Conic-body for cathode-ray tube

A cathode ray and tube technology, applied in the direction of cathode ray tube/electron beam tube, cathode ray/electron beam tube shell/container, discharge tube, etc., can solve problems such as time delay and gap rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described based on the drawings.

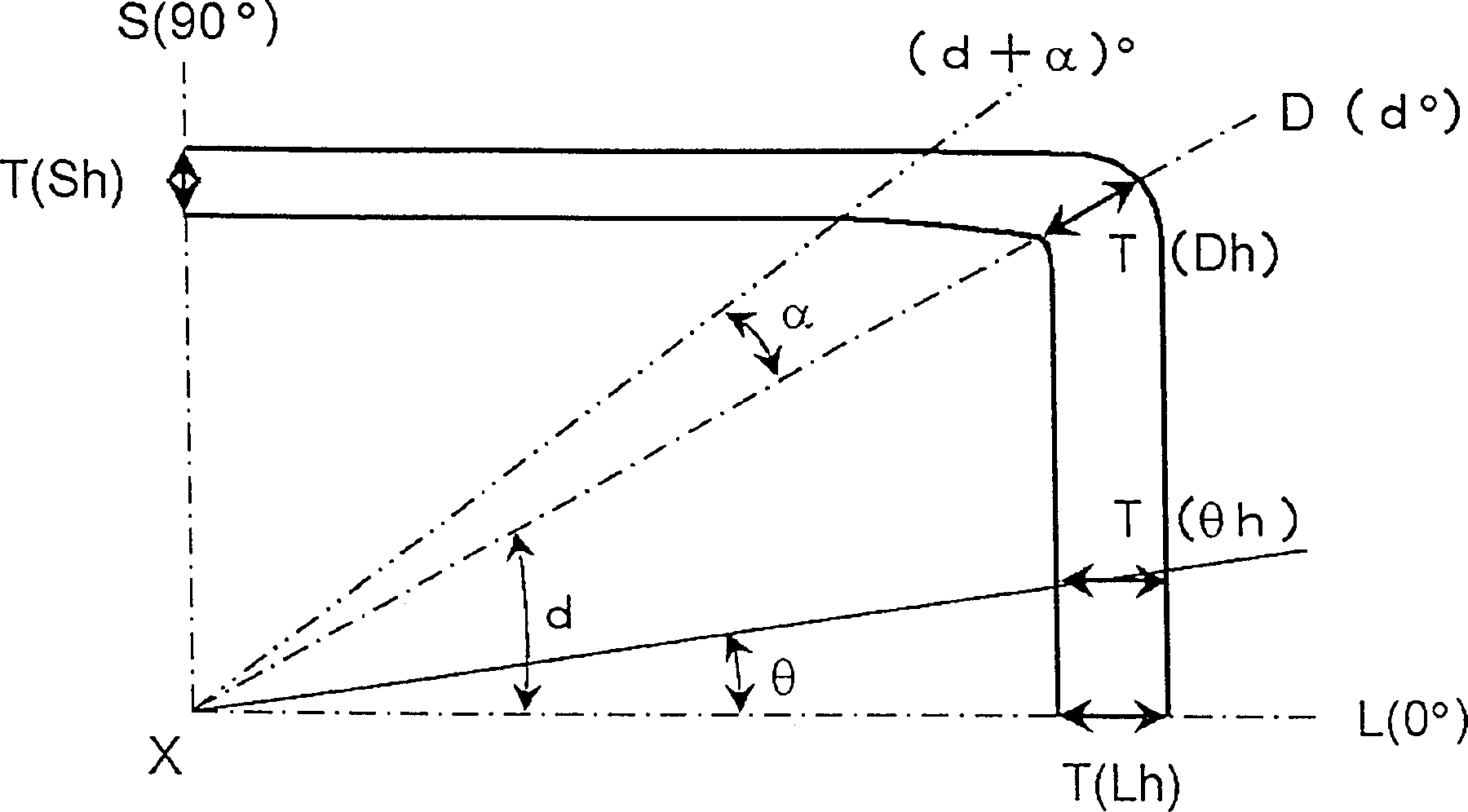

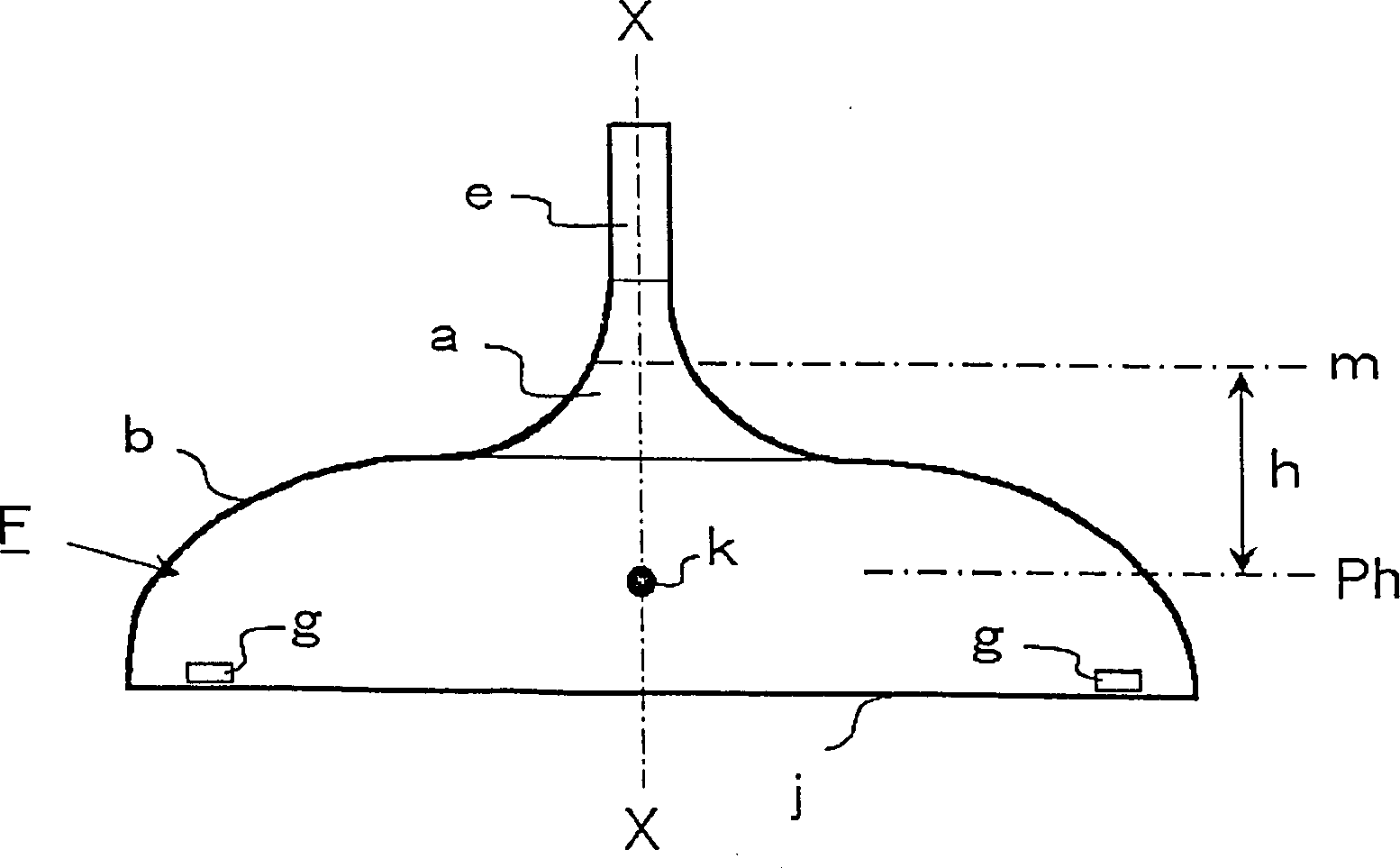

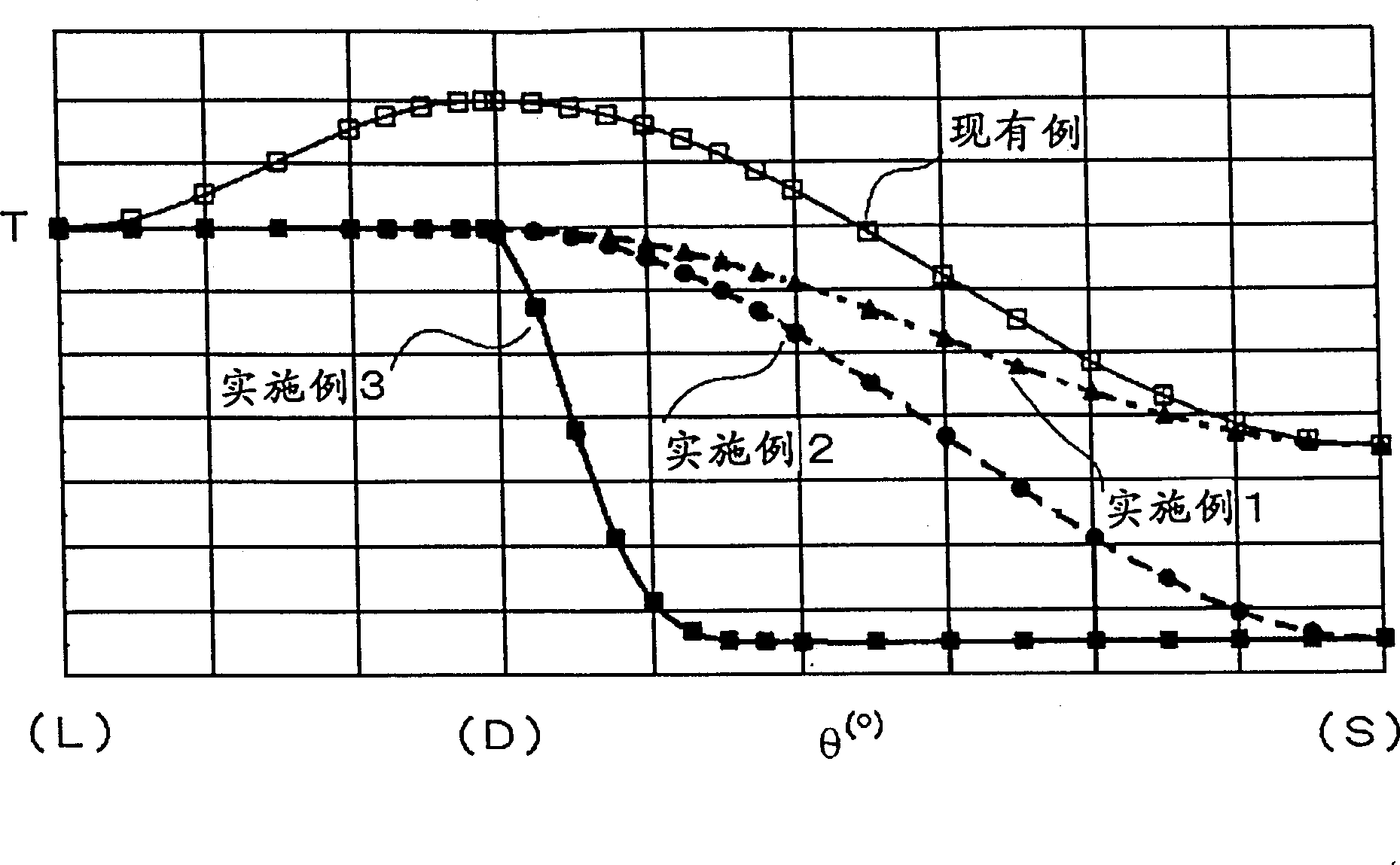

[0019] Fig. 1(A) is a cross-sectional view of a 90° portion (first quadrant) of a cone for a cathode ray tube at an arbitrary height h from the reference line for explaining the wall thickness distribution of the present invention, and Fig. 1(B) is the cone The side view of the whole body, figure 2 It is a graph showing an example of the thickness distribution state of the 90° portion (first quadrant) of the cone of the present invention.

[0020] As shown in Figure 1 (A) and Figure 1 (B), the cathode ray tube cone F is composed of a deflection system portion a on the small opening end side and a main body portion b on the large opening end side. The vertical cross-section is roughly quadrangular, with a long axis L, a short axis S, and a diagonal axis D. Except for the neck portion e, the deflection system portion a, the edge portion j, the anode buckle portion k, and the calibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com