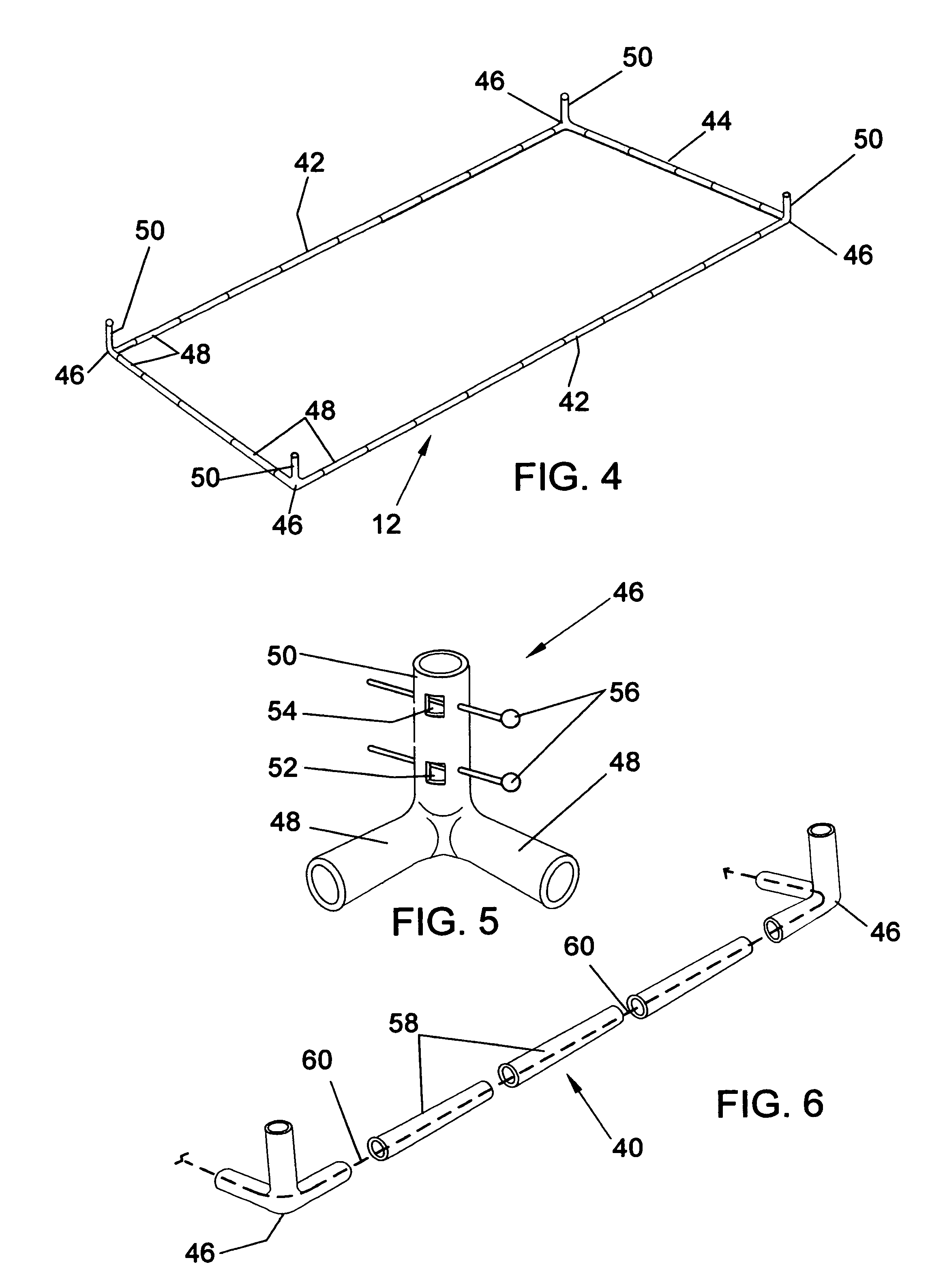

Beach blanket assembly

The present invention may be used as a beach blanket. A blanket may be generally rectangular in shape with a tab attached at each corner. There may also be an interior tab attached on a bottom surface approximately on a corner diagonal axis adjacent each of the tabs. A frame may be generally an open rectangular shape with two opposed spaced apart longitudinal tubular members attached to two opposed and spaced apart lateral tubular members by four corner members. The corner members may have two orthogonal horizontal arms and an orthogonal vertical arm wherein each of the vertical arms have a lower attachment element and an upper attachment element for attachment of one of the tabs and one of the interior tabs.

Owner:WEINER MITCH

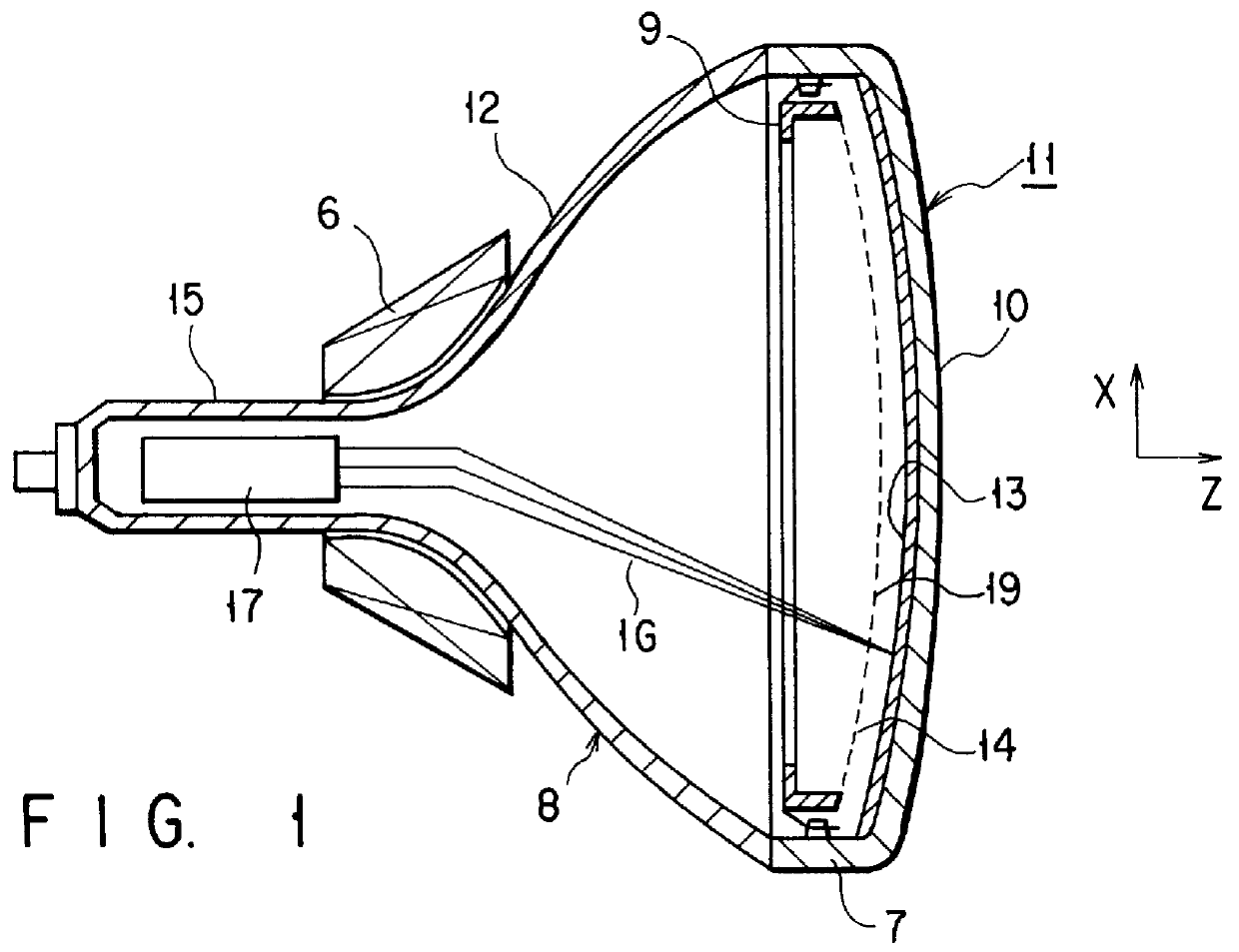

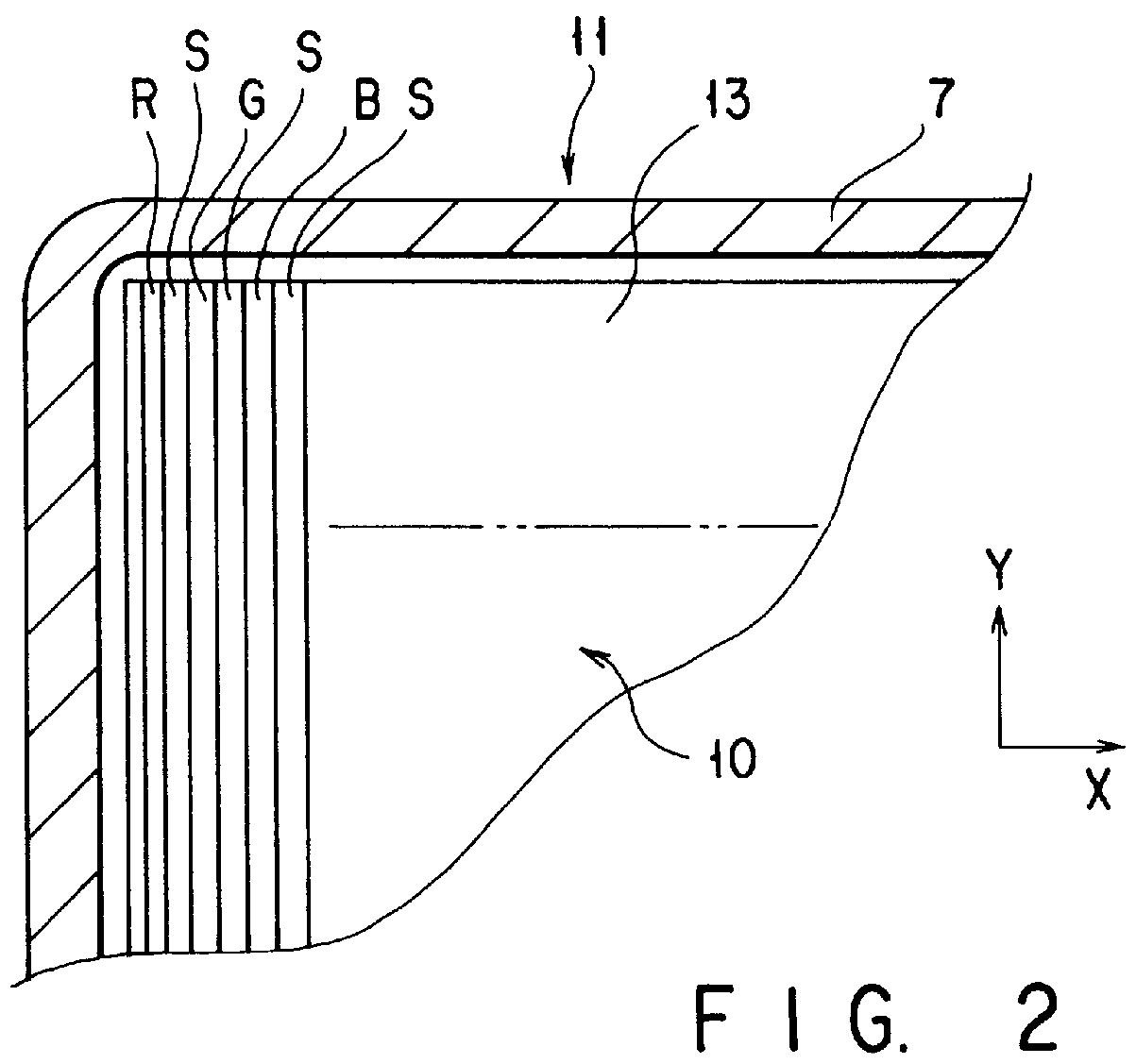

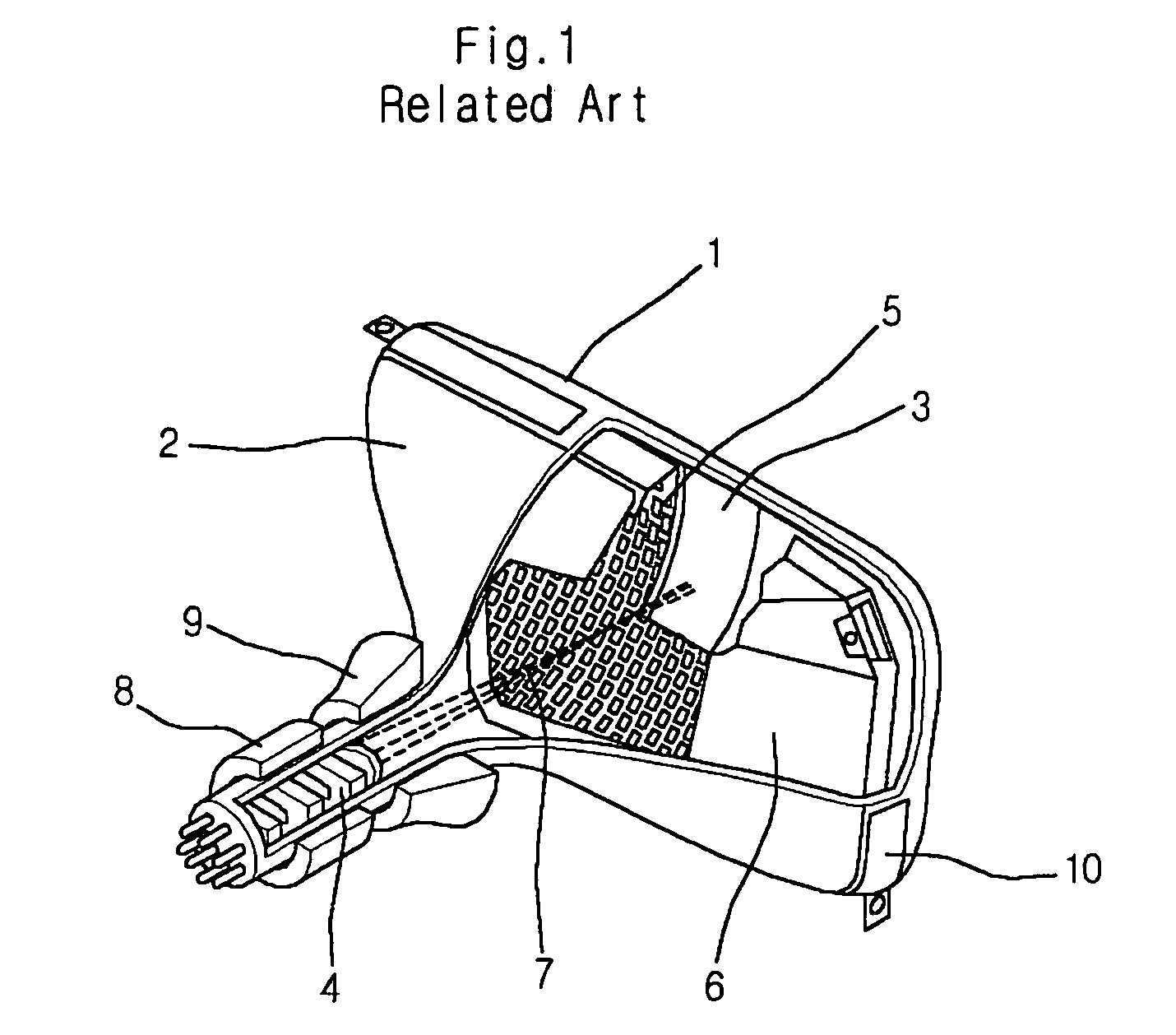

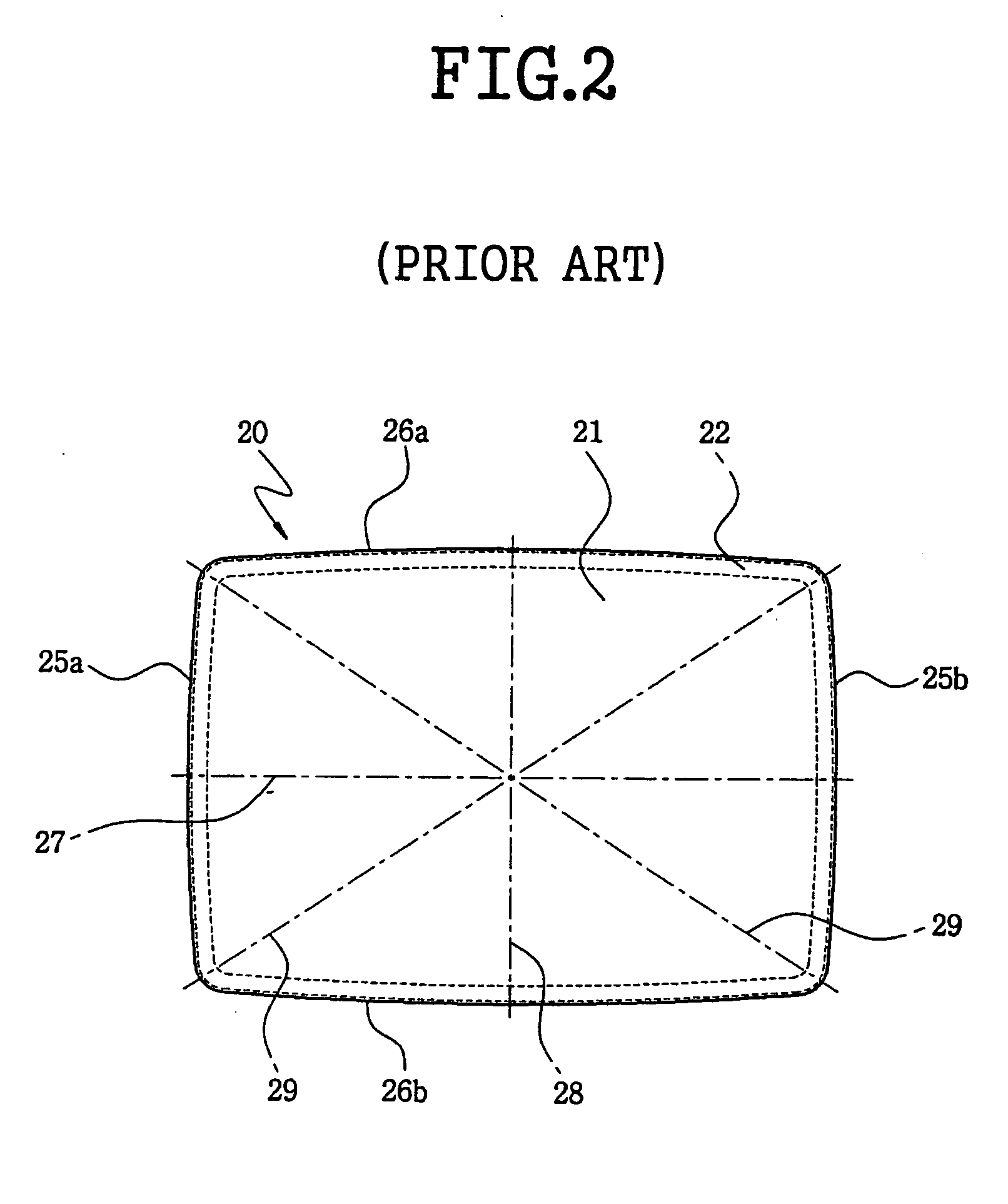

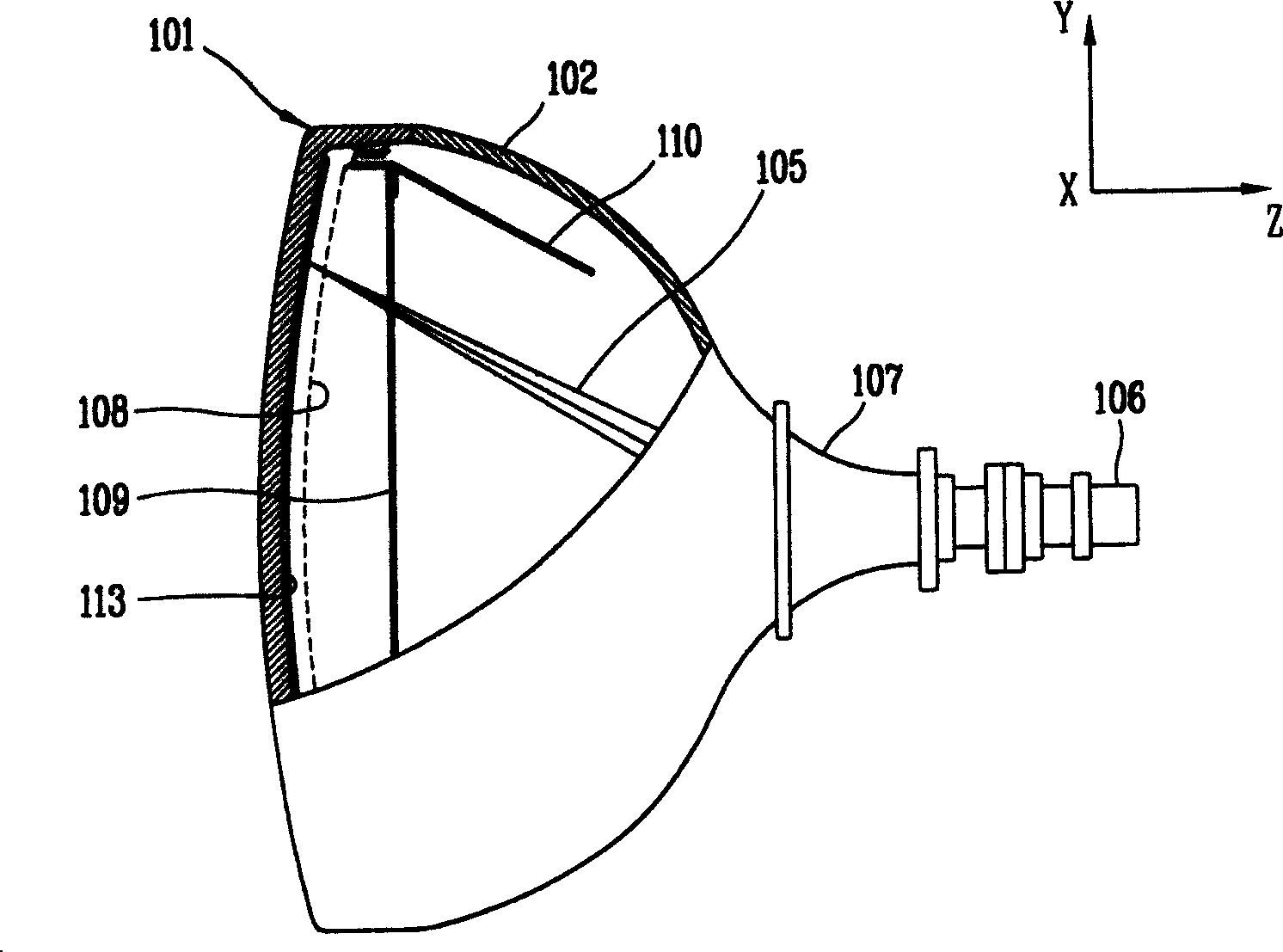

Color cathode ray tube

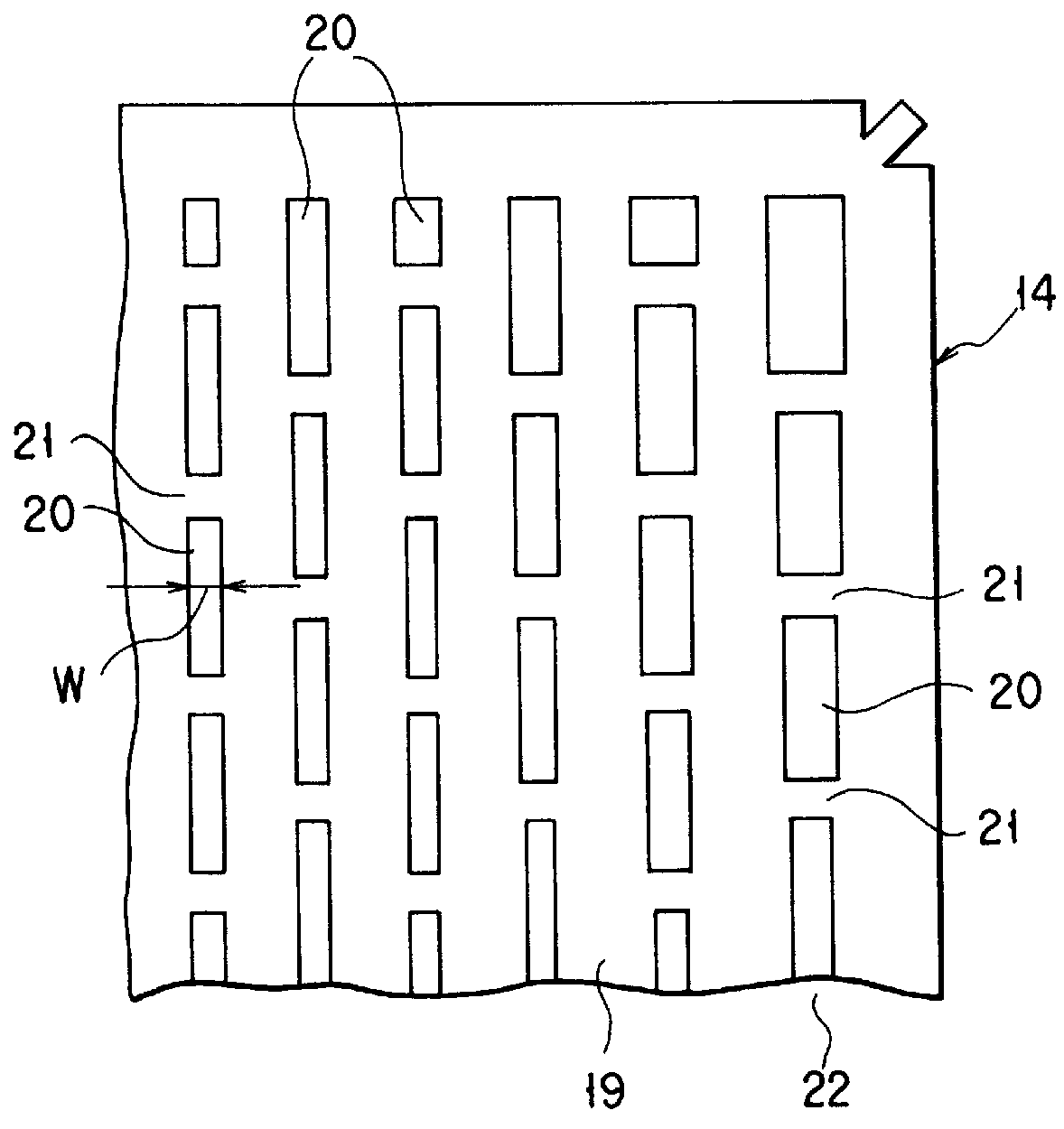

InactiveUS6124668AHigh color purityElectrode and associated part arrangementsRectangular apertureEffective surface

PCT No. PCT / JP97 / 03994 Sec. 371 Date Jul. 2, 1998 Sec. 102(e) Date Jul. 2, 1998 PCT Filed Oct. 31, 1997 PCT Pub. No. WO98 / 20514 PCT Pub. Date May 14, 1998A shadow mask disposed to face a phosphor screen of a cathode ray tube includes a substantially rectangular effective surface on which a number of substantially rectangular apertures are formed. The effective surface has horizontal and vertical axes which perpendicularly cross in the center thereof and diagonal axes passing through the center. The apertures are arranged to form a plurality of vertical rows of apertures extending in the direction of the vertical axis. Each of the vertical rows of apertures includes a plurality of apertures arranged in the direction of the vertical axis with a bridge portion being interposed between two adjacent apertures, and those vertical rows of apertures are arranged in the direction of the horizontal axis at a predetermined pitch. The width W of the apertures in the direction of the horizontal axis is formed so as to gradually increase from that of the aperture located at the center of the effective surface to that of the apertures located at the peripheries of the effective surface in the direction of the horizontal axis. The width of each of corner apertures located in the vicinity of the ends of the diagonal axes is larger than the width of the aperture located on the horizontal axis in the same vertical row of apertures to which the corner aperture belongs.

Owner:KK TOSHIBA

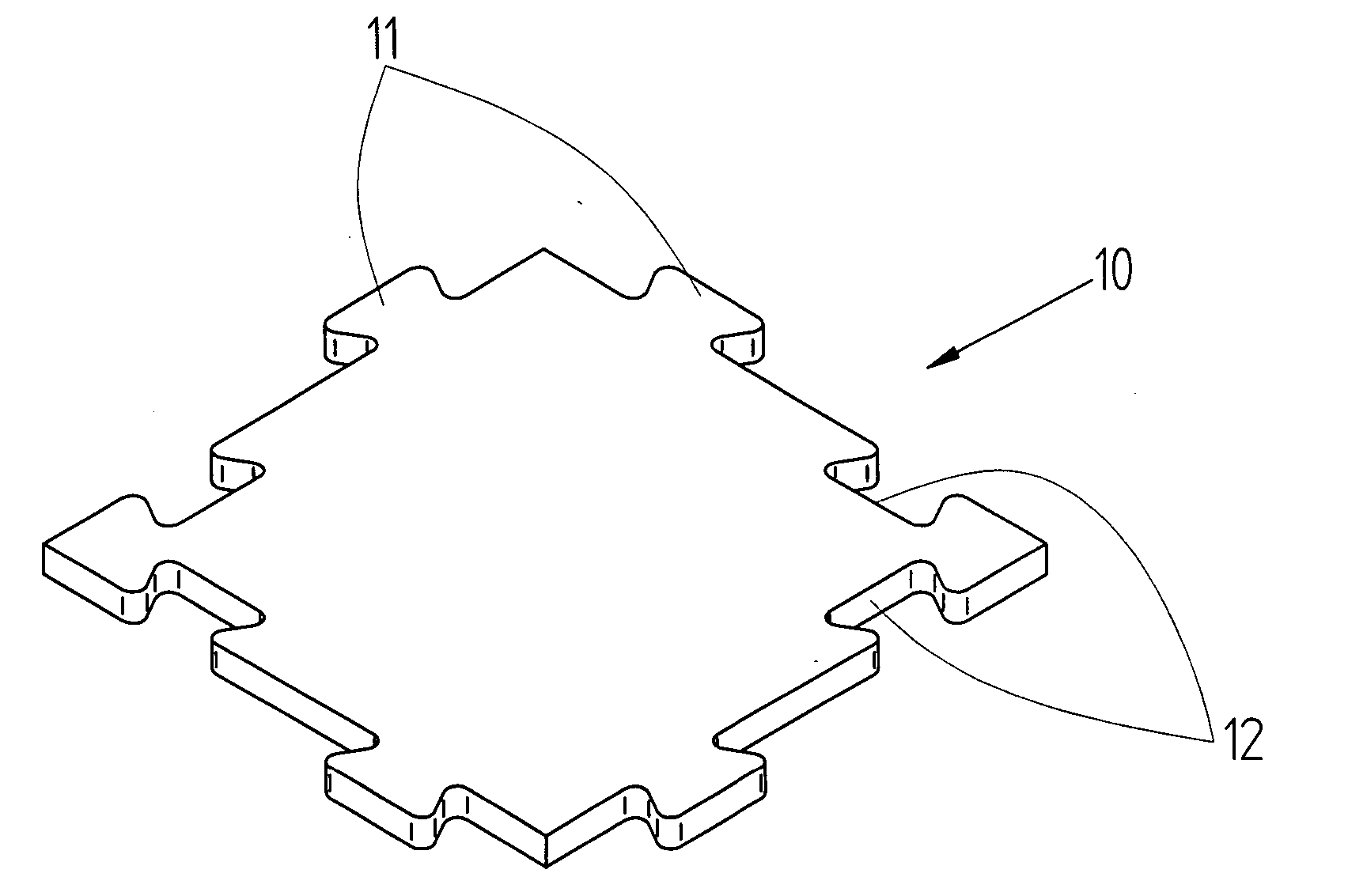

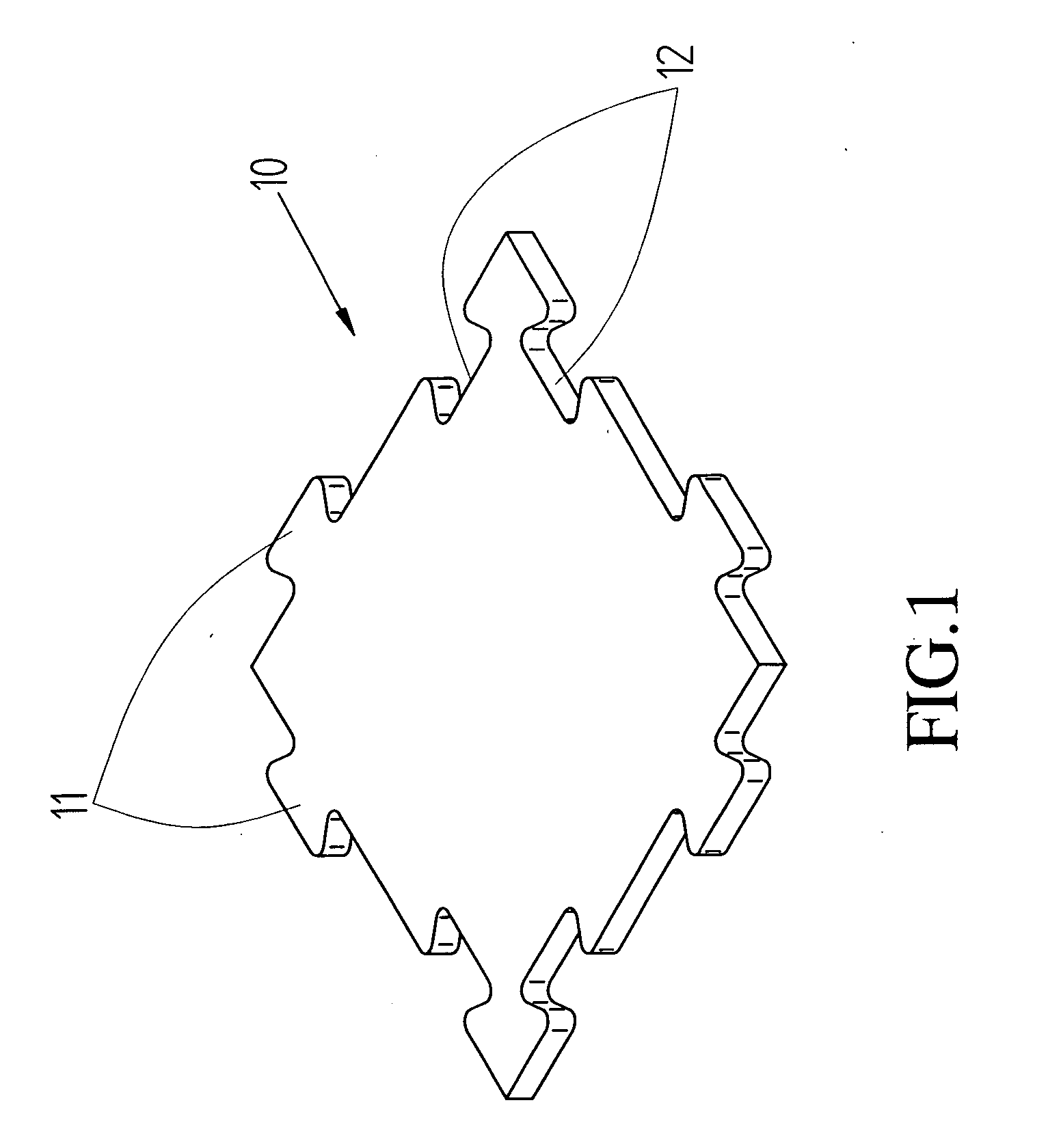

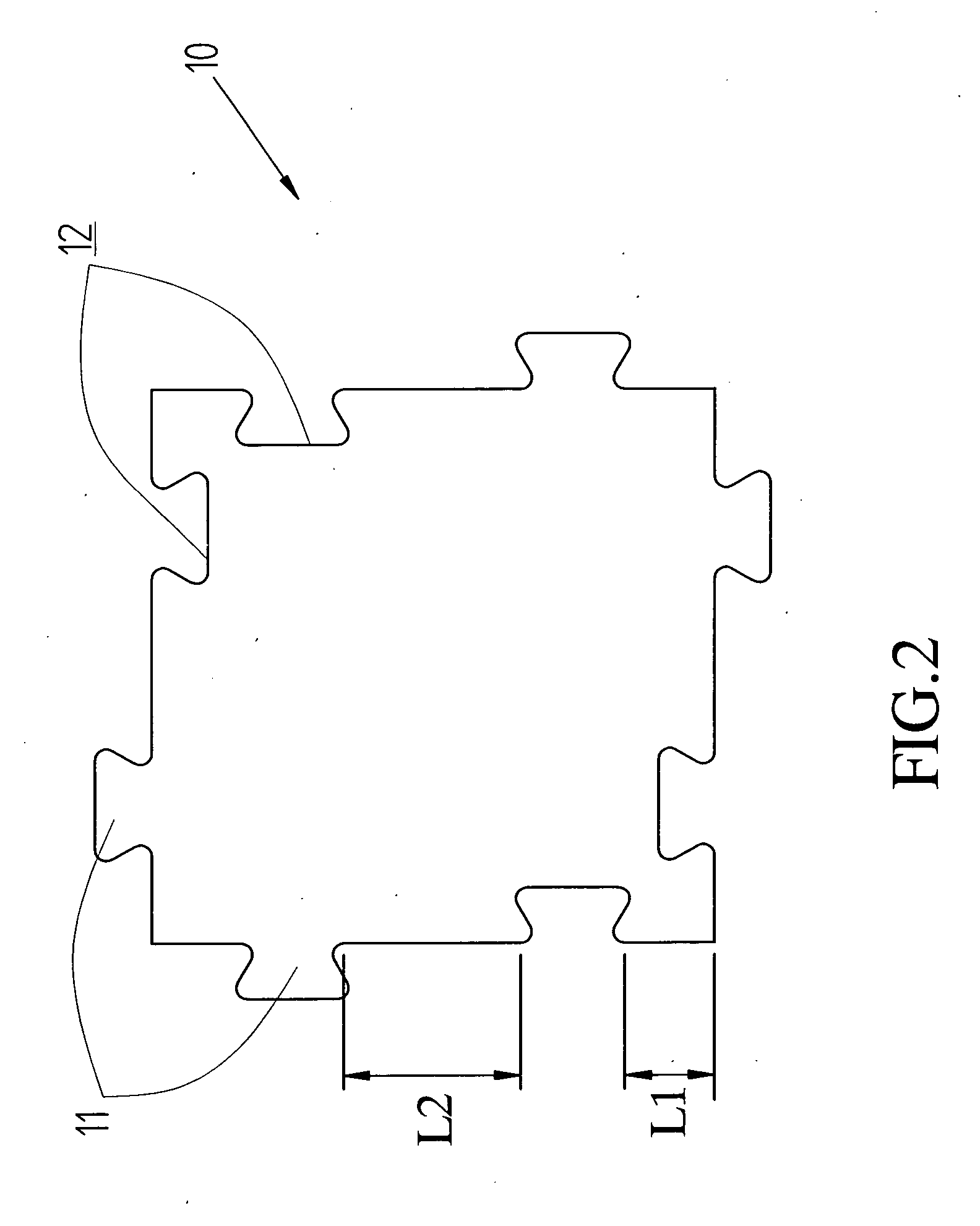

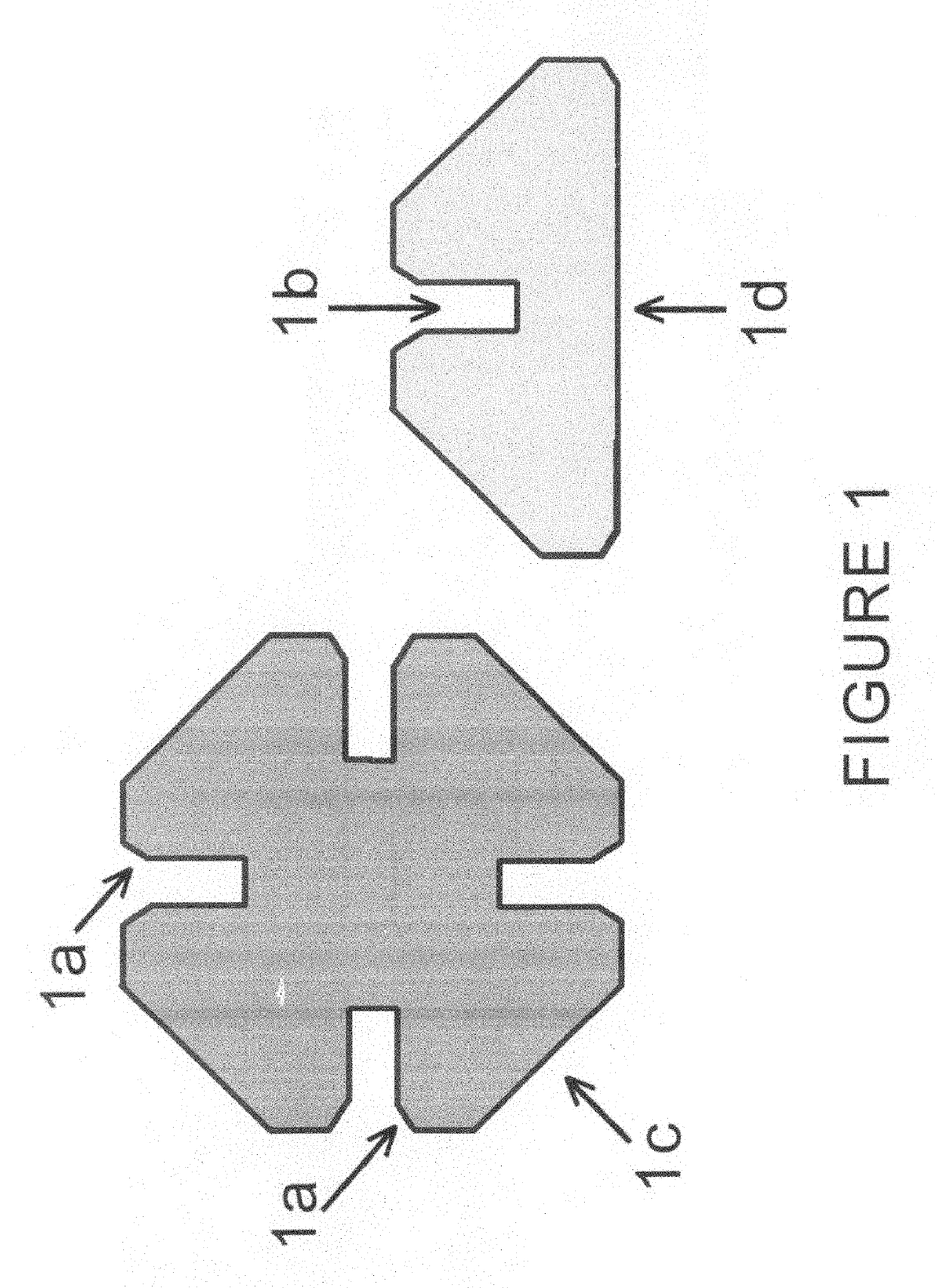

Floor pads

A square-shaped floor pad includes two protrusions extending from two adjacent sides of each of the two corners on a first diagonal axis of the pad and two recesses are defined in two adjacent sides of each of two corners on a second diagonal axis of the pad. The protrusions are shaped to be matched with the recesses. The floor pads are able to be matched with each other by engaging the protrusion with the recesses in different directions and sides.

Owner:LIN CHIEN JEN

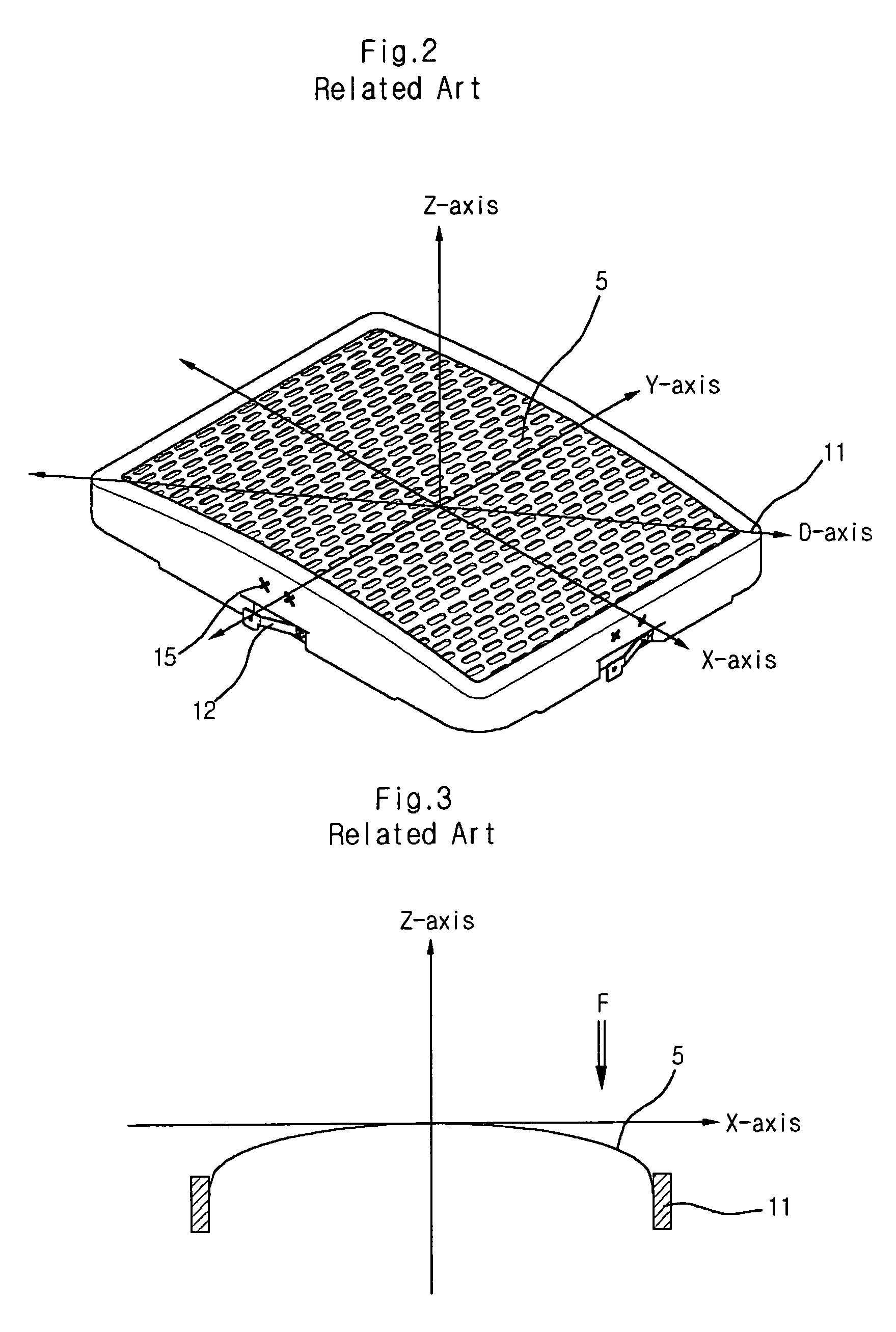

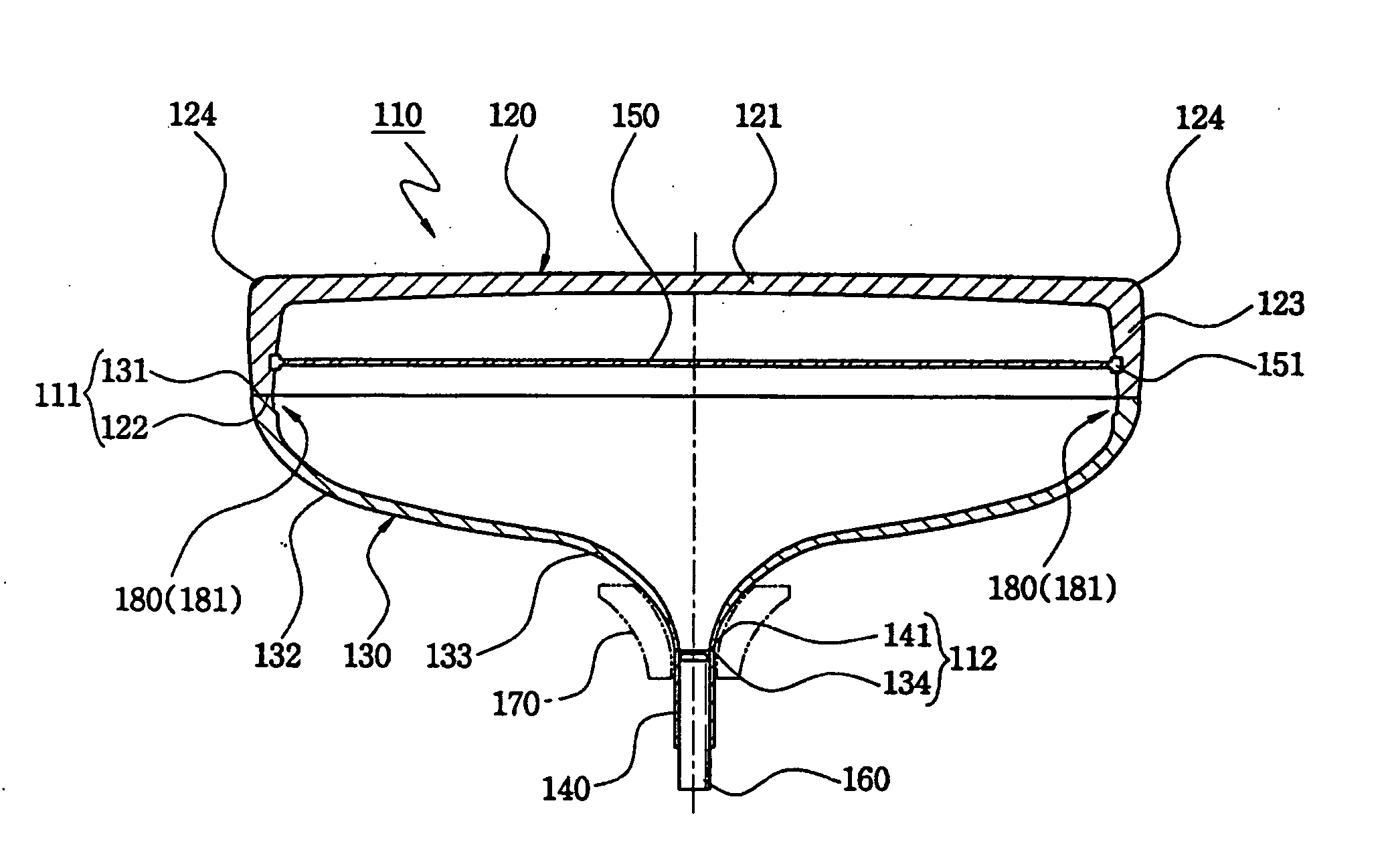

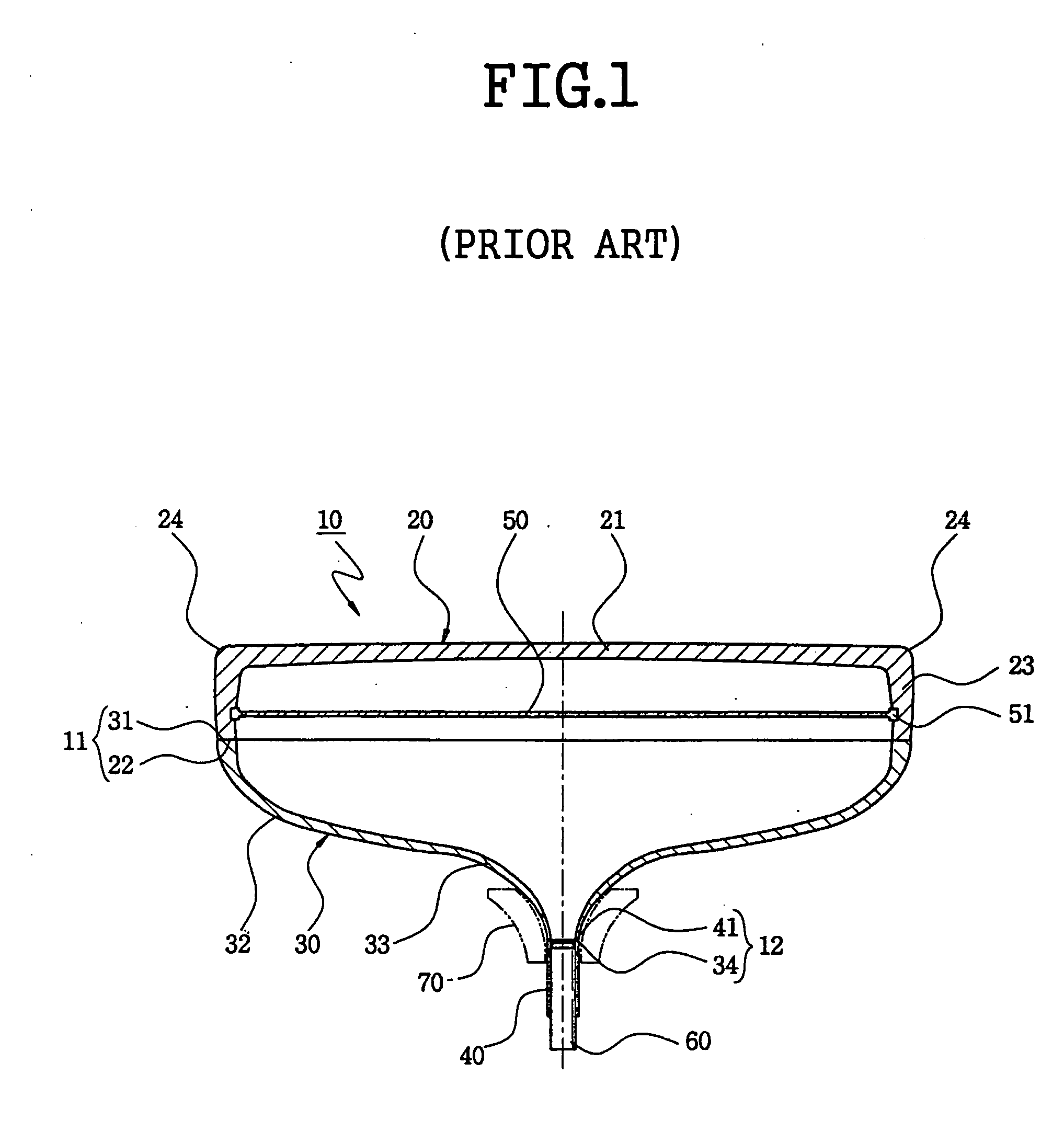

Cathode ray tube having an improved shadow mask

InactiveUS7098582B2Maximized drop strengthSimple structureCathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsFluorescenceLong axis

A cathode ray tube comprises a panel having a fluorescent formed on an inner surface thereof; a funnel connected to the panel; an electron gun housed in the funnel emitting electron beams; a deflection yoke for deflecting the electron beams in horizontal and vertical directions; a shadow mask for selecting colors of the electron beams; and a mask frame for supporting the shadow mask, in which an outer surface of the panel is substantially flat and an inner surface has a designated curvature, and a radius of curvature from a center of the shadow mask in a major-axis, minor-axis and diagonal-axis direction is substantially same.

Owner:MERIDIAN SOLAR & DISPLAY

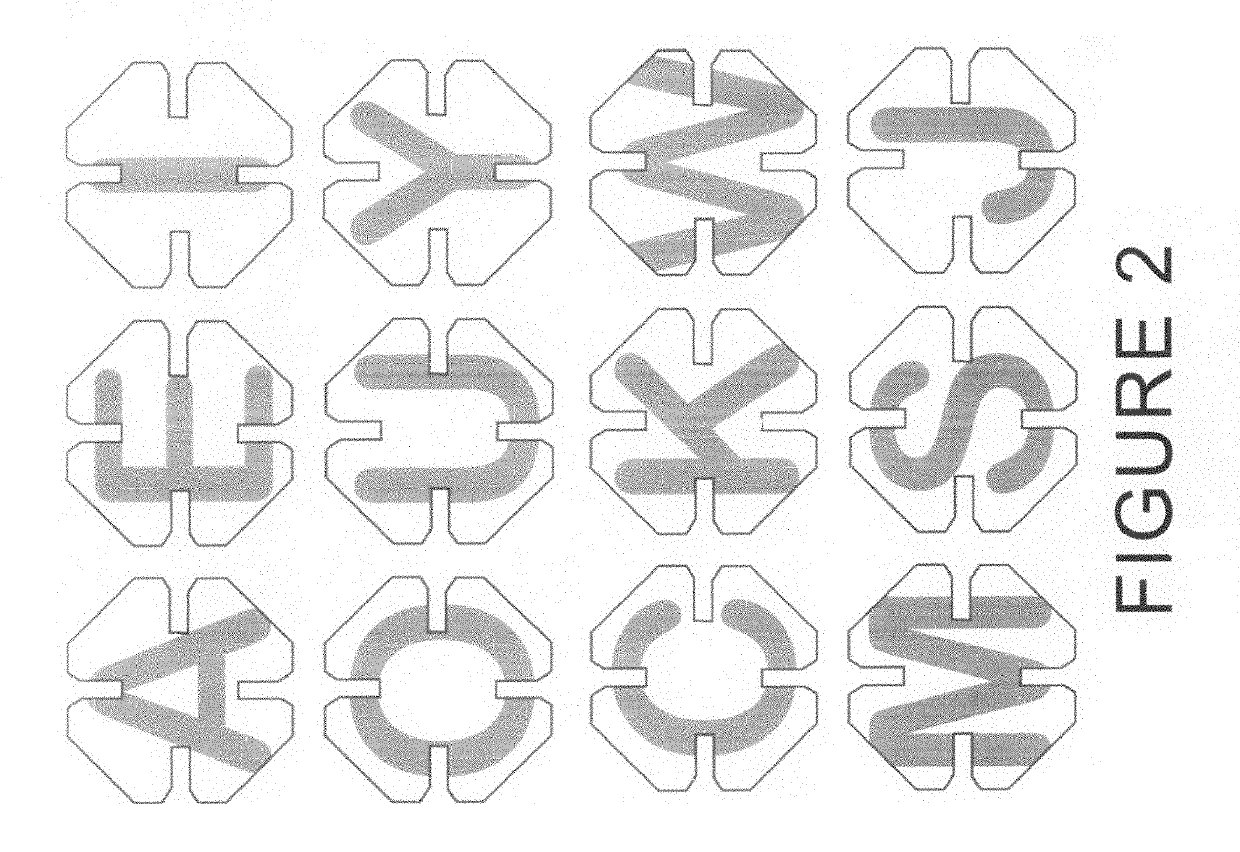

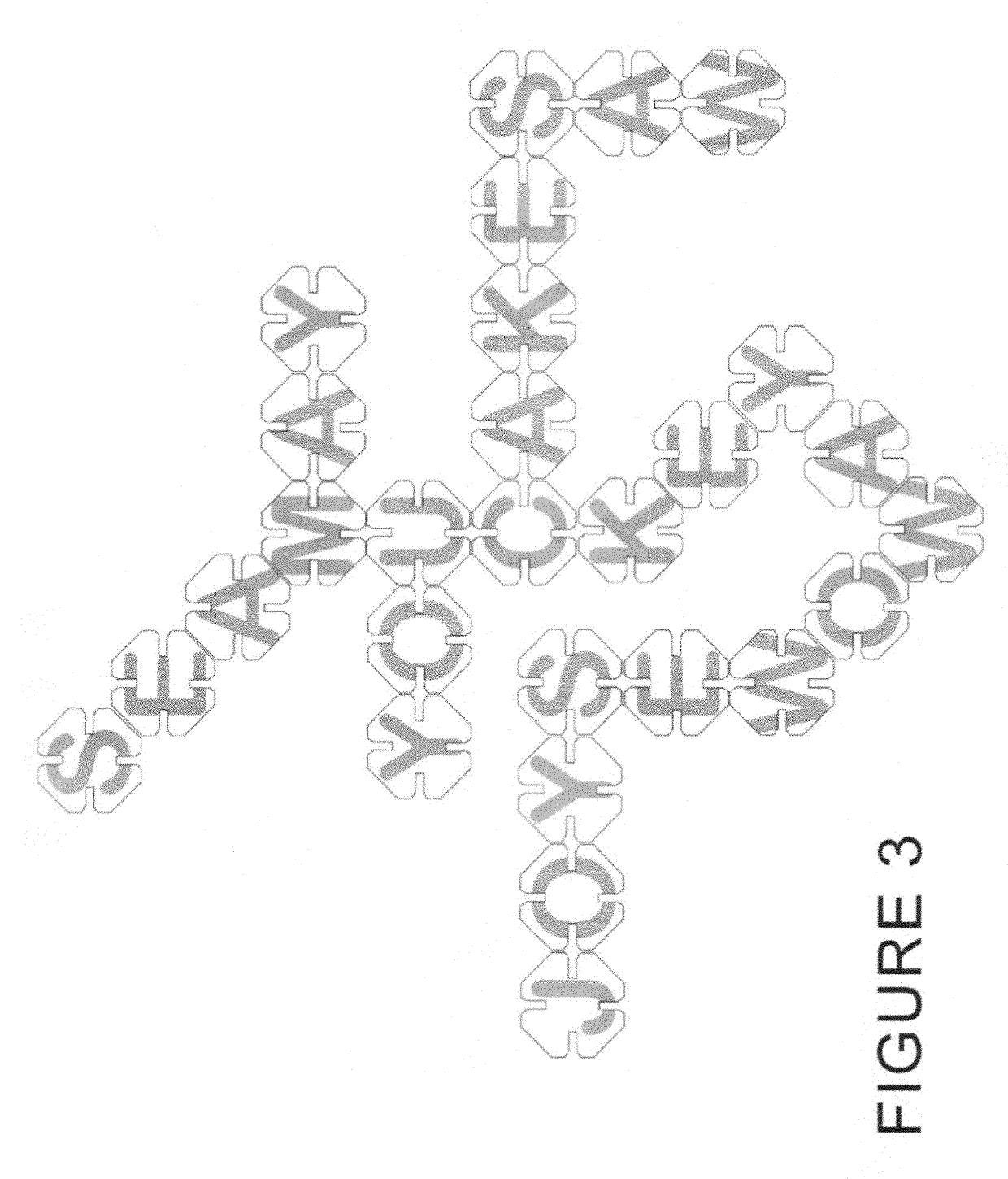

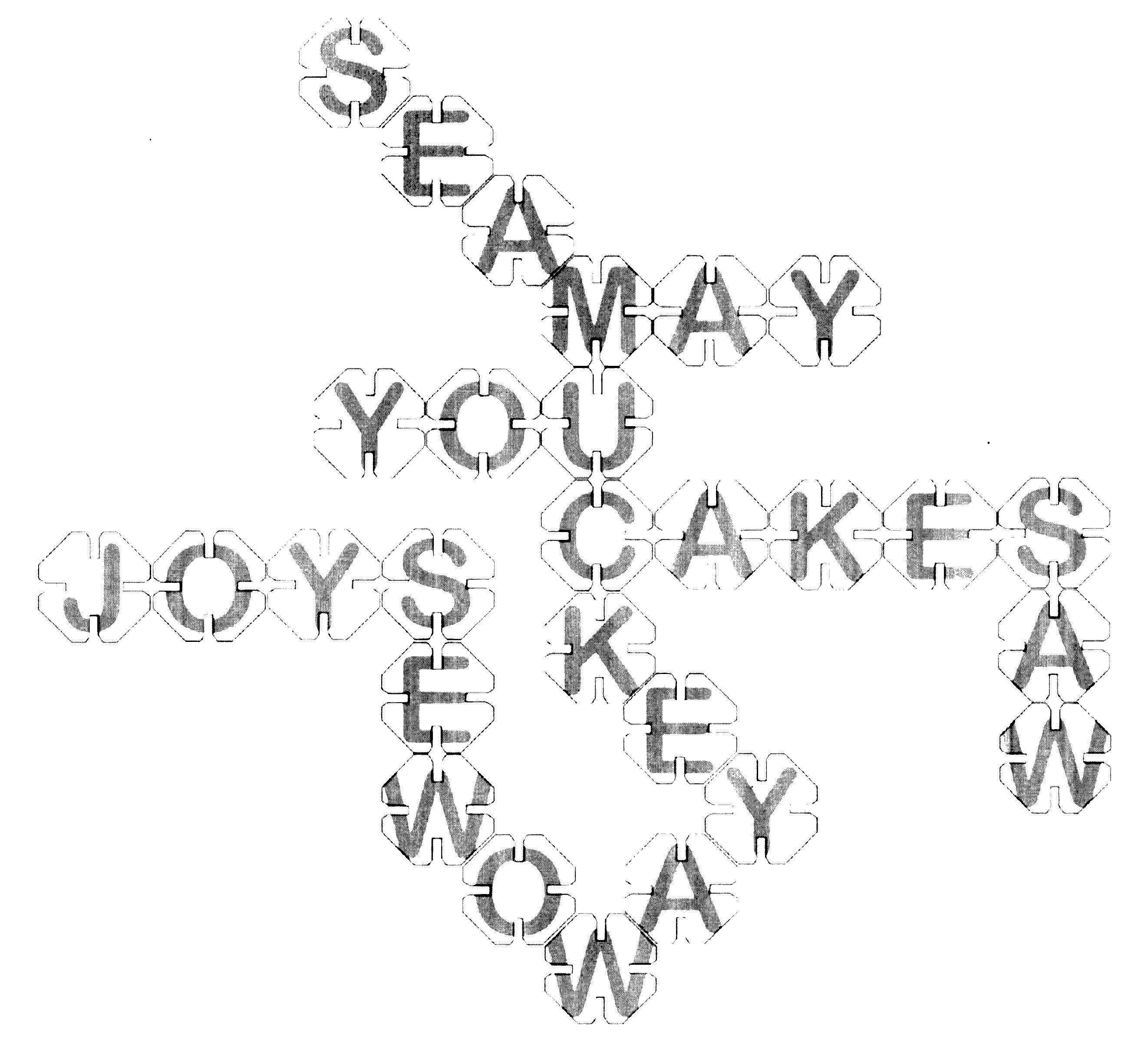

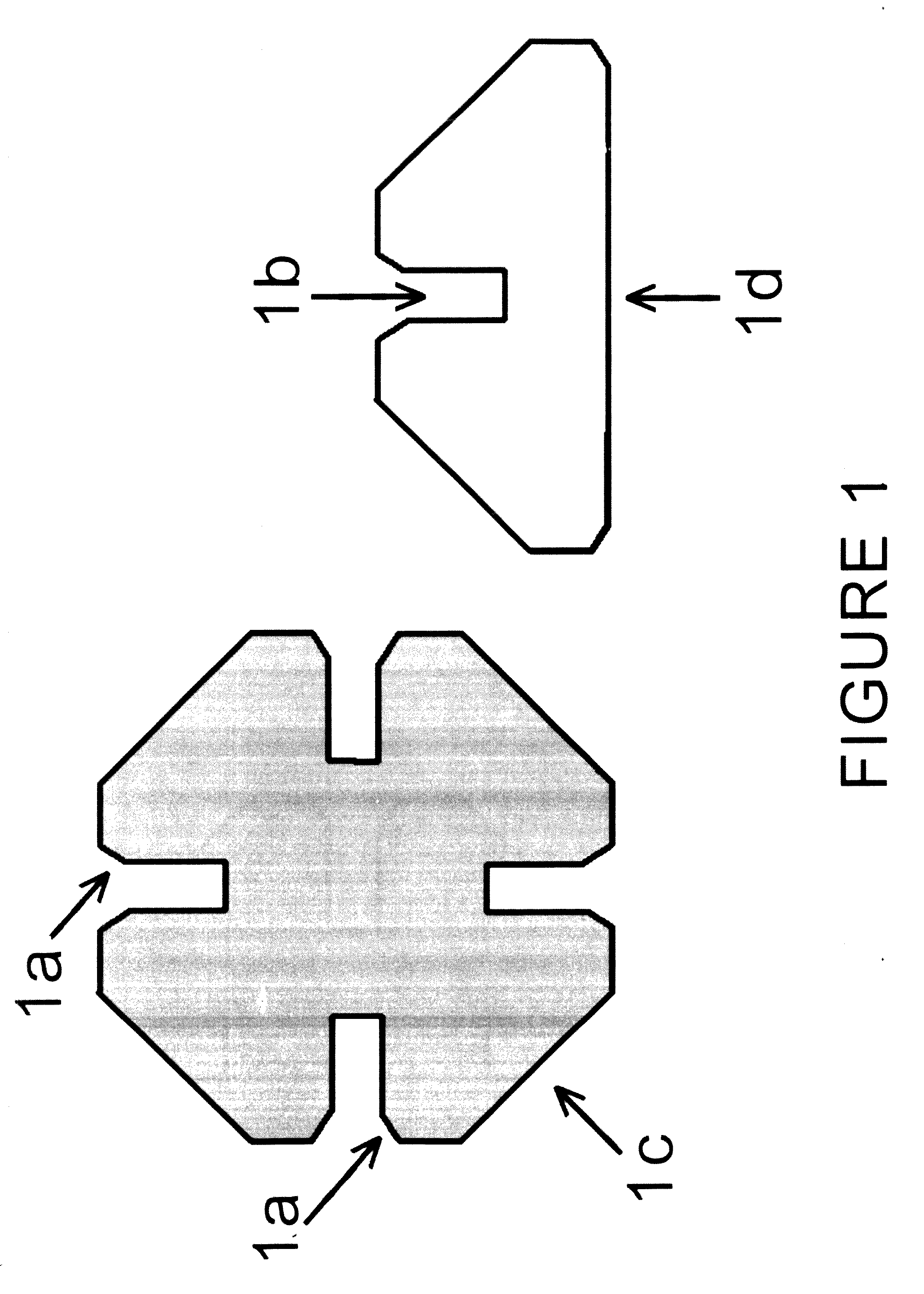

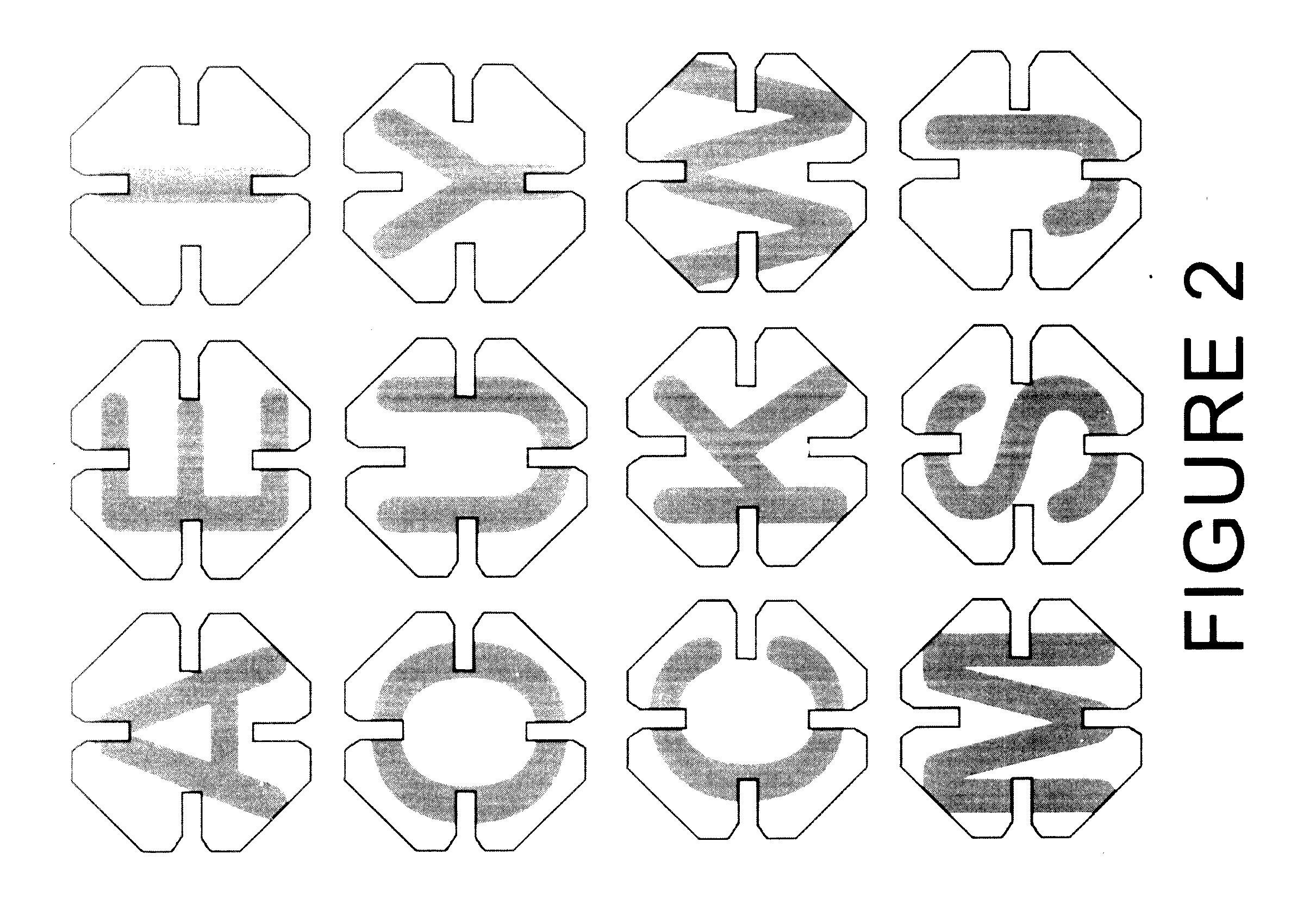

Word game with multi-sided pieces with notches for interlocking of the pieces at various angles

Game apparatus comprising a plurality of multi-sided, game and base pieces having notches whereby the pieces may be interlocked, and said pieces having two faces with indicia or other markings on at least some of the faces whereby words and / or equations and / or other things can be formed along horizontal and / or vertical and / or diagonal axes by placing game pieces adjacent to each and / or game pieces and / or base pieces interlocked into each other. Methods for playing games with said apparatus in two and / or three dimensions is disclosed.

Owner:KIM DOUGLAS SHIN

System and method of pattern recognition and metrology structure for an X-initiative layout design

InactiveUS7001830B2Improve accuracyReduce yieldNavigation by terrestrial meansSemiconductor/solid-state device manufacturingMetrologyDiagonal

The present invention relates to inspection methods and systems utilized to provide a best means for inspection of a wafer. The methods and systems include wafer-to-reticle alignment, layer-to-layer alignment and wafer surface feature inspection. The wafer-to-reticle alignment is improved by the addition of diagonal lines to existing alignment marks to decrease the intersection size and corresponding area that a desired point can reside. Layer-to-layer alignment is improved in a similar manner by the addition of oblique and / or non-linear line segments to existing overlay targets. Also, providing for wafer surface inspection in a multitude of desired diagonal axes allows for more accurate feature measurement.

Owner:GLOBALFOUNDRIES INC

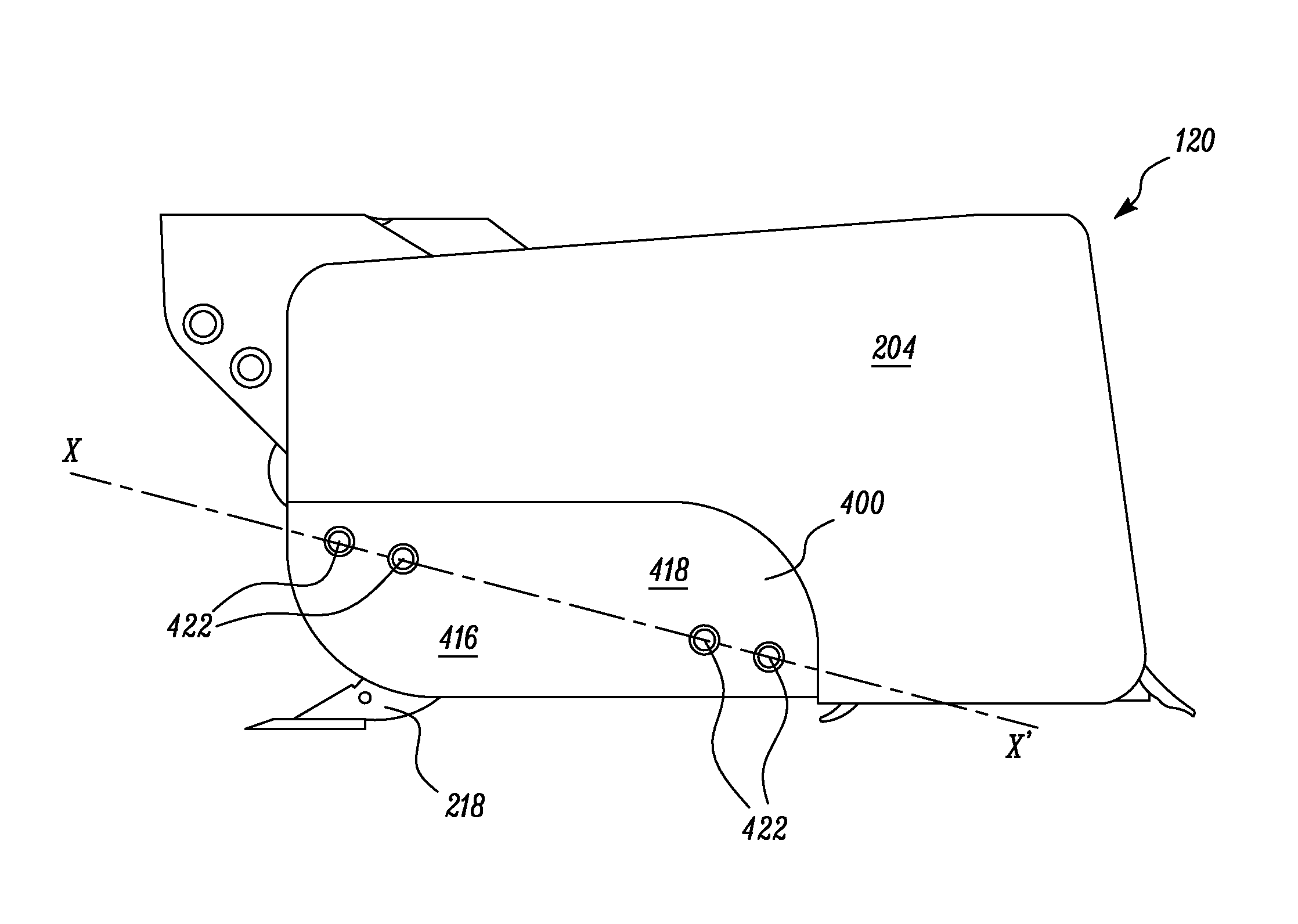

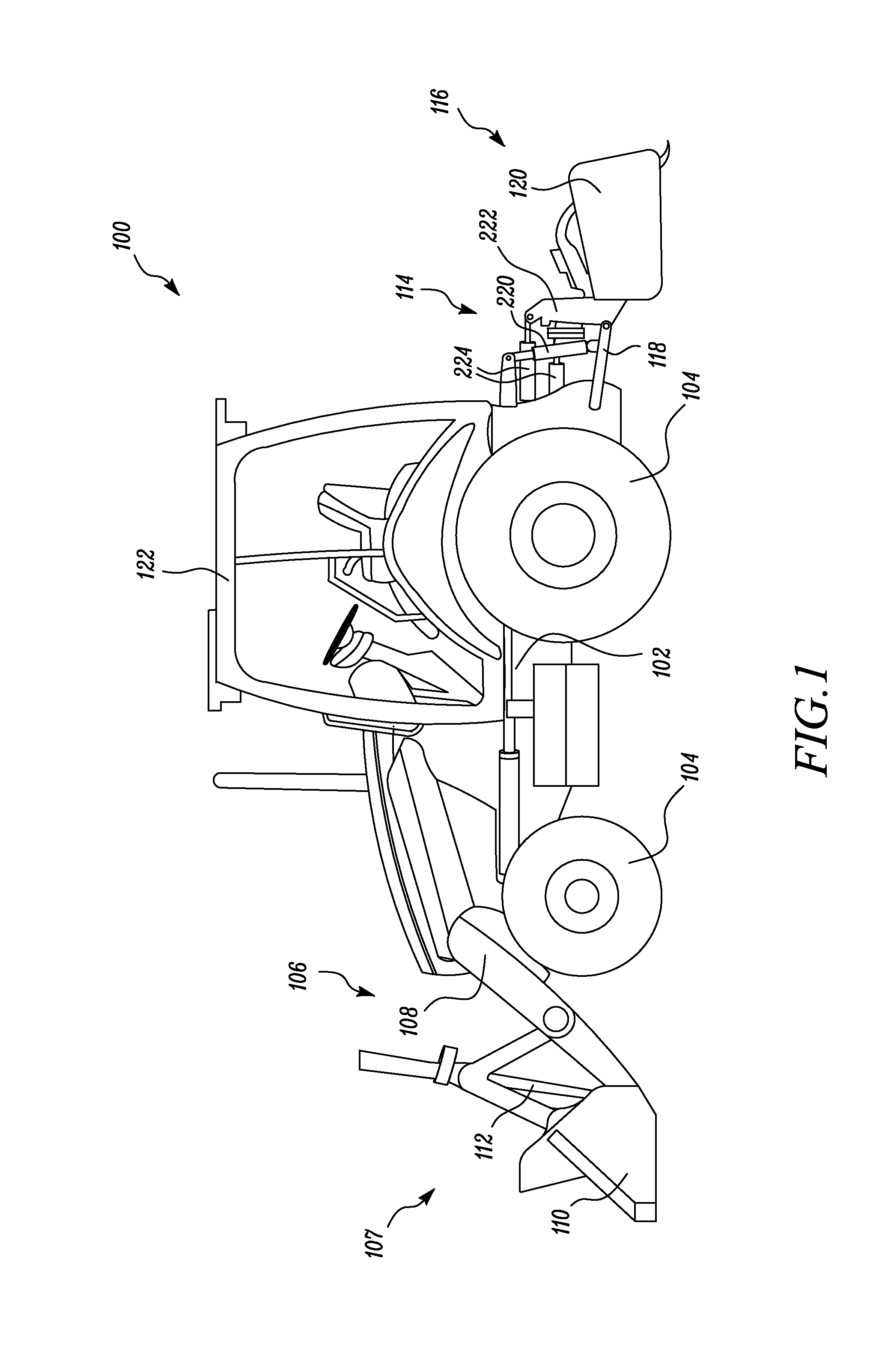

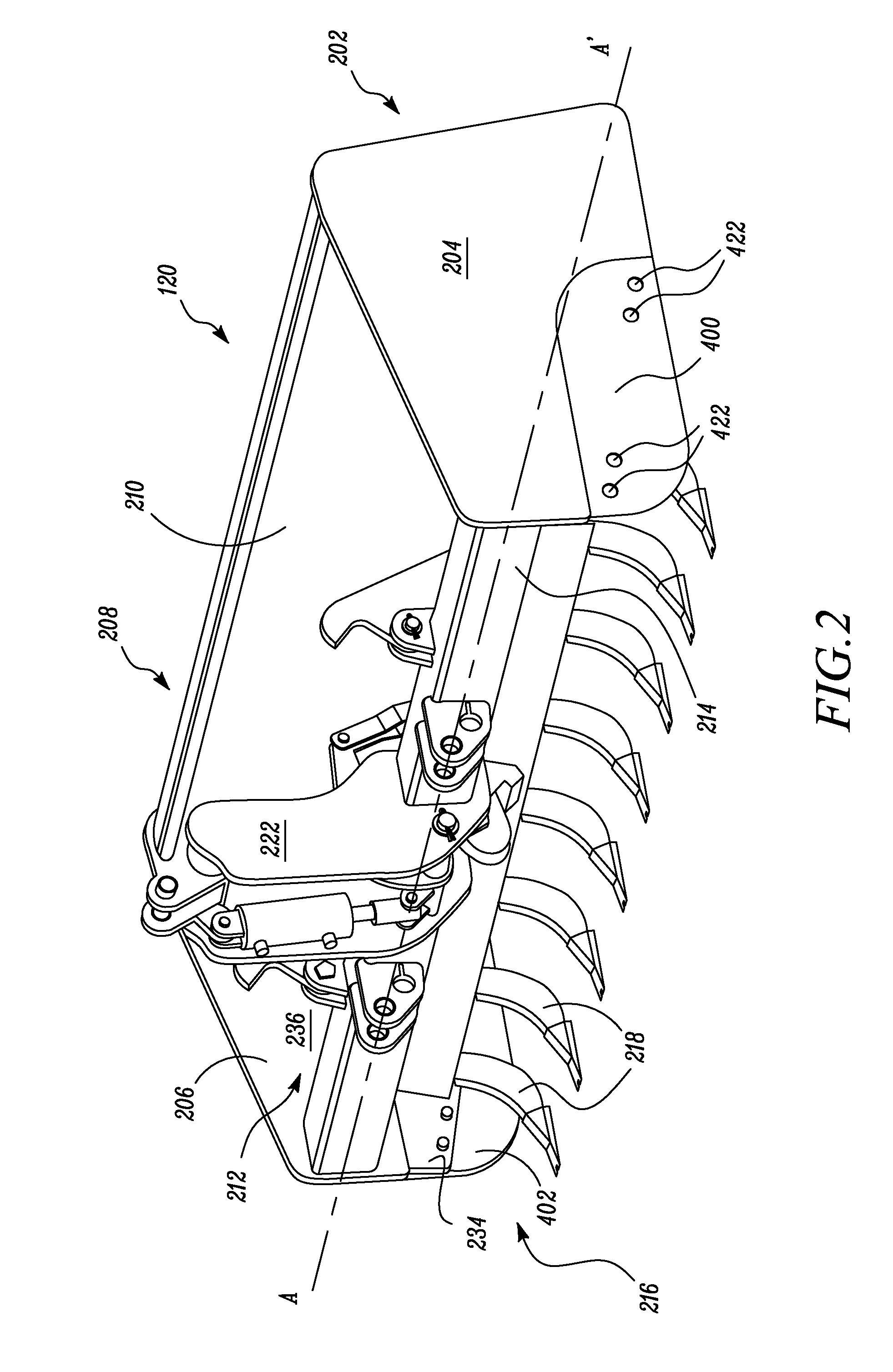

Wear plate for box blade

A wear plate for a box blade is provided. The wear plate includes a first surface and a second surface. The first and second surfaces are spaced apart from each other and define a thickness of the wear plate therebetween. The wear plate also includes a plurality of openings formed on the wear plate and communicating with the first and second surfaces thereof. The plurality of openings is positioned along a diagonal axis of the wear plate. The plurality of openings is configured to be aligned with corresponding openings formed on a backer plate of the box blade to receive mechanical fasteners therethrough for attaching the wear plate to the backer plate. The wear plate includes a first wear surface defined on one side of the diagonal axis of the wear plate and a second wear surface defined on the other side of the diagonal axis.

Owner:CATERPILLAR INC

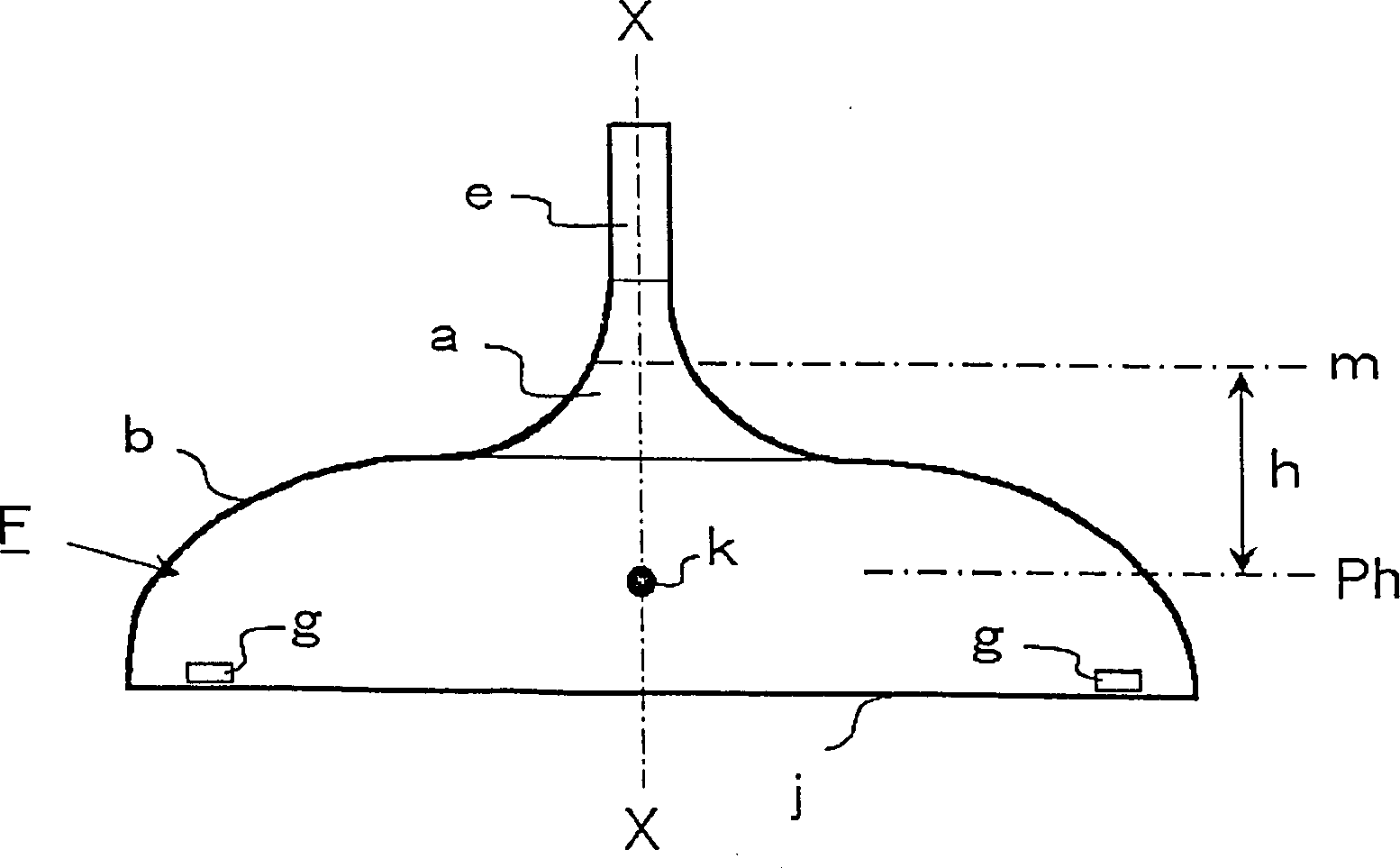

Glass funnel for a cathode ray tube and cathode ray tube

InactiveUS6919677B2Less-prone to fractureEasy to produceCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersDiagonalEngineering

The present invention has an object to provide a glass funnel, which is safe, highly reliable and lightweight. The object is solved by a glass funnel wherein an outwardly projecting bent portion is provided along at least a part of an outer peripheral area, where the body portion intersects with a plane perpendicular to a bulb axis, and which includes intersecting points between the outer peripheral area and a plane containing a diagonal axis and the bulb axis, and the bent portion is provided at a specific position.

Owner:ASAHI GLASS CO LTD

Word game with multi-sided pieces with notches for interlocking of the pieces at various angles

Game apparatus comprising a plurality of multi-sided, game and base pieces having notches whereby the pieces may be interlocked, and said pieces having two faces with indicia or other markings on at least some of the faces whereby words and / or equations and / or other things can be formed along horizontal and / or vertical and / or diagonal axes by placing game pieces adjacent to each and / or game pieces and / or base pieces interlocked into each other. Methods for playing games with said apparatus in two and / or three dimensions is disclosed.

Owner:KIM DOUGLAS SHIN

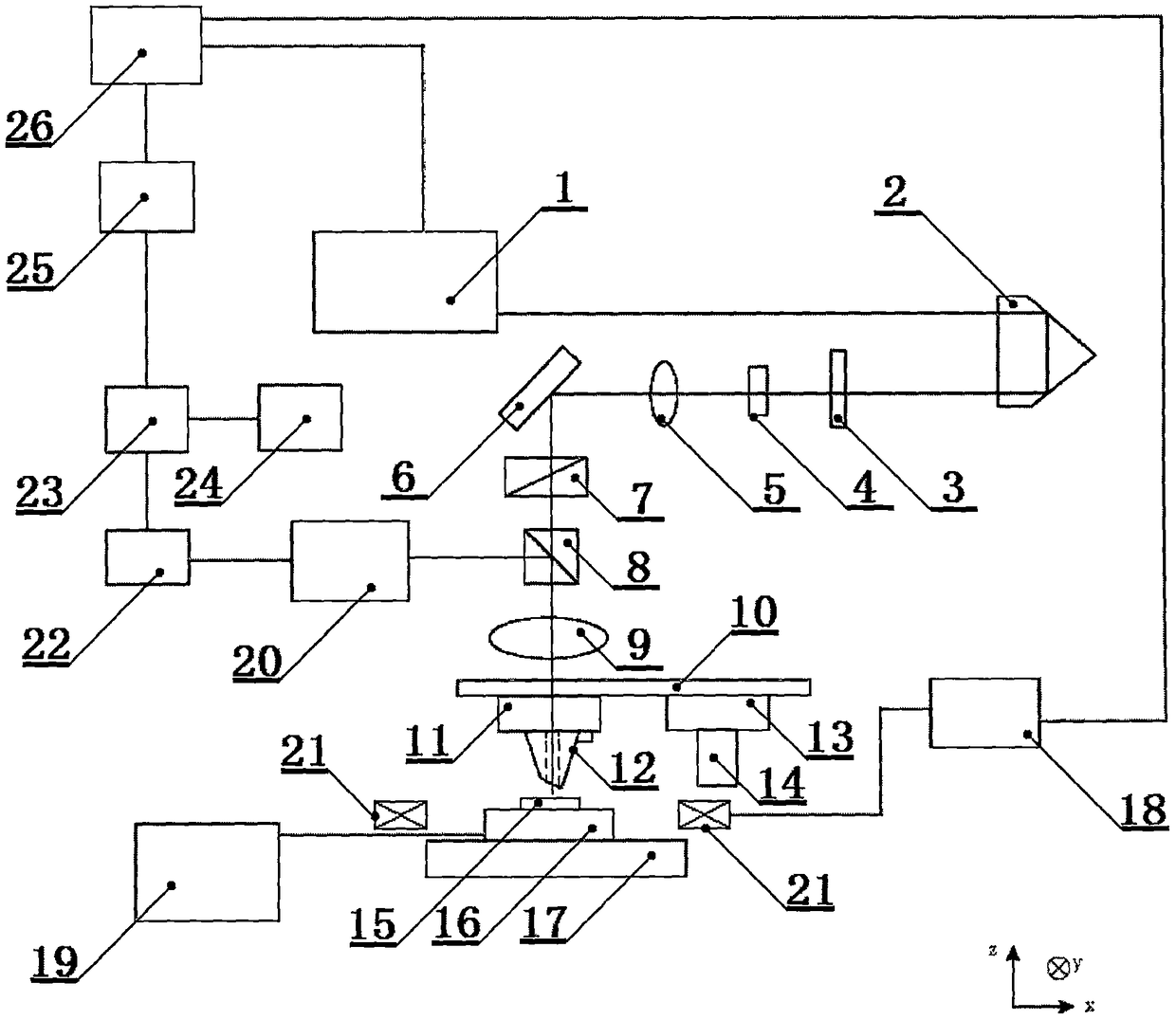

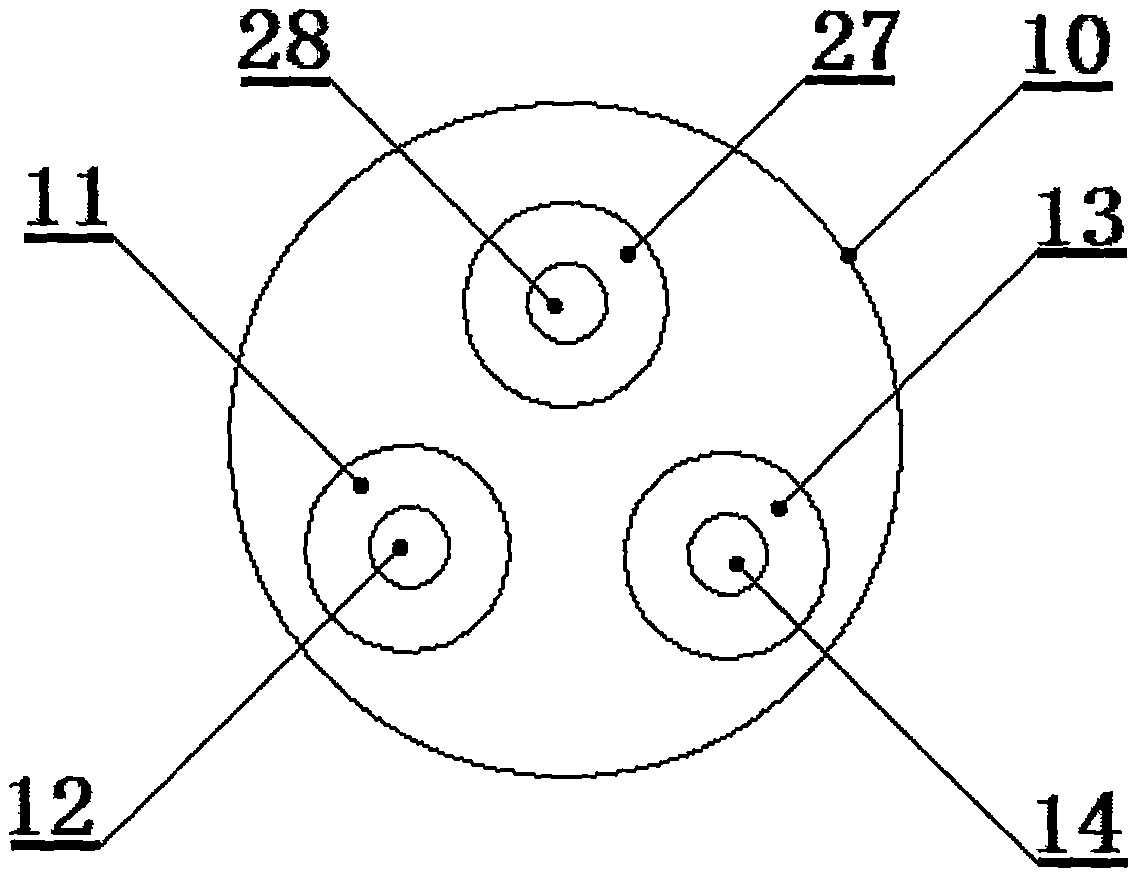

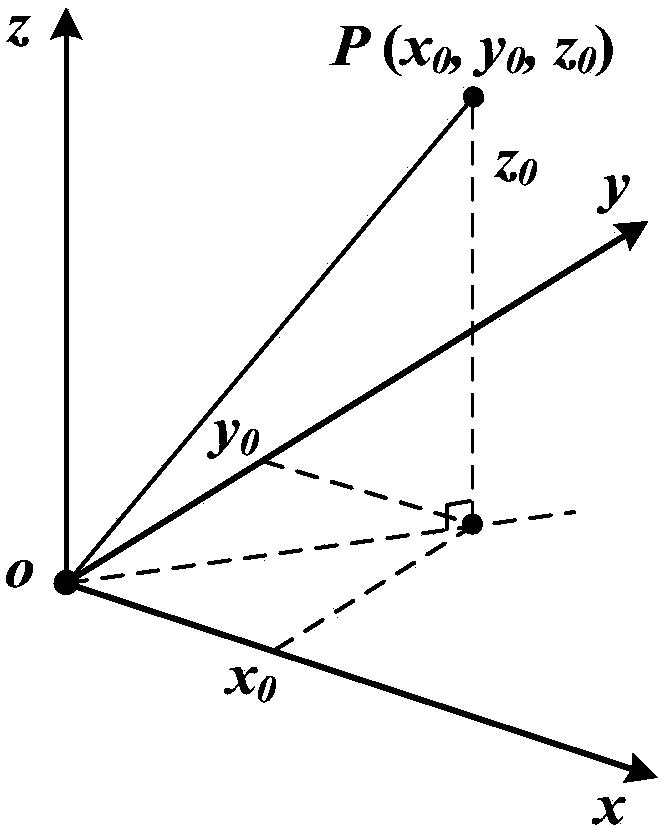

Surface nano-structure magnetic measuring device

InactiveCN108414952AExtended service lifeLow costMagnetisation measurementsMagnetic field measurement using magneto-optic devicesAtomic force microscopyNano structuring

The invention relates to an electromagnetic detecting device in the field of optical technology measurement, and provides a surface nano-structure magnetic measuring device. The surface nano-structuremagnetic measuring device comprises a laser device, a delayer, a 1 / 4 wave plate, a concave lens, a convex lens I, a plane mirror, a polaroid, a beam splitter, a convex lens II, a lens table, an atomic force microscope I, a probe I, a lens seat, an objective lens, a sample, a Hall plate, a sample table, a signal generator, an oscilloscope, a detector, a magnet, a pre-amplifier, a differential amplifier, a compensator, an analog-digital converter, a computer, an atomic force microscope II and a probe II, the probe I and the probe II are atomic force microscope probes with the same overall dimension, the appearances of the probe I and the probe II are circular truncated cones, the probe I is provided with a through hole in the axis direction of the circular truncated cone, a wedge-shaped block is cut off on one side of a diagonal axis through a point, which is the closest to the forward direction of an x axis, on the periphery of the bottom surface of the circular truncated cone of the probe I, an oblique plane is formed on the bottom surface of the probe I, a five-degree angle is formed between the oblique plane and the horizontal plane, and a magnetic is formed by connecting four secondary magnets which are the same.

Owner:JINHUA VOCATIONAL TECH COLLEGE

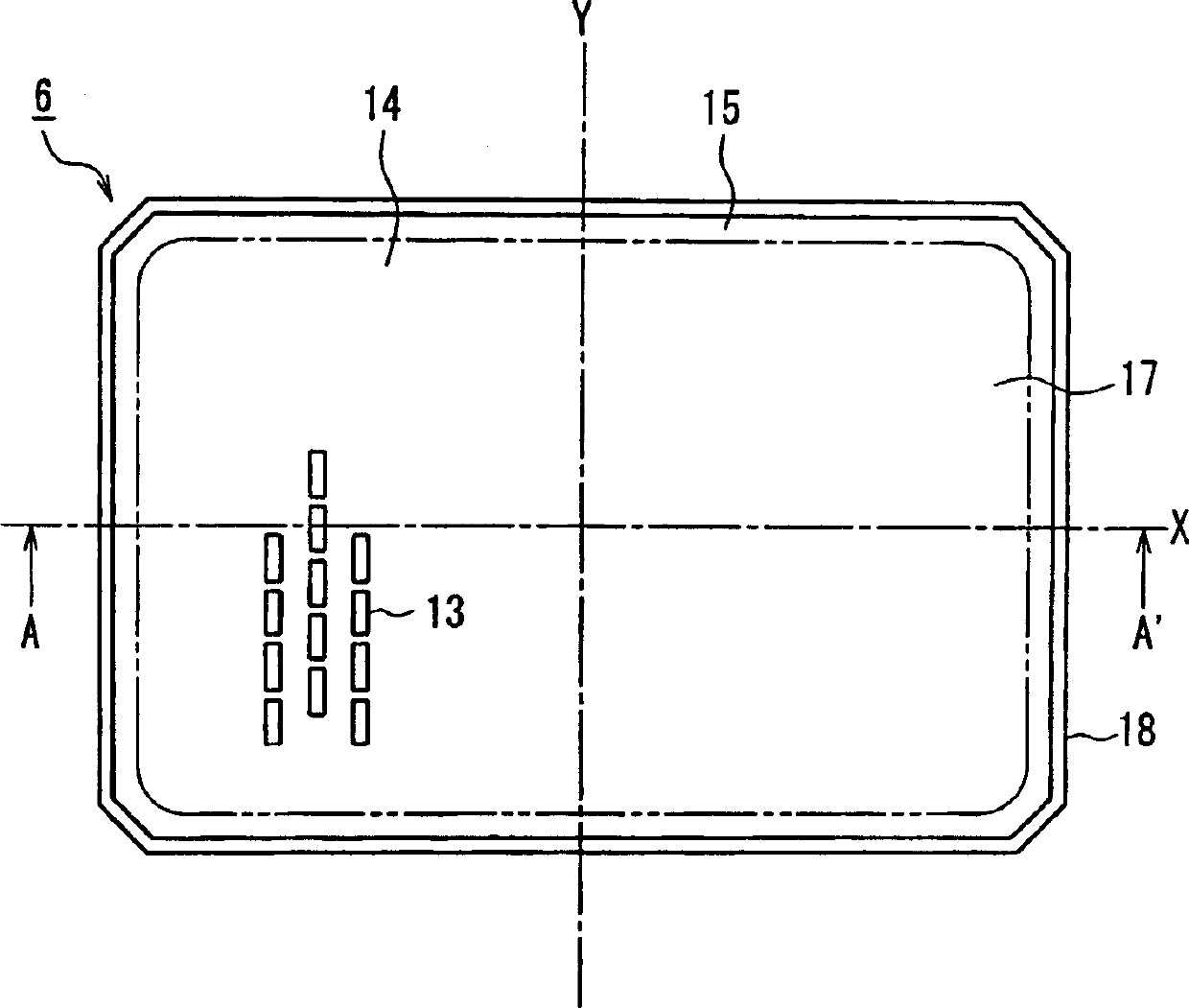

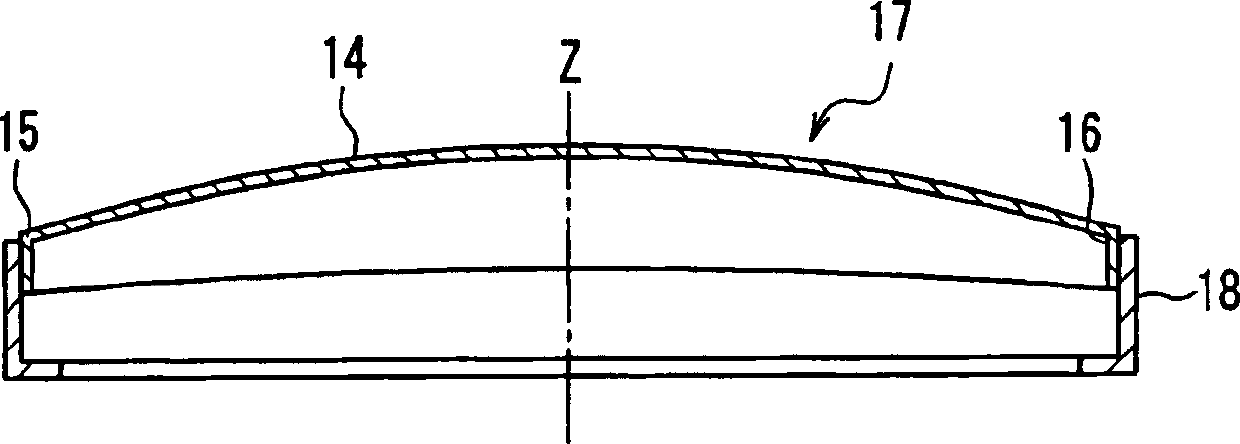

Cathode ray tube

InactiveCN1763900AImproved surface retention strengthReduce offsetCathode ray tubes/electron beam tubesEffective surfaceCathode ray

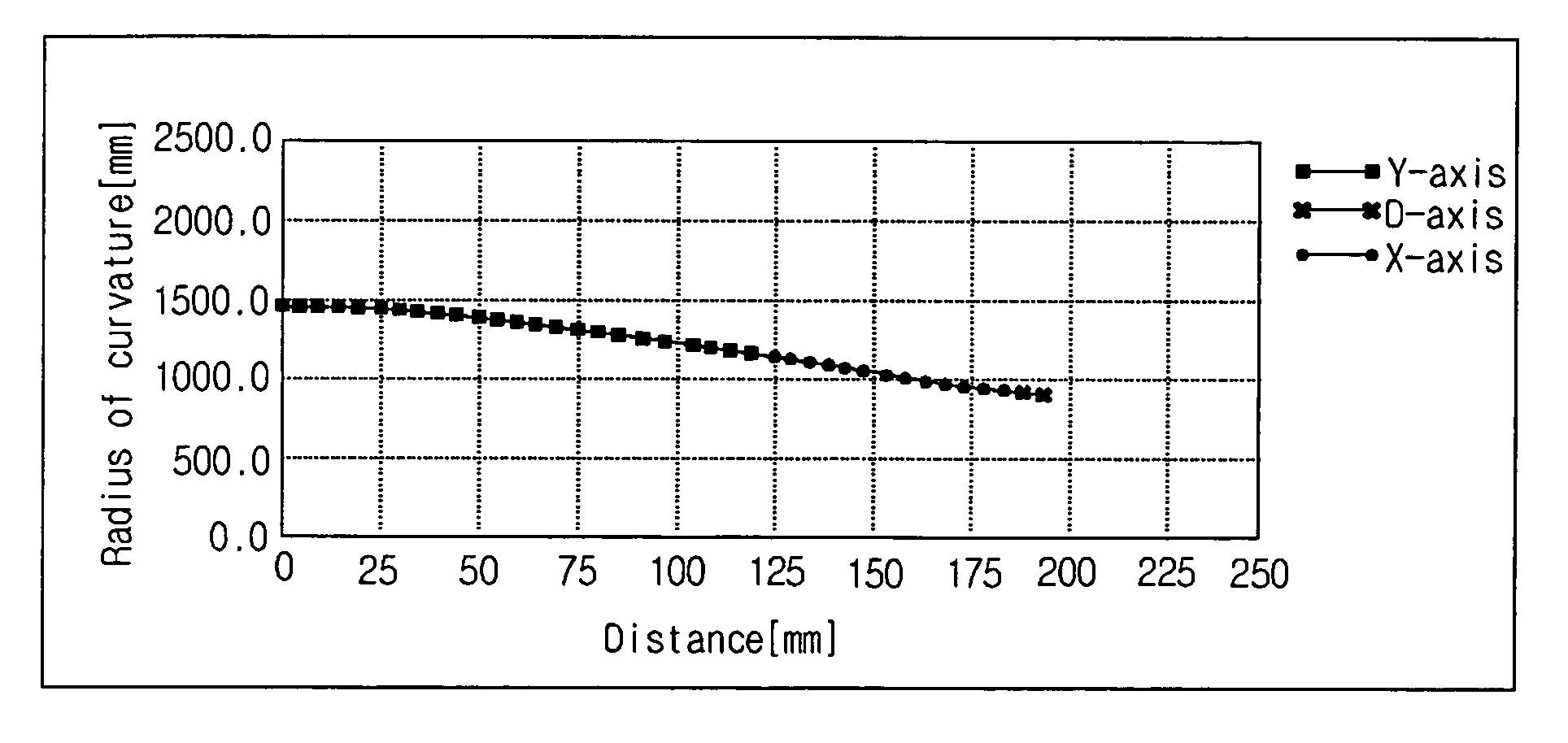

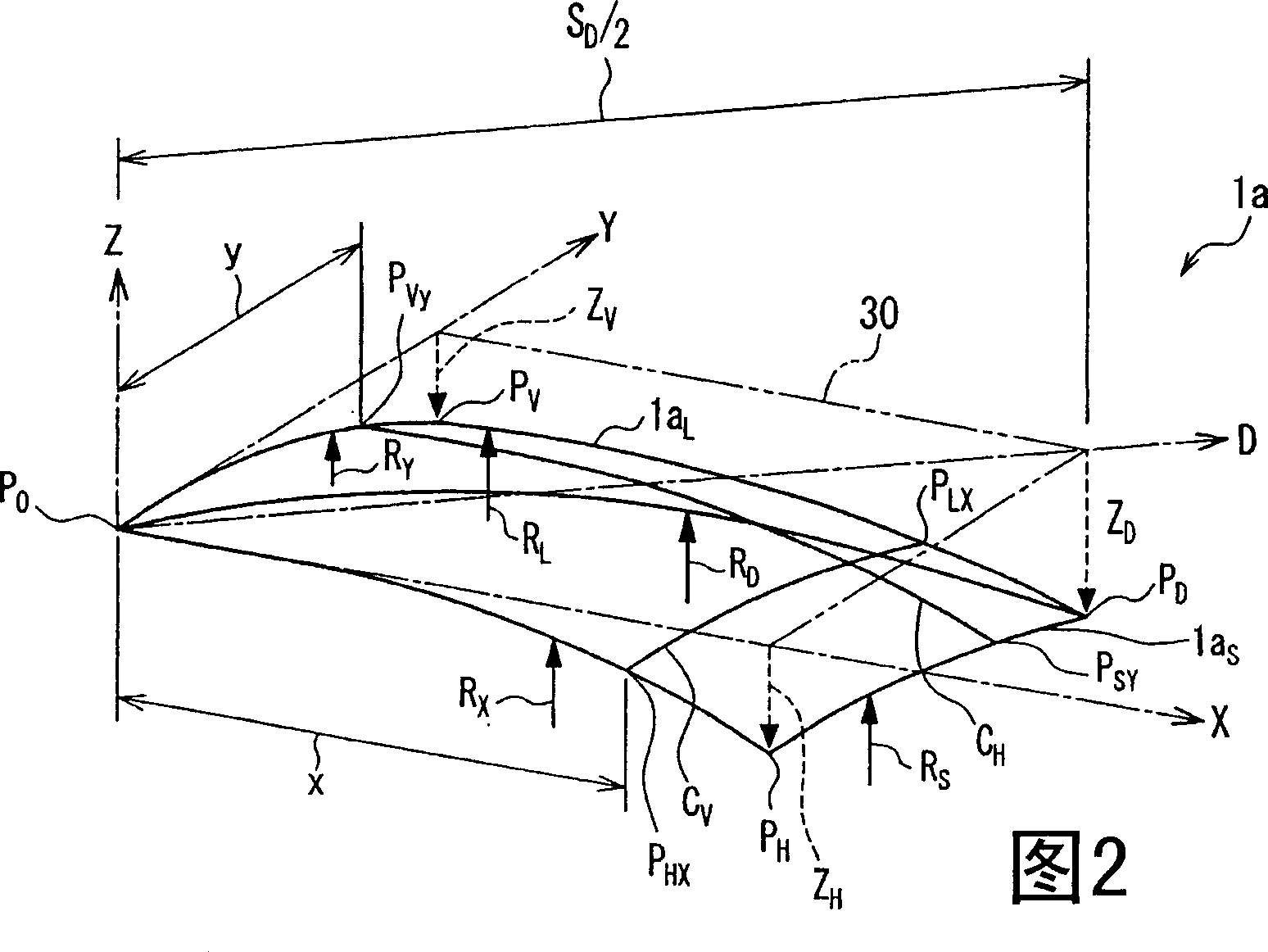

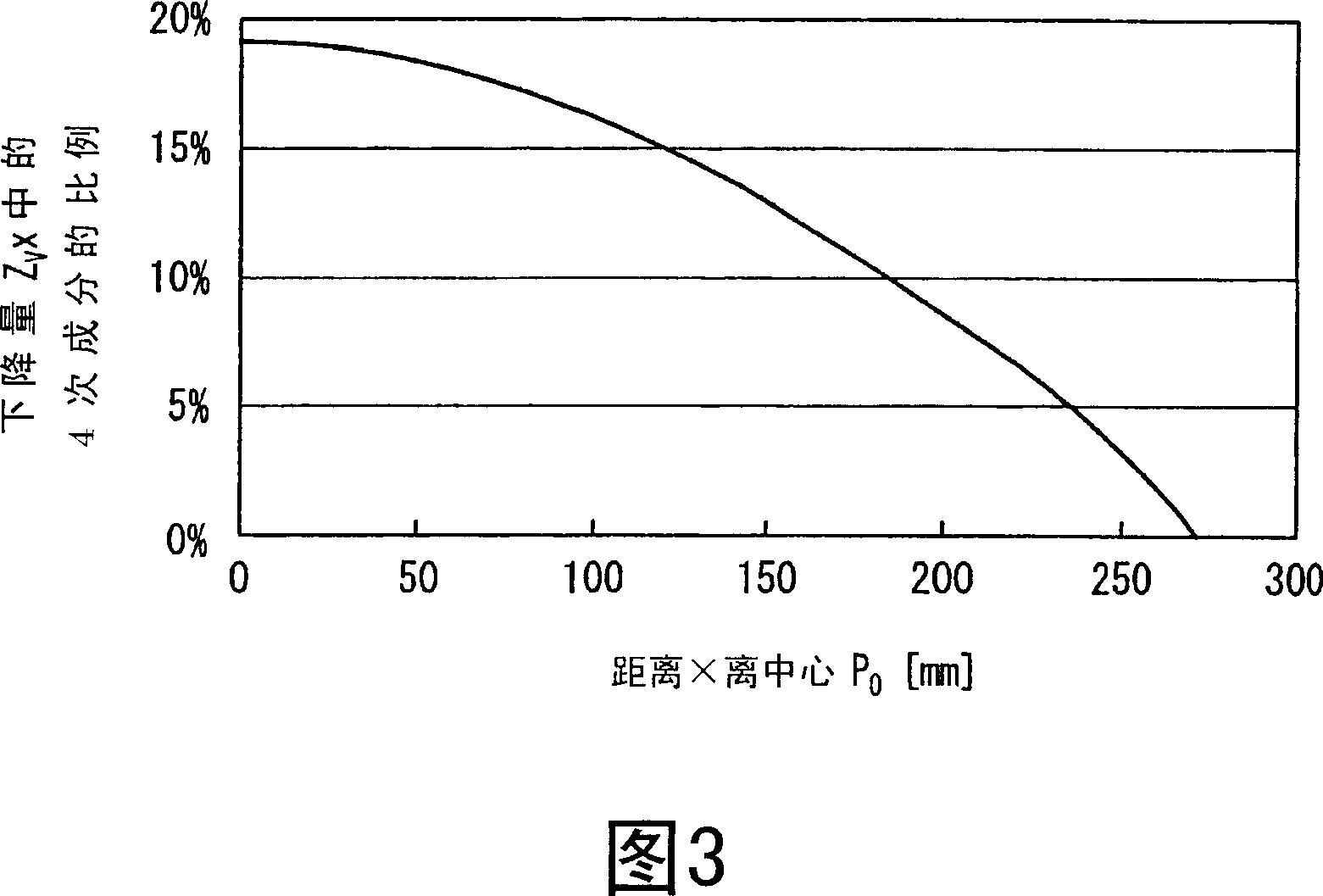

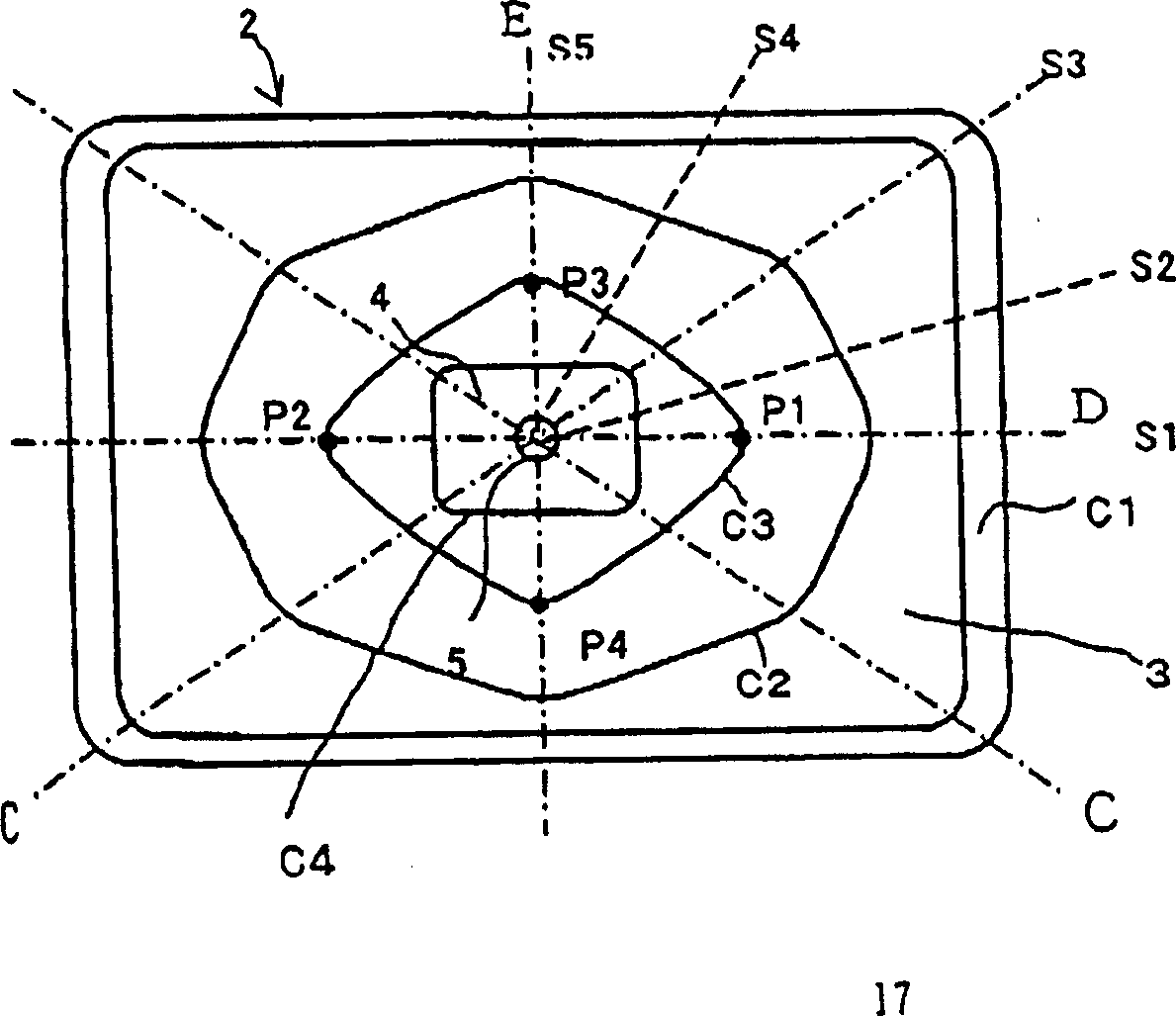

The shadow mask main body 17 includes an effective surface 14 in which electron beam passage holes 13 are formed and a non-porous portion 15 surrounding the effective surface 14 . When we let Ry be the curvature radius of the curve on the Y-axis direction of the effective surface 14 of the shadow mask main body 17, and Rx be the curvature radius of the curve on the X-axis direction, calculate the curvature radius of the curved surface on the effective surface 14 with Rk2=Rx×Ry Rk, and let Rk(d) be the radius of curvature of the curved surface near the endpoint of the diagonal axis of the effective surface 14, Rk(h) be the radius of curvature of the curved surface near the X-axis endpoint, and Rk(c) be the curvature of the curved surface in the middle portion When the radius is used, the following relationships are satisfied: Rk(c)>Rk(h), Rk(c)>Rk(d) and -800mm≤Rk(h)-Rk(d)≤800mm.

Owner:MATSUSHITA TOSHIBA PICTURE DIS

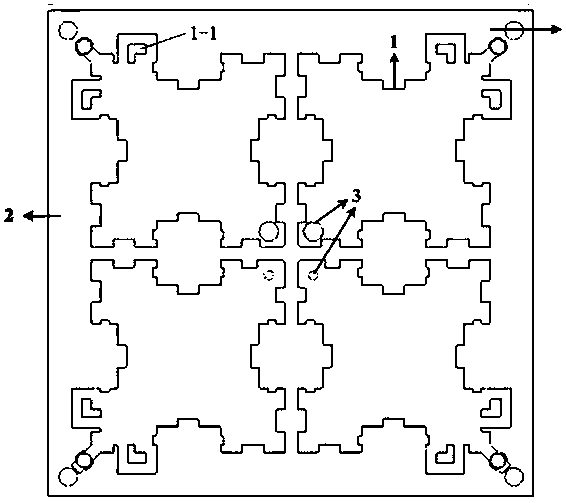

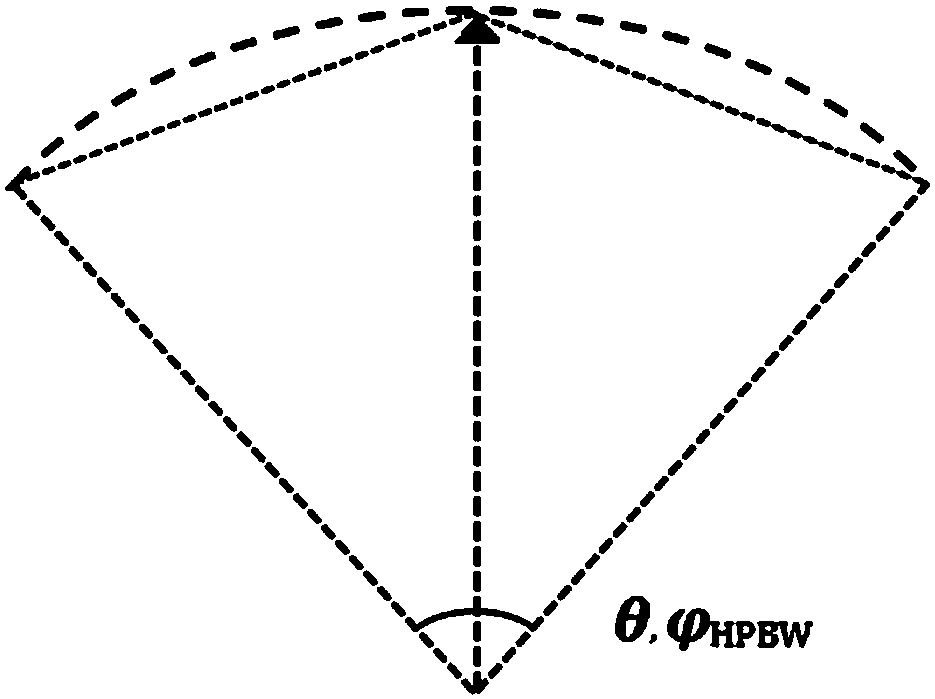

A low profile high gain fractal small base station antenna

ActiveCN105048066BRealize size miniaturizationLow profileAntenna adaptation in movable bodiesSection planeEar shaping

The invention discloses a low-profile high-gain fractal small-scale base station antenna, which is characterized in that it includes a radome, a reflector assembly, a substrate substrate, a metal partition array, a dielectric substrate printed with an antenna vibrator, and an antenna vibrator. The feeding coaxial feeder; the antenna vibrator includes four sheet-shaped units that are symmetrical about left and right, up and down, two units on each opposite corner of the four-sheet units form a pair of dipoles, and the four sheet-shaped units form a cross oscillator; Iterative I2 square von Koch fractal curves are connected head to tail to construct a Minkowski fractal ring, and then filled as a plane piece, and a pair of diagonals are constructed at the upper right corner or upper left corner of the fractal ring with the diagonal as the axis of symmetry Ears, formed by merging them with fractal rings. Through the reasonable design of the antenna structure of the fractal small base station, the present invention realizes significant suppression of low profile back lobe, significant improvement of front-to-back ratio and cross polarization ratio; realizes high gain and high efficiency that cannot be achieved by a pair of conventional cross oscillators.

Owner:GUANGDONG SHENGLU TELECOMM TECH +1

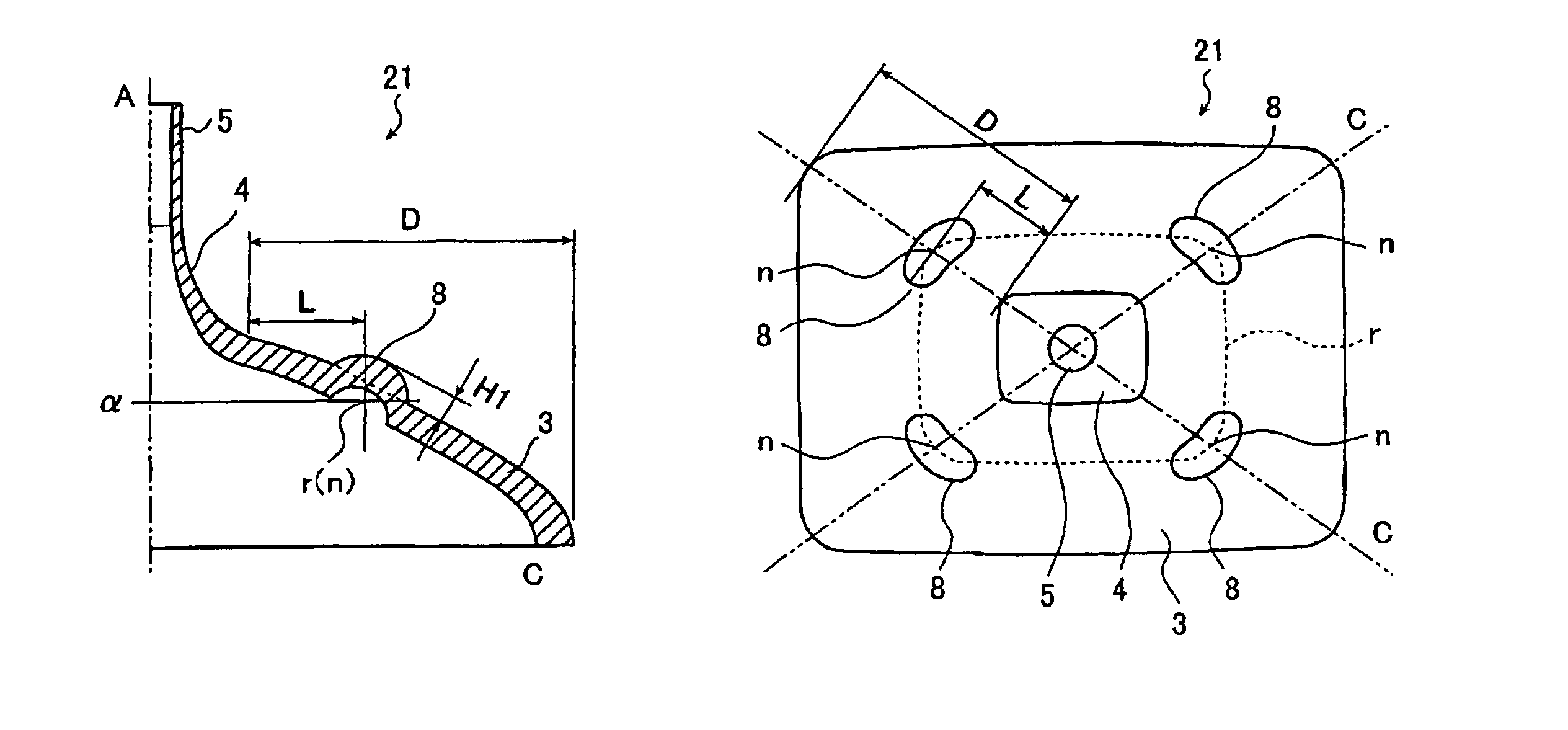

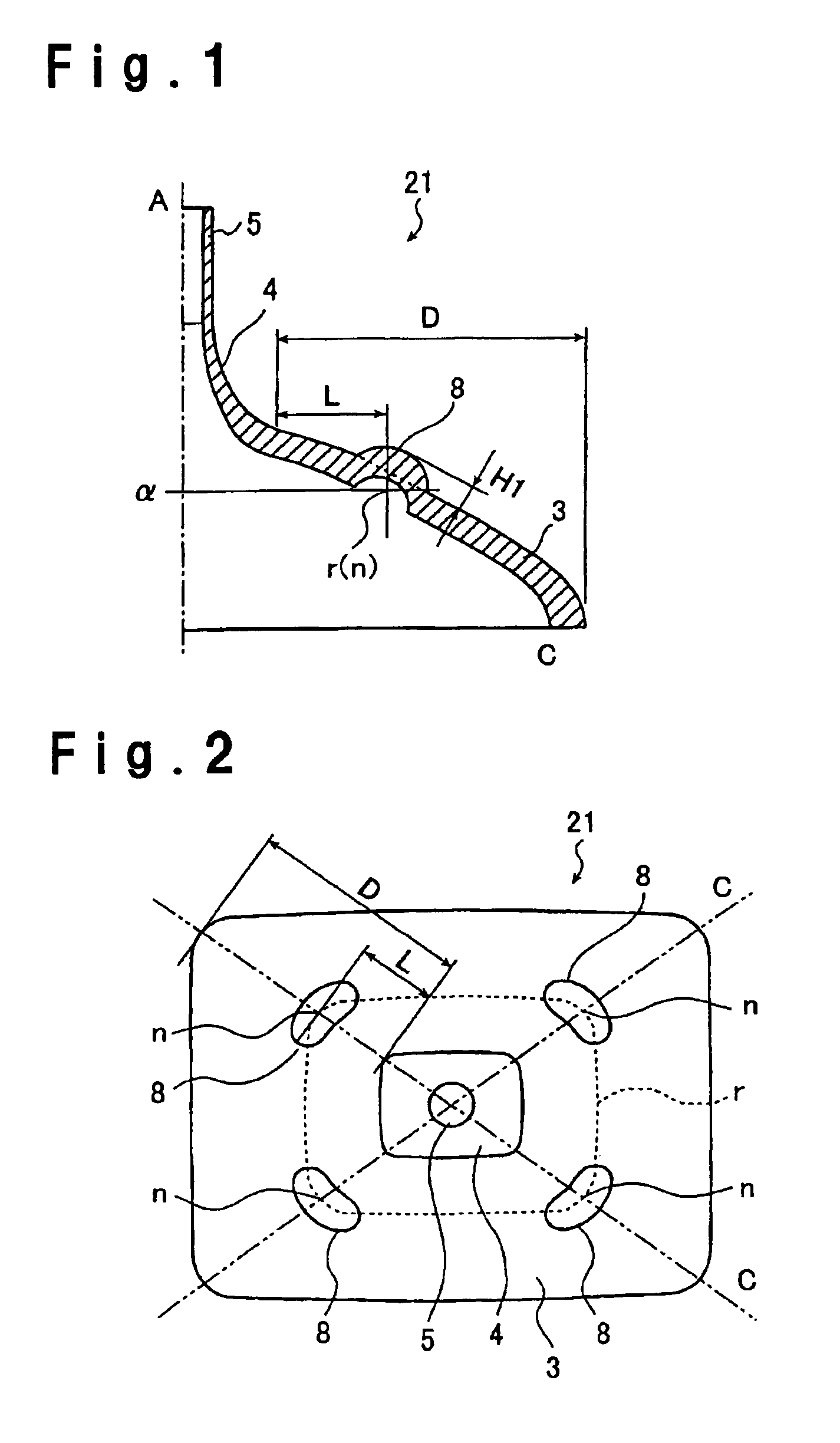

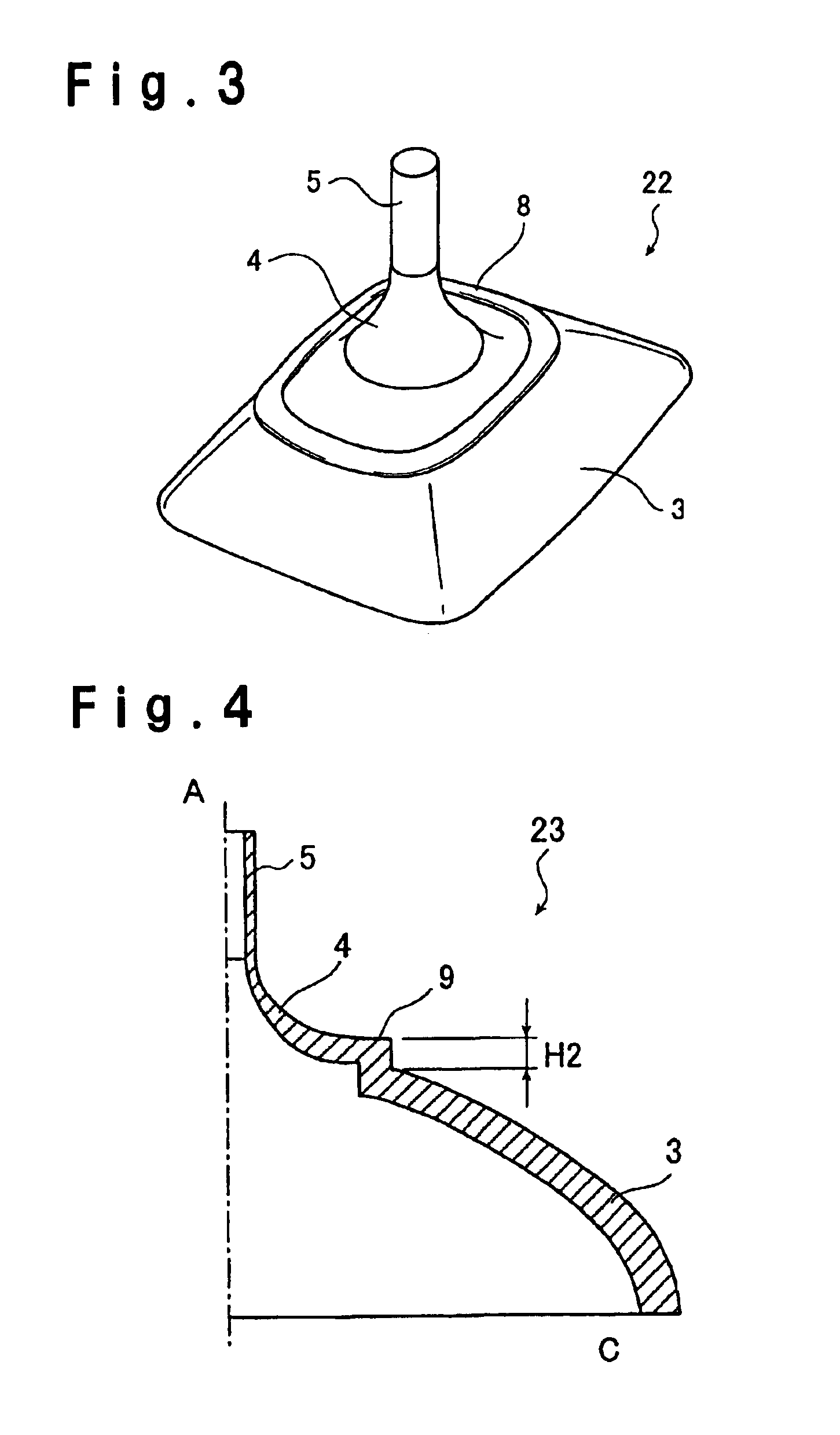

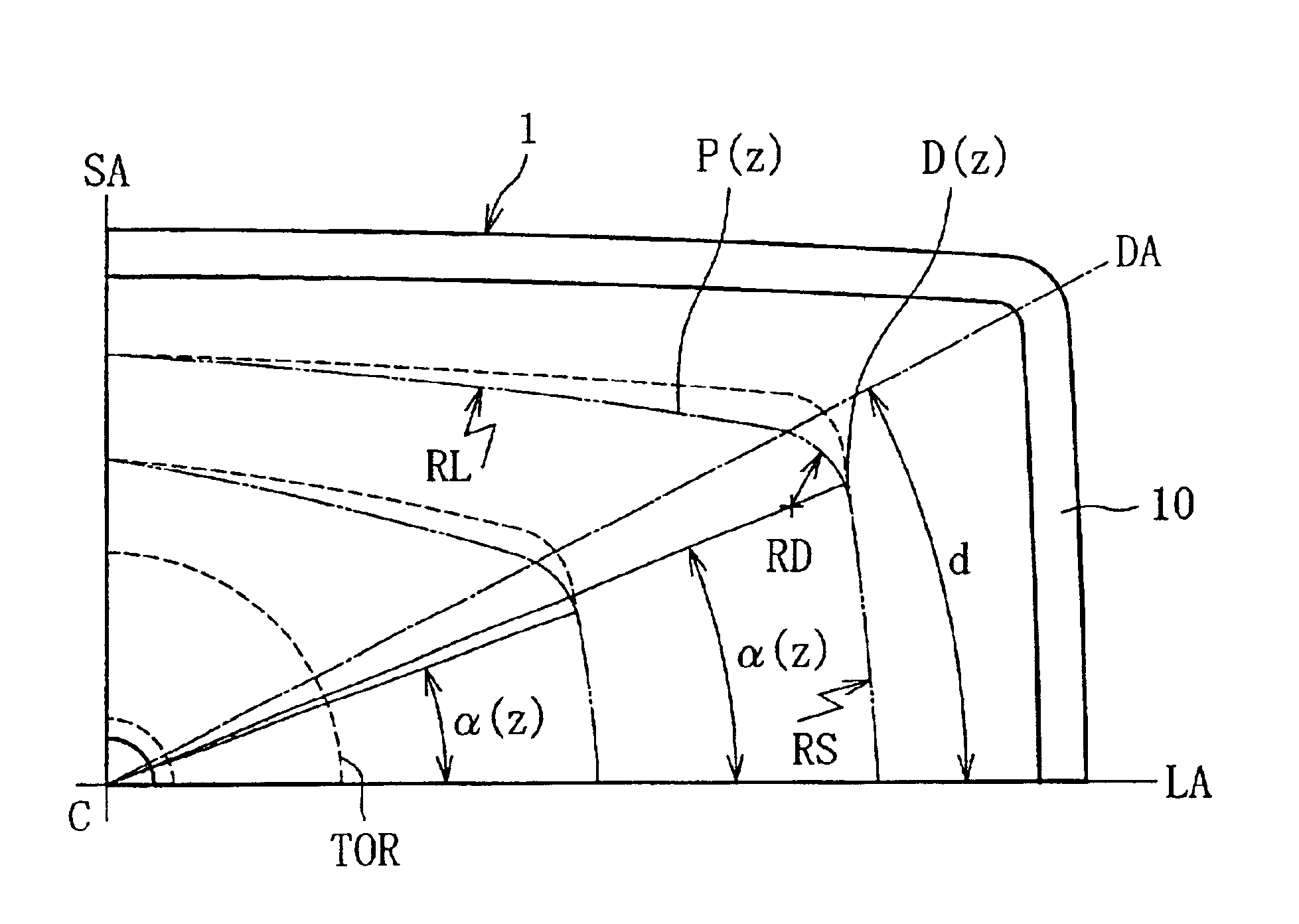

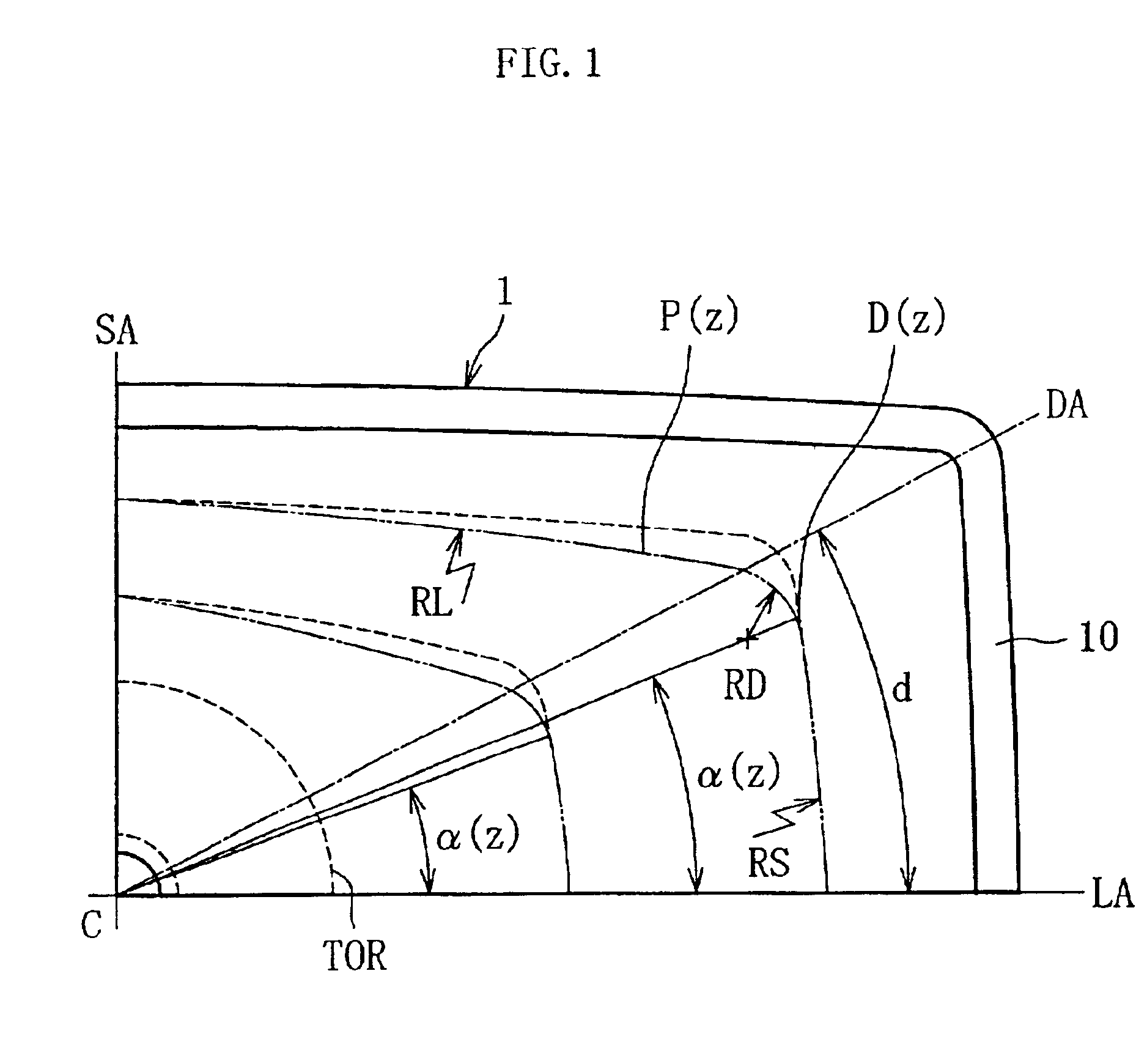

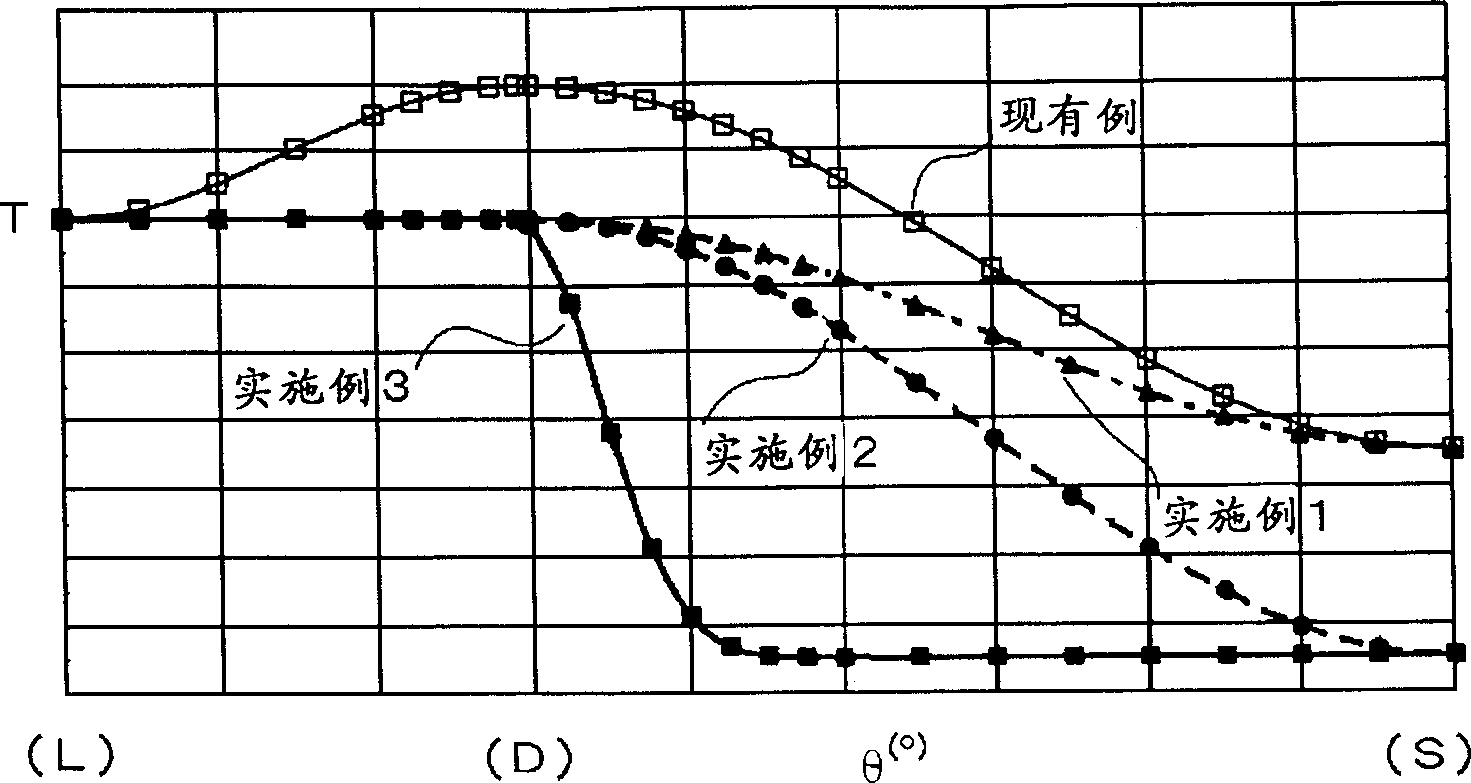

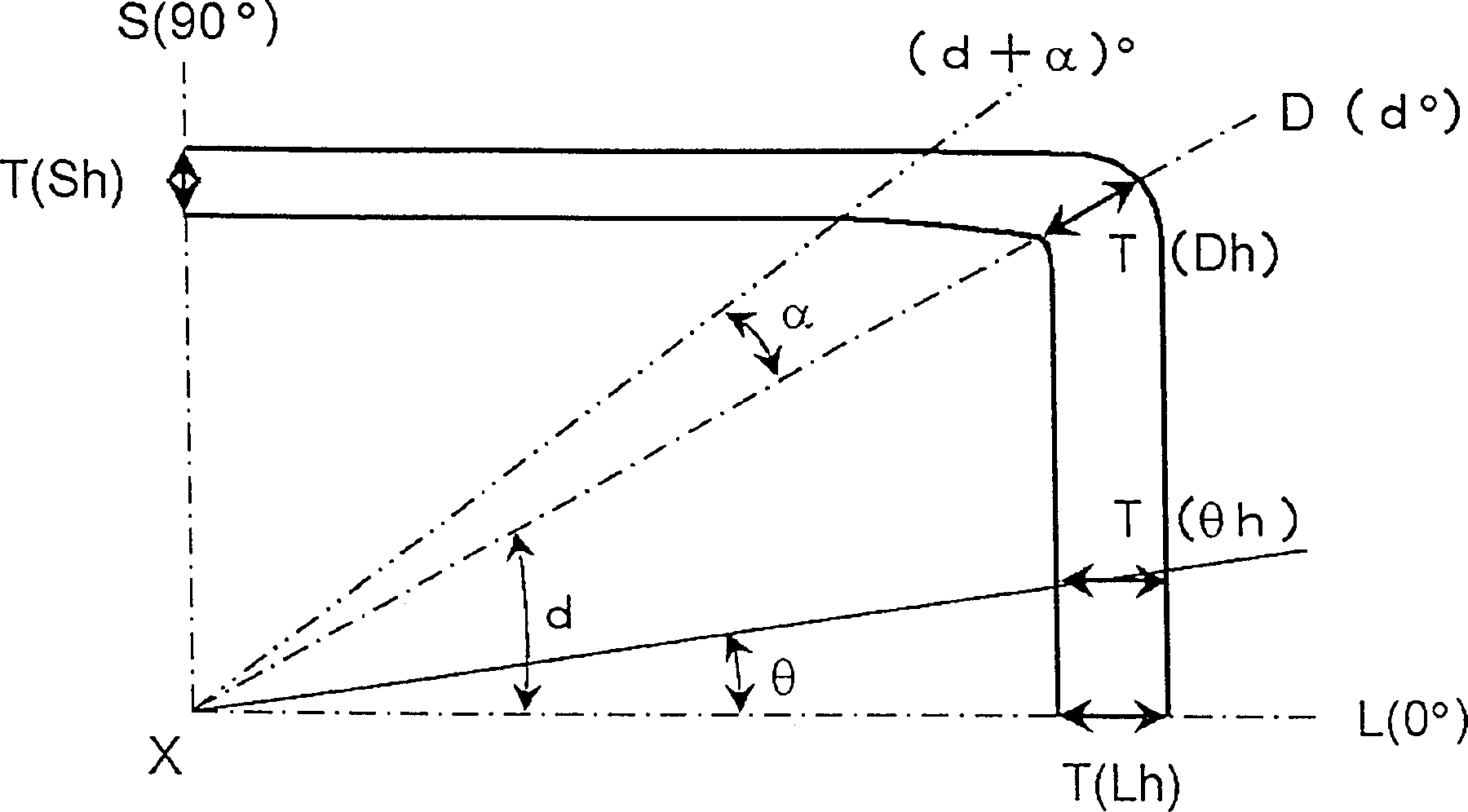

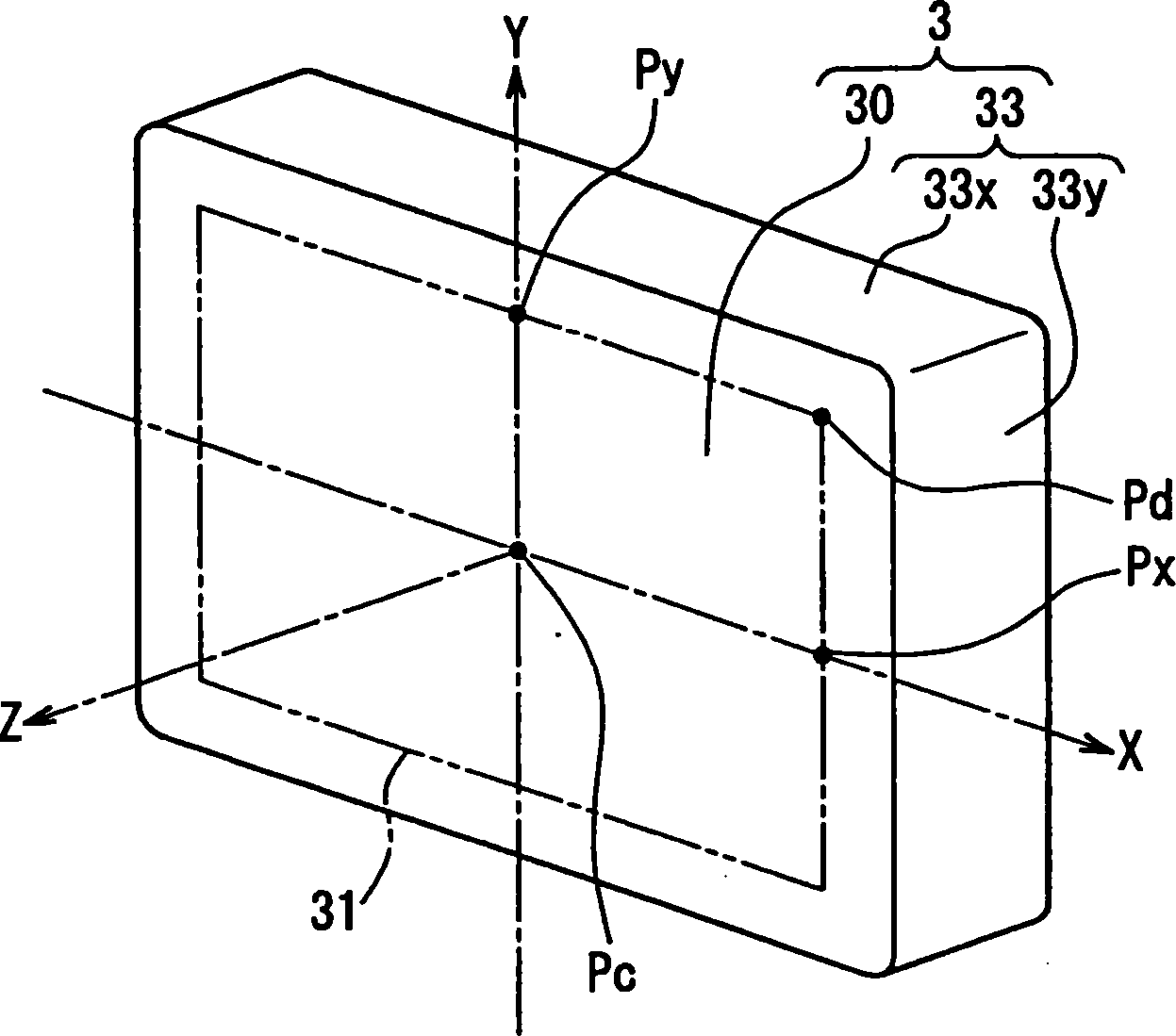

Funnel for cathode ray tube

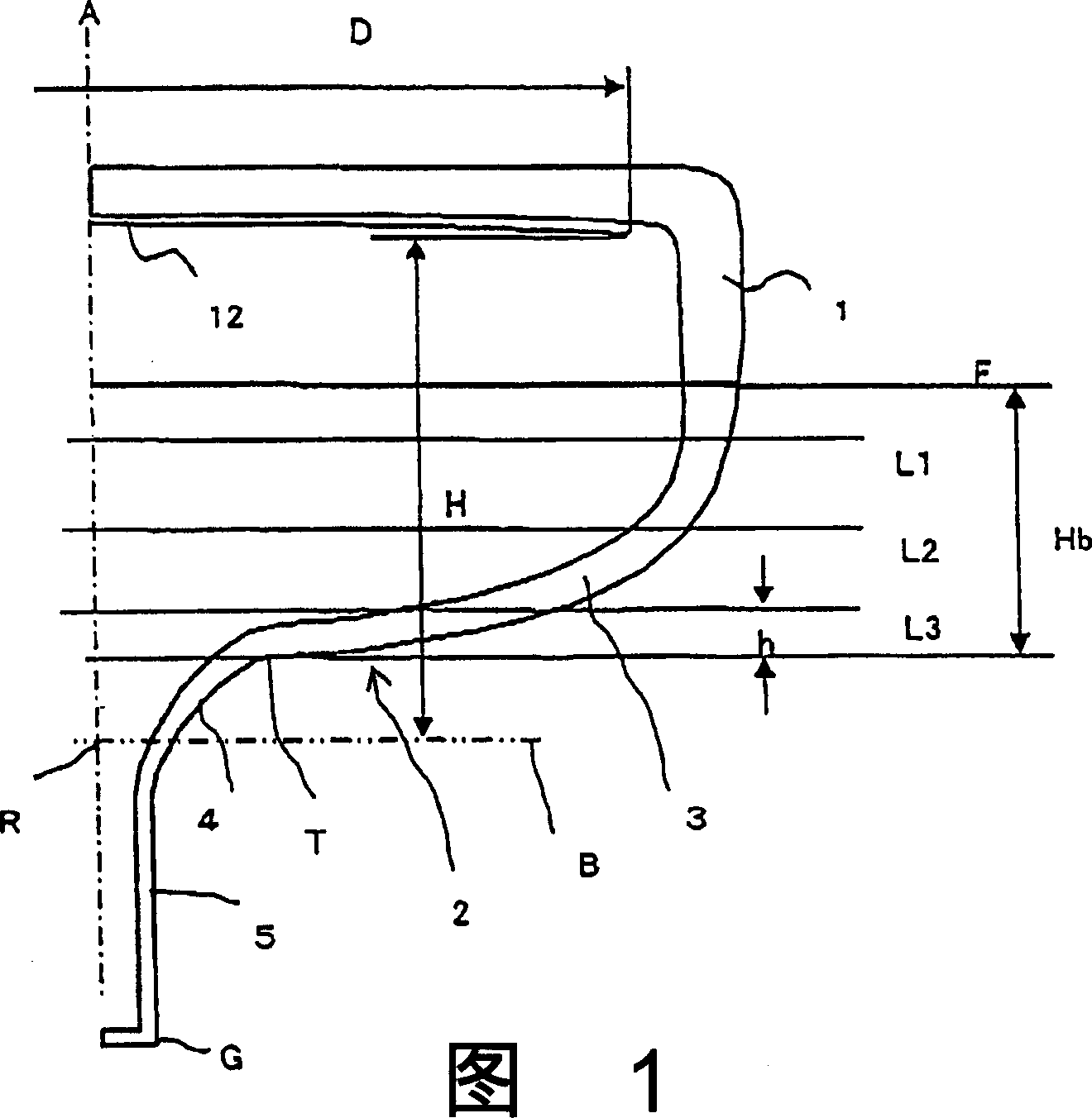

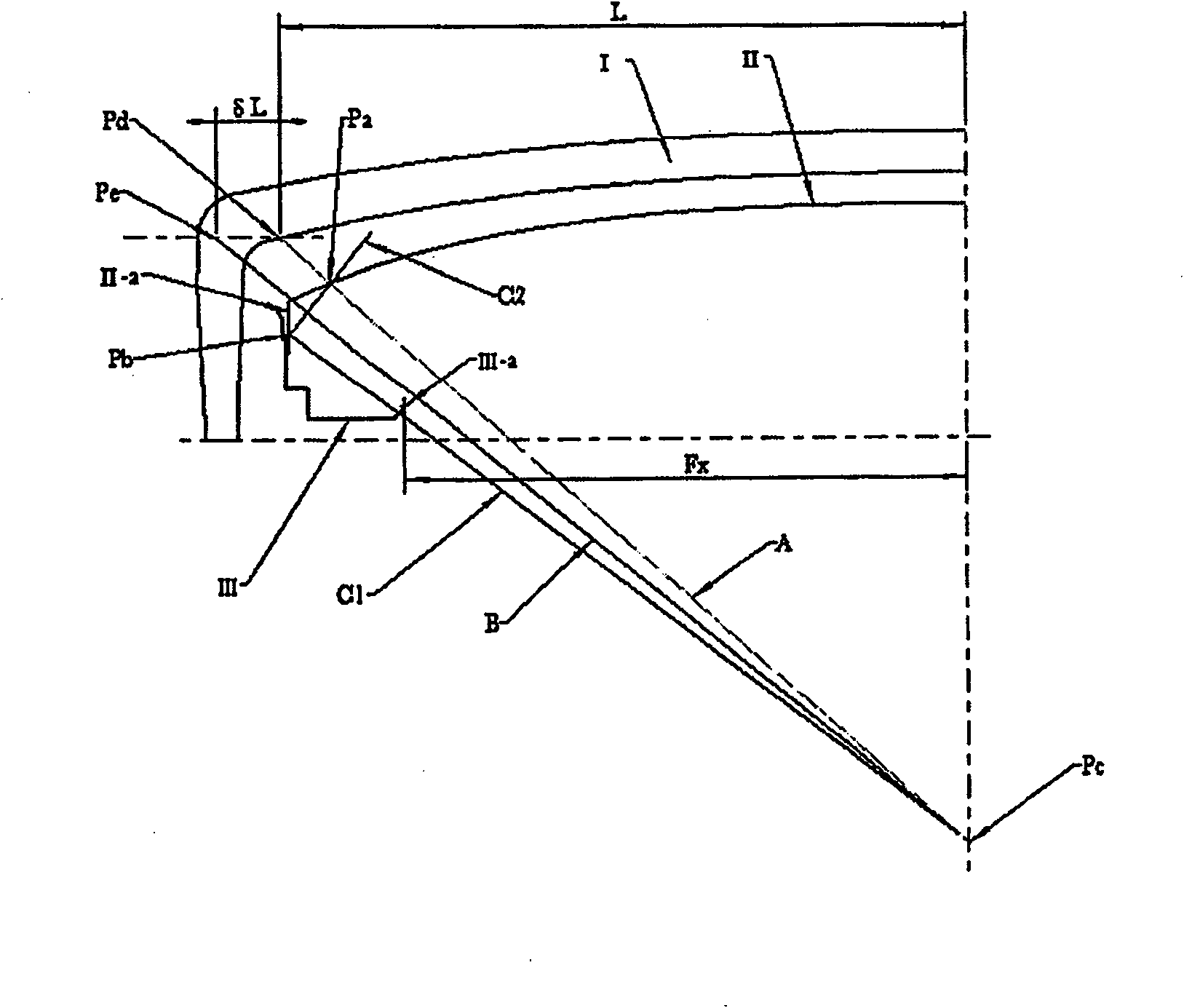

InactiveUS6861795B2Avoid extensive crackingExtension of timeCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersLong axisEngineering

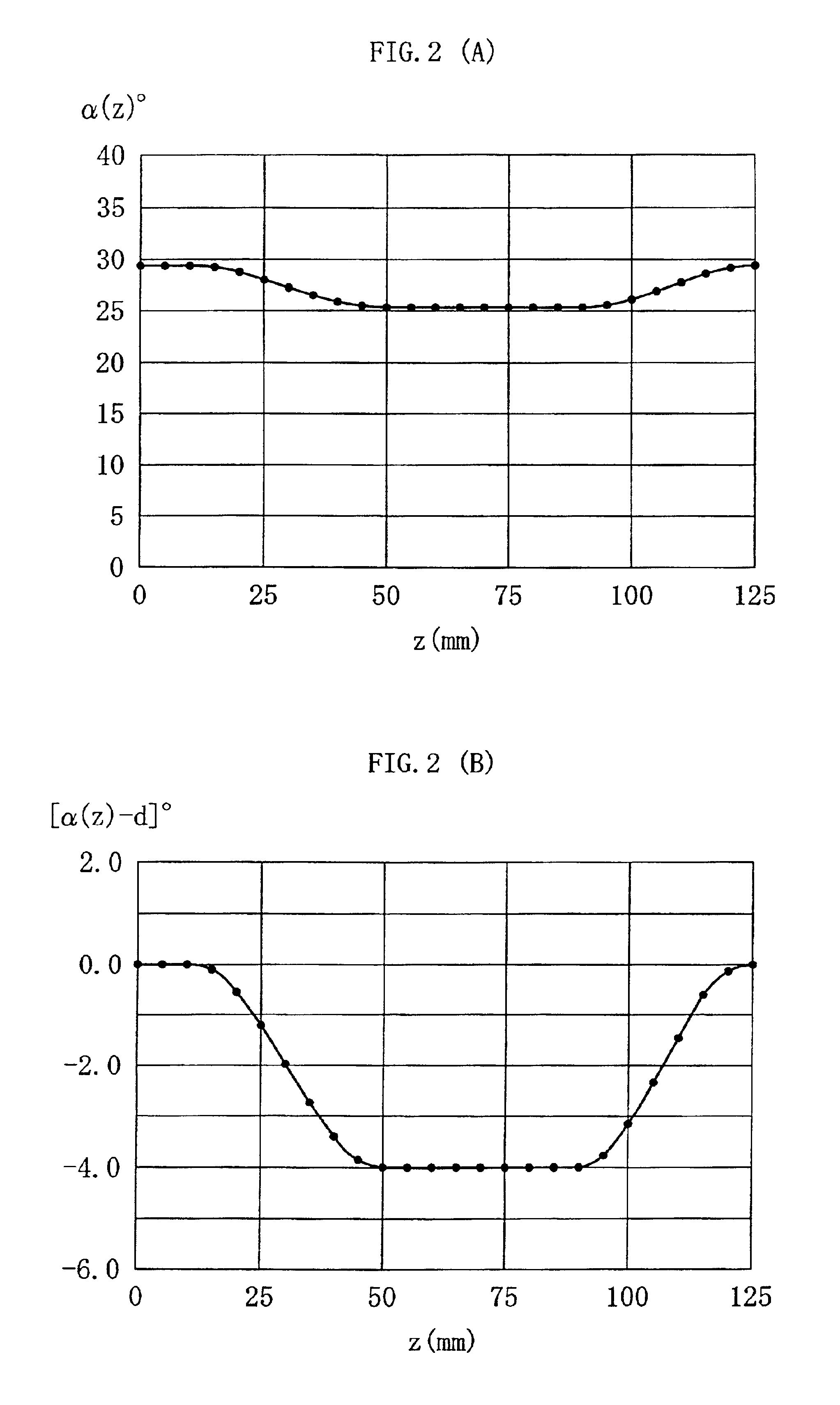

A funnel for a cathode ray tube has a relationship 0<α(z)<d in an arbitrary cross section P(z) parallel with a plane including an open end portion, where α(z) is an angle (°) defined between a line and a major axis (LA) of the funnel, the line being connecting an outermost part D(z) on at least one of an outer surface and an inner surface of the body portion and a center axis (C) of the funnel, and d is an angle (°) defined between a diagonal axis (DA) of the funnel and the major axis (LA).

Owner:NIPPON ELECTRIC GLASS CO LTD

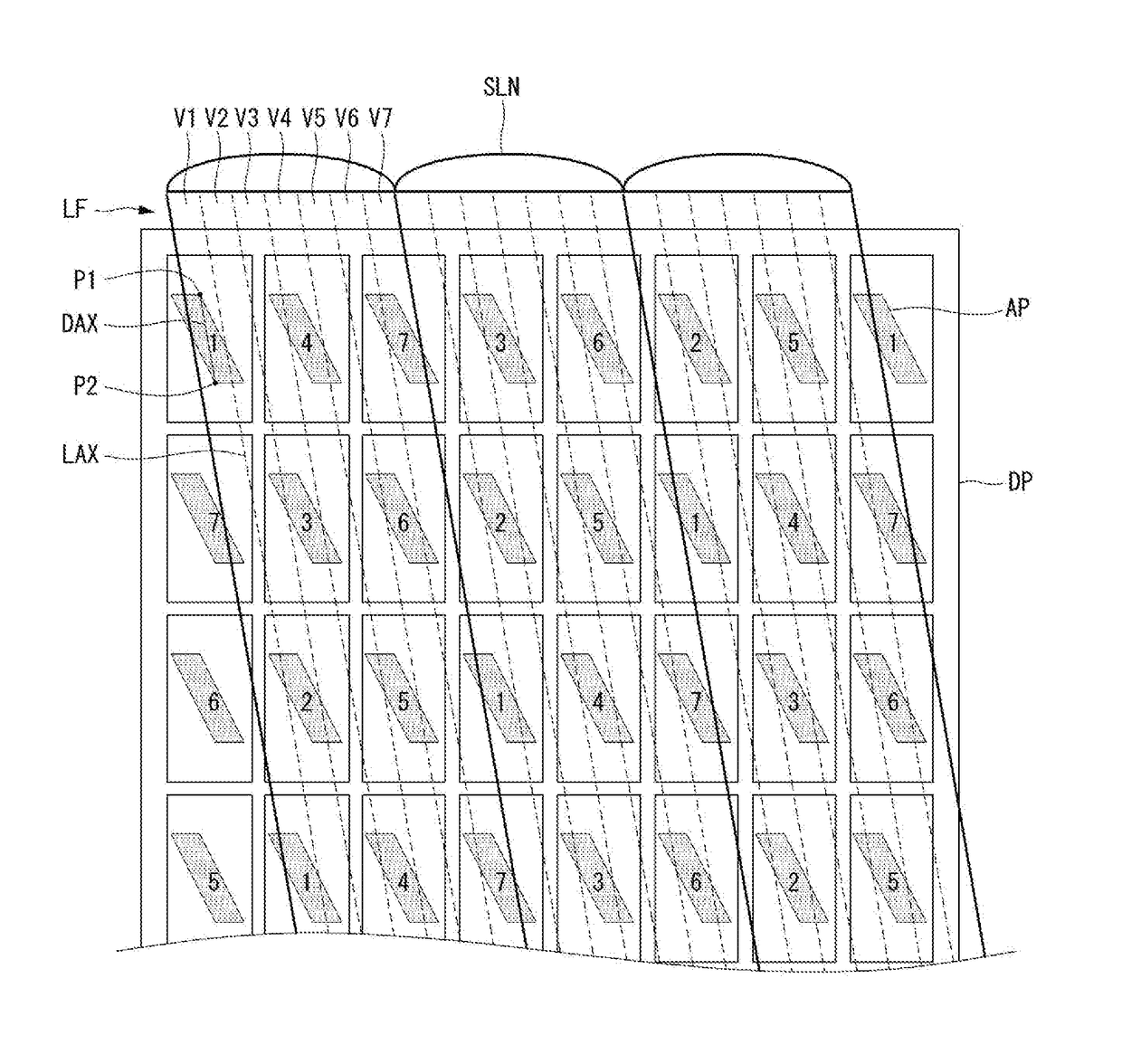

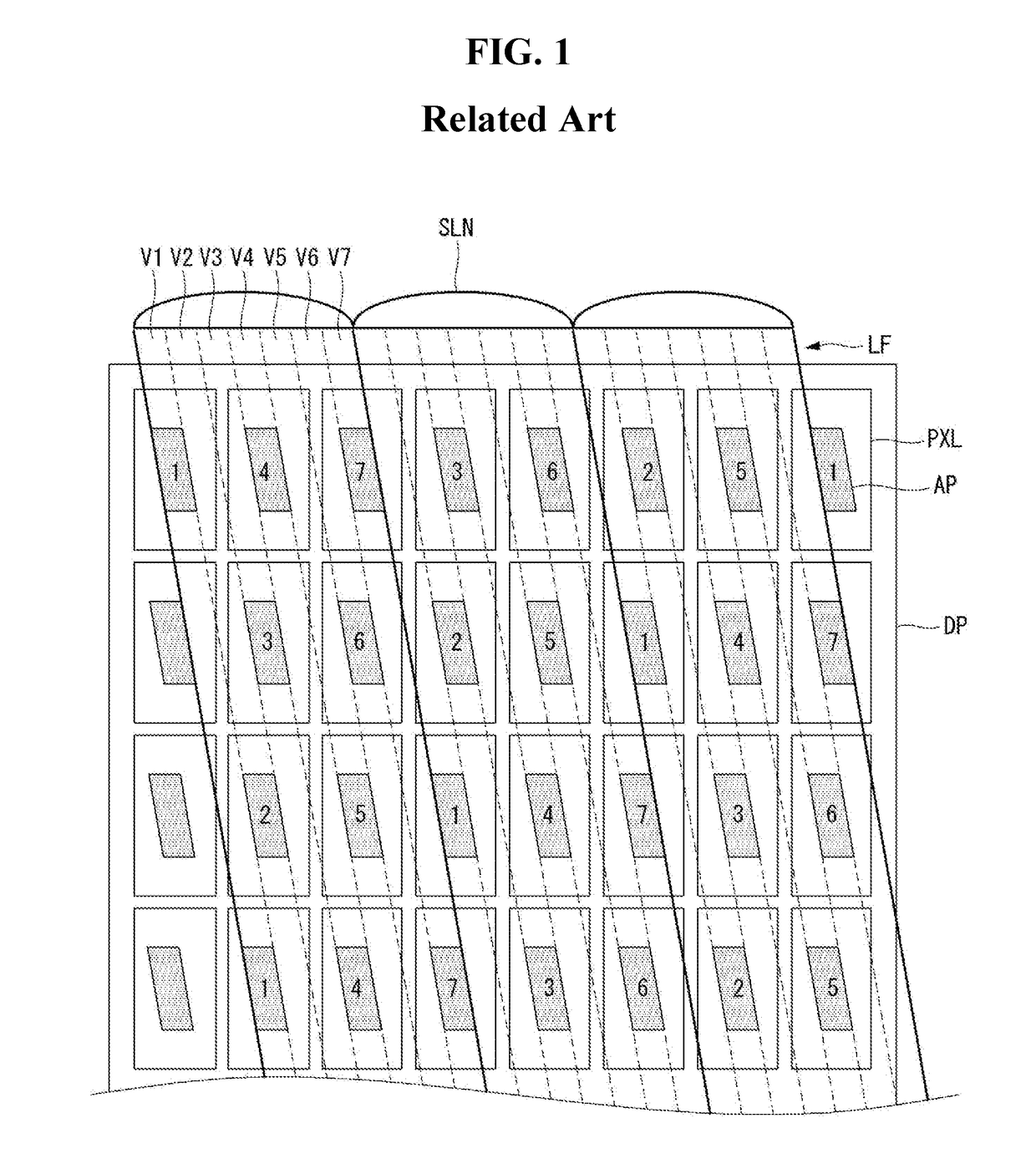

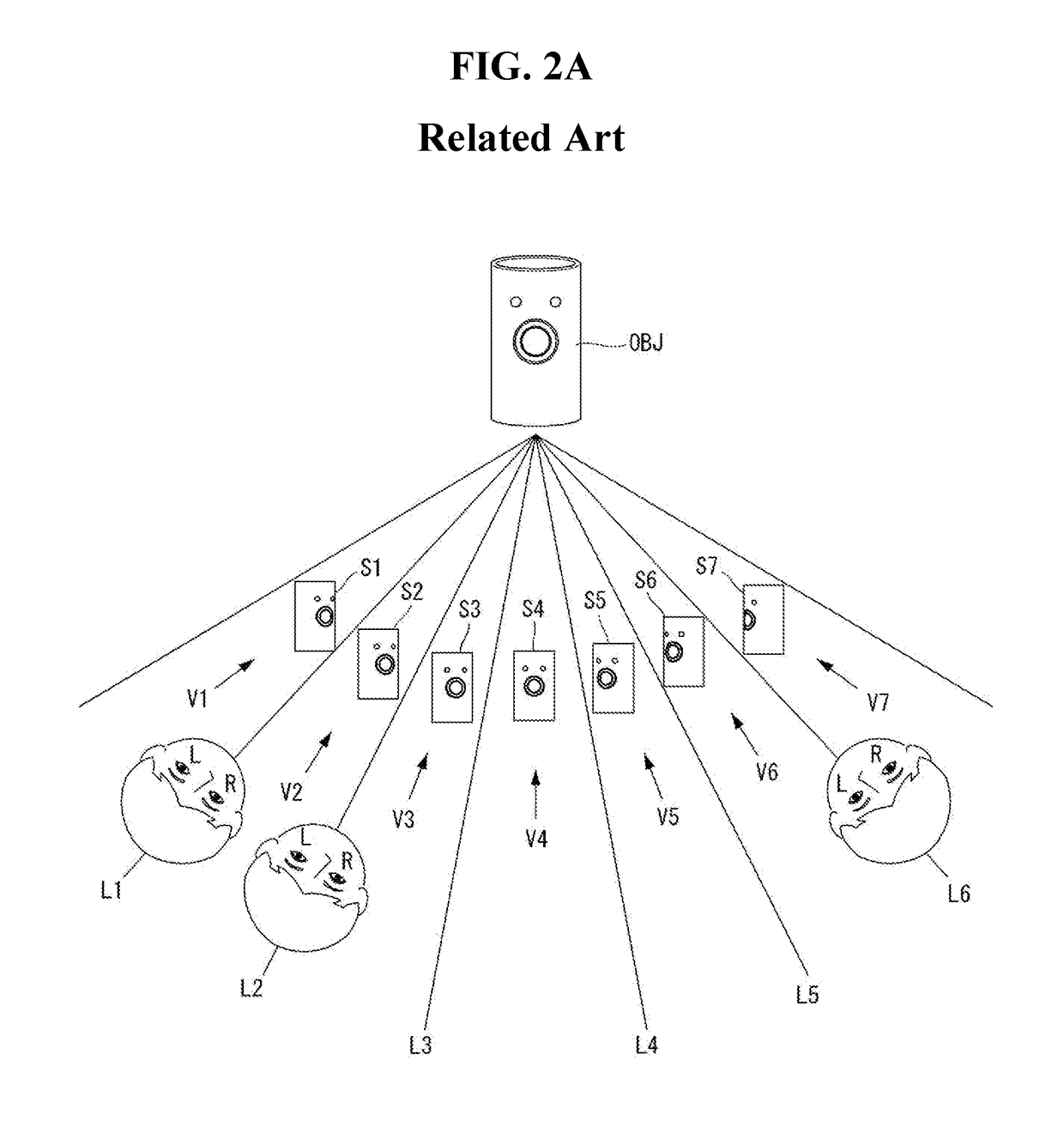

Autostereoscopic 3-dimensional display

ActiveUS10735715B2Remarkable variationNo luminance variationSteroscopic systemsDisplay deviceEngineering

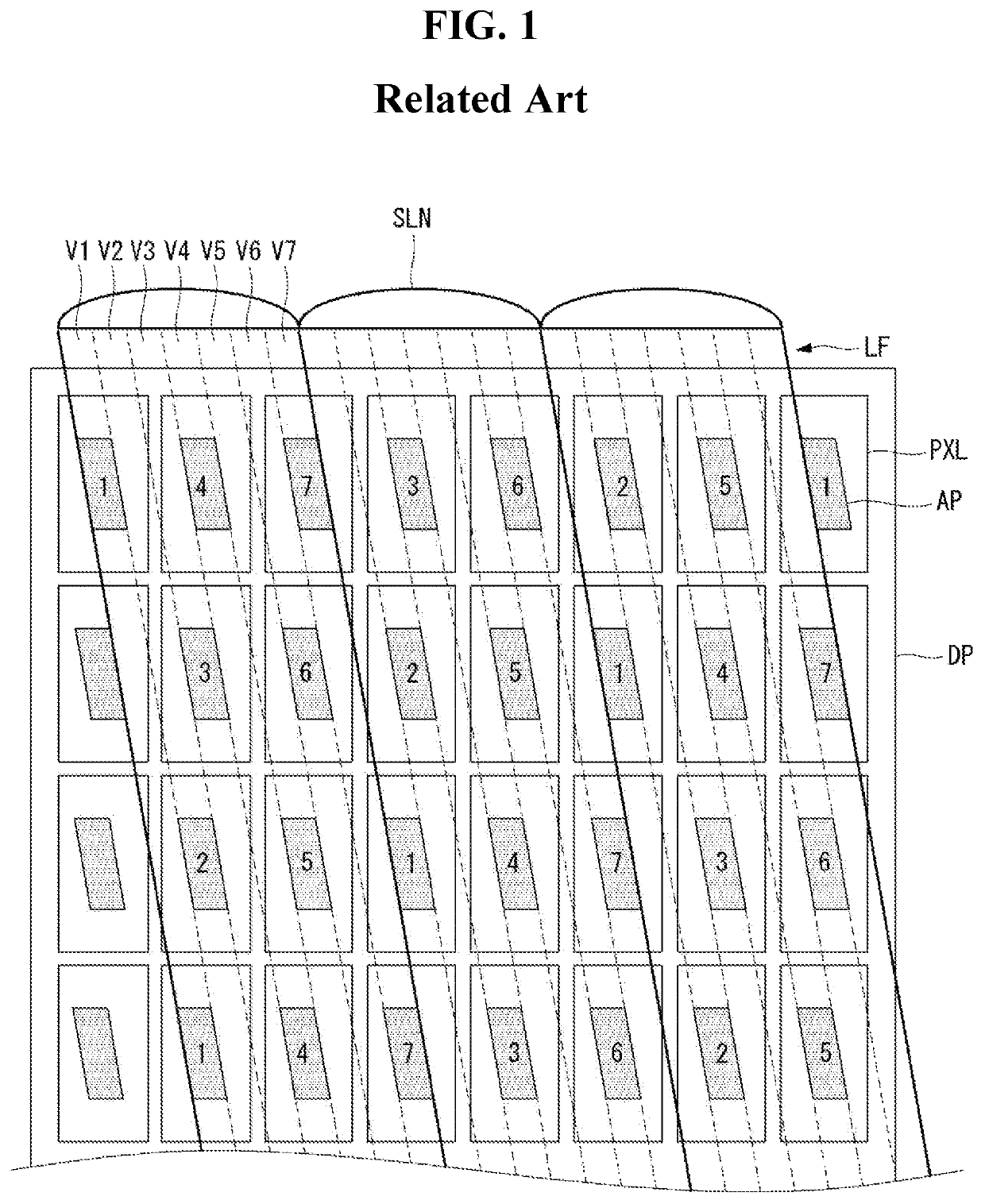

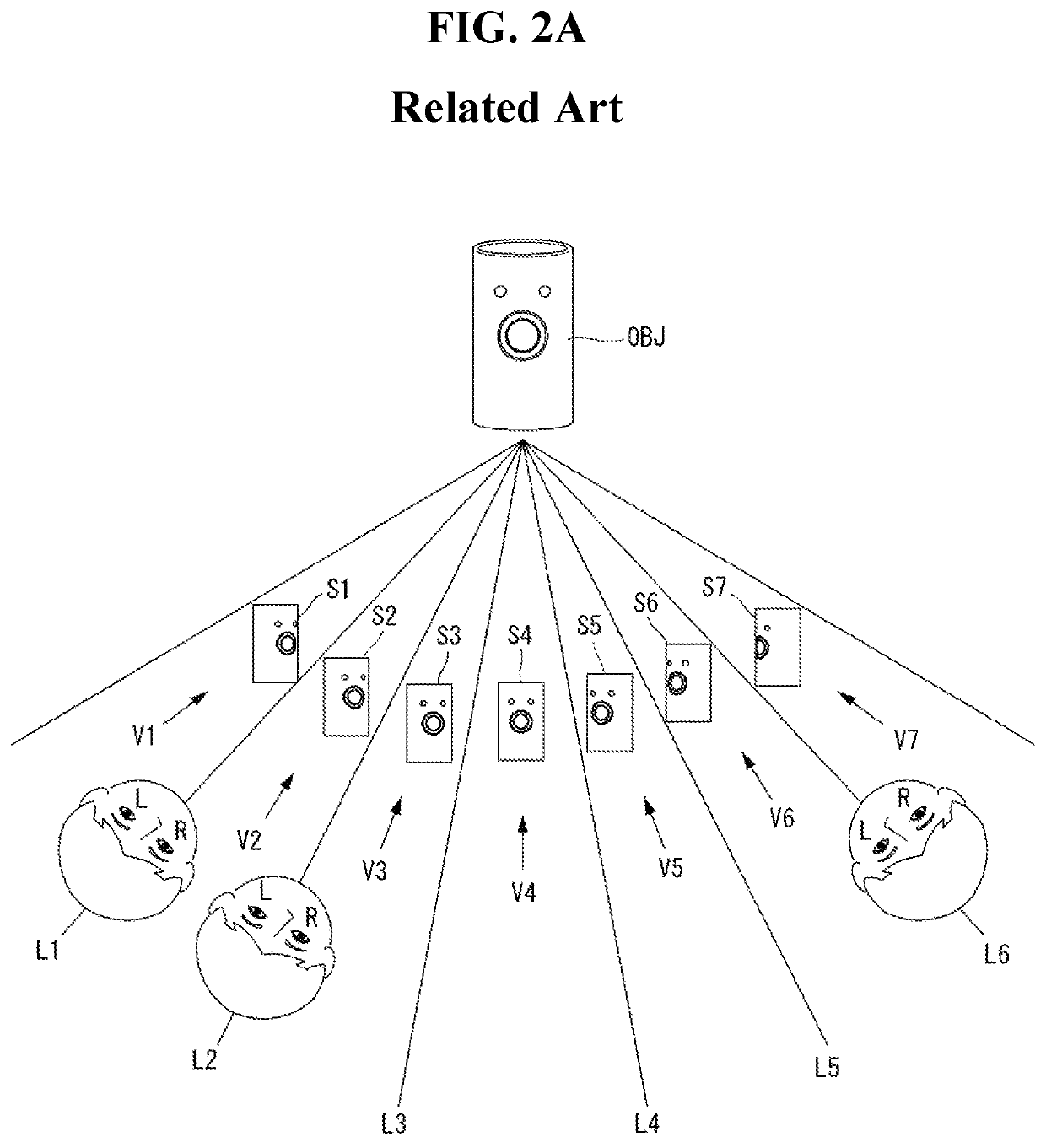

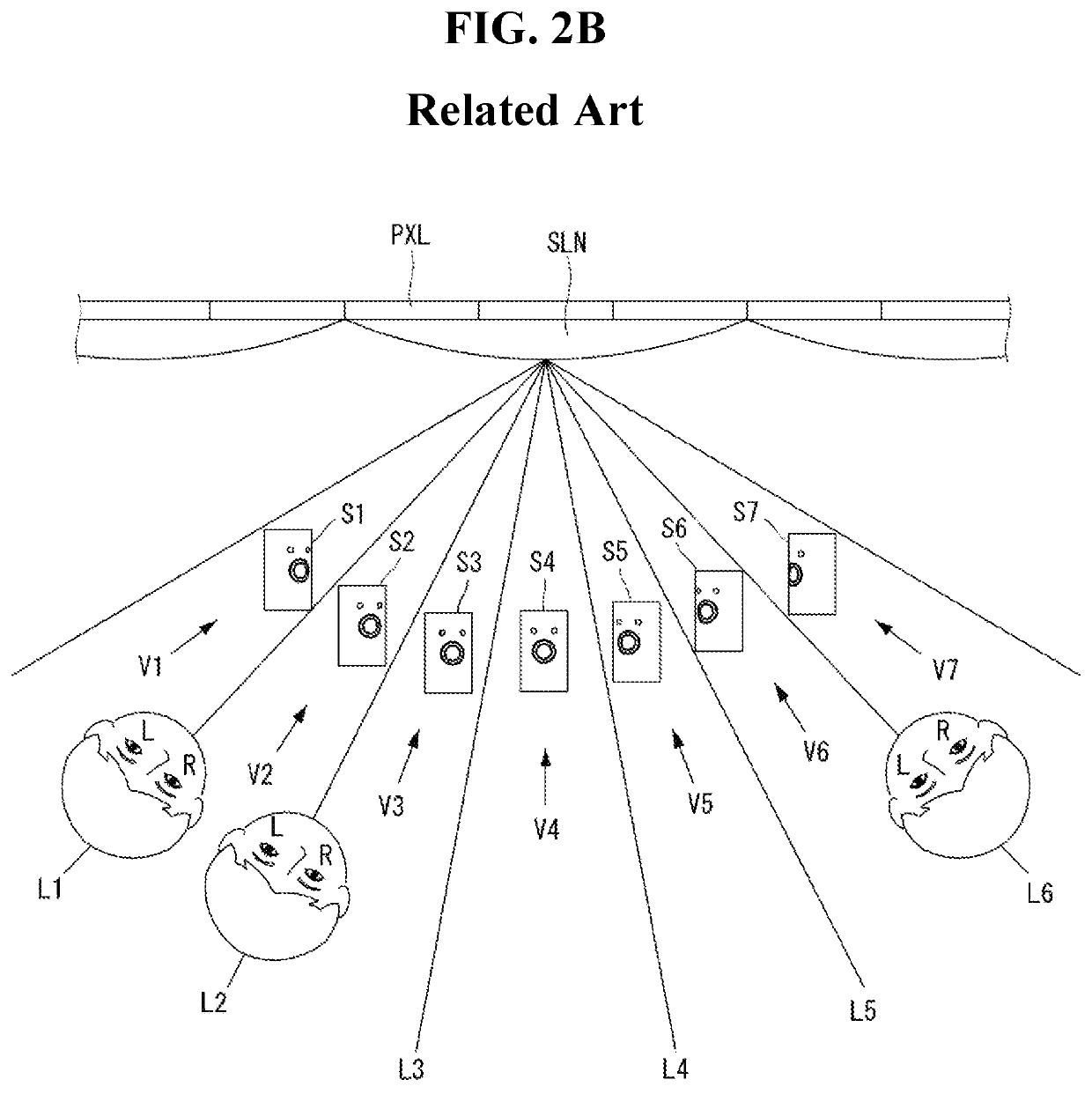

An autostereoscopic three-dimensional (3D) display, in which a multi view structure is configured by using a lenticular lens, includes a display panel including a plurality of pixels, and an aperture area disposed at each pixel; and a lens film disposed on a front surface of the display panel and including a plurality of lenticular lenses, the lenticular lenses having a slanted axis and continuously arrayed along to a lateral direction, in which the aperture area includes a parallelogram shape, and the slanted axis is parallel with any one diagonal axis of the aperture area.

Owner:LG DISPLAY CO LTD

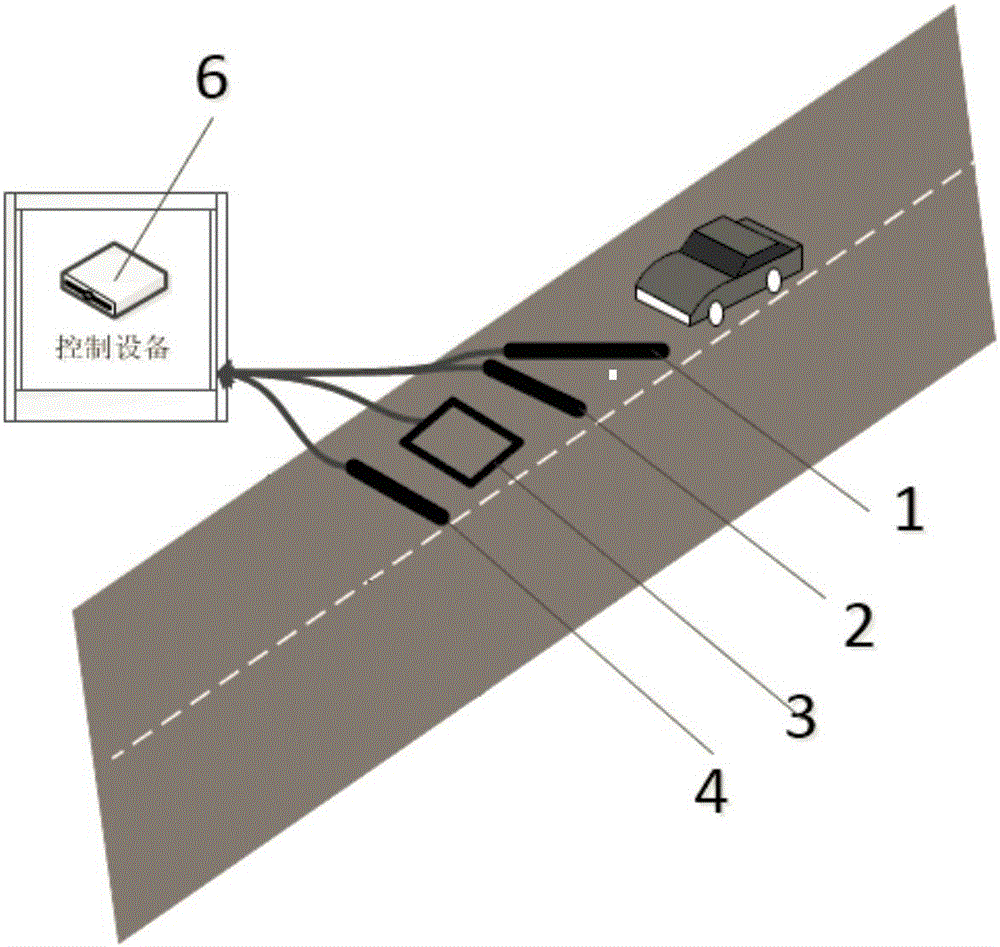

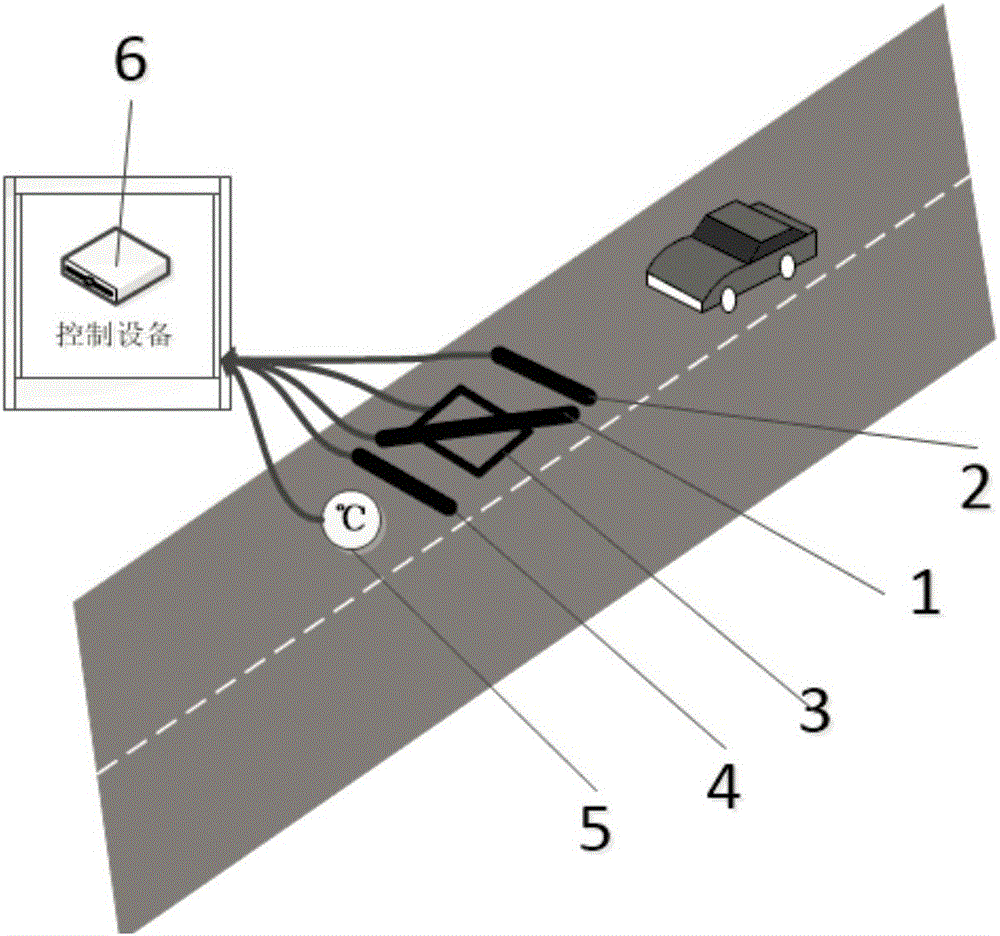

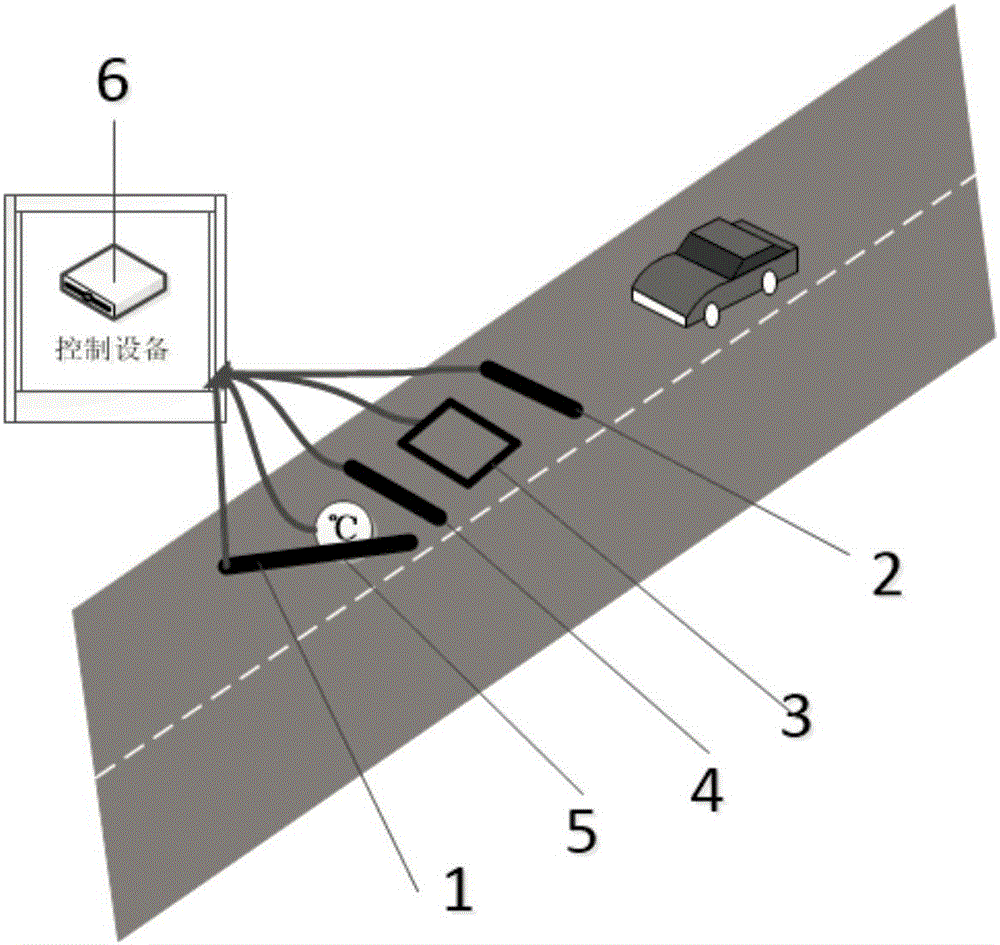

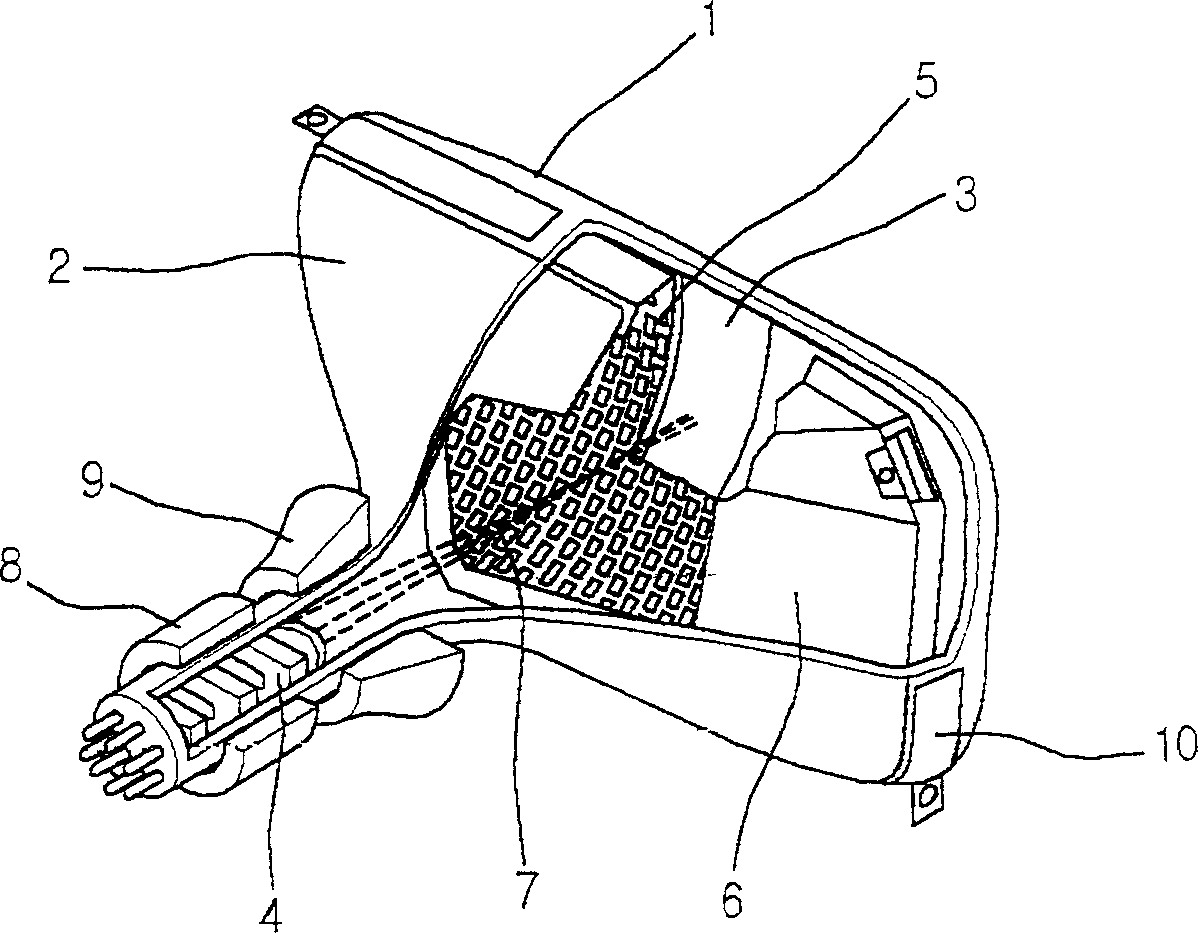

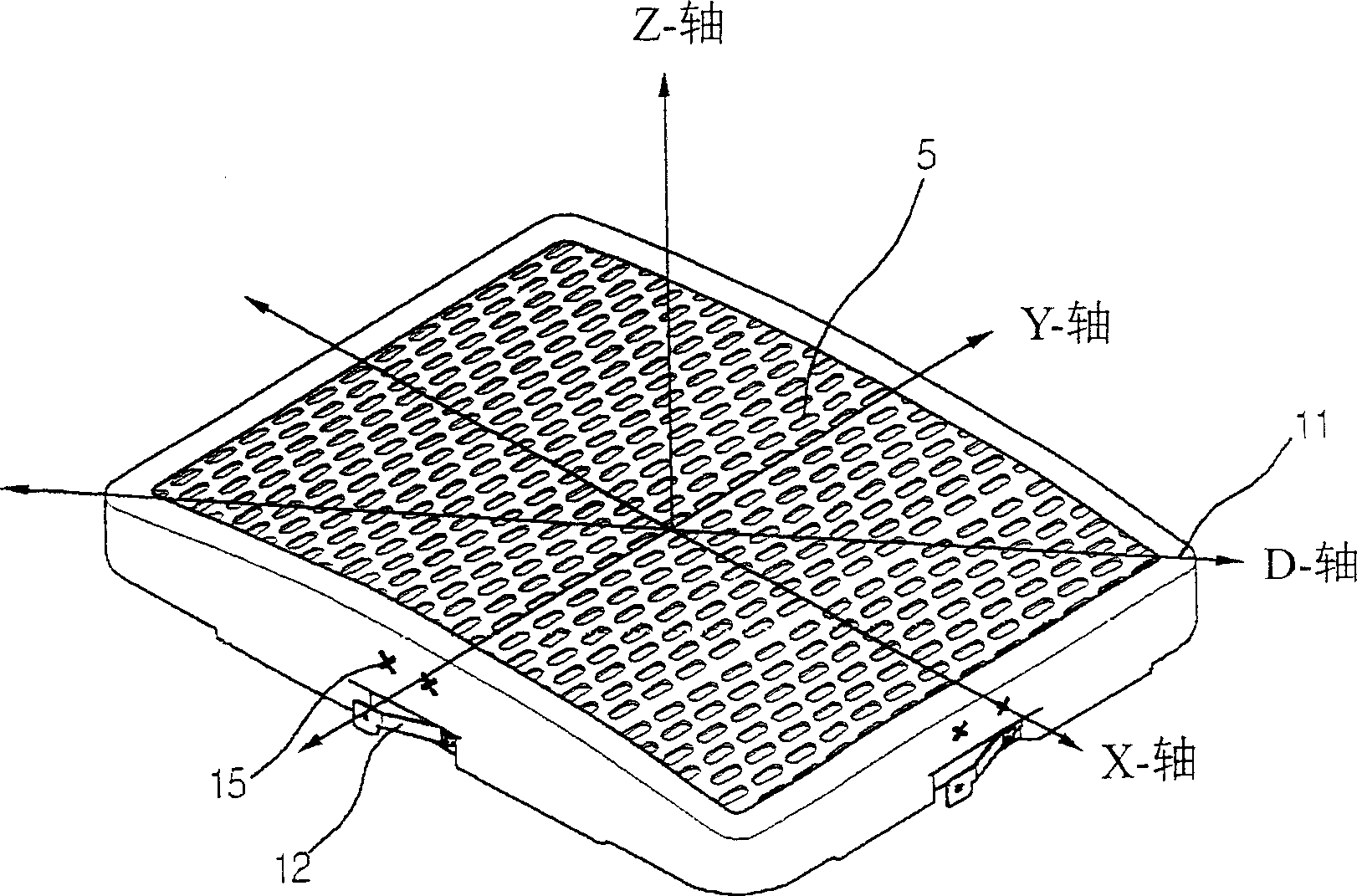

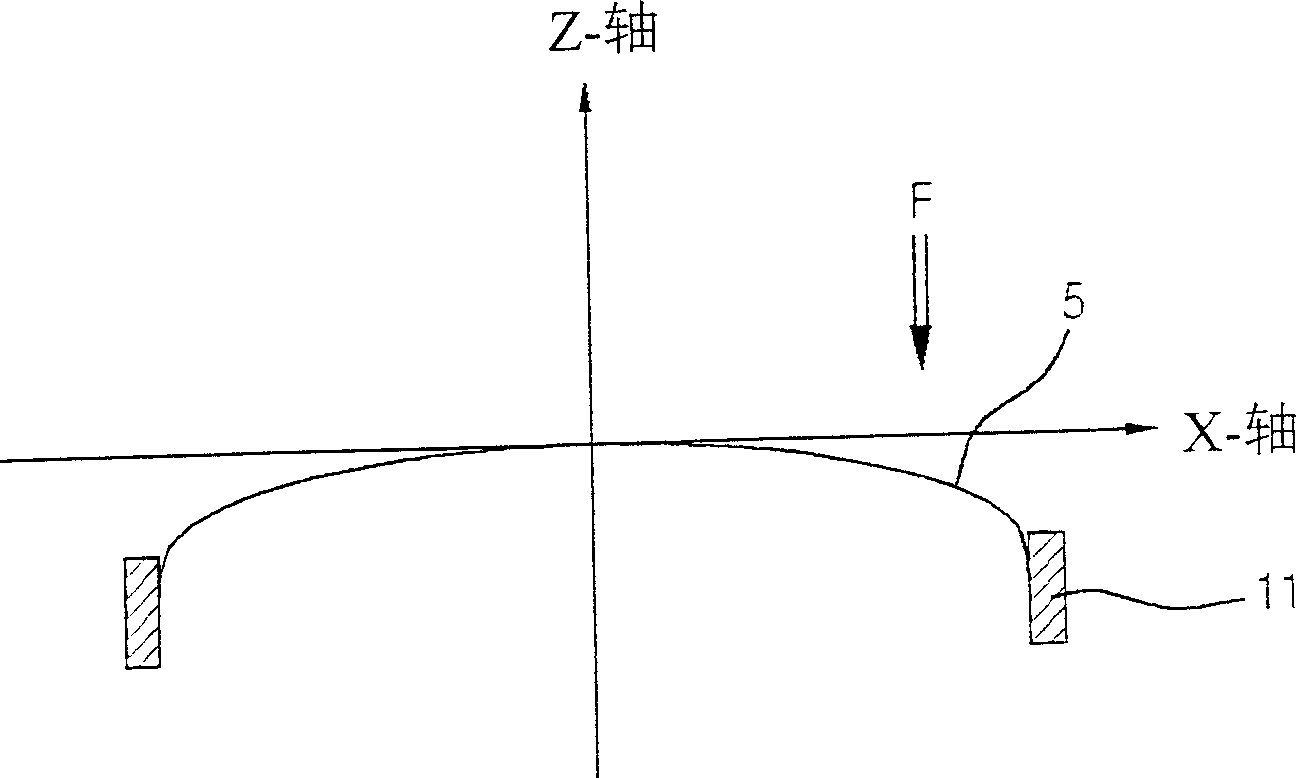

Diagonal axis type dynamic weight measurement system and diagonal axis type dynamic weight measurement method

InactiveCN106644007AEasy to correctHigh precisionWeighing apparatus testing/calibrationSpecial purpose weighing apparatusEngineeringTruck

The invention provides a diagonal axis type dynamic weight measurement system and a diagonal axis type dynamic weight measurement method. The system comprises a diagonal piezoelectric axis, a driving-in speed piezoelectric axis and a driving-out speed piezoelectric axis which are arranged in a weight measurement area, and a control device which is connected with the diagonal piezoelectric axis, the driving-in piezoelectric axis and the driving-out speed piezoelectric axis. The control device calculates the weight of a truck according to electrical signals output by the diagonal piezoelectric axis, the driving-in piezoelectric axis and the driving-out speed piezoelectric axis, and displays the weight of the truck. The method comprises the following steps: the time difference is calculated according to two voltage curve peaks obtained when the two front wheels of a truck in a measurement area drive into the driving-in speed piezoelectric axis and the driving-out speed piezoelectric axis, and the speed of the truck is determined; the positions of the wheels are calculated according to the time difference between the two peaks of the front wheels obtained when the two front wheels drive into the diagonal piezoelectric axis; and the control device establishes a relevant database based on the peak area, truck speed, wheel position and ambient temperature obtained through integration of the voltage curve peaks acquired by the two front wheels, the driving-in speed piezoelectric axis and the driving-out speed piezoelectric axis, and a voltage curve is calculated and corrected to get the weight of the truck. The system and the method are used in traffic overweight detection and industrial park anti-theft detection.

Owner:辉因科技(北京)有限公司

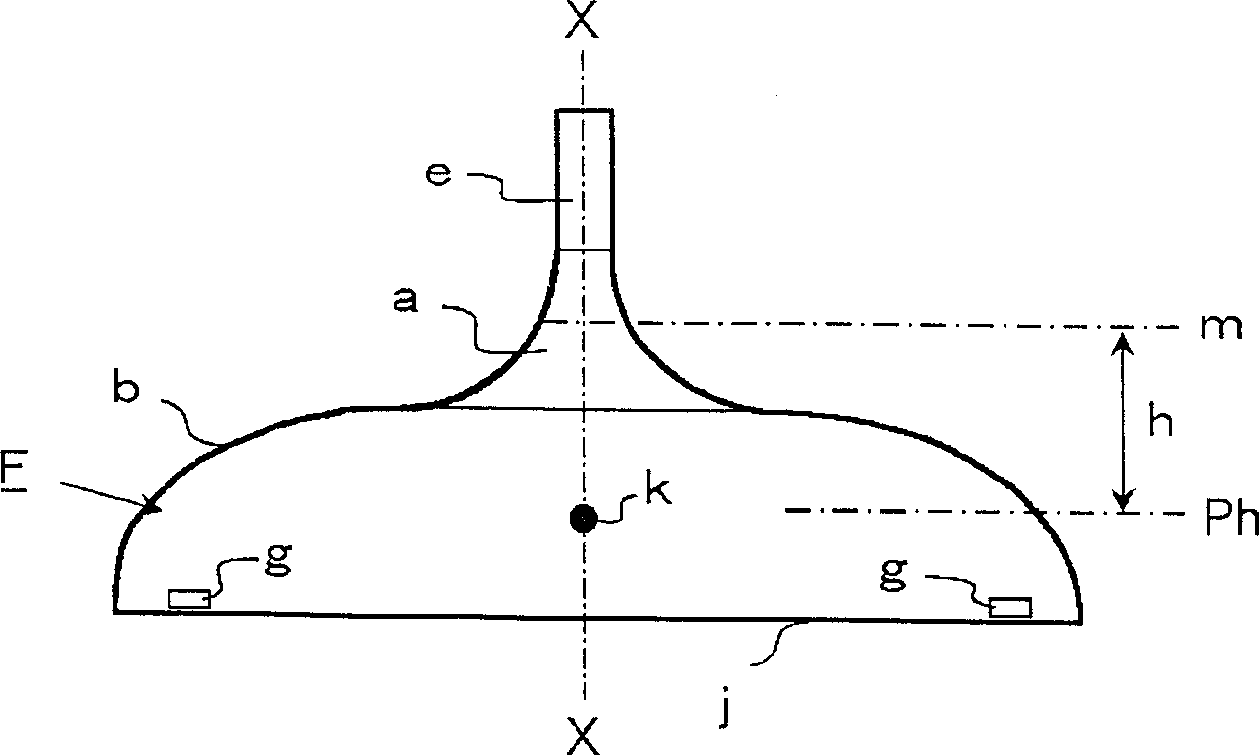

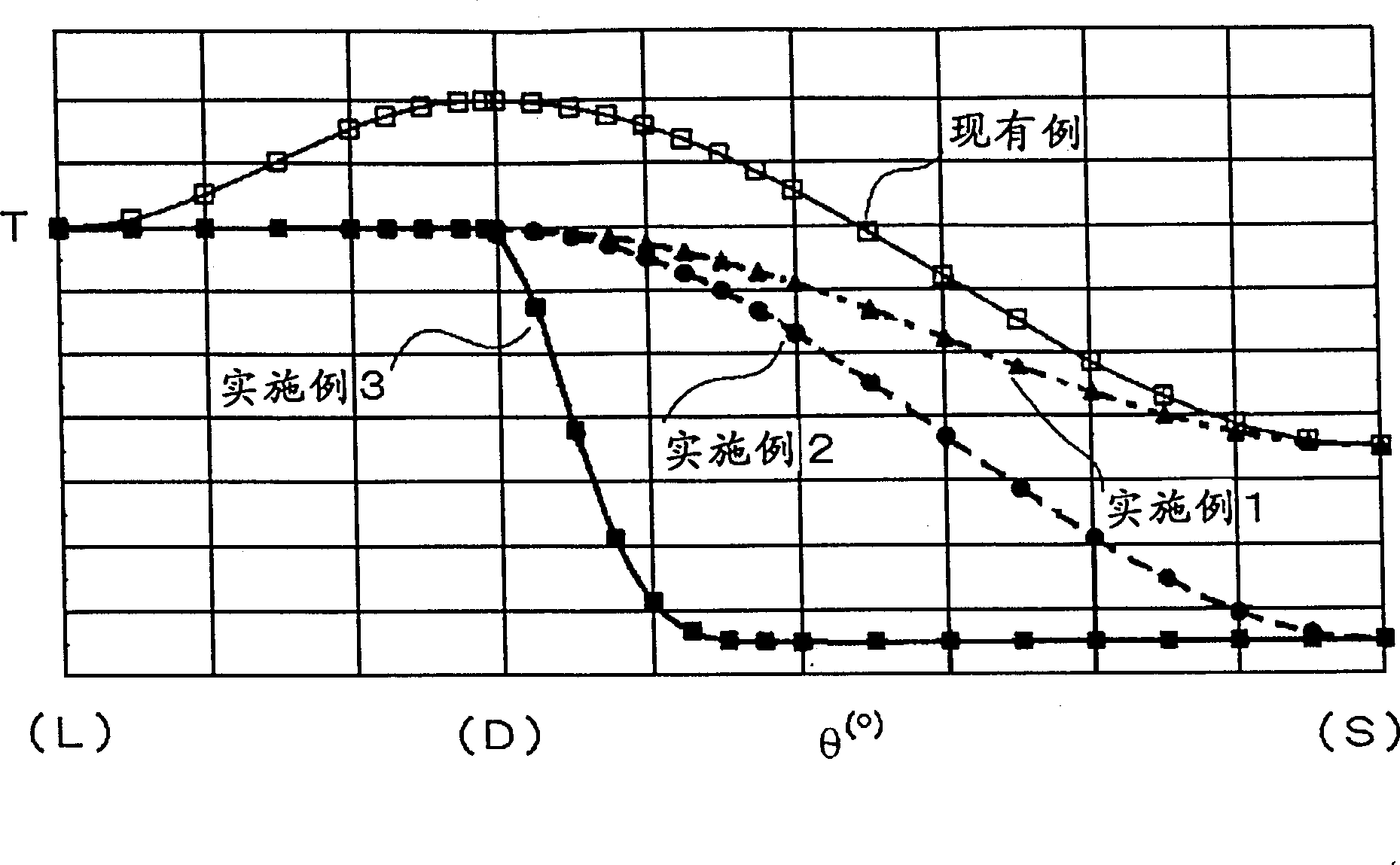

Conic-body for cathode-ray tube

InactiveCN1375855ANo loss of mechanical strengthDoes not reduce formabilityCathode-ray/electron-beam tube vessels/containersStructural engineeringUltimate tensile strength

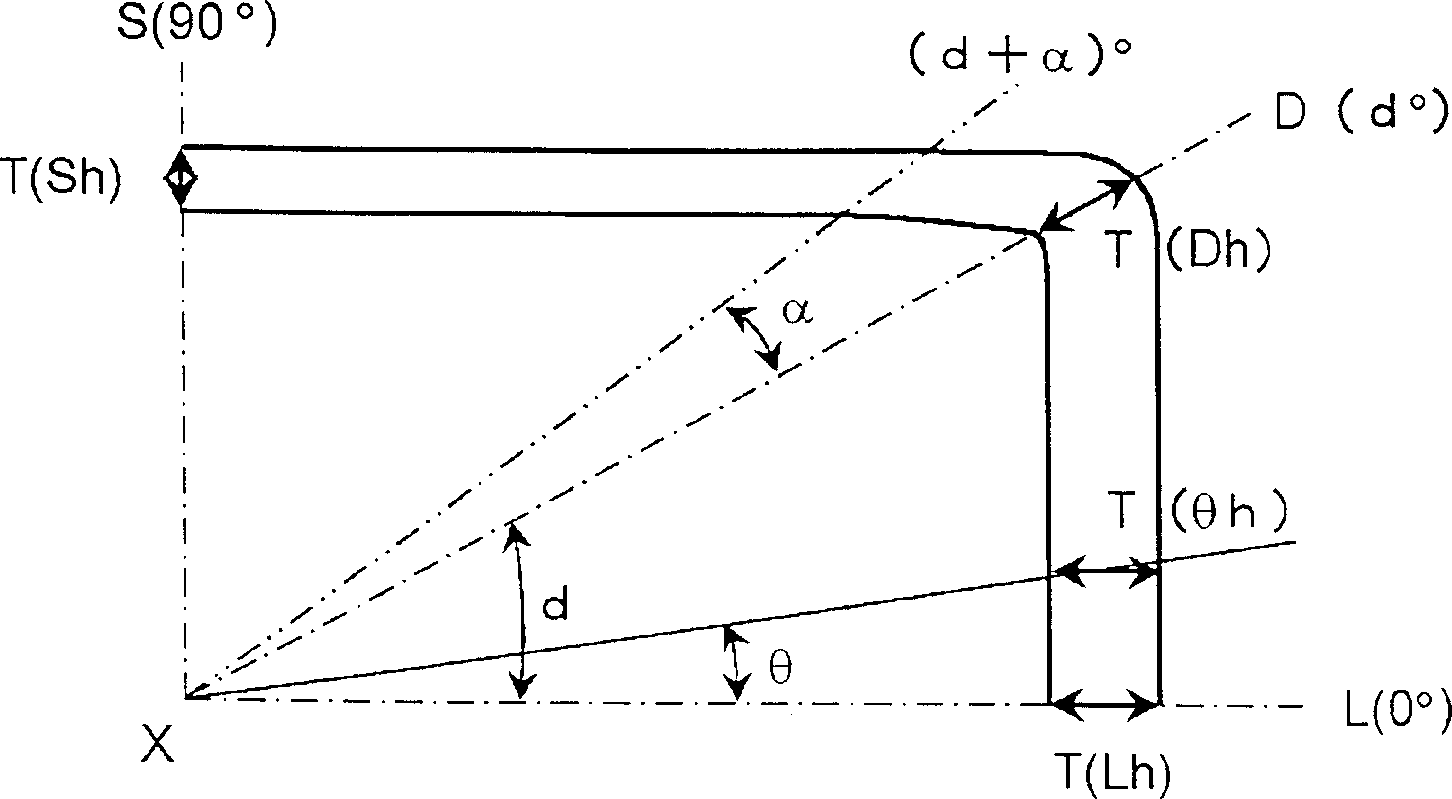

By setting the wall thickness on the long axis L as in the past, there is no loss of mechanical strength, and since the wall thickness in the area from the long axis L to the diagonal axis D is equal to the wall thickness on the long axis L and the diagonal axis D The difference in wall thickness between them is within 0.3mm, and they are formed approximately the same in the shape of the cone, and the wall thickness difference between the wall thicknesses on the minor axis S is within 0.3mm, which is approximately the same in the shape of the cone. The wall thickness region is formed within the range from 90°-(d+α)° to the minor axis S, so that the weight can be reduced.

Owner:NIPPON ELECTRIC GLASS CO LTD

Funnel for use in a cathode ray tube

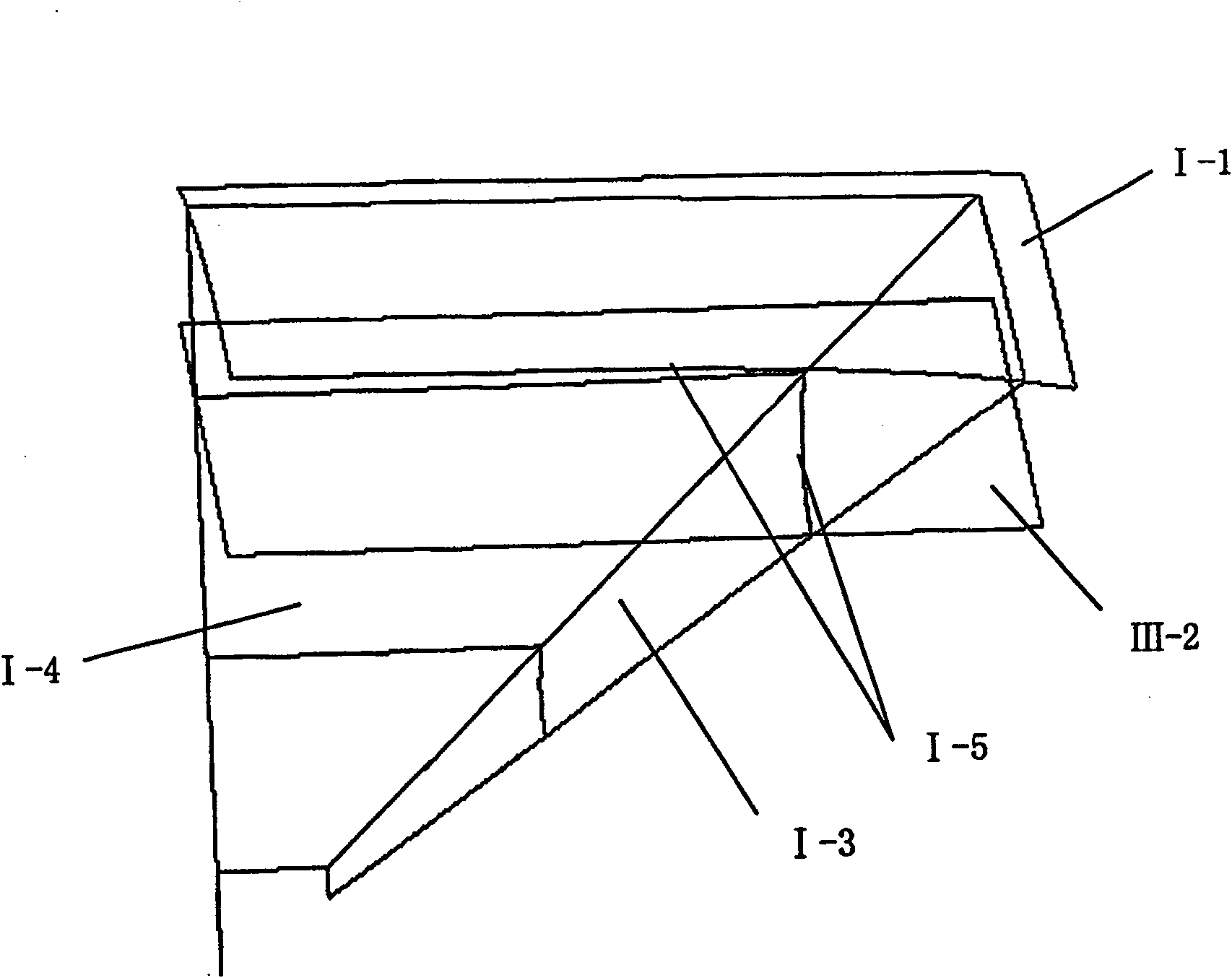

InactiveUS20060145590A1Slimming downImprove glass strengthCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersLong axisCathode ray

A funnel for use in a cathode ray tube having a panel includes a body portion having a seal edge to be connected to the panel and having a major axis of two longer sides of the body portion, a minor axis of two shorter sides of the body portion and diagonal axes; a yoke portion extending backward from the body portion; and an inflection portion formed on at least one portion of an inner surface of the body portion at a predetermined distance from the seal edge. The inflection portion is formed such that a thickness of the seal edge is less than that of the body portion.

Owner:SAMSUNG CORNING CO LTD

Conic-body for cathode-ray tube

InactiveCN1264188CNo loss of mechanical strengthDoes not reduce formabilityCathode-ray/electron-beam tube vessels/containersStructural engineeringUltimate tensile strength

Wall thickness on a major axis L is set to the same value as before to prevent mechanical strength from being impaired. Furthermore, the wall thickness of a region from a major axis L to a diagonal axis D is made almost the same in molding the funnel with the wall thickness difference of 0.3 mm or less between the wall thickness on the major axis L and that on the diagonal axis D, and a uniform wall thickness area of almost the same wall thickness in molding the funnel with the wall thickness difference of 0.3 mm or less from the wall thickness on a minor axis S is formed over the range of the minor axis S from 90 DEG -(d+alpha ) DEG. The weight can thereby be reduced.

Owner:NIPPON ELECTRIC GLASS CO LTD

Color picture tube

InactiveCN1975977AIncrease surface retention strengthReduce uniformityCathode-ray/electron-beam tube vessels/containersVisibilityEngineering

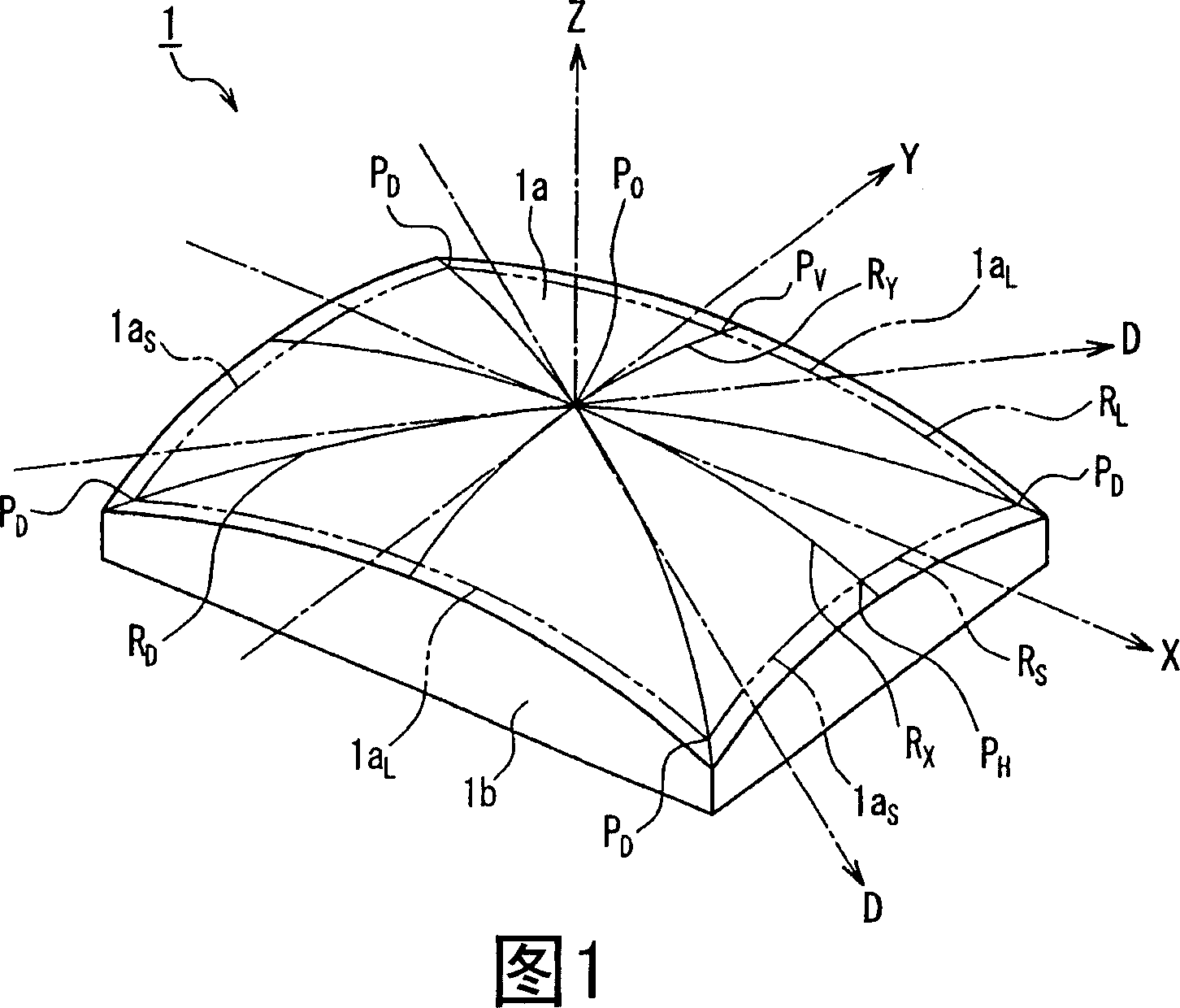

The radii of curvature RD, RS and RL along a diagonal axis, a short side and a long side of an outer surface of a useful portion of a panel whose inner surface is provided with a phosphor screen satisfy RD>=10 m, RS>RD, and RL>RD. This makes it possible to provide a color picture tube that has an excellent visibility and is not susceptible to the deterioration in color purity due to doming, while including a shadow mask with excellent formability and strength.

Owner:MATSUSHITA TOSHIBA PICTURE DIS

Autostereoscopic 3-dimensional display

ActiveUS20180152696A1Remarkable variationNo luminance variationSteroscopic systemsComputer graphics (images)Display device

The present disclosure relates to an autostereoscopic three-dimensional (3D) display in which the multi view structure is configured by using a lenticular lens. The autostereoscopic 3D display includes a display panel including a plurality of pixels, and an aperture area disposed at each pixel; and a lens film disposed on a front surface of the display panel and including a plurality of lenticular lenses, the lenticular lenses having a slanted axis and continuously arrayed along to a lateral direction, wherein the aperture area includes a parallelogram shape, and wherein the slanted axis is parallel with any one diagonal axis of the aperture area.

Owner:LG DISPLAY CO LTD

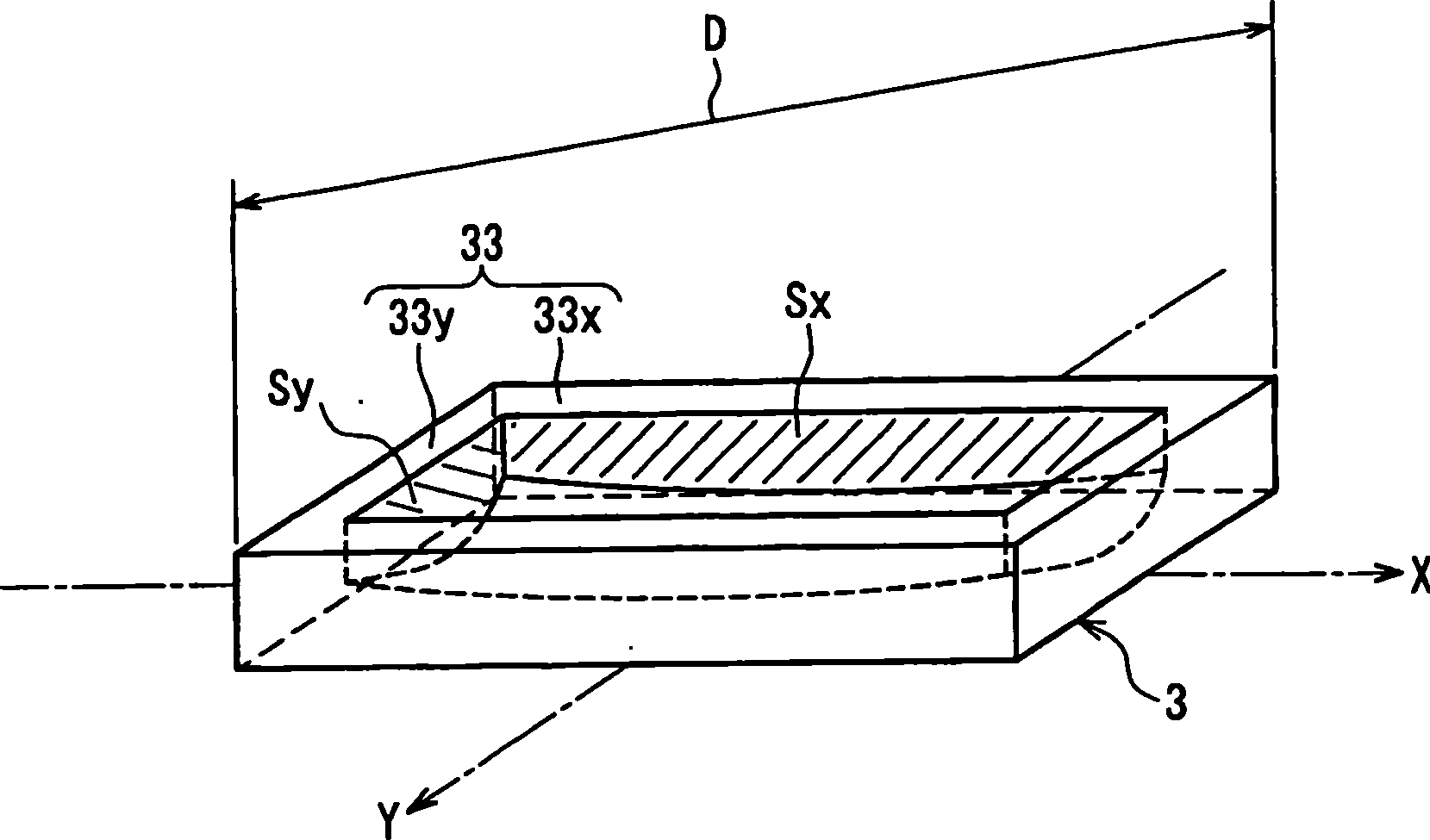

Cathode ray tube

InactiveCN1881521AAvoid breakingThe overall thickness is thinCathode-ray/electron-beam tube vessels/containersCold cathode manufactureEngineeringCathode ray

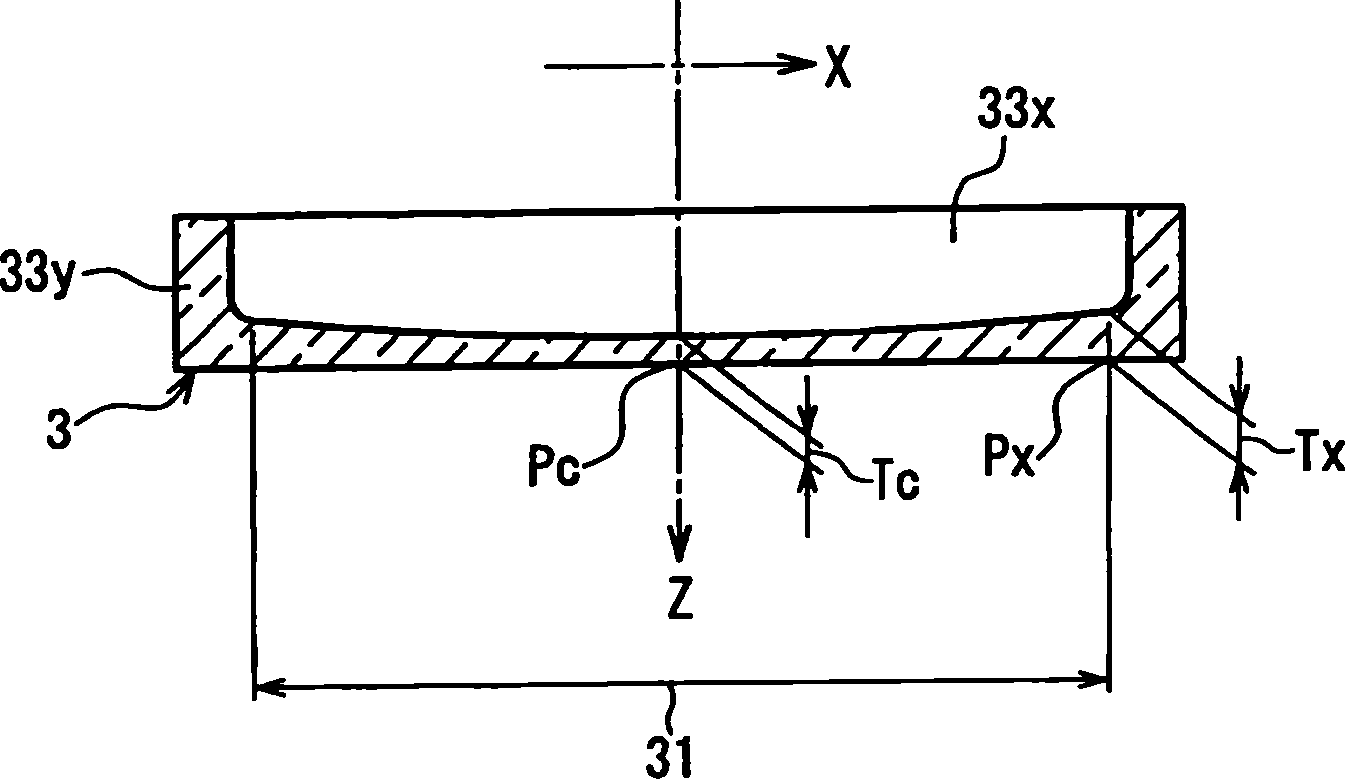

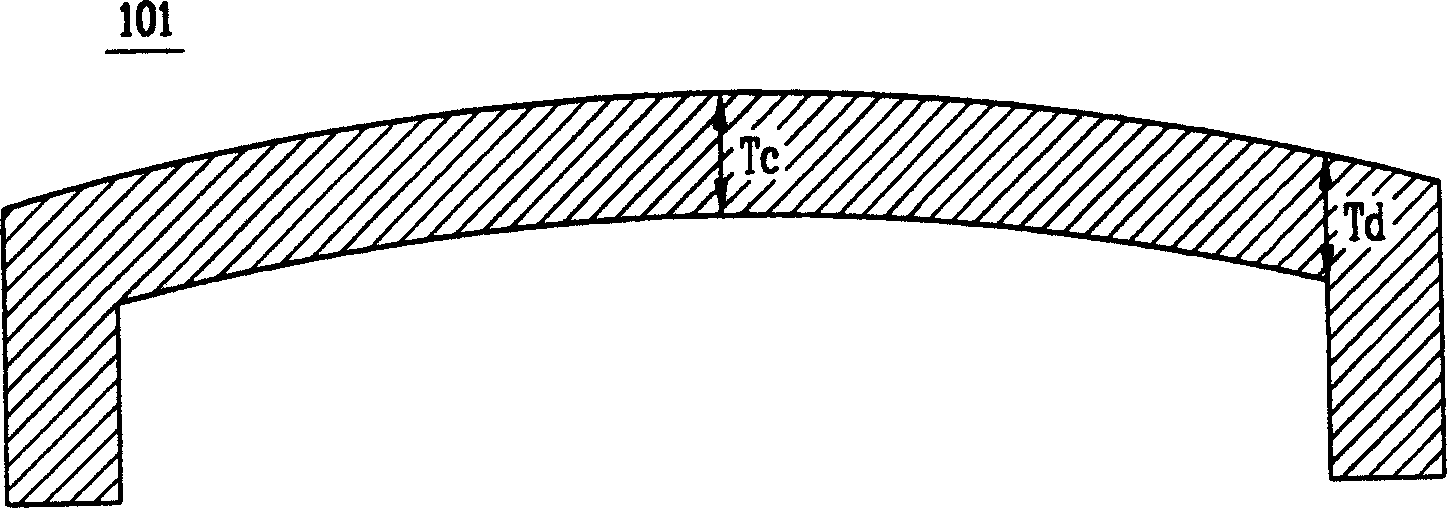

The invention provides color cathode tube.When the thickness of the panel at an X axis end of the useful portion is expressed by Tx (mm), the thickness thereof at a Y axis end is expressed by Ty (mm), the thickness thereof at the center is expressed by Tc (mm) and an outer dimension of the panel along the diagonal axis direction is expressed by D (mm), 0.8<=(100xTC / D)2x(Tx / Ty)<=2.2 and 0.012<=Tc / D<=0.019 are satisfied. Accordingly, the stress generated in a short side and that generated in a long side in a sealing portion in an exhausting process are substantially equalized. As a result, cracking of the panel can be reduced in the exhausting process even when the panel is made thinner. Therefore, it is possible to provide a cathode ray tube that is easy to manufacture and has a lighter and less expensive panel.

Owner:MATSUSHITA TOSHIBA PICTURE DIS

Color picture tube

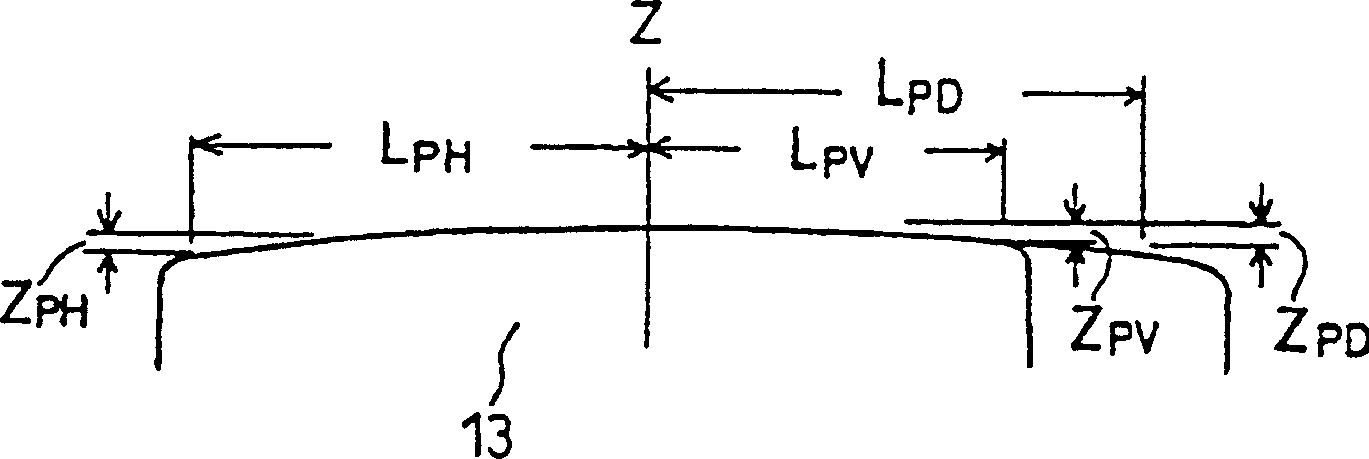

InactiveUS20070018556A1Good formabilityImprove visibilityCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersVisibilityPhosphor

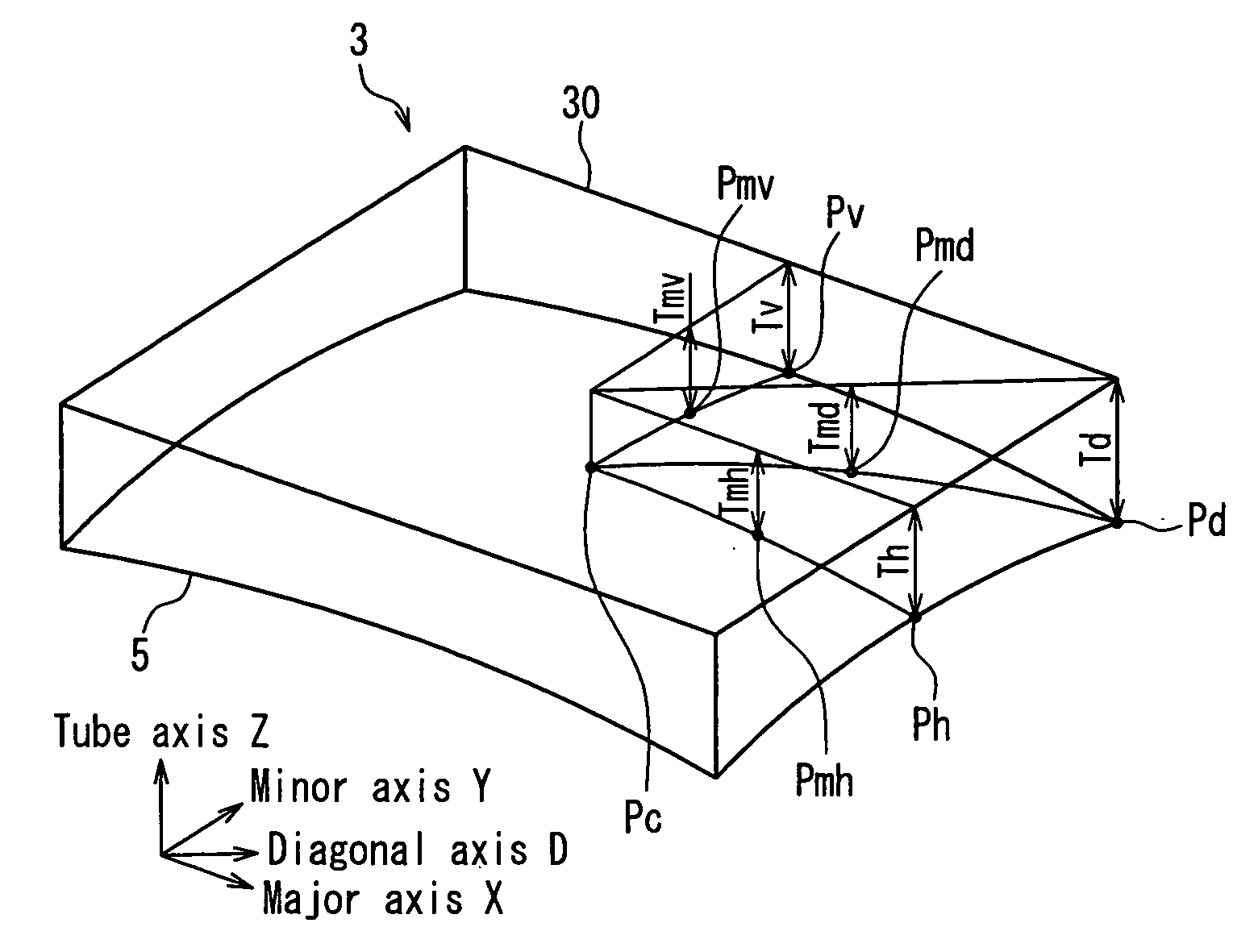

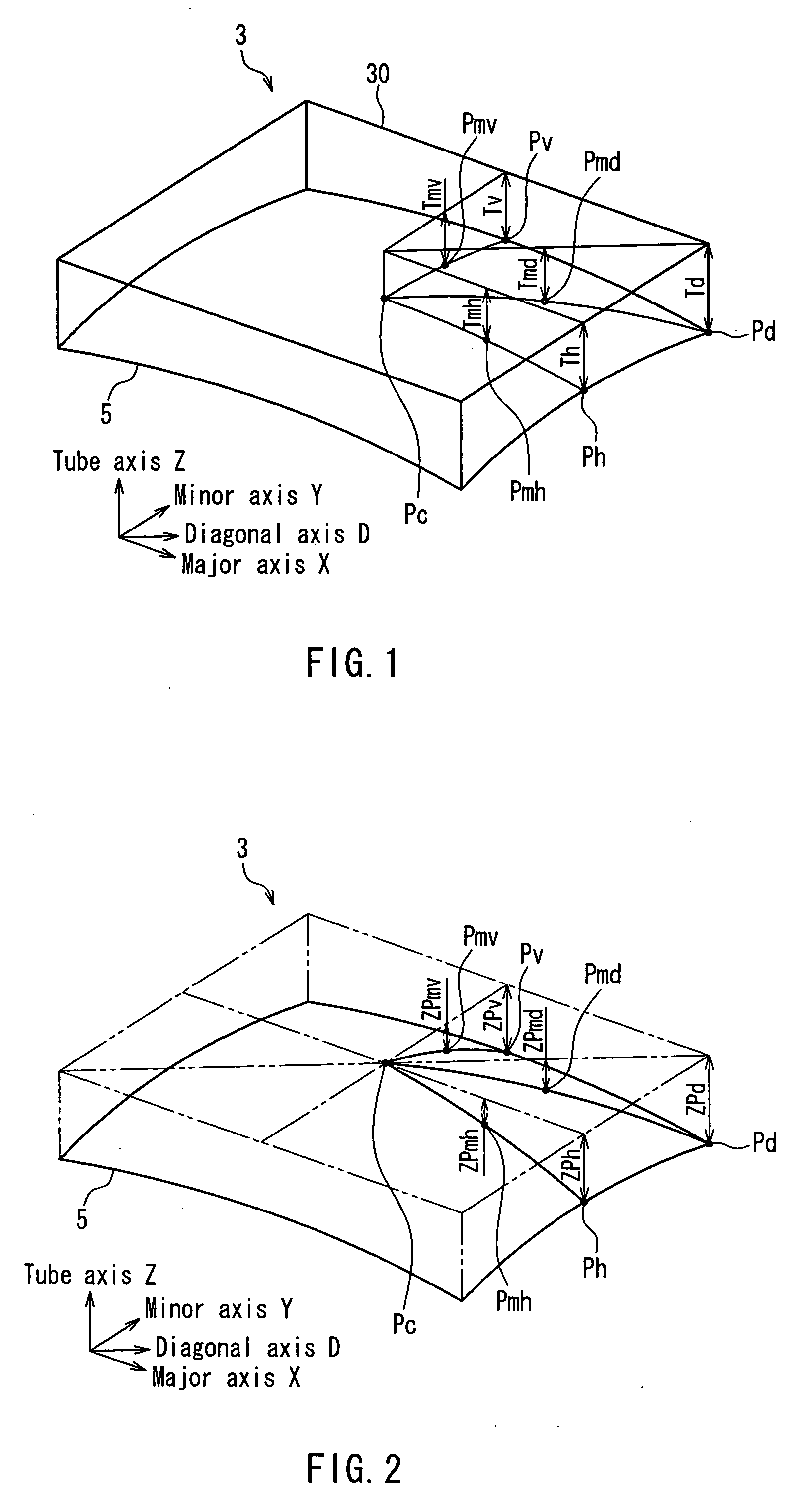

A radius of curvature of an arc passing through three points on an outer surface of a panel, which respectively correspond to a pair of diagonal axis ends on one diagonal axis of a phosphor screen and a center of the phosphor screen, is 10,000 mm or more. A shadow mask is made of an aluminum killed material. Assuming that a thickness of the panel is Td at the diagonal axis end of the phosphor screen, Tmd at an intermediate point between the diagonal axis end and the center, Th at a major axis end of the phosphor screen, and Tmh at an intermediate point between the major axis end and the center, 0.5 ≦Tmd / Td≦0.62, and 0.65≦Tmh / Th≦0.80 are satisfied. Because of this, an inexpensive color picture tube can be provided, in which the visibility is excellent, the degradation in color purity caused by doming is suppressed, and the formability of the shadow mask is enhanced.

Owner:MATSUSHITA TOSHIBA PICTURE DISPLAY CO LTD

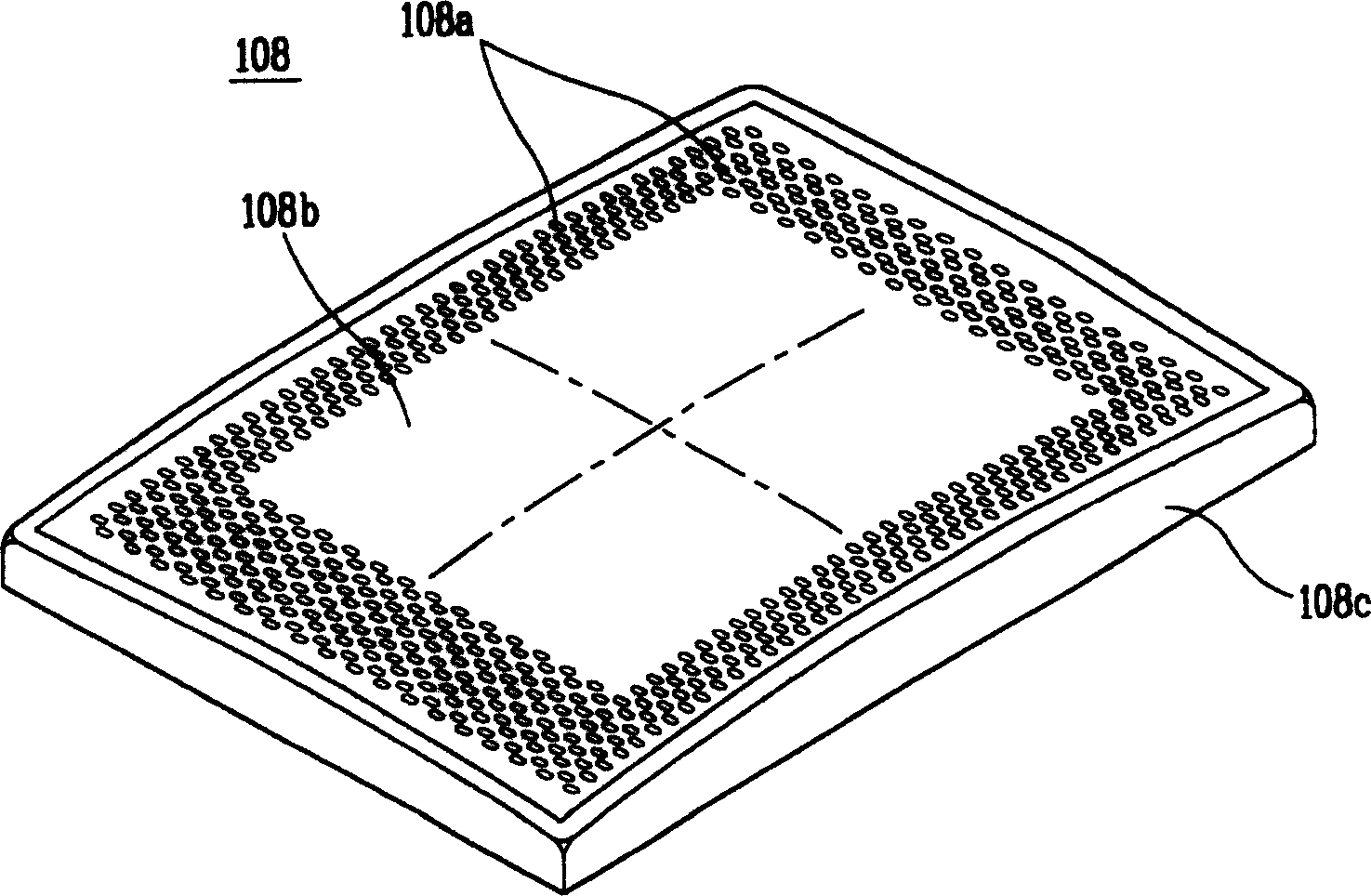

Shadow mask

InactiveCN1761023AInterrupted Problem SuppressionThe problem of suppressing occlusionCathode ray tubes/electron beam tubesHorizontal axisEngineering

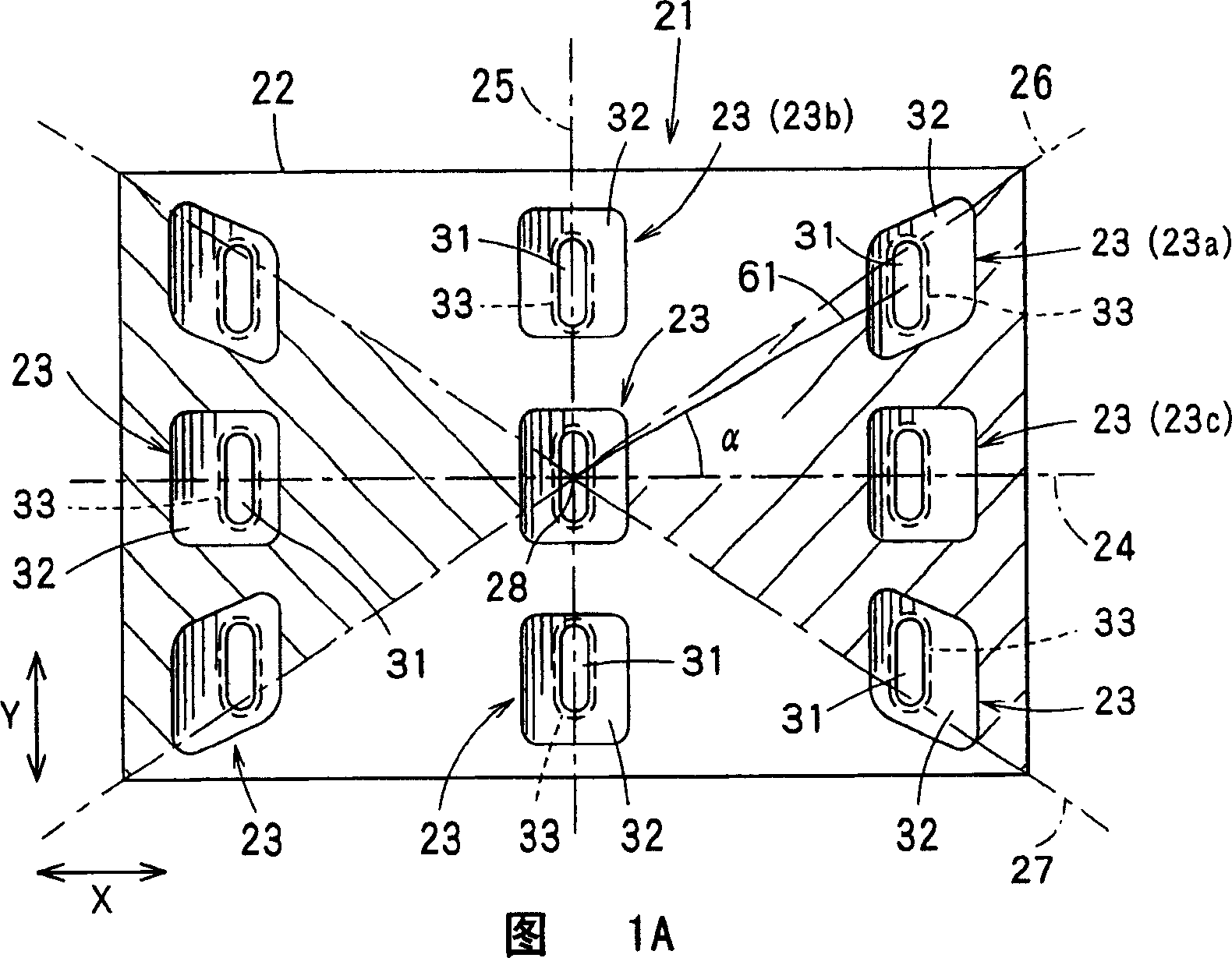

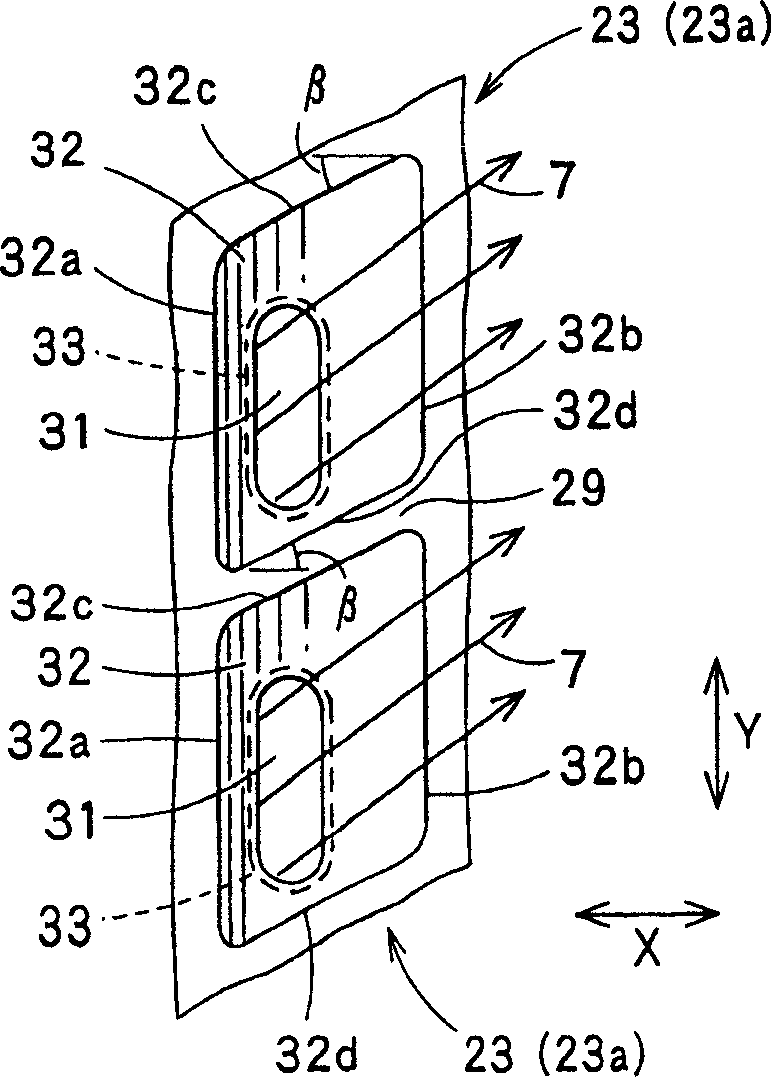

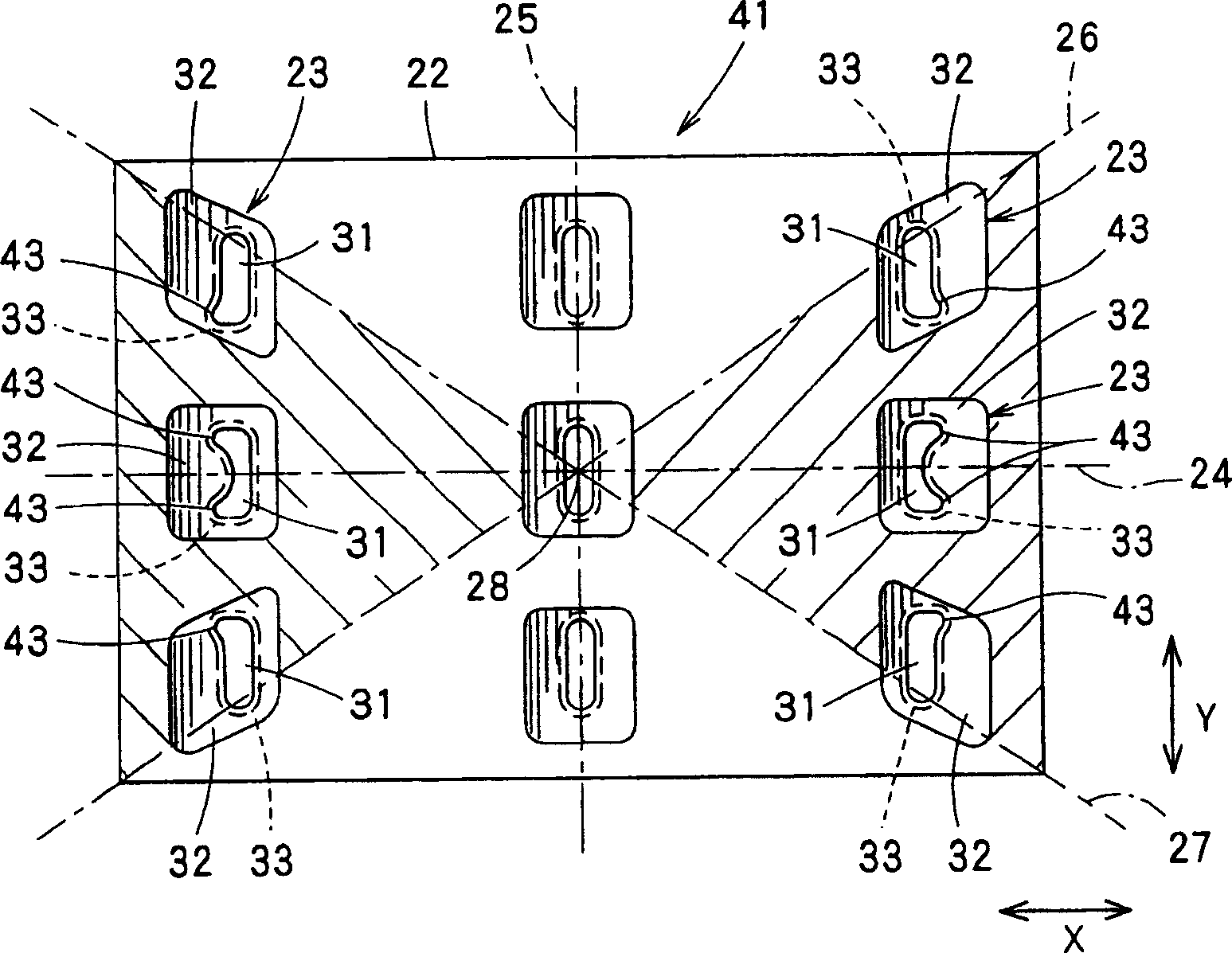

In a shadow mask 21, a large number of slots 23 are made in a mask body 22 in the horizontal direction X and in the vertical direction Y. Each slot 23 has a roughly rectangular backside opening 33, a roughly rectangular front-side opening 32, and a through-hole 31 that connects these two openings 33, 32. Of the multiple slots 23 made in the mask body 22, the slots 23 situated at least in those areas of the mask body 22 that are surrounded by a horizontal axis 24 and two diagonal axes 26, 27 that pass through the center point 28 of the mask body 22 have such front-side openings 32 that a pair of the upper and lower short sides 32c, 32d of the rectangular outline of the front-side opening 32 of each slot 23 are inclined, relative to the horizontal axis 24, along the radiate line 61 radiating from the center point 28 of the mask body 22 toward the slot 23. The angle [beta] of inclination of the short sides 32c, 32d is preferably in the range of +- 10 DEG , where +- is the angle [alpha] between the radiate line 61 radiating from the center point 28 of the mask body toward the slot 23 and the horizontal axis 24.

Owner:DAI NIPPON PRINTING CO LTD

Glass bulb for cathode ray tube

InactiveCN1797680AFlat shapeEasy to removeCathode-ray/electron-beam tube vessels/containersBobbinMaximum diameter

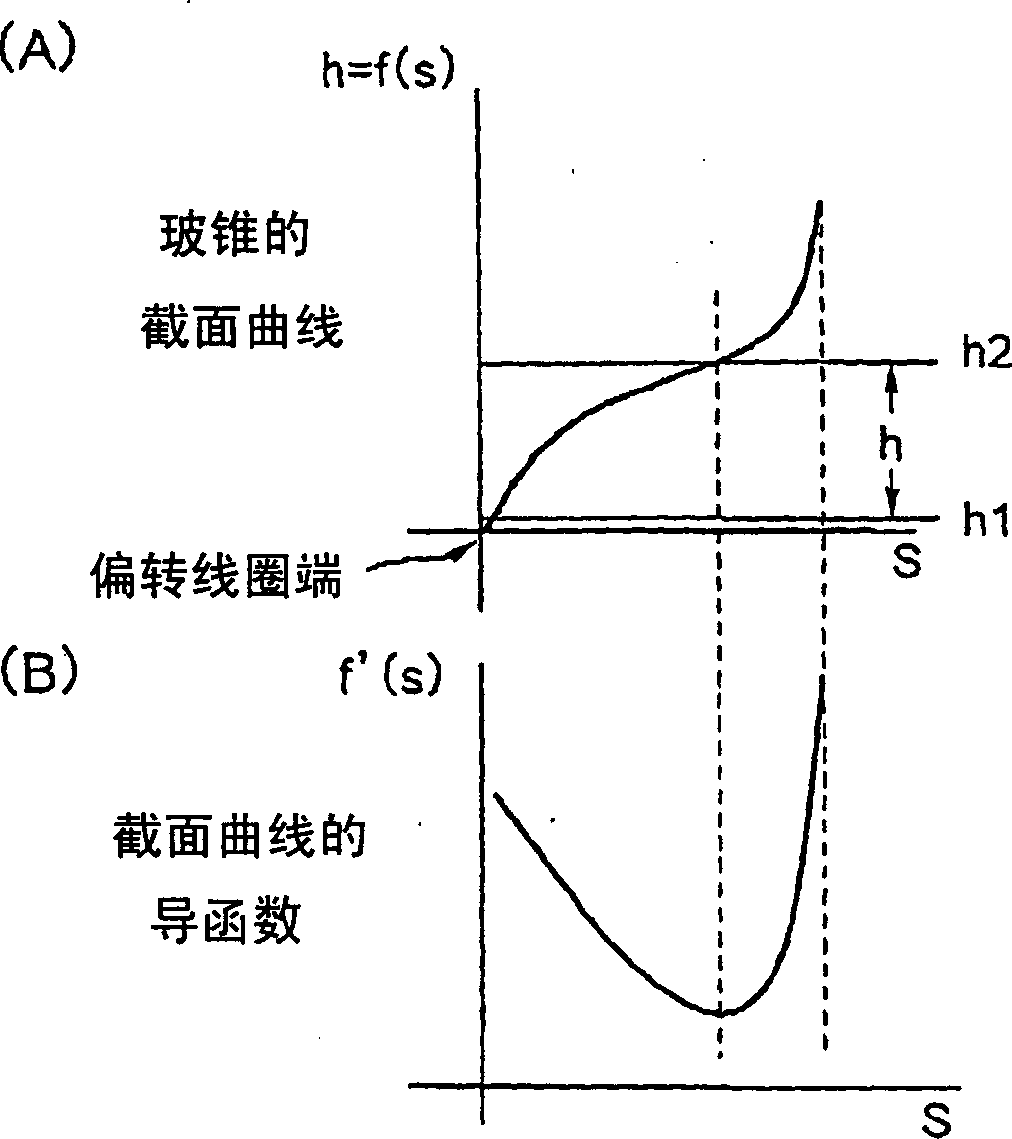

To provide a glass bulb for a flat cathode-ray tube small in weight and excellent in productivity. In this highly reliable flat cathode-ray tube, the outline thereof near a yoke part in a cross section vertical to the tube axis of a body part 3 is formed in an approximately rhombus shape or an approximately bobbin shape. The direction of the maximum diameter of the approximately rhombus shape in cross section is aligned with the direction of the major axis of a funnel. When the outline is formed in the approximately bobbin shape, its maximum diameter part is disposed between the major axis and a diagonal axis. Where a distance from the maximum diameter part to a yoke end is (s) in the vertical direction to the tube axis, the minimum value of the differential value of H = f (s) is set to 0 or higher, and the body part is formed of a smooth continuous surface without step parts, projections, or dents to reduce a stress generated in a yoke portion.

Owner:ASAHI GLASS CO LTD

Method for designing CRT frame

InactiveCN100552863CImprove the success rate of the first designImprove one-time success rateCathode ray tubes/electron beam tubesEffective surfaceEngineering

The invention discloses a method for designing a CRT frame. The method obtains the size and shape of the bottom opening of the frame by designing the optimal size of the long axis, short axis and diagonal axis section of the frame bottom opening, which can guarantee the strength and reduce the Small thermal arches, anti-reflection, and cost reduction have been contradictoryly unified, which significantly improves the first-time success rate of frame design. Especially in widescreen CRTs, the effect of reducing thermal arching is very significant. In the research and development of a wide-screen tube type, under the condition that other conditions remain unchanged, the method of the present invention is used to reduce the thermal arch drift of the sensitive area in the effective surface of the screen by 30% by improving the size and shape of the opening at the bottom of the frame.

Owner:IRICO DISPLAY DEVICES

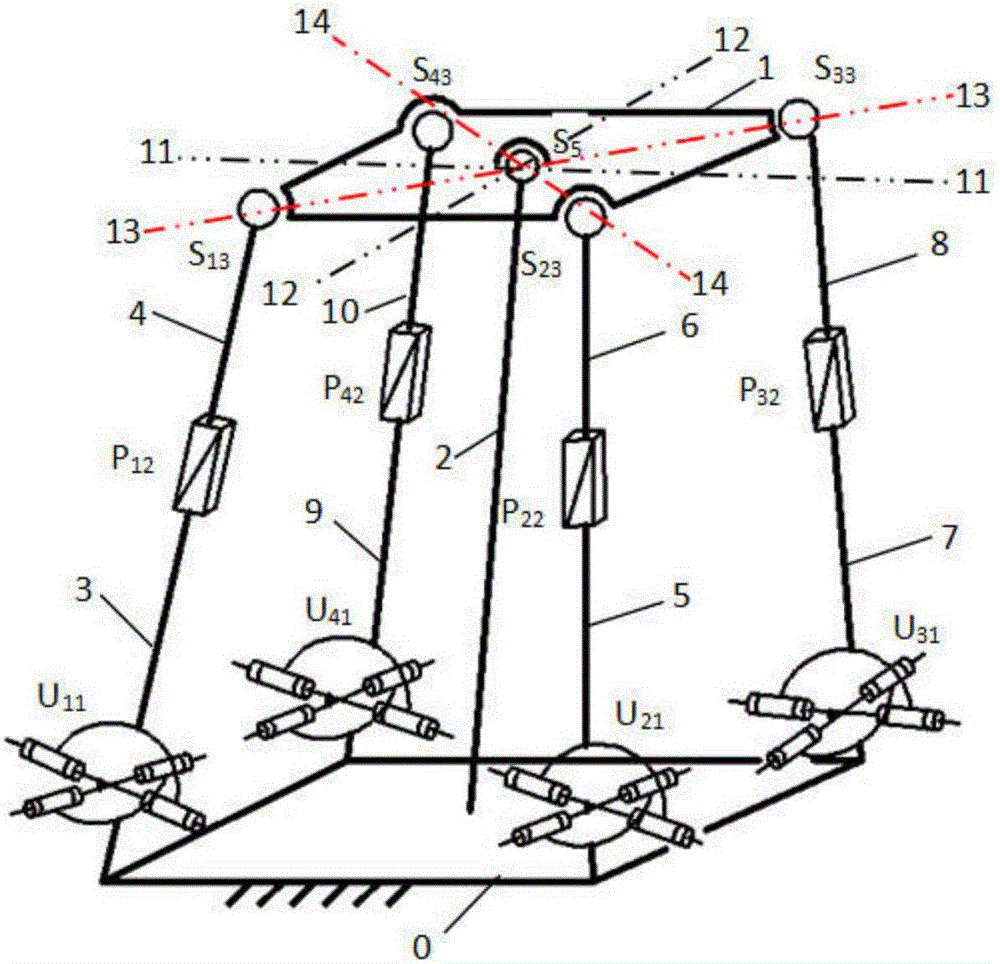

Four-rotation detection platform for automatic optical detection system

InactiveCN106053480AKeep the object distance constantMeet the needs of visual inspectionOptically investigating flaws/contaminationAxis of symmetryDiagonal

The invention relates to a four-rotation detection platform. The four-rotation detection platform comprises a detecting platform (1), a static platform (0), four UPS branches of identical structure and a middle branch, wherein the middle branch is located at the dead center of the detecting platform (1) and the static platform (0), one end of a link I (2) of the middle branch is fixedly connected with the static platform (0), the other end of the link I (2) is connected with a ball pair I (S5), and the ball pair I (S5) is connected with the detecting platform (1); the four UPS branches are all located at four top ends of the static platform (0), one end of each branch is connected with the static platform (0) through a Hooke hinge (U11), each Hooke hinge (U11) is connected with a moving pair I (P12) through a link II (3), each moving pair I (P12) is connected with a ball pair II (S13) through a link III (4), and each ball pair II (S13) is connected with the detecting platform (1); the moving pairs of the four UPS branches are driving pairs. According to the four-rotation detection platform, the rotational degree of freedom for the detecting platform (1) along two central axes of symmetry and two diagonal axes of the detecting platform (1) can be achieved separately, so that the four-rotation detection platform is adaptable to meeting the requirements of an automatic visual detection system on gesture adjustment.

Owner:CHANGZHOU UNIV +1

Cathode ray tube

InactiveCN1577705AImprove impact resistanceImprove structural strengthCathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsClassical mechanicsDiagonal

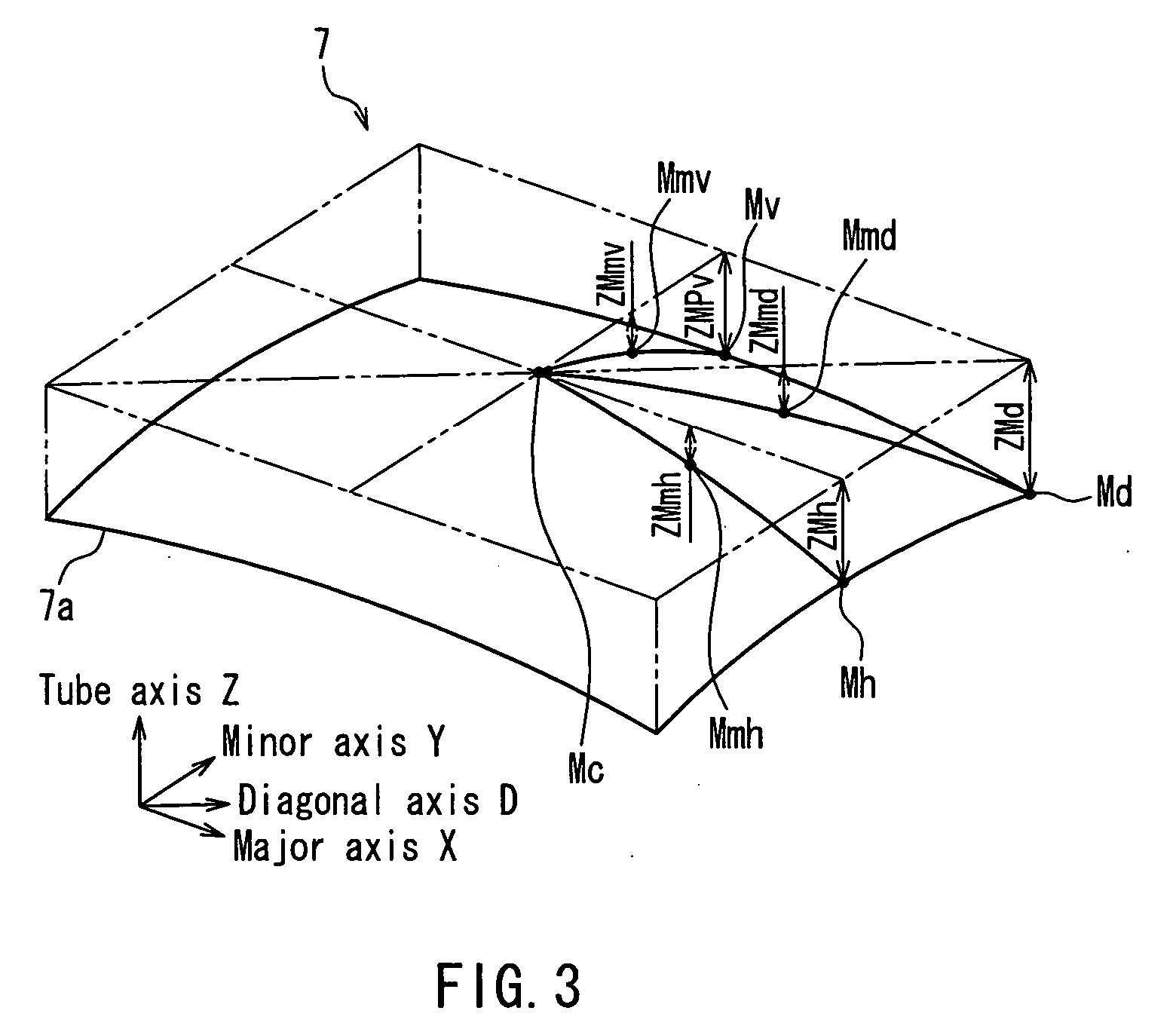

A cathode ray tube comprising a panel of which an outer surface is substantially flat and an inner surface has a certain curvature, and a shadow mask arranged with a certain interval from an inner surface of the panel and having a plurality of apertures through which electron beams pass, wherein the shadow mask satisfied a condition of 0.9<=ZmD / (ZmX+ZmY)<=1.1, in which an arbitrary point on a diagonal axis of the shadow mask is supposed to be Dr, points on a long axis and a short axis meeting with perpendiculars drawn to the long axis and the short axis from the point Dr are respectively supposed to be Xr and Yr, and intervals between the respective points Xr, Yr, and Dr and the shadow mask in a tube axis direction are respectively supposed to be ZmX, ZmY, and ZmD.

Owner:MERIDIAN SOLAR & DISPLAY

Color cathode ray tube

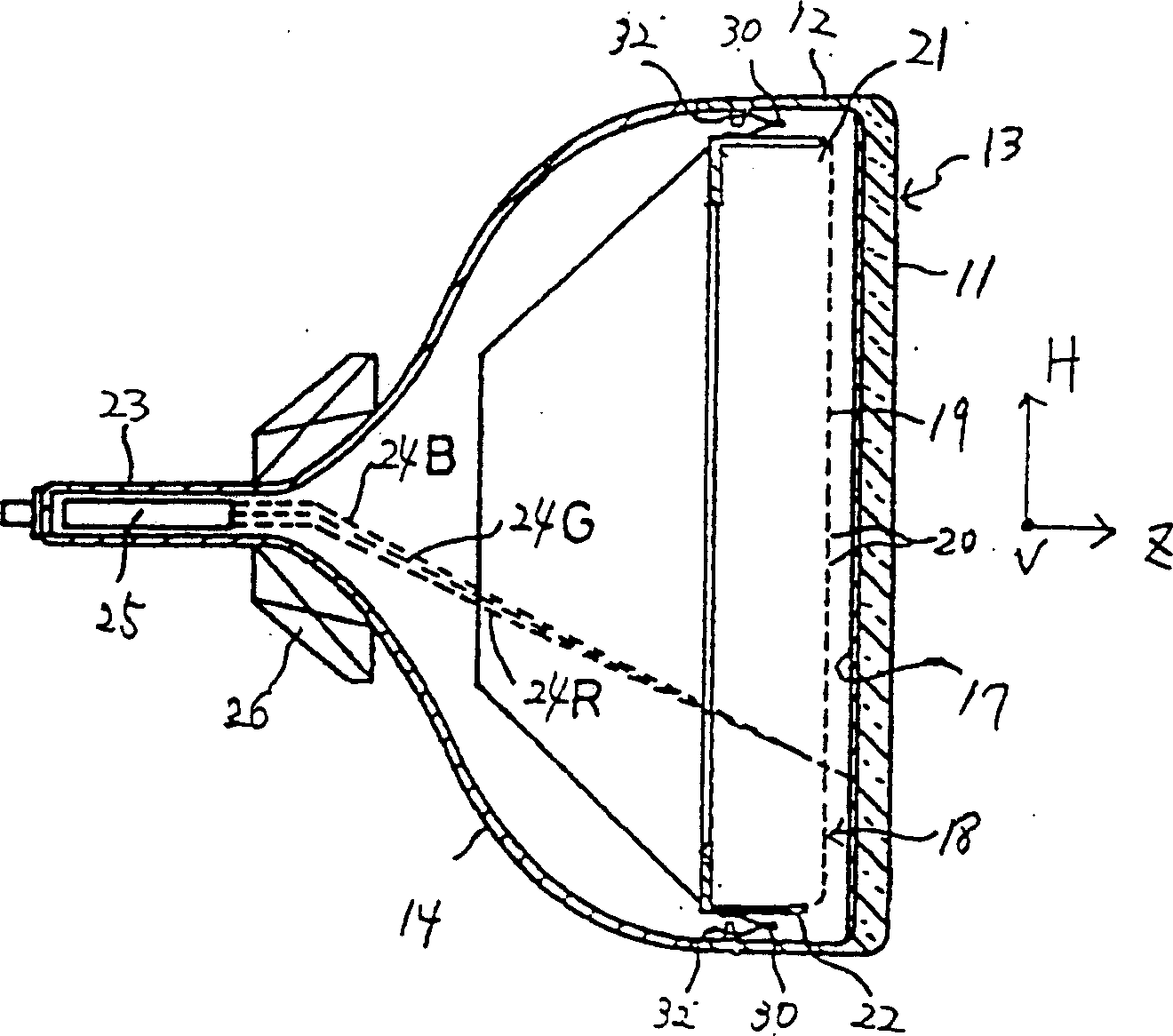

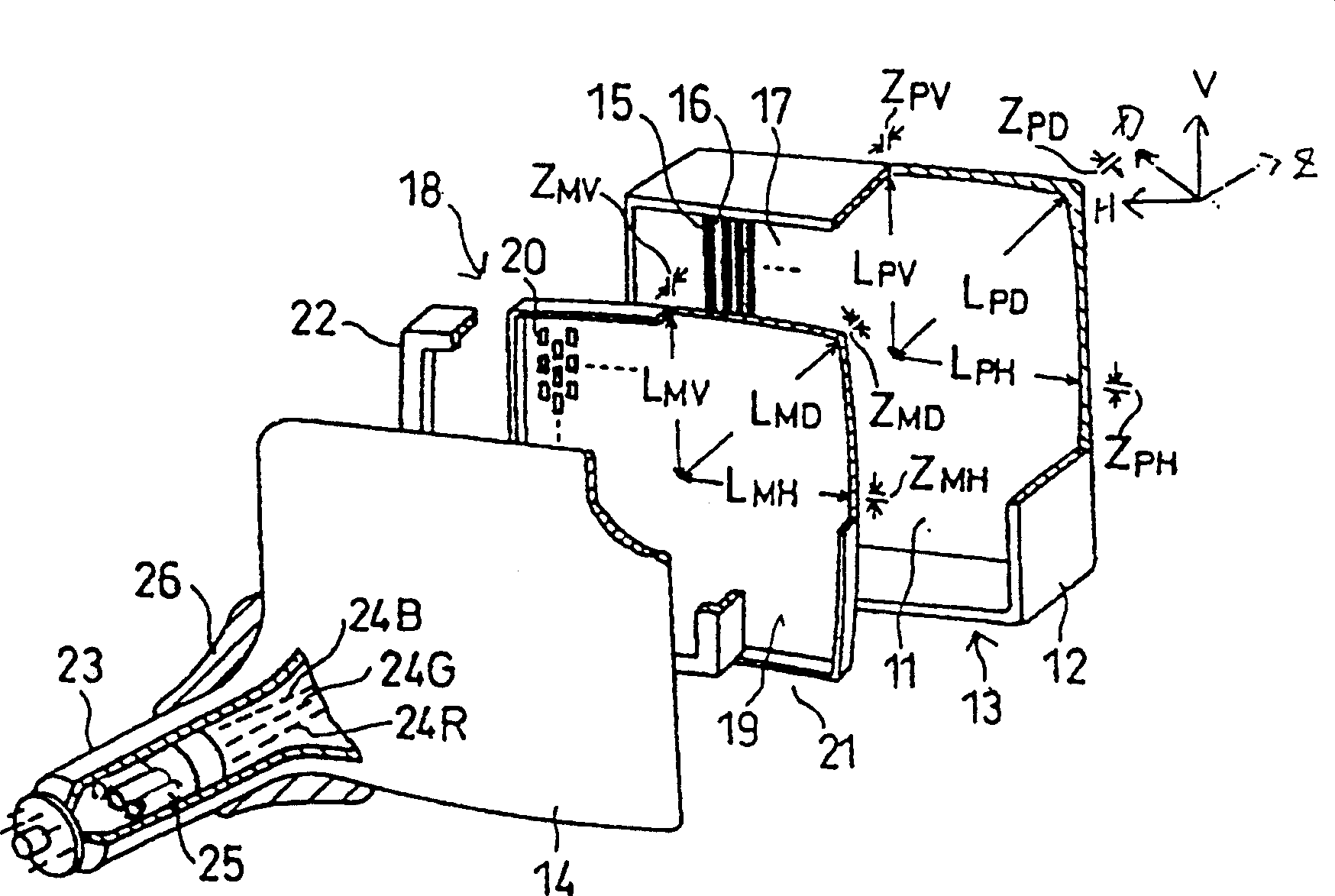

InactiveCN1251288CCathode-ray/electron-beam tube vessels/containersImage/pattern display tubesEffective surfacePhosphor

A color cathode ray tube comprises a face panel having a phosphor screen formed on the inner surface thereof and a shadow mask. A mask body of the shadow mask has an effective surface opposed to the phosphor screen and formed having a plurality of electron beam passage apertures. The face panel and mask body are formed so as to establish relations: ZPD>ZPV>ZPH, ZMD>ZMH>ZMV, ZPDZMV, where ZPD, ZPH, and ZPV are sags at a diagonal-axis end, horizontal-axis end, and vertical-axis end, respectively, with respect to the center of the inner surface of the face panel, and ZMD, ZMH, and ZMV are sags at the individual axis ends with respect to the center of the effective surface of the mask body.

Owner:KK TOSHIBA

Cathode ray tube having an improved shadow mask

InactiveCN1577706ACathode-ray/electron-beam tube vessels/containersElectrode and associated part arrangementsFluorescenceLong axis

A cathode ray tube comprises a panel having a fluorescent formed on an inner surface thereof; a funnel connected to the panel; an electron gun housed in the funnel emitting electron beams; a deflection yoke for deflecting the electron beams in horizontal and vertical directions; a shadow mask for selecting colors of the electron beams; and a mask frame for supporting the shadow mask, in which an outer surface of the panel is substantially flat and an inner surface has a designated curvature, and a radius of curvature from a center of the shadow mask in a major-axis, minor-axis and diagonal-axis direction is substantially same.

Owner:LG PHILIPS DISPLAY KOREA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com