A kind of automobile wheel hub, processing device and technology thereof

A processing device and a technology for automobile hubs, which are applied in the field of automobile parts, can solve the problems of low consistency of anti-torque performance, etc., and achieve the effects of high processing precision, simple assembly process, and simple heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

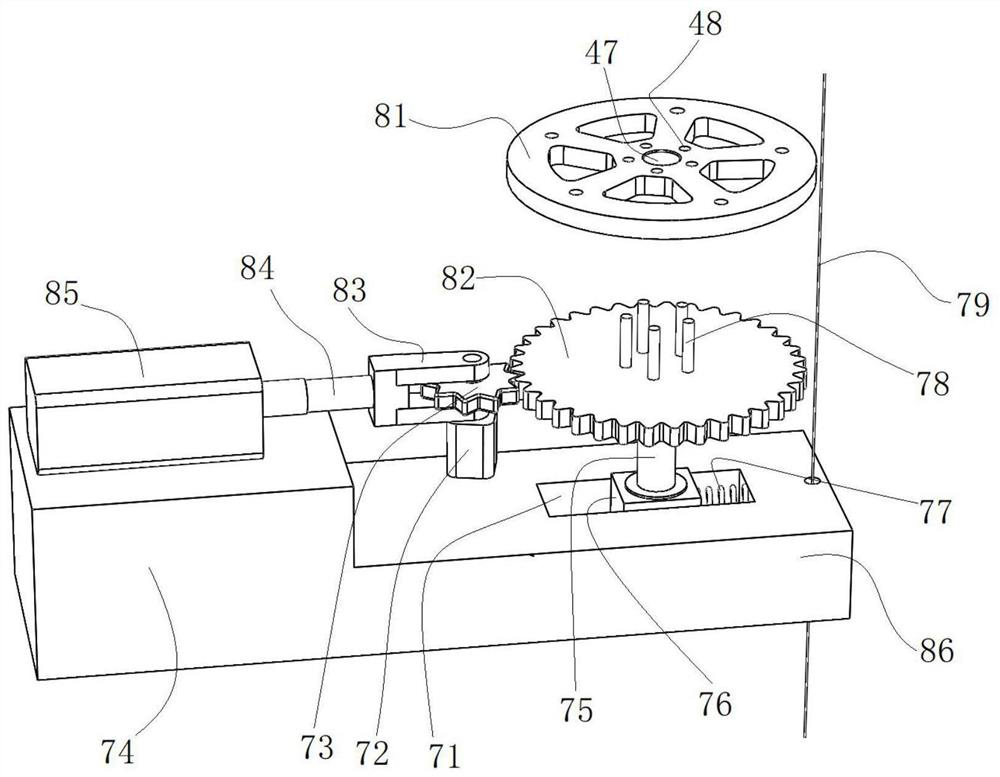

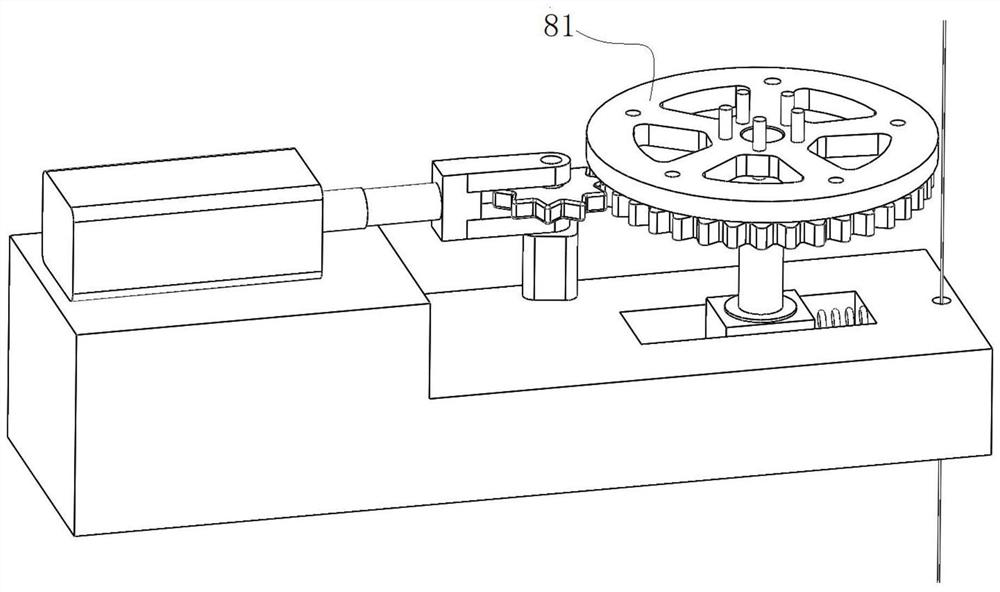

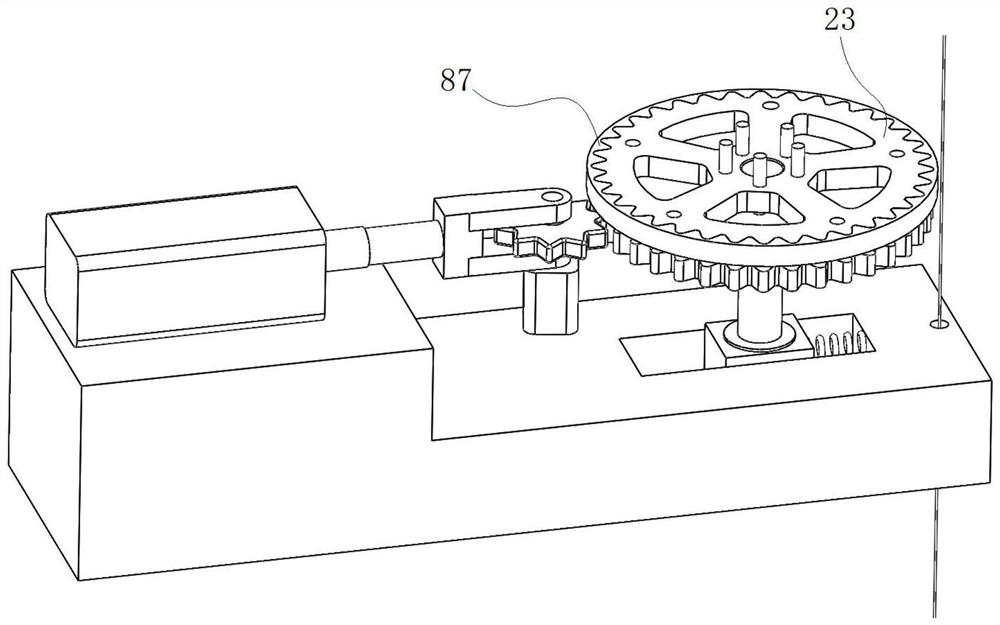

[0030] as attached Figures 1 to 11 A kind of automobile hub processing device shown, comprises wire cutting equipment, and described wire cutting equipment comprises working platform 86, and described working platform 86 is provided with horizontal sliding groove 71, and the inside of described sliding groove 71 is provided with slide Block 76 also includes supporting vertical rotating shaft 75, and the lower end of said vertical rotating shaft 75 is rotated and arranged on said slide block 76; the top of said vertical rotating shaft 75 is fixedly supported and connected with a wire cutting platform 82 with a horizontal attitude; said wire cutting The outline of the platform 82 is a gear outline, and the gear outline of the wire cutting platform 82 is consistent with the outline of the outer ring of the rim disc 23 after the wire cutting is completed; the upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com