Patents

Literature

36results about How to "No loss of mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atmosphere pressure plasma treatment fasciculus or fibre string surface device and method thereof

InactiveCN101096820AImprove surface structureImprove surface propertiesFibre typesUltrasonic/sonic fibre treatmentFiberPower parameter

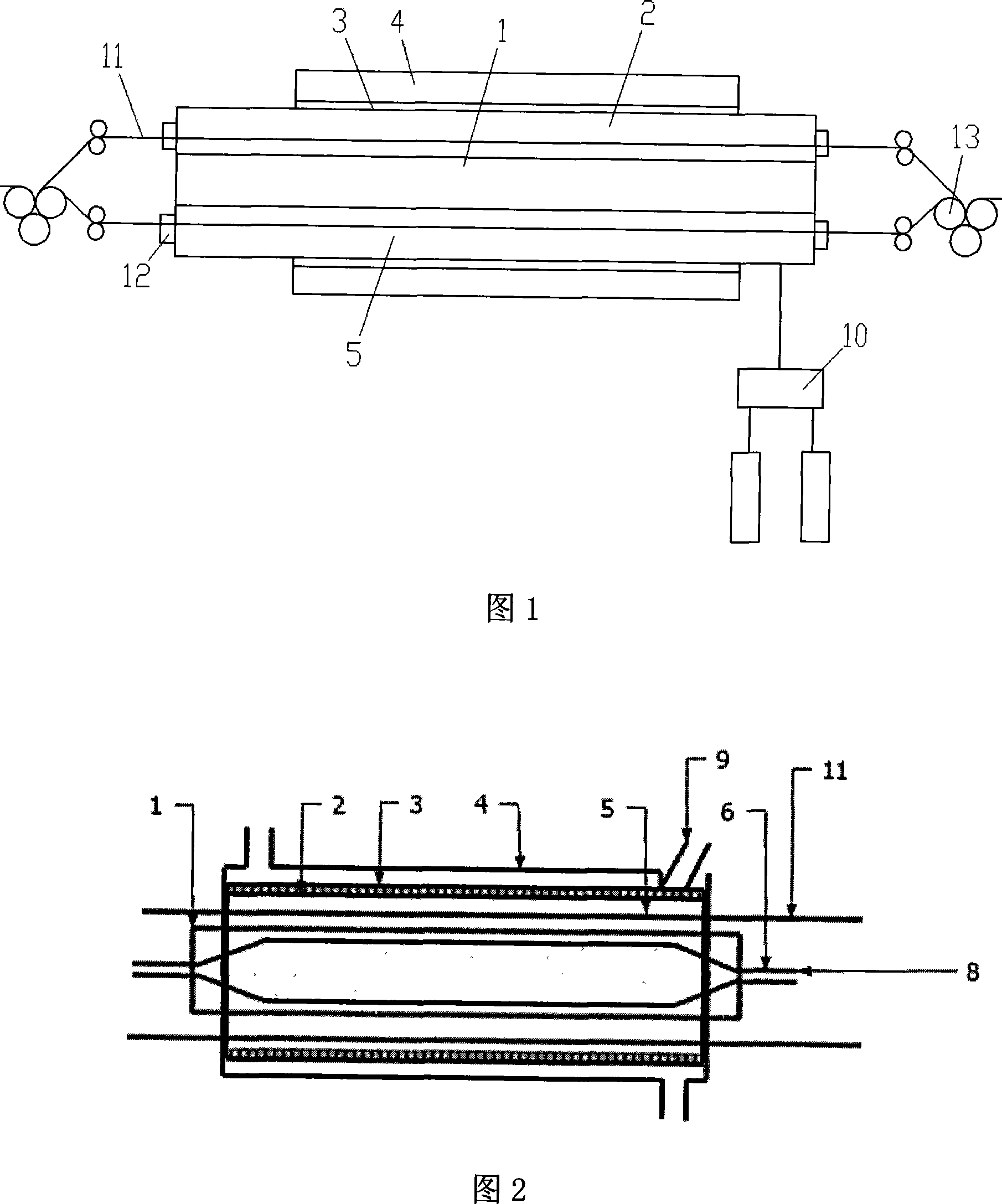

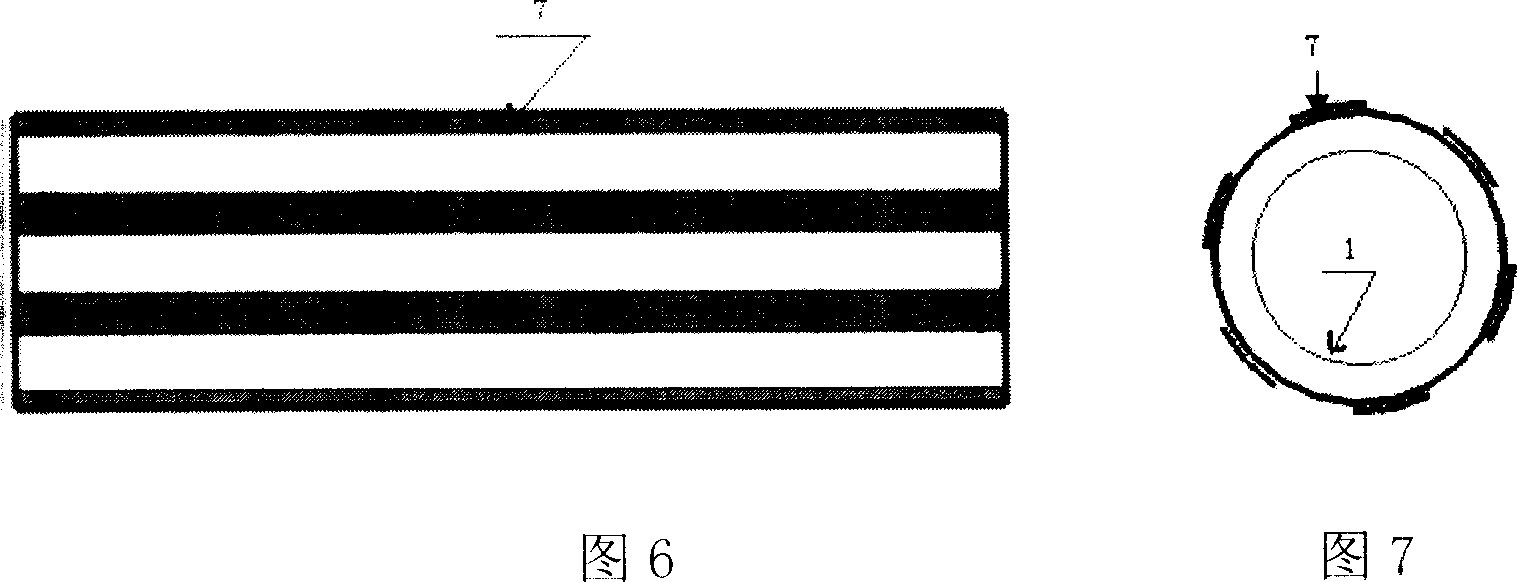

The invention discloses an atmosphere pressure plasma dealing fiber tuft or fiber thread surface device and method, which is characterized by the following: arranging quartz liner pipe in coaxial cover; constructing gas discharging plasma zone with quartz outer tube; forming high pressure electrode with inner surface or outer surface of the quartz linear through vacuum deposition plated metallic film; cup-jointing stainless steel cloth and water coat sandwich on the outer surface of the quartz outer tube; constructing earth electrode; using coaxial quartz glass tube to construct asymmetric electrode structure of medium discharge resistance; keeping special laminar flow disperse for gas in sandwich; diminishing consumption of gas; decreasing treating temperature effectively. This invention can choose proper high pressure electrode form, gas component, power parameter and treating speed according to different fiber material, which can proceed highly effective, low consumption and environment protection treat for the surface of fiber tuft or fabric cord.

Owner:DONGHUA UNIV

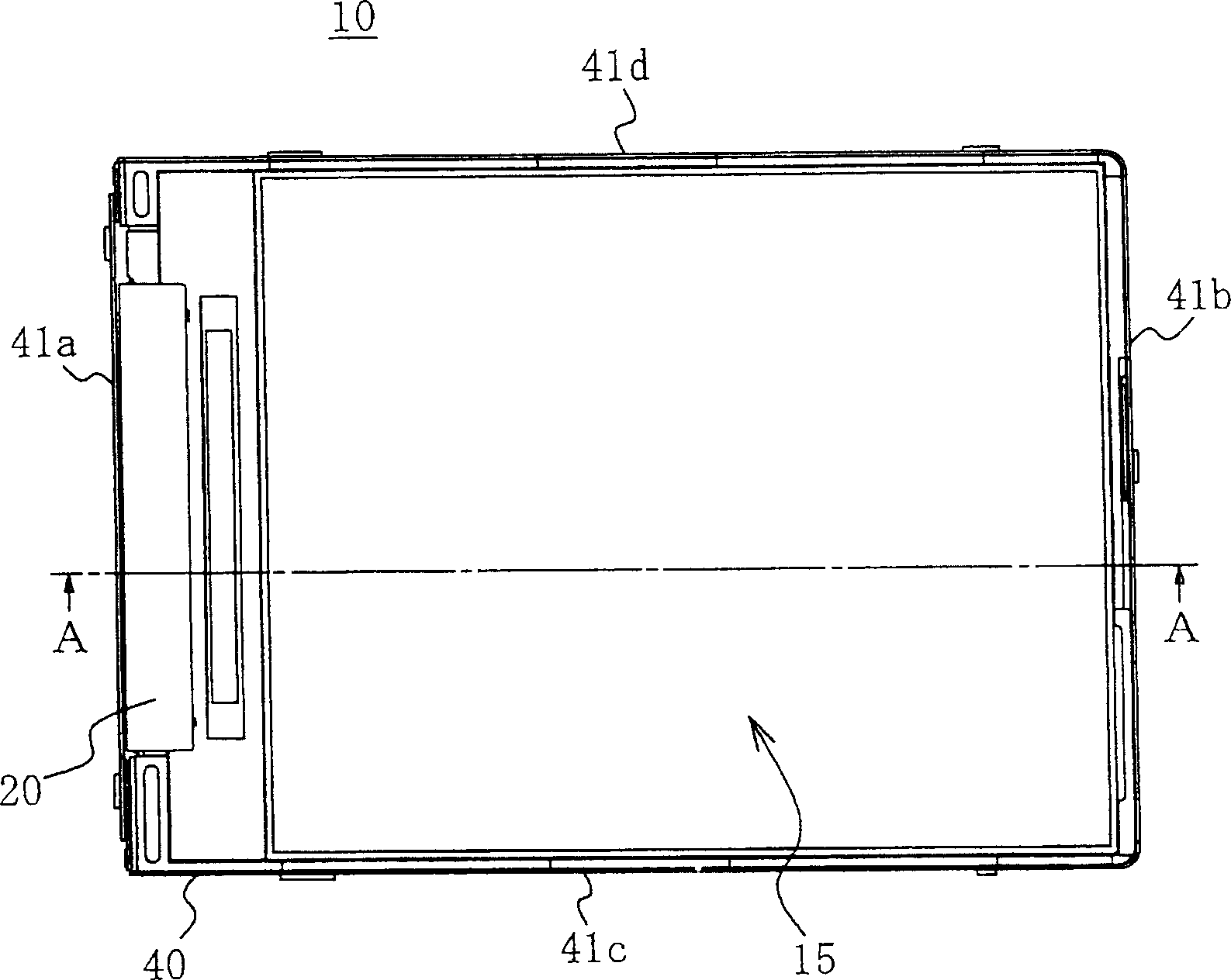

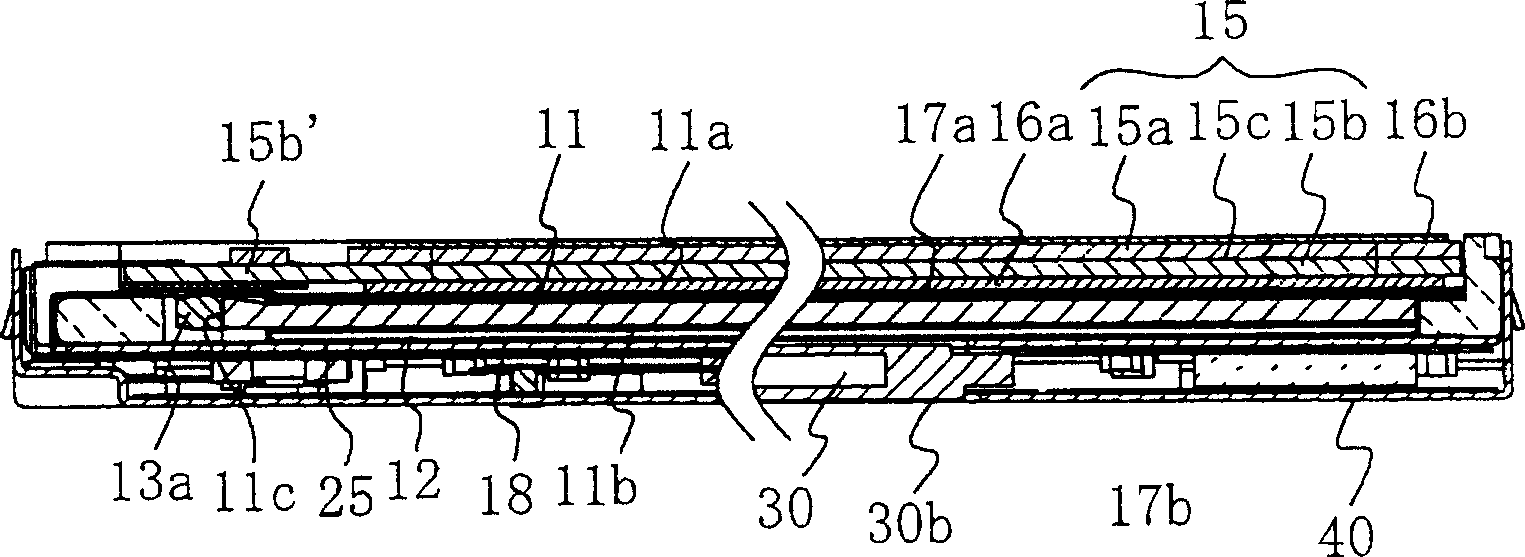

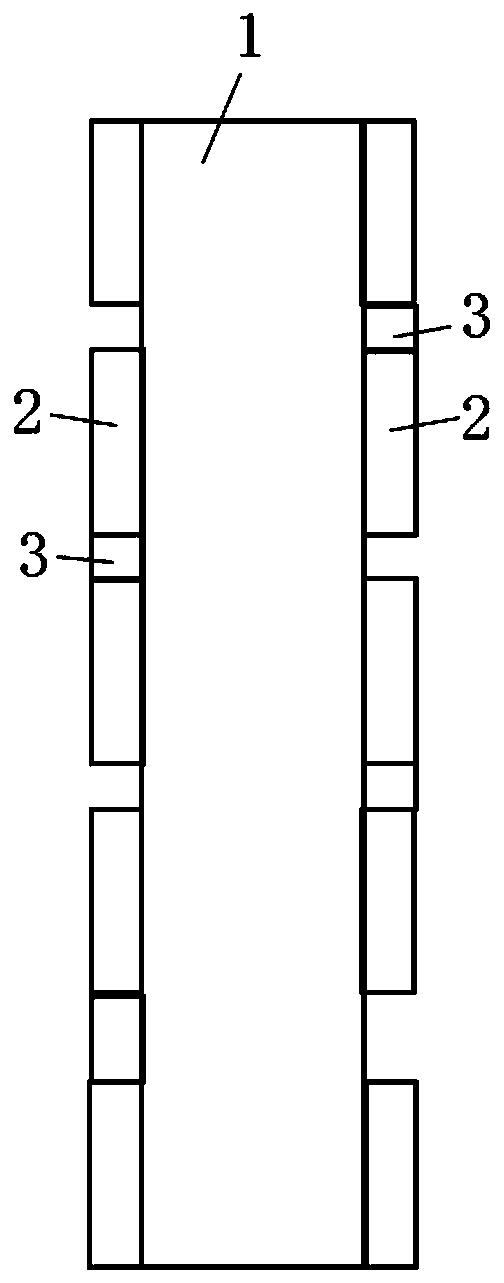

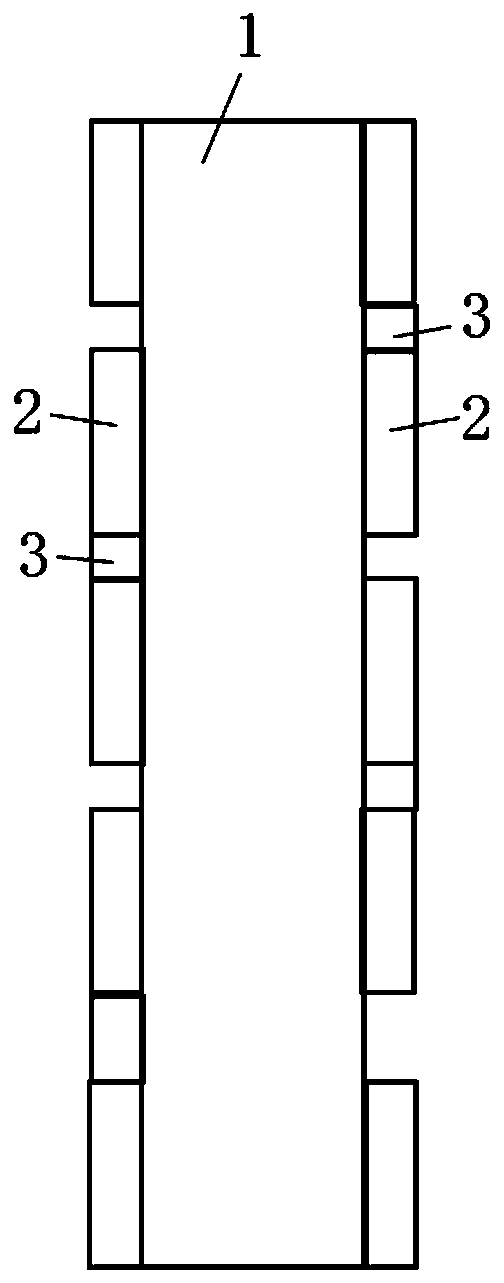

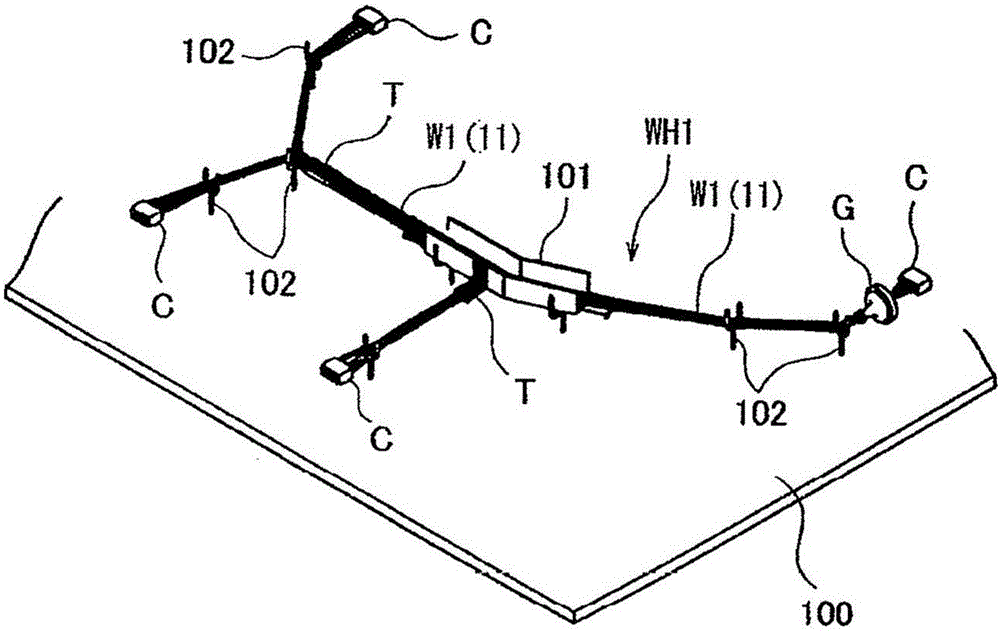

Liquid crystal display device and a mobile information terminal including a liquid crystal display device

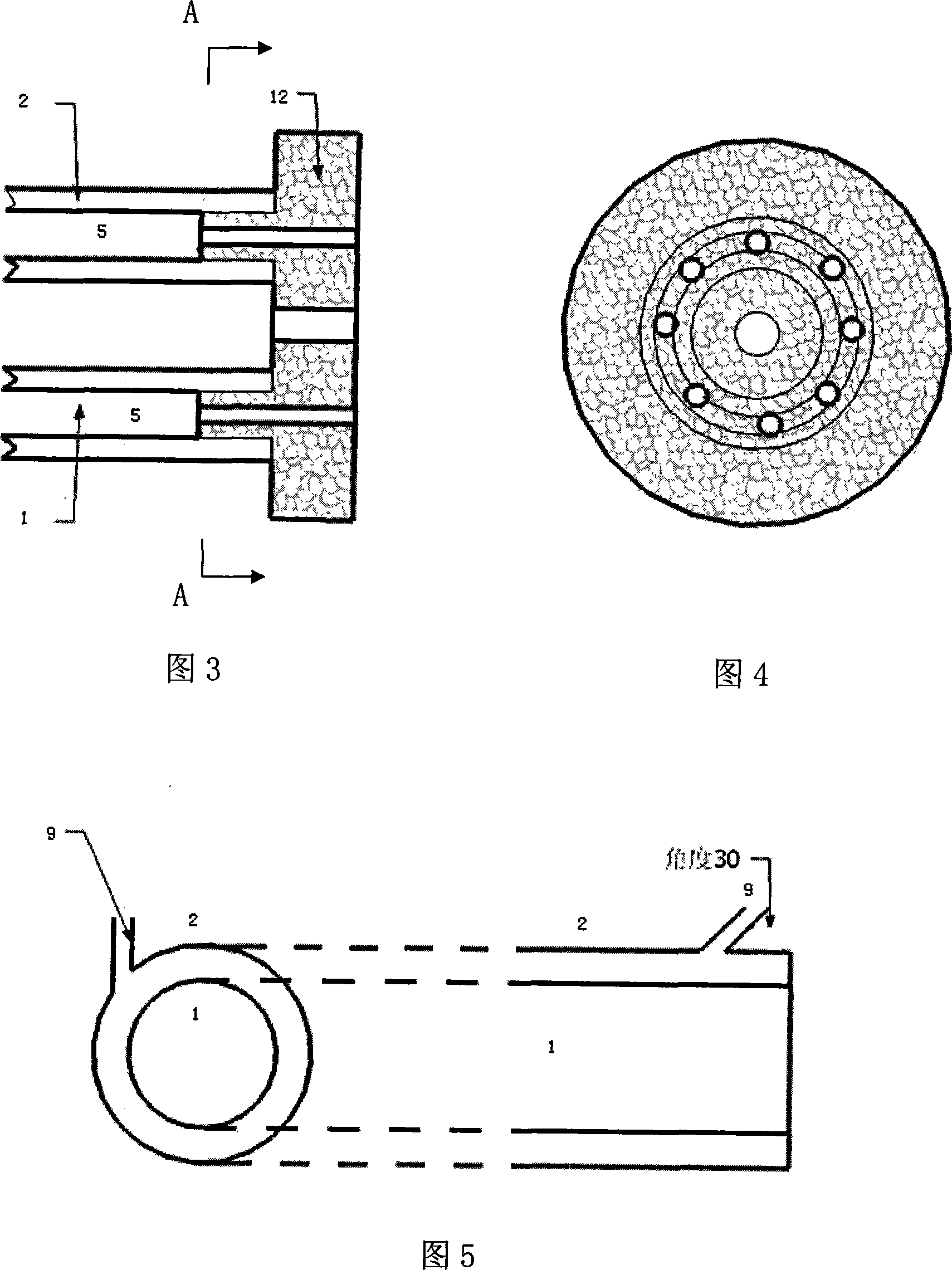

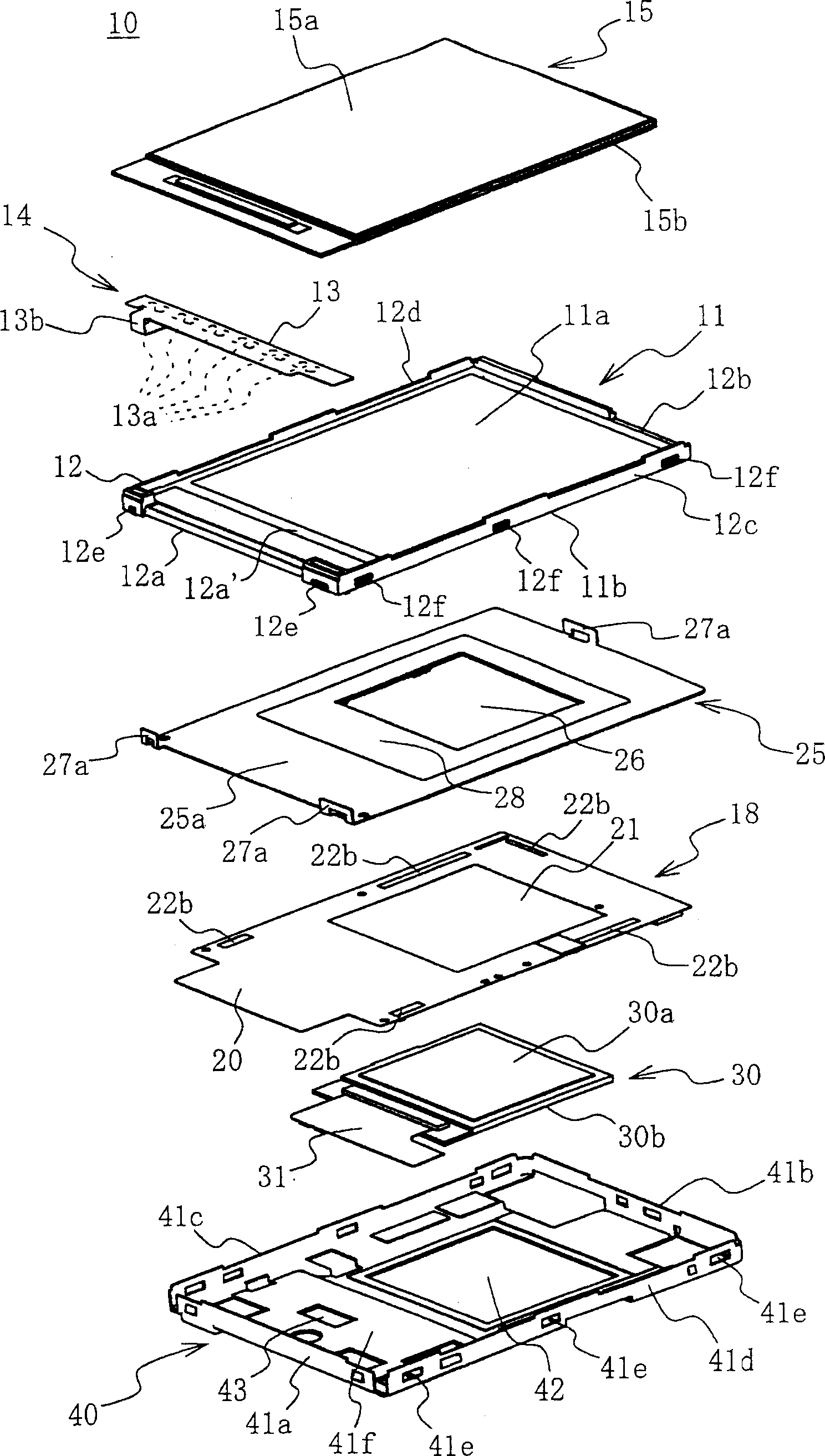

ActiveCN1749830AIncrease the utilization areaAchieve thinningStatic indicating devicesDevices with multiple display unitsLiquid-crystal displayCountermeasure

The invention provides a liquid crystal display device of which the thickness reduction is realized while retaining a predetermined mechanical strength and the measures against noise production is taken, and also provide a portable information terminal using the same. In the liquid crystal display device 10 constructed by disposing a first liquid crystal display panel 15 on a surface of a light guide plate 11, which guides light to both front and rear faces, and a second liquid crystal display panel 30, which is more compact than the first liquid crystal display panel 15, on the other surface thereof, and laminating them, the liquid crystal display device has a circuit substrate 18, which controls the first and second liquid crystal display panels 15, 30 and has contact portions 22a, 22b for grounding on at least one out of the front and rear faces, interposed between the light guide plate 11 and the second liquid crystal display panel 30, wherein the contact portions 22a, 22b for grounding are in contact with metal members 25, 40 mounted on at least one out of the front and rear faces of the circuit substrate 18, and the portable information terminal uses the liquid crystal display device.

Owner:JAPAN DISPLAY INC

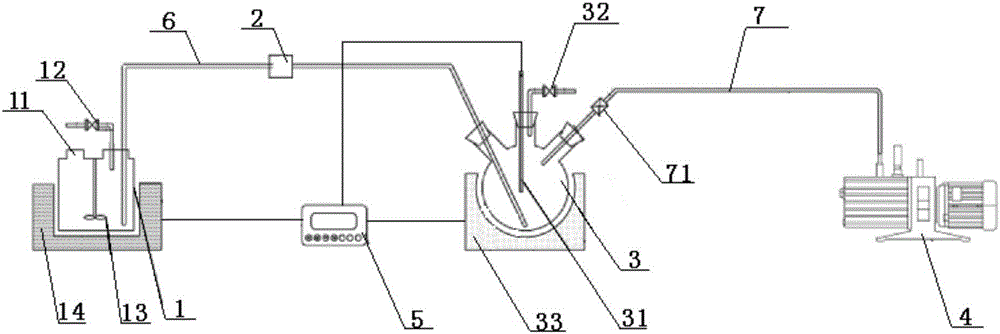

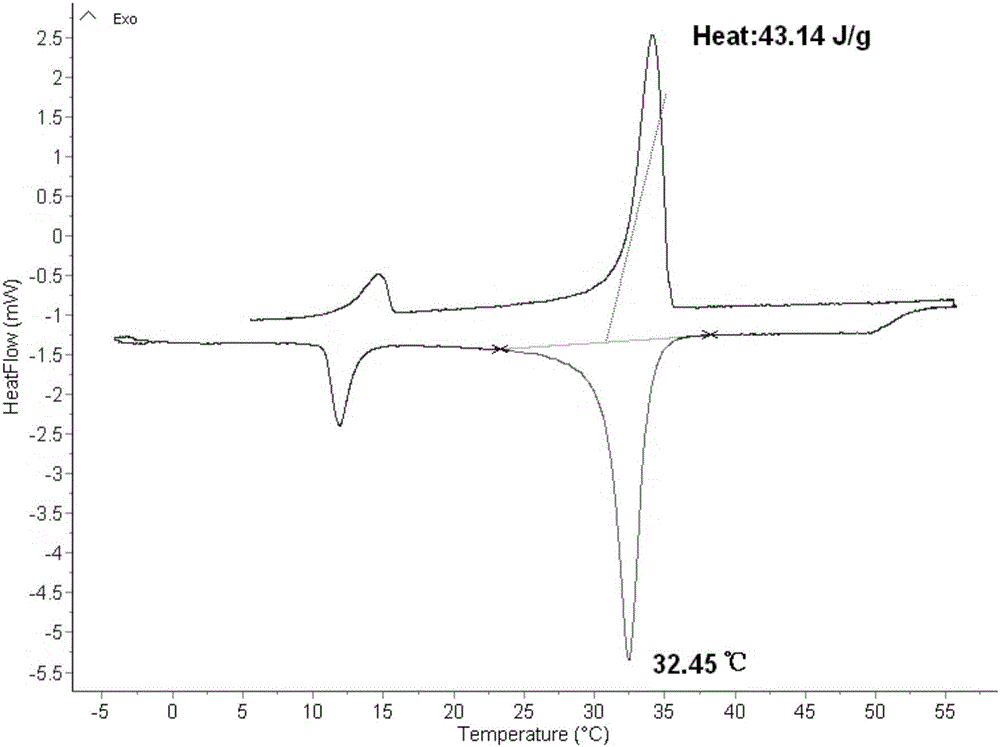

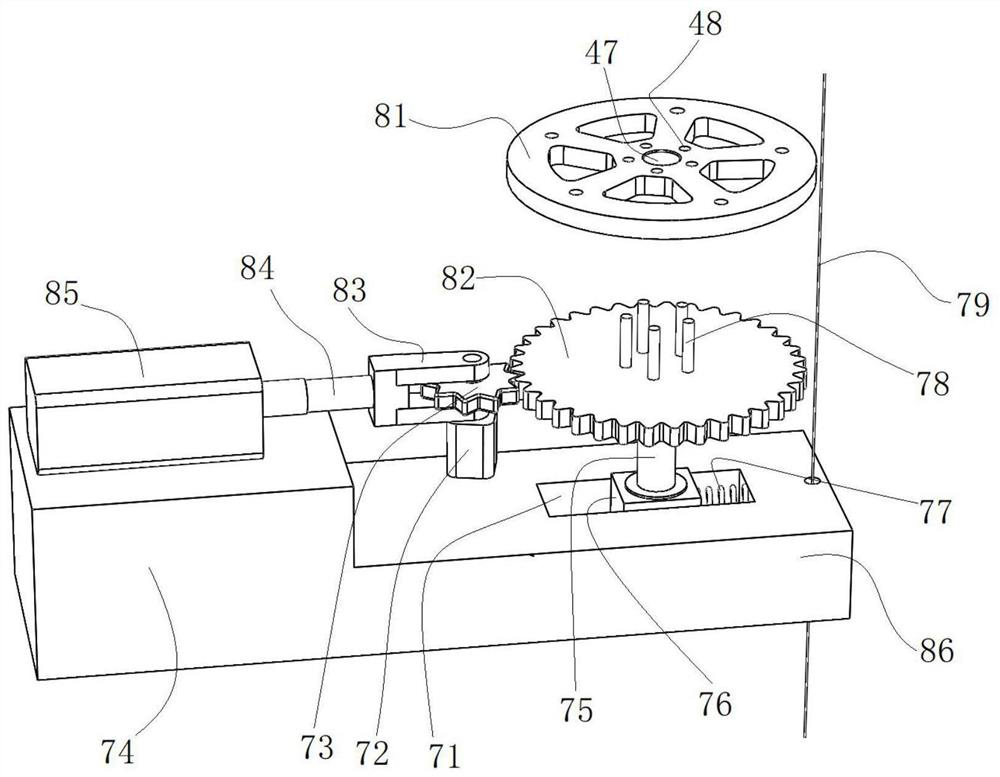

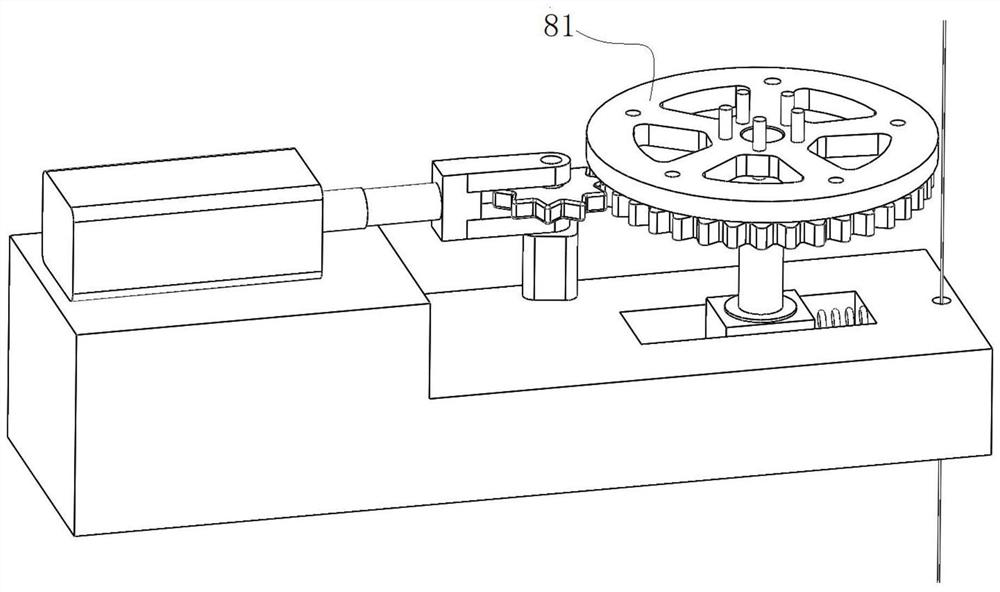

Preparation method and preparation device of porous medium composite phase-change material

The invention discloses a preparation method and preparation device of a porous medium composite phase-change material. The method and device can be used for packaging a low-temperature organic phase-change material by a porous propping material to obtain the high-airtightness composite phase-change material. The preparation method comprises the following steps: carrying out vacuum treatment on a porous propping material; preparing an organic precursor solution; preparing a packaging substance emulsion; compounding the packaging substance emulsion and porous propping material; and drying and curing to form the porous medium composite phase-change material. The preparation device comprises a phase-change substrate emulsification container, a liquid automatic sampler, a packaging composite container, a vacuum pump and a temperature controller. The porous medium composite phase-change material prepared by the preparation method has the advantages of firm packaging, low leakage tendency, convenient manufacturing process, simple technique, favorable economy and high applicability.

Owner:SHENYANG AEROSPACE UNIVERSITY

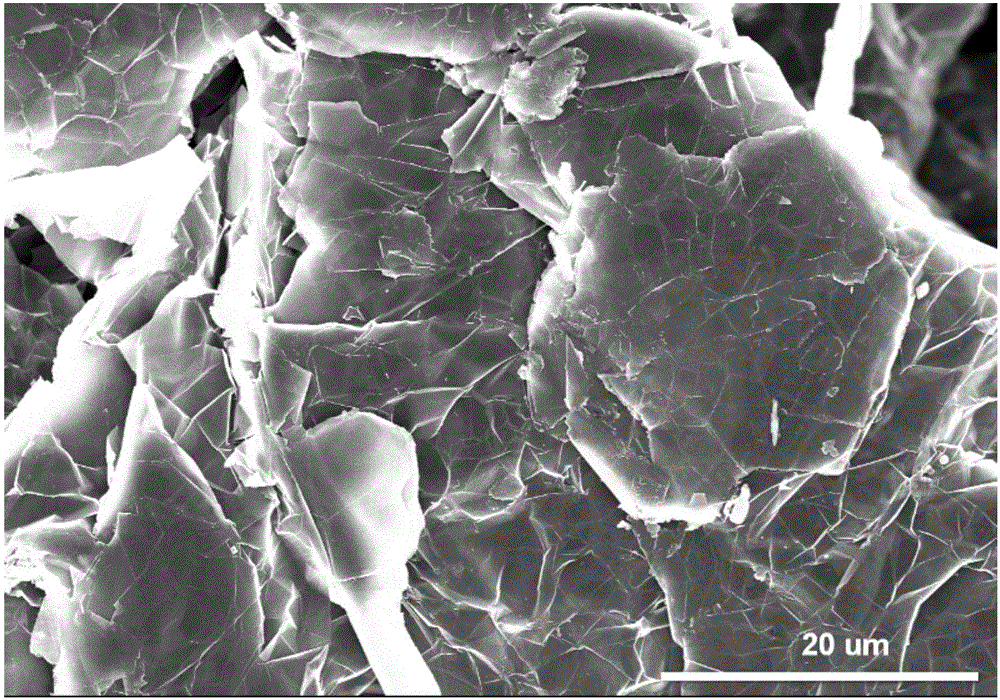

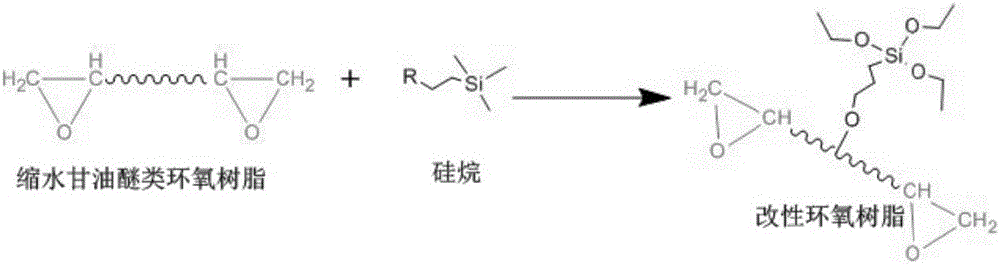

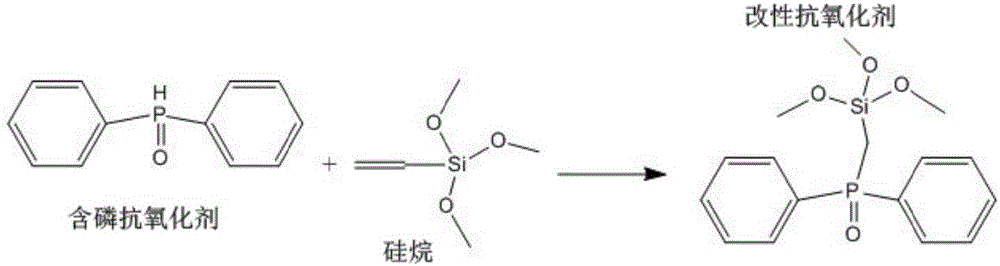

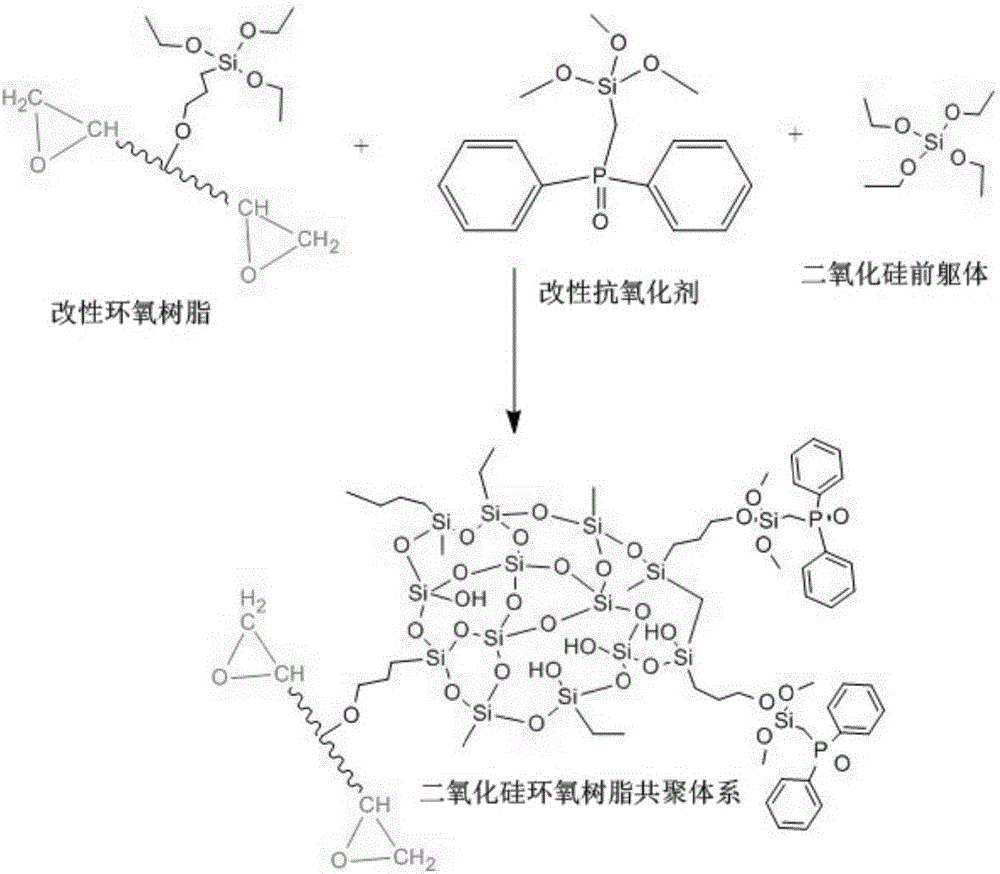

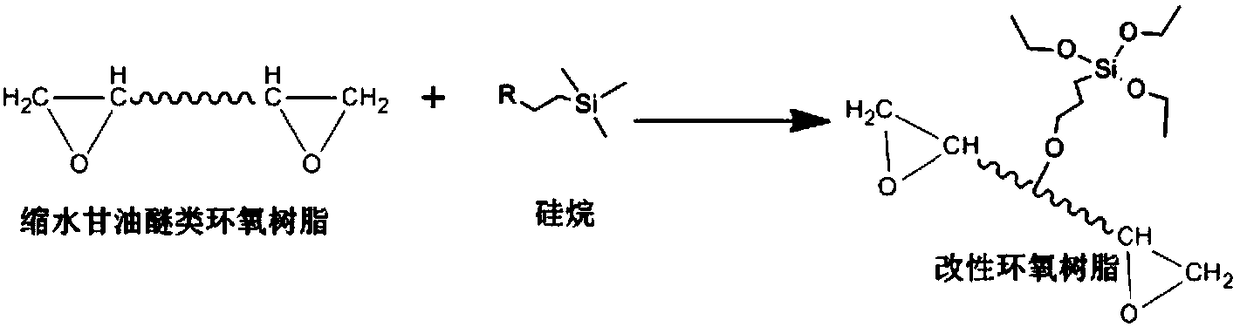

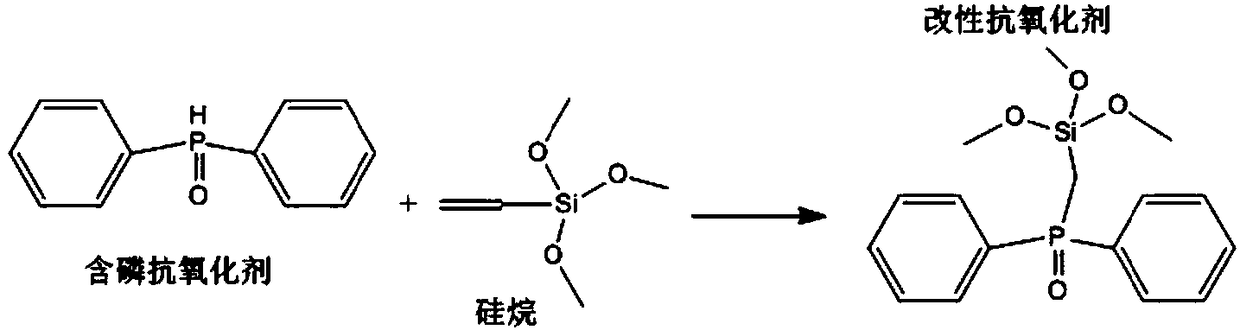

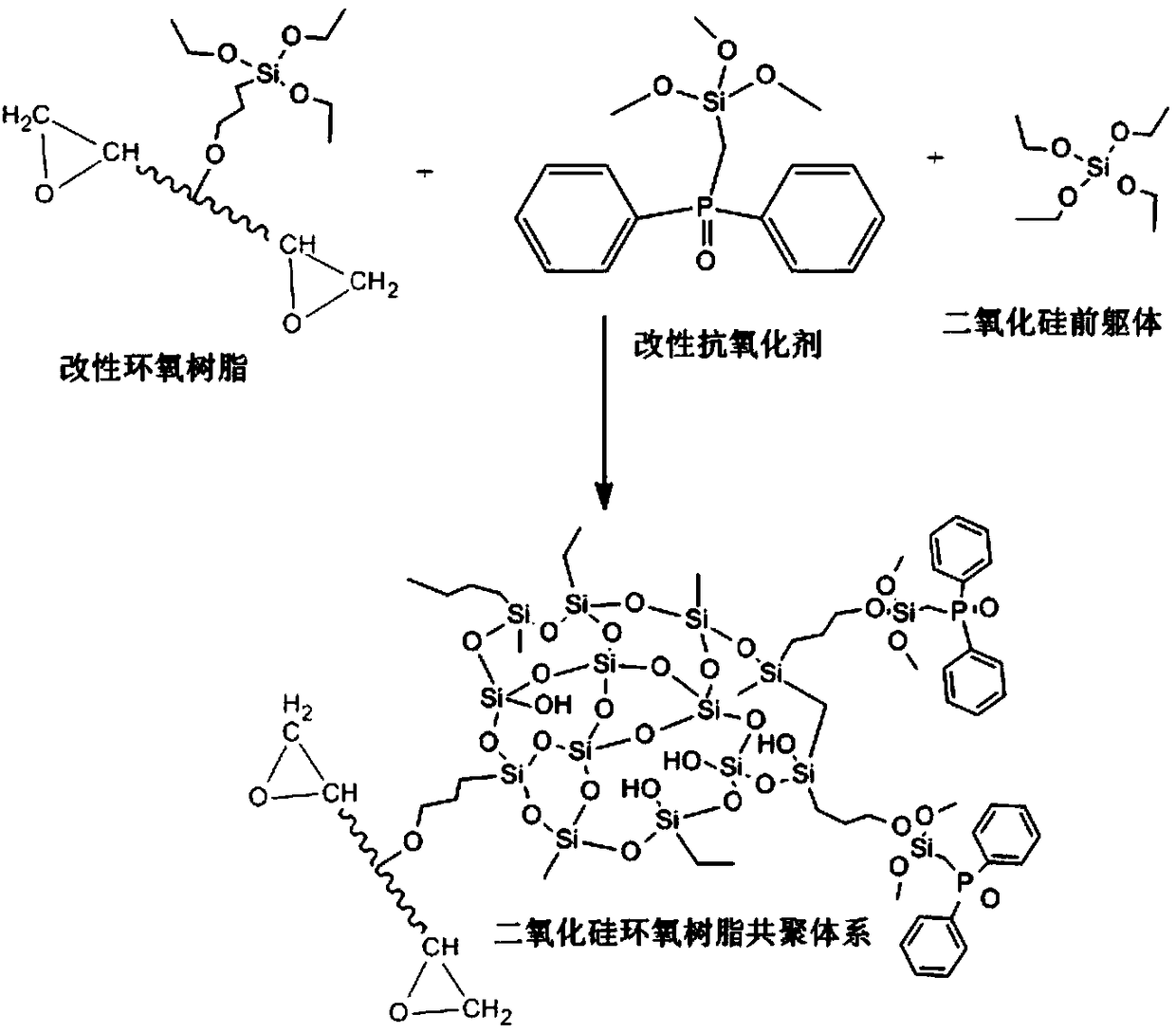

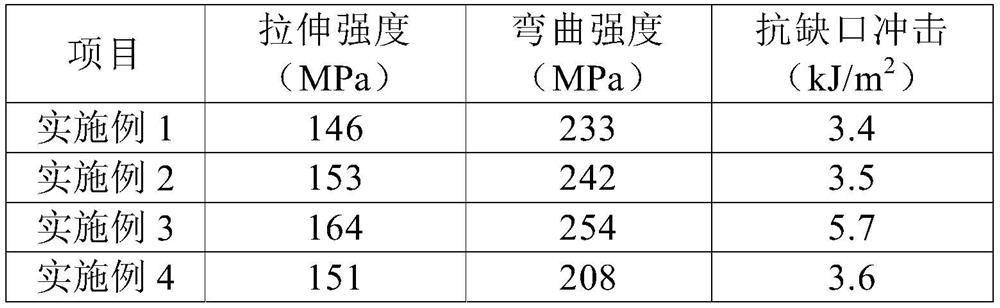

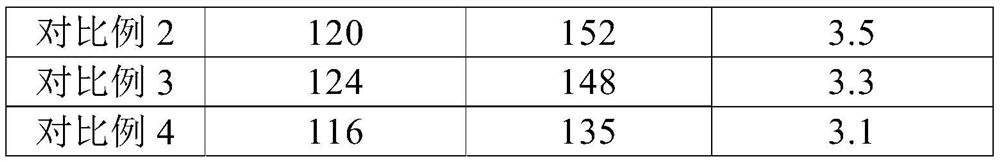

Preparation method for composite resin system copolymerized by silicon dioxide and epoxy resin and compatible with liquid oxygen

The invention discloses a preparation method for a composite resin system copolymerized by silicon dioxide and epoxy resin and compatible with liquid oxygen. The preparation method comprises the following steps: 1, subjecting glycidyl ether epoxy resin and silane to a reaction so as to prepare silane modified epoxy resin; 2, subjecting a phosphorus-containing antioxidant substance and silane to a reaction so as to prepare a silane modified antioxidant; 3, mixing the silane modified epoxy resin, the silane modified antioxidant and a silicon dioxide precursor, dissolving the mixture into a solvent, and carrying out heating to 40 to 60 DEG C; and 4, adding deionized water and a catalyst, carrying out a reaction for 1 to 5 hours, and carrying out decompressing so as to remove product water and the solvent. According to the invention, a nanometer silicon dioxide unit and antioxidant molecules are covalently introduced into the epoxy resin system, and well-known mechanical strength may not be decreased after introduction, so the antioxidant may not be precipitated and leaked out of a resin substrate; and through the introduction of the silicon dioxide unit, the toughness of the cured resin is significantly improved, and the use safety of the epoxy resin used as a substrate material of a liquid oxygen storage tank is greatly improved.

Owner:DALIAN UNIV OF TECH

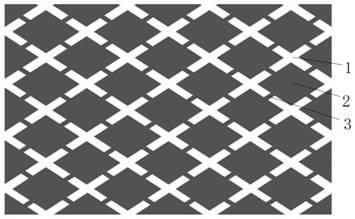

Artificial grain spraying method for solid wood board

InactiveCN102173276ANo loss of mechanical strengthIncrease added valueDecorative surface effectsSpecial ornamental structuresCoated surfaceSolid wood

The invention discloses an artificial grain spraying method for a solid wood board, which comprises the following steps of: (1) manufacturing a template; (2) engraving a mold; (3) selecting a base board; (4) mixing color; (5) pressing the mold and spraying; (6) removing the mold and curing the coating; and (7) spraying transparent paint on the surface of the coating. The solid wood board painted with the artificial grain through the steps can be widely applied to decoration of indoor floor boards, wall boards and roofs. The artificial grain spraying method disclosed by the invention has a simple and convenient process and high applicability, does not influence the mechanical strength of the base board body, can be used for spraying various grains on the surface of the base board, ensures that the bonding strength between the sprayed pattern grains and the base board is high, overcomes the deficiency of simplex property of the traditional floor pattern, enlarges the using range of woodof trees with simplex grains, and improves the additional value of products.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Lithium battery by using lightweight current collector

ActiveCN111129505ALight in massImprove conductivityElectrode carriers/collectorsLi-accumulatorsPhysicsElectro conductivity

The invention discloses a lithium battery by using a light-weight current collector. The lithium battery comprises a positive plate, a diaphragm and a negative plate which are laminated or wound, thepositive plate comprises a positive current collector; the negative plate comprises a negative current collector; the positive electrode current collector and / or the negative electrode current collector are / is composed of a conductive film base layer and a metallized film layer. The thickness of the conductive film base layer is 5-20 [mu]m, the conductivity of the conductive film base layer is 1-100 s / cm, the thickness of the metallized film layer is 0.2-2 [mu]m, the metallized film layer of the positive electrode current collector is an aluminum layer or a nickel layer, and the metallized film layer of the negative electrode current collector is one of a copper layer, an iron layer and a tungsten layer. The positive electrode current collector and / or the negative electrode current collector are / is composed of the conductive film base layer and the metallized film layer, and the conductive film base layer is prepared from the polymer base material, so that the mass of the current collector is effectively reduced while the function of the current collector is realized, and the purpose of light weight of the current collector is achieved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

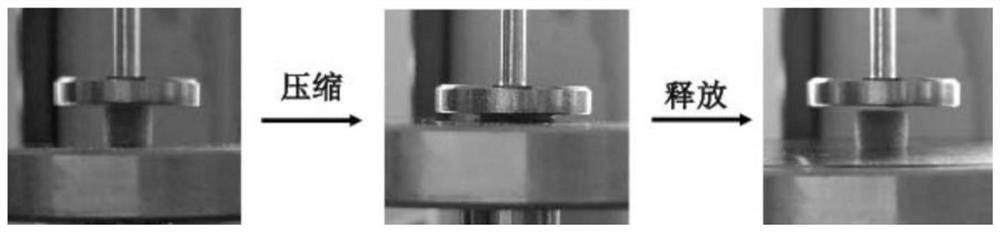

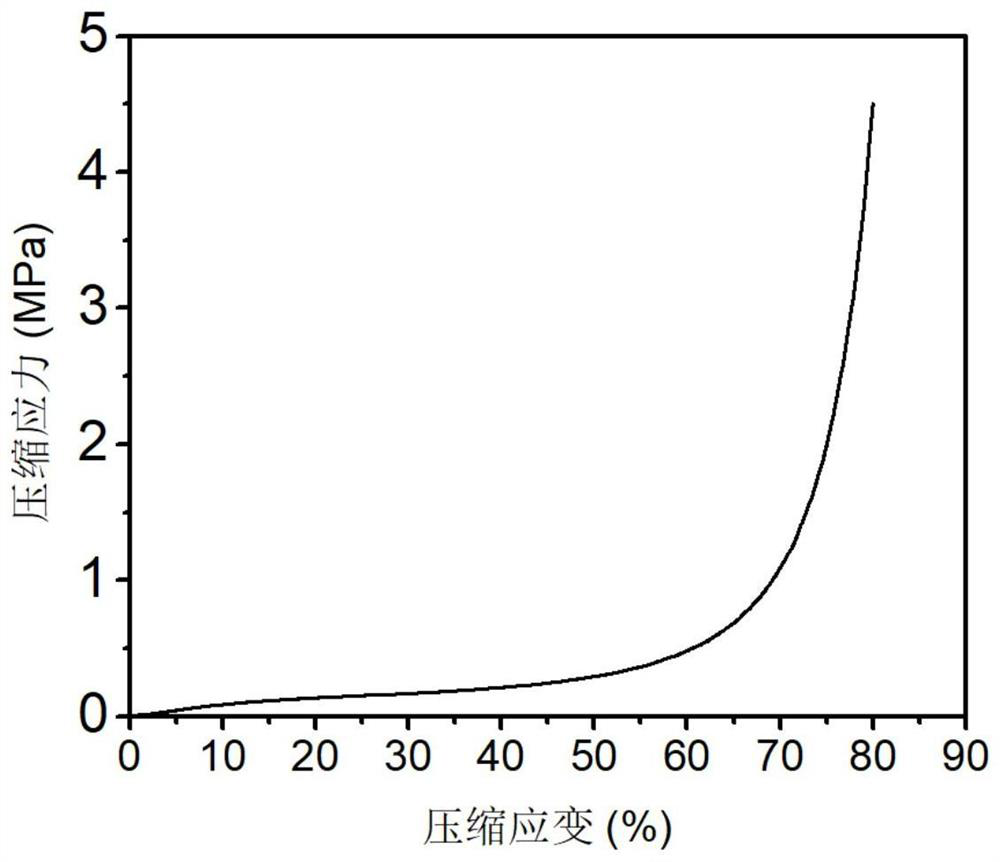

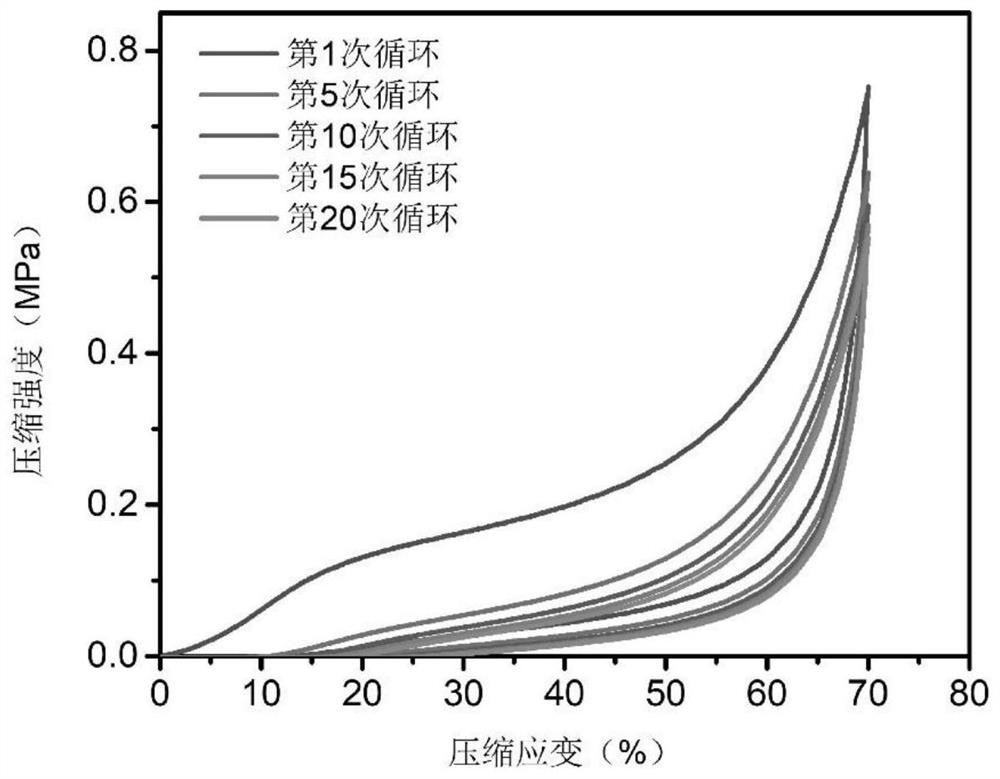

Preparation method of high-elasticity and high-strength double-crosslinked porous hydrogel

The invention discloses a preparation method of high-elasticity high-strength double-crosslinking porous hydrogel, which comprises the following steps: preparing acrylic acid, a hydrophilic monomer, achemical crosslinking agent, an initiator and a solvent into a prepolymer solution; adding a pore-foaming agent into the pre-polymerization solution until the pre-polymerization solution is in a saturated filling state; transferring the saturated filled prepolymer solution into ultraviolet to initiate polymerization to obtain chemical cross-linked hydrogel; and soaking the chemically crosslinkedhydrogel in an iron ion solution, and carrying out physical crosslinking to obtain the double-crosslinked porous hydrogel. The method is simple and easy to implement and is free of special equipment;the porous hydrogel prepared through the method has the characteristics of high elasticity and high strength; in addition, the original mechanical strength of the porous hydrogel can be rapidly recovered under the room temperature condition after the porous hydrogel is fatigued and the good anti-fatigue characteristic is achieved. The product has important application prospects in the fields of artificial muscle, environment treatment materials, flexible electronics and the like.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

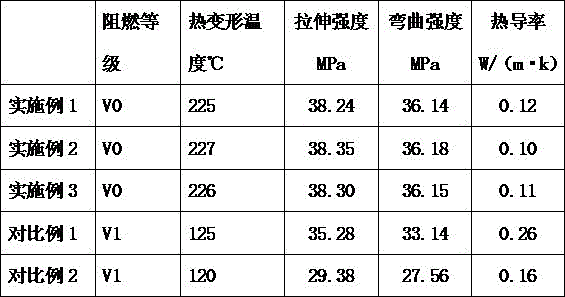

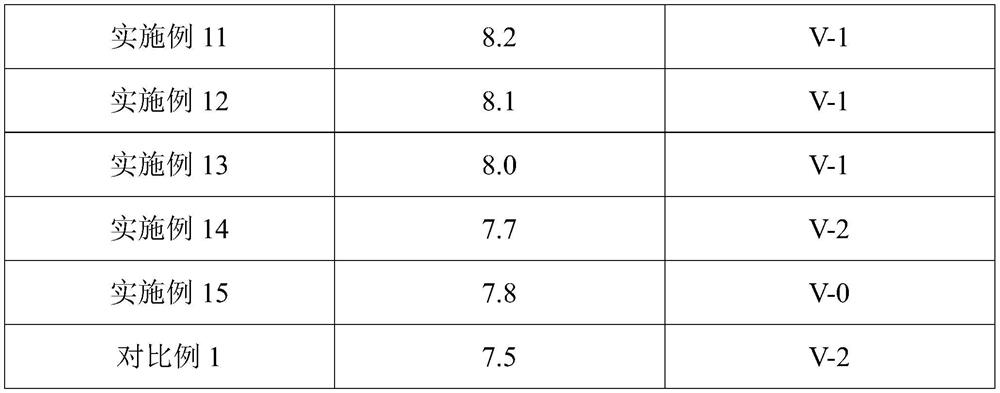

Flame retardant plastic shell for capacitor

ActiveCN106366586AGood mechanical propertiesImprove flame retardancyPolytetramethylene terephthalateChemistry

The invention discloses a flame retardant plastic shell for a capacitor. The flame retardant plastic shell is prepared from, by weight, polybutylene terephthalate, ABS plastic, a filling agent, color master batch, dimethyl trimethylsilylmethylphophonate, polyvinyl chloride resin, a lubricant and a flame retardant. The prepared plastic shell for the capacitor is good in mechanical performance, high in flame retardance, good in processability and low in cost and melt viscosity.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

Method for pretreating linen-rayon elastic fabric

InactiveCN107313260AImprove dye uptakeImprove homochromaticitySingeingDry-cleaning apparatus for textilesAmylasePectinase

The invention discloses a method for pretreating a linen-rayon elastic fabric, which includes the following steps: singeing, desizing and scouring and bleaching, wherein desizing and scouring are desizing and scouring by compound enzyme, and the compound enzyme consists of amylase, xylanase, pectinase and cellulase. By choosing the suitable enzymes to be compounded and adopting an appropriate desizing and scouring process, the method can improve the microstructure of fibers in the linen-rayon elastic fabric while ensuring that the linen-rayon elastic fabric has appropriate elastic and mechanical properties, preparing for later dyeing, consequently, the dye uptake of the fabric is increased, moreover, the shading problem of linen fibers and rayon fibers is improved, and the homochromatism of the fabric is increased; since suitable bleaching treatment is adopted, while the fabric is bleached, the elasticity and mechanical strength of the fabric cannot be decreased, furthermore, the treatment period is short, the process is simple, and the method is convenient to operate.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Implant material for promoting bone wound healing and preparation method thereof

InactiveCN108030960AHigh mechanical strengthLarge specific surface areaMicrocapsulesProsthesisPorosityReticular formation

The invention discloses an implant material for promoting bone wound healing and a preparation method thereof, which relate to the technical field of a medical material. The bone implant material is composed of a polylactic acid matrix and a medical magnesium alloy frame hanged in the polylactic acid matrix, the medical magnesium alloy frame is obtained by weaving the medical magnesium alloy wiresto form a wave-shape net structure through superposition, the surface of the polylactic acid matrix is modified with a porous hydroxy apatite layer, and the micropores of the hydroxy apatite layer are filled with danshinolic acid B and vancomycin microcapsules. The implant material has good biological compatibility, large specific surface area, and high amount of porosity, is suitable for newbornosteocyte growth, promotes fracture position bridging healing, has strong fixing stability during a fracture bridging healing process, and can prevent secondary fracture; danshinolic acid B and vancomycin with effective concentration can be kept in a medicine system for long-term, so that the continuous inflammation resisting and bridging healing promotion for the fracture can be realized.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

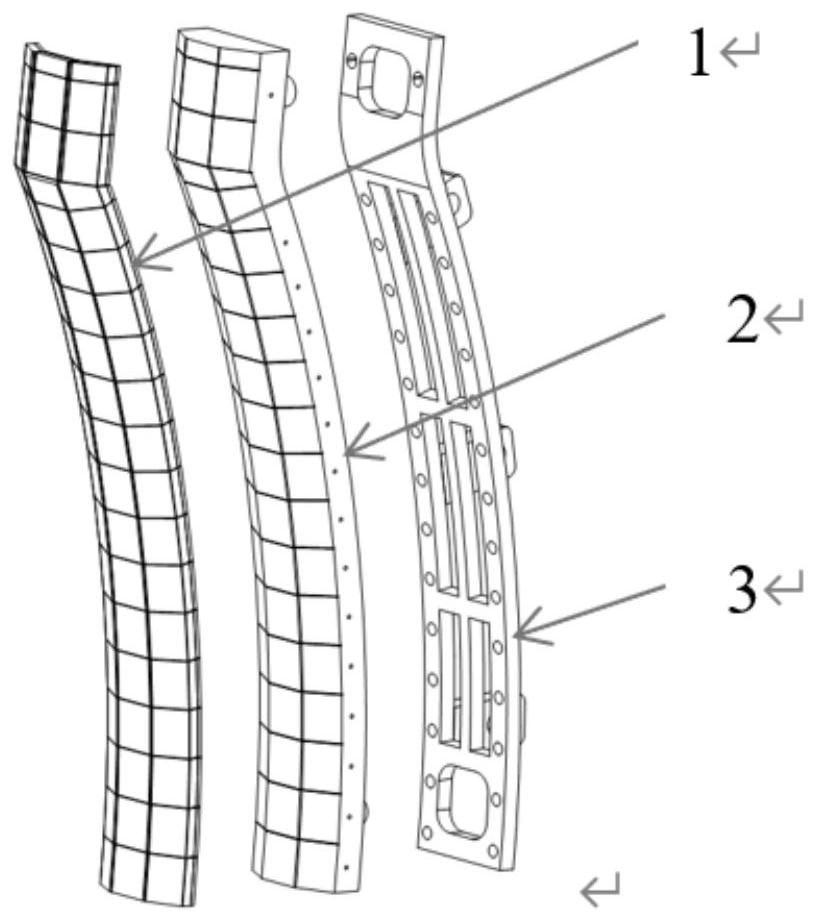

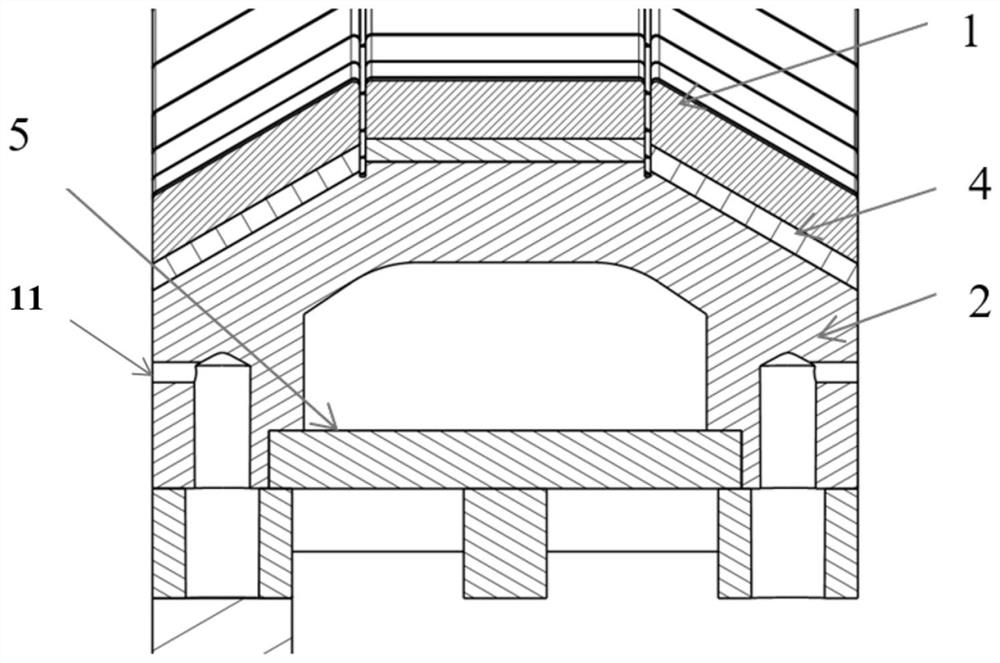

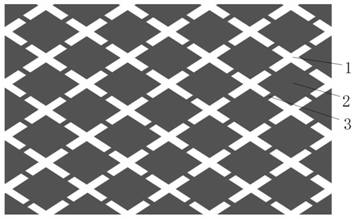

Carbon fiber reinforced composite (CFC) protection limiter

PendingCN112992384AEfficient and stable operationReduce heat transfer resistanceNuclear energy generationThermonuclear fusion reactorPhysicsHeat sink

The invention discloses a carbon fiber reinforced composite (CFC) protection limiter, which mainly comprises CFC modules, an oxygen-free copper metallization layer, a chromium zirconium copper heat sink body and a stainless steel framework. The CFC modules of the limiter are arranged in an annular array along the longitudinal direction of an antenna and are arranged in an isosceles trapezoid in the transverse direction, and the CFC modules are kept at a preset interval. A stress releasing groove is machined in the surface of the heat sink body, the CFC modules and the chromium zirconium copper are sealed in a high-temperature brazing mode, and a heat load on the surface of the CFC takes away heat through an active cooling water channel. The invention provides a high-heat-load-resistant (greater than 2MW / m<2>) limiter structure and a reliable preparation method, and sputtering damage of high-energy particles to the surface of an antenna component during long-pulse high-temperature plasma operation is effectively avoided.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

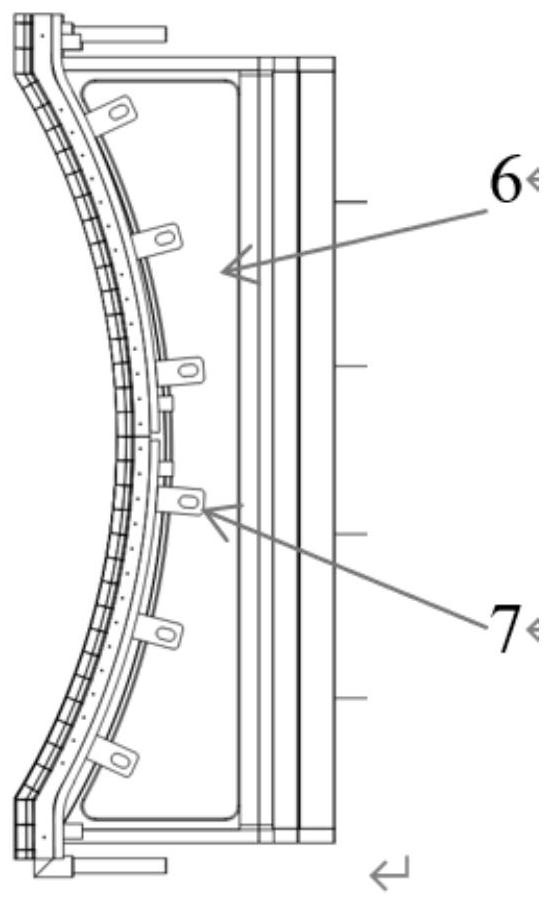

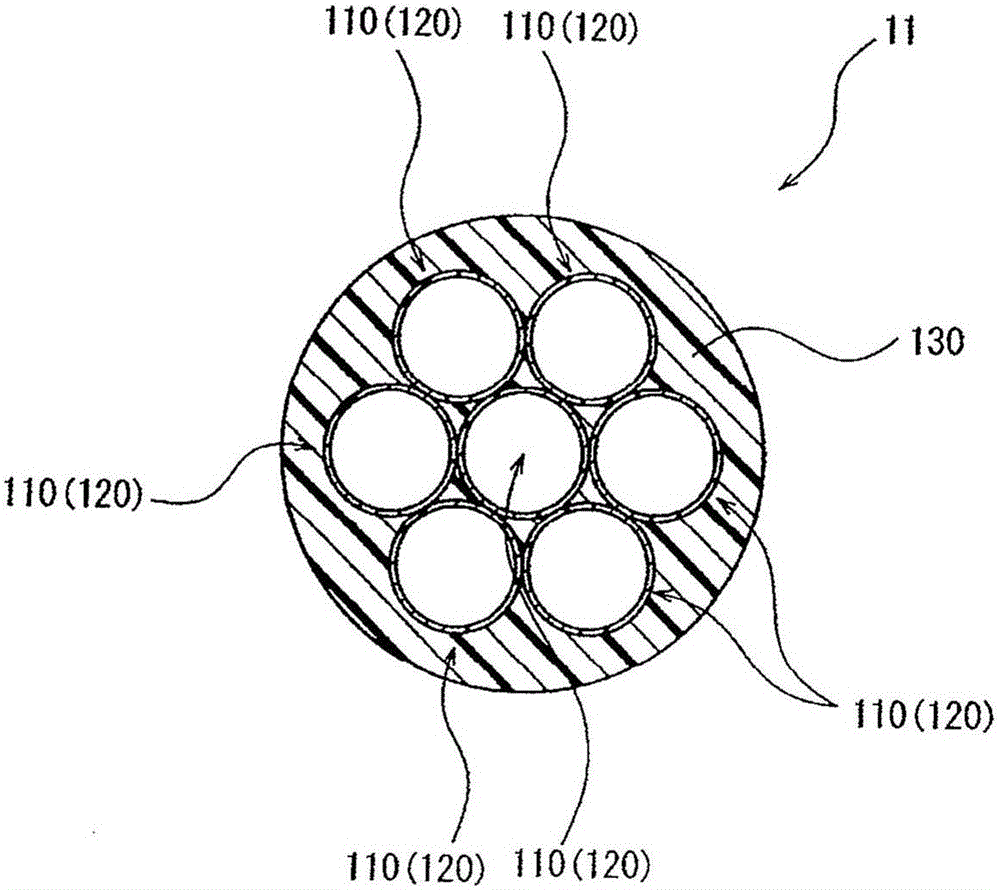

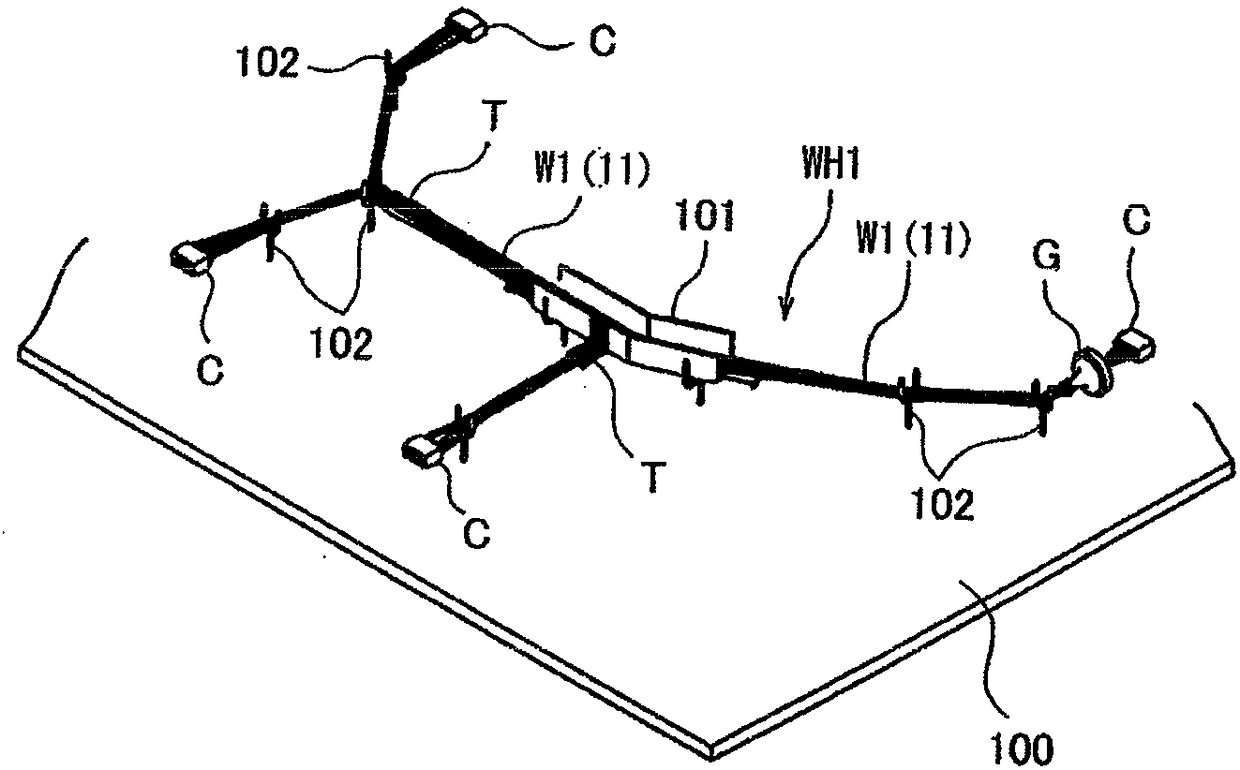

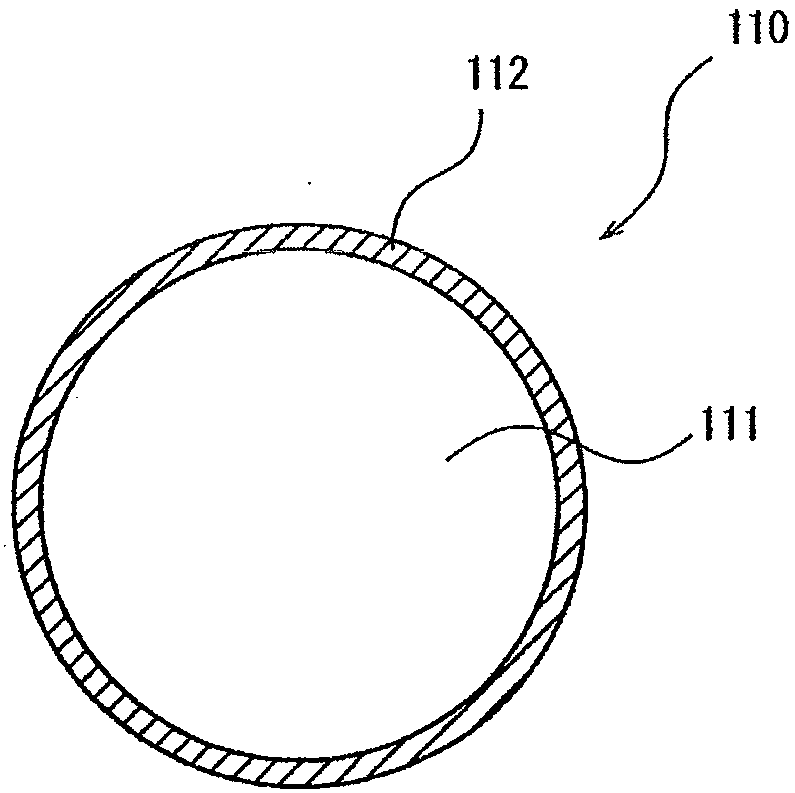

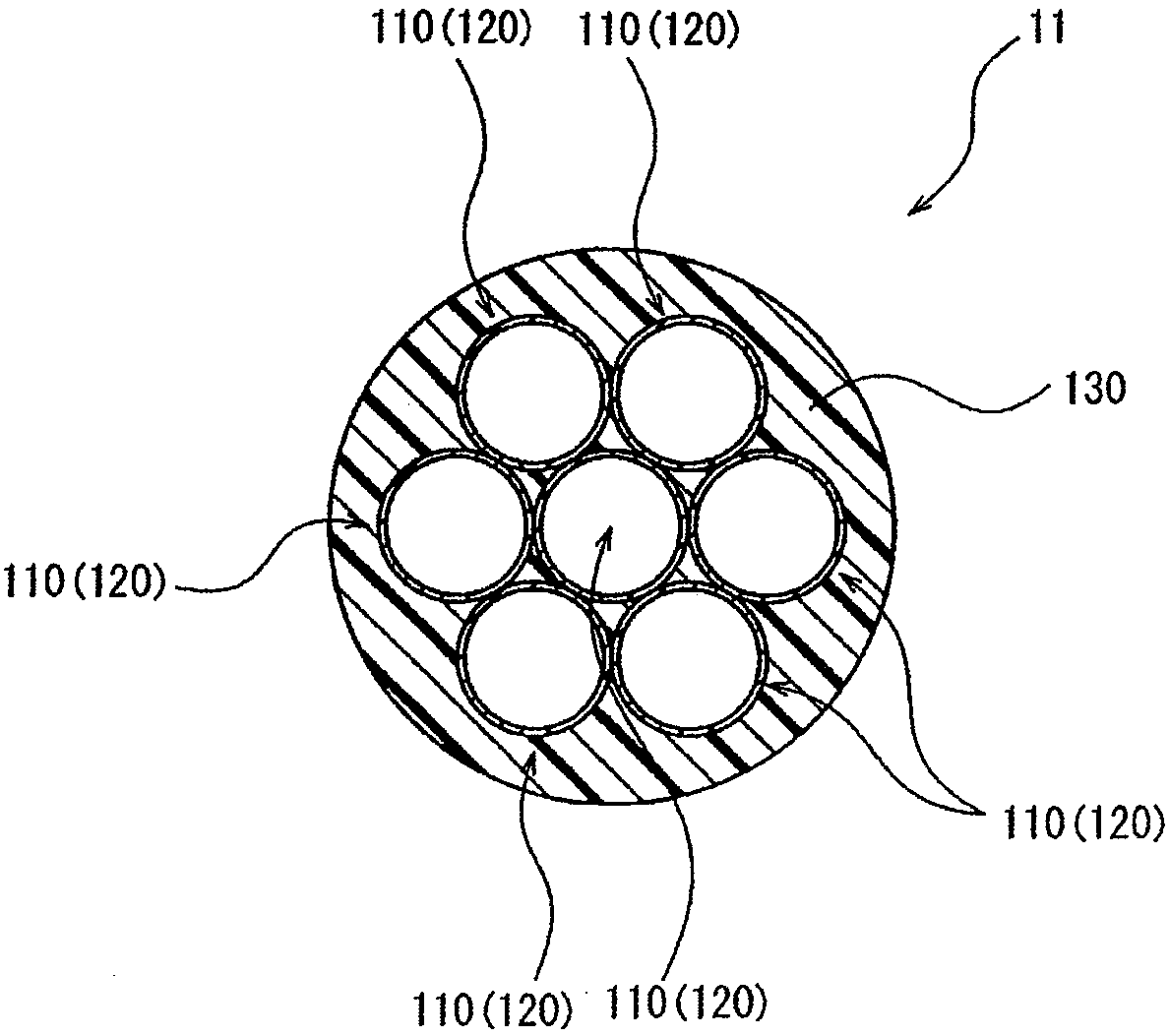

Plated fiber, carbon fiber, wire harness and plating method

ActiveCN106049034AAvoid breakingImprove precipitation effectCarbon fibresConductive materialFiberCarbon fibers

The invention provides plated fiber, carbon fiber, wire harness and a plating method. A plated fiber that is obtained by applying a metal plating onto a fiber having an elongation percentage which is more than or equal to 1% and less than or equal to 10%. An elongation percentage of the metal plating is higher than the elongation percentage of the fiber. A carbon fiber wherein the surface oxygen amount as a value obtained by dividing an O1S peak intensity measured by X-ray photoelectron spectroscopy by a C1S peak intensity measured by the spectroscopy is more than or equal to 0.097 and less than or equal to 0.138.

Owner:YAZAKI CORP

Halogen-free flame-retardant resin and preparation method thereof

The invention provides a halogen-free flame-retardant resin and a preparation method thereof. The halogen-free flame-retardant resin comprises the following components in parts by weight: 100 parts ofpolyamide 56, 5-20 parts of an organic halogen-free flame retardant, 5-40 parts of glass fibers, 0.05-0.5 part of a lubricant and 0.05-0.5 part of an antioxidant. The halogen-free flame-retardant resin disclosed by the invention adopts renewable substances as main raw materials, is environment-friendly, and further has good flame-retardant property and good mechanical property.

Owner:CATHAY R&D CENT CO LTD +1

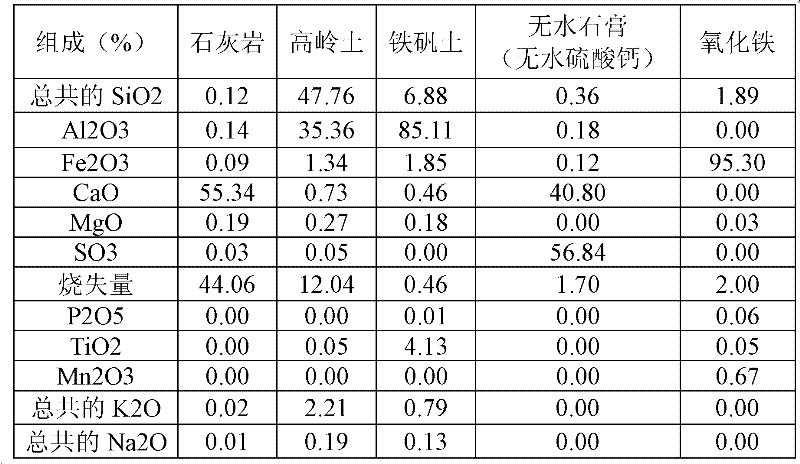

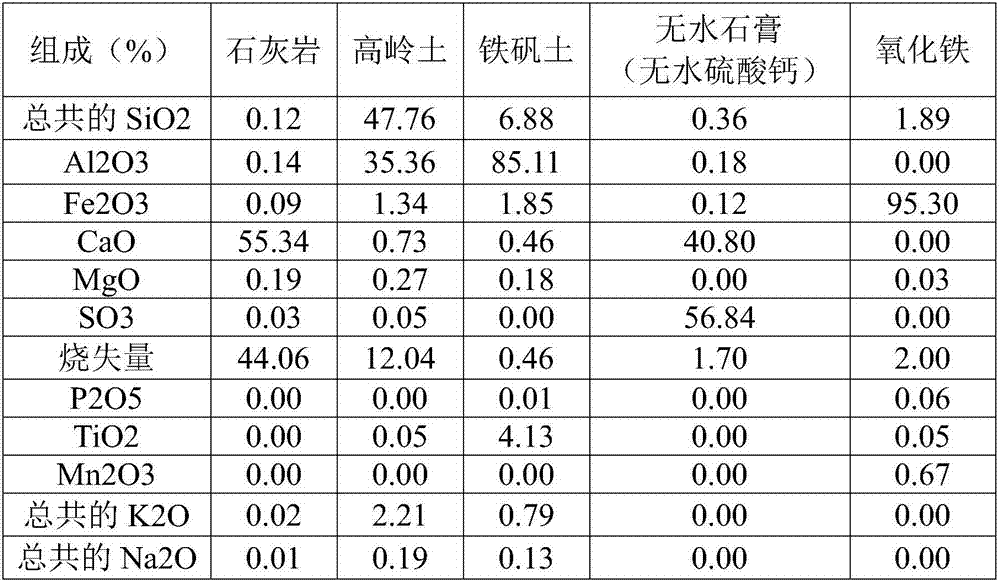

Additives for a hydraulic binder based on a belite-calcium-sulphoaluminate-ferrite clinker

InactiveCN102482148ALong-term high mechanical strengthReduce the amount of clinkerSolid waste managementCement productionCarboxylic acidMaterials science

The subject of the present invention is a composition comprising at least, in % expressed by weight relative to the total weight of composition, from 0.01 to 3% of polycarboxylic acid or one of the salts of said polycarboxylic acid comprising from 2 to 4 carboxyl groups per molecule; and from 97 to 99.99% of a Belite-Calcium-Sulphoaluminate-Ferrite clinker (BCSAF clinker).

Owner:LAFARGE SA

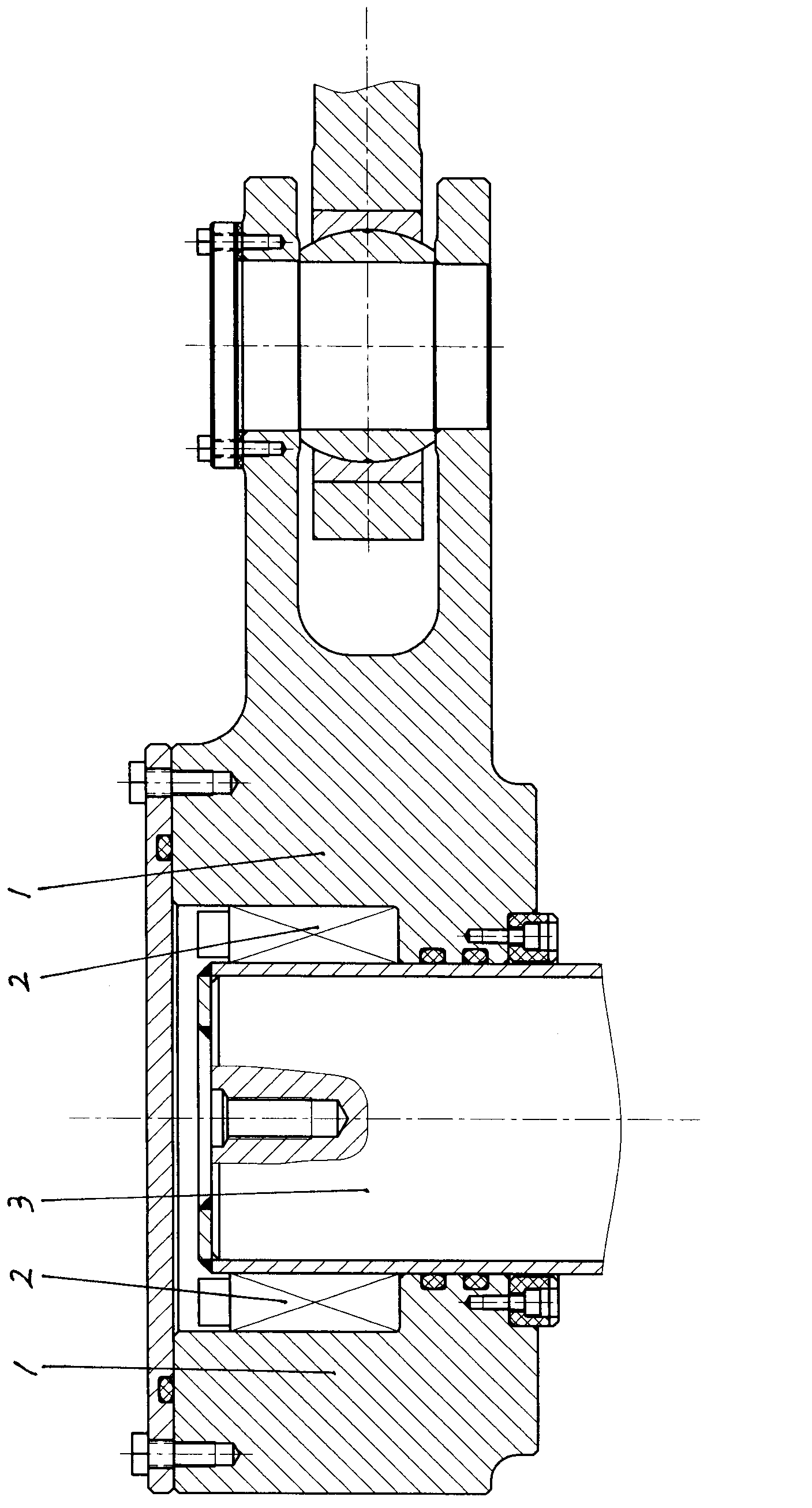

Wing rudder driving device of flap type rudder

InactiveCN103818538AReduce precisionReduce processing costsSteering ruddersRudderMechanical strength

The invention relates to ship equipment, in particular to an advanced a flap type rudder of a ship. The wing rudder driving device of the flap type rudder comprises a wing rudder blade, a wing rudder rod and a rudder rod sleeve, wherein the lower portion of the wing rudder rod is fixedly connected onto the top of the wing rudder blade, the rudder rod sleeve sleeves the top of the wing rudder rod, and an expansion connection sleeve is mounted between the wing rudder rod and the rudder rod sleeve. Since a rudder sleeve tube can be mounted outside the wing rudder rod, the wing rudder rod is protected from being corroded by sea water, processing precision and cost for the flap type rudder can be reduced, and mechanical strength of the wind rudder rod and a rudder shifting effect of the flap type wing rudder cannot be affected.

Owner:JIANGSU HUAYANG HEAVY IND +1

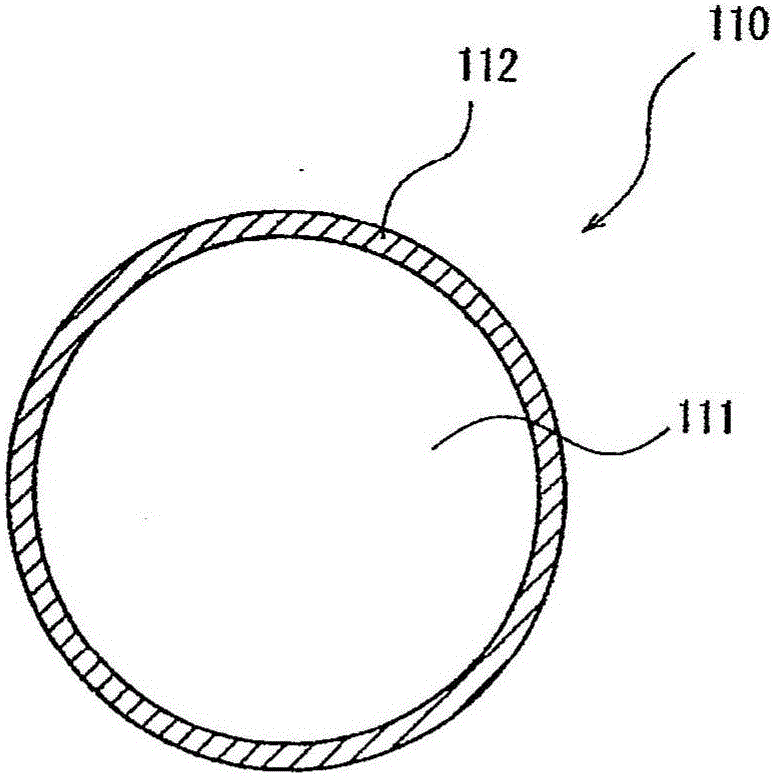

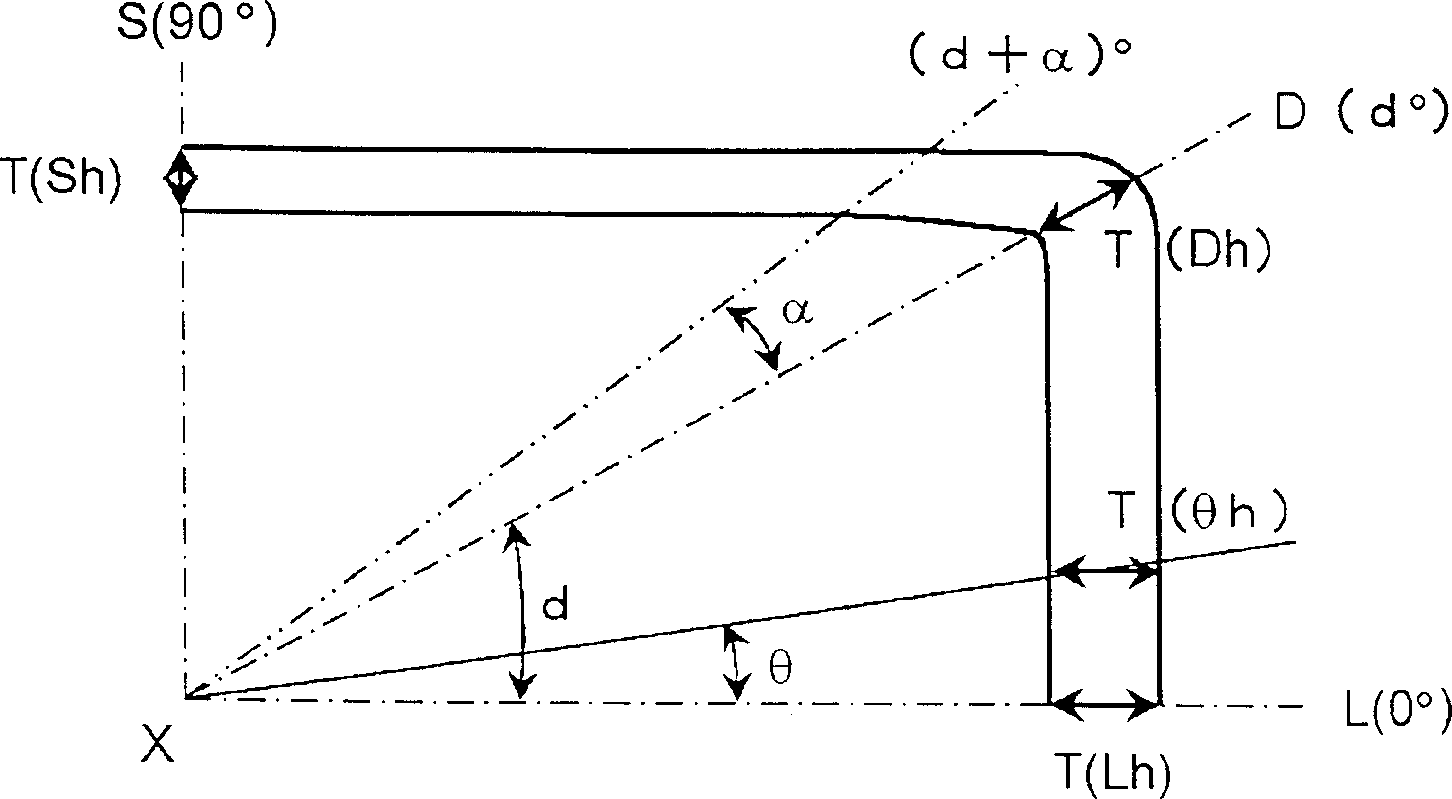

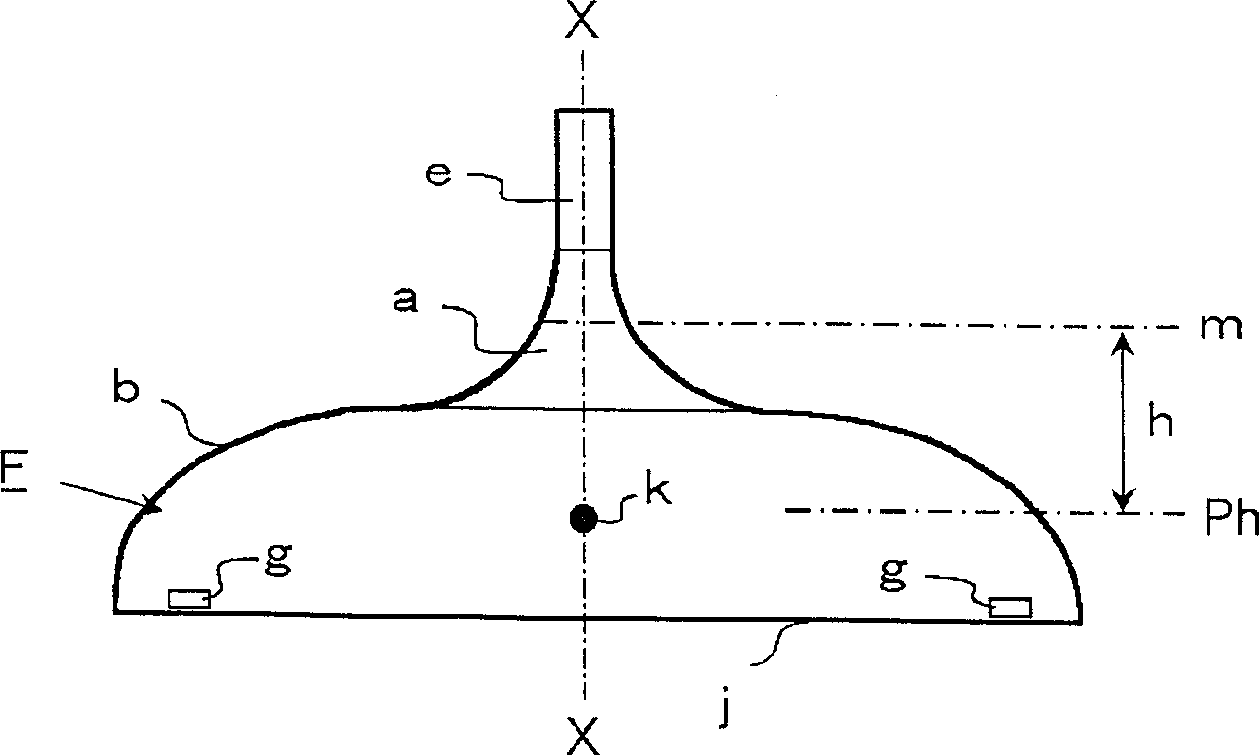

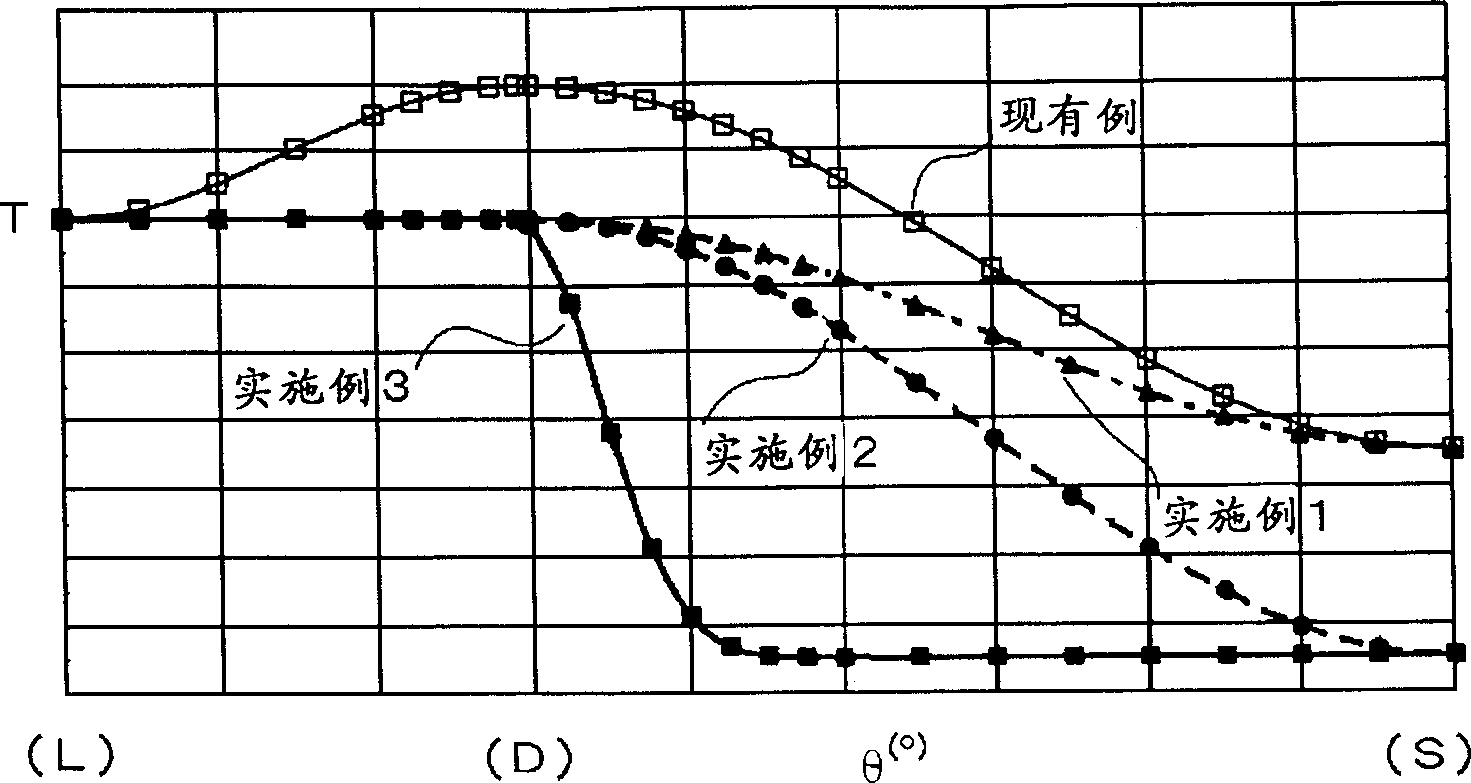

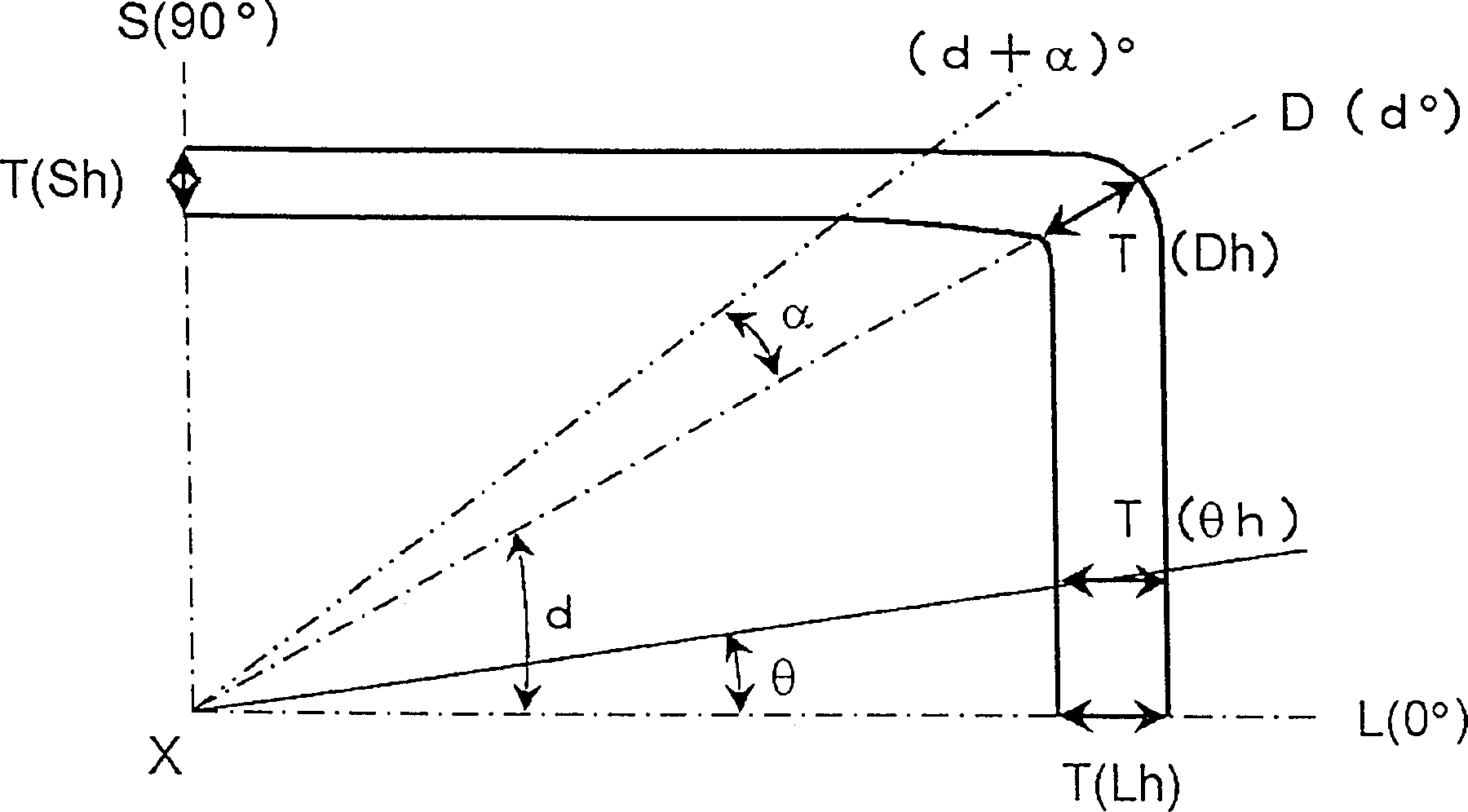

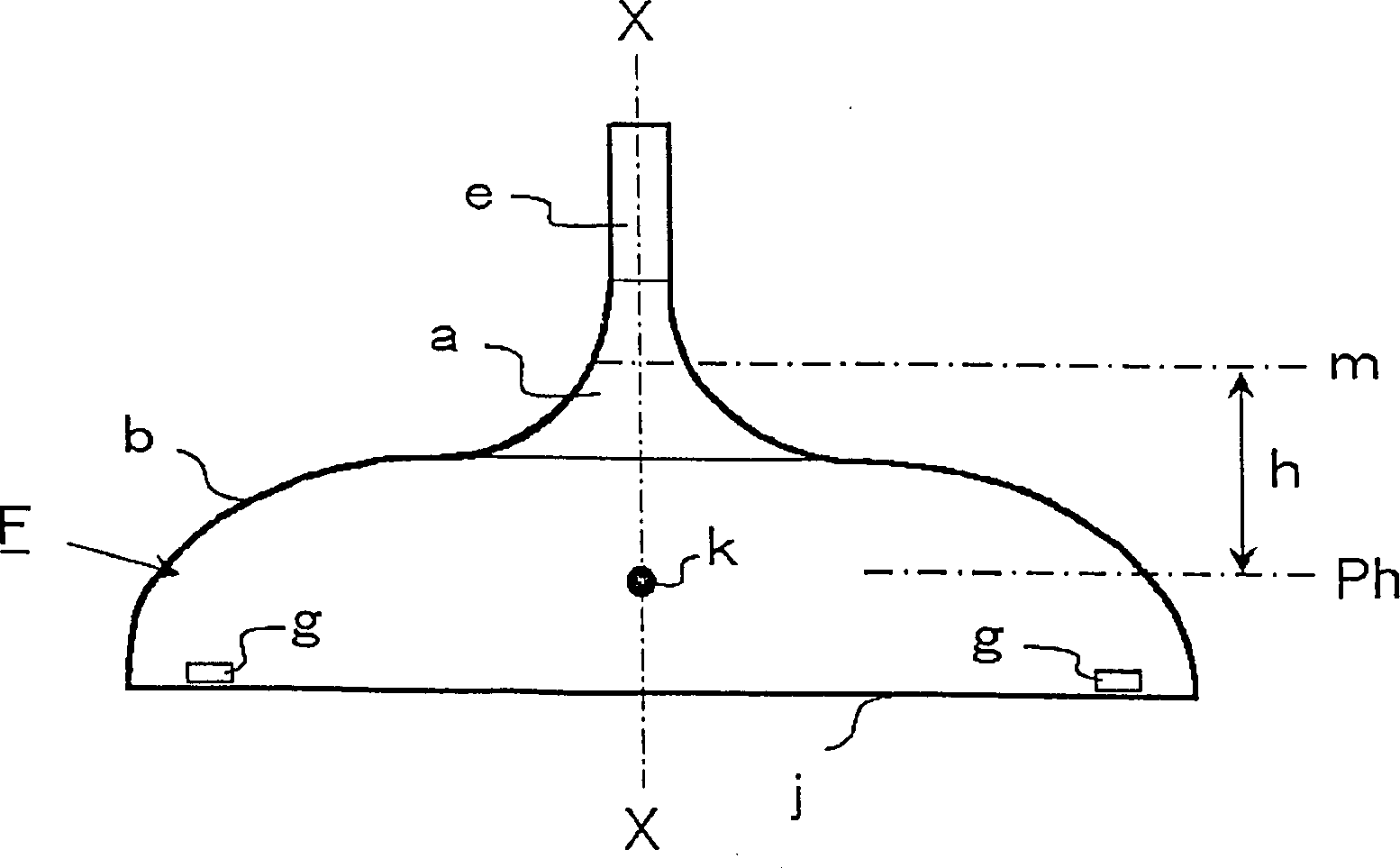

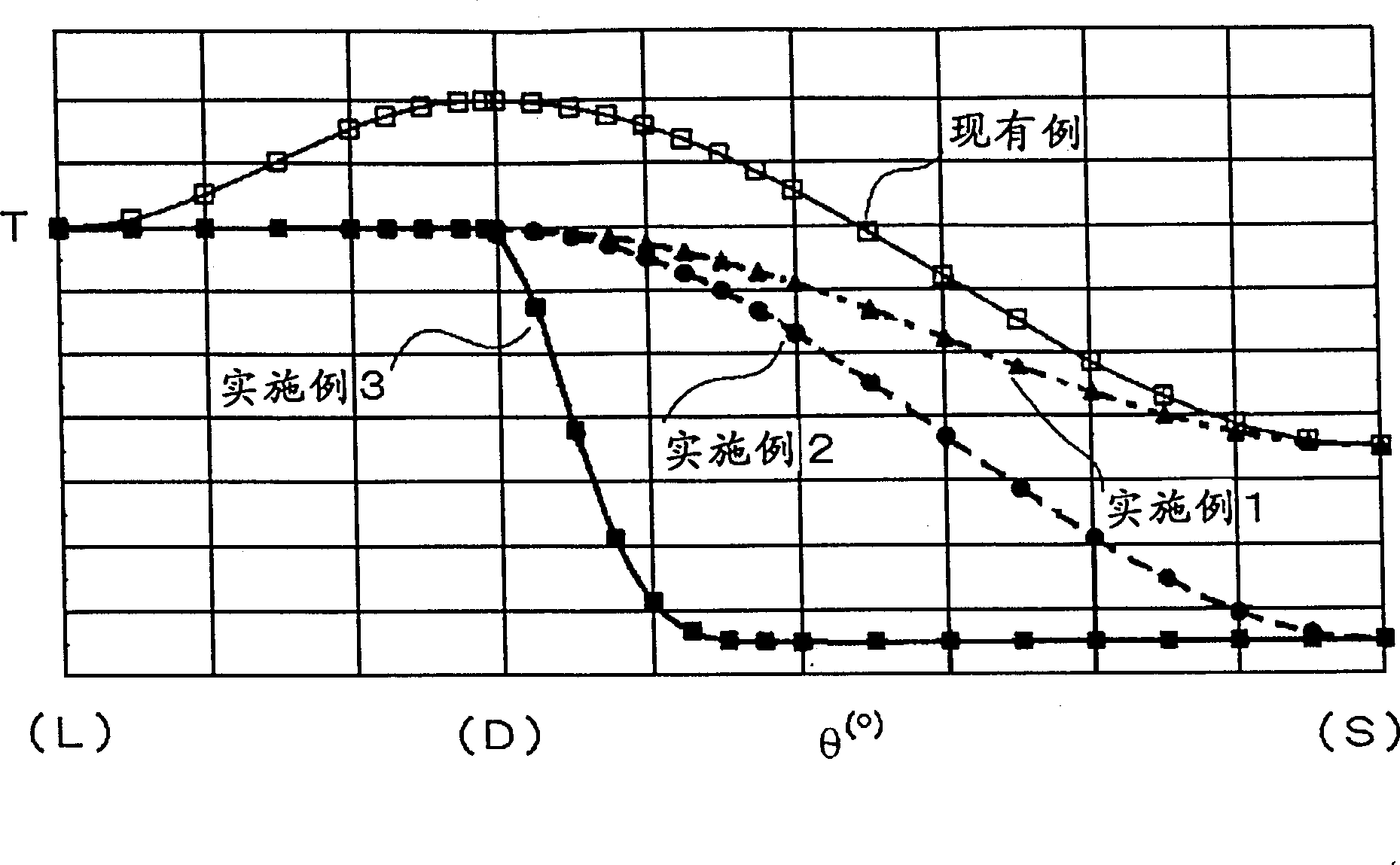

Conic-body for cathode-ray tube

InactiveCN1375855ANo loss of mechanical strengthDoes not reduce formabilityCathode-ray/electron-beam tube vessels/containersStructural engineeringUltimate tensile strength

By setting the wall thickness on the long axis L as in the past, there is no loss of mechanical strength, and since the wall thickness in the area from the long axis L to the diagonal axis D is equal to the wall thickness on the long axis L and the diagonal axis D The difference in wall thickness between them is within 0.3mm, and they are formed approximately the same in the shape of the cone, and the wall thickness difference between the wall thicknesses on the minor axis S is within 0.3mm, which is approximately the same in the shape of the cone. The wall thickness region is formed within the range from 90°-(d+α)° to the minor axis S, so that the weight can be reduced.

Owner:NIPPON ELECTRIC GLASS CO LTD

Additives for a hydraulic binder based on a belite-calcium-sulphoaluminate-ferrite clinker

InactiveCN107082583ALong-term high mechanical strengthReduce the amount of clinkerSolid waste managementCement productionCarboxylic acidMaterials science

The invention relates to additives for a hydraulic binder based on a belite-calcium-sulphoaluminate-ferrite clinker. A composition includes at least, in % expressed by mass relative to the total mass of the composition, from 0.01 to 3% of polycarboxylic acid or salts thereof, the polycarboxylic acid including 2 to 4 carboxyl groups per molecule; and from 97 to 99.99% of a Belite-Calcium-Sulphoaluminate-Ferrite clinker (BCSAF clinker).

Owner:HOLCIM LTD

A lithium battery using a lightweight current collector

ActiveCN111129505BLight in massTo achieve the purpose of lightweightElectrode carriers/collectorsLi-accumulatorsFilm baseElectro conductivity

The invention discloses a lithium battery using a lightweight current collector, which comprises a positive electrode sheet, a diaphragm, and a negative electrode sheet in a stacked or wound manner, the positive electrode sheet includes a positive electrode collector, and the negative electrode sheet includes a negative electrode sheet. Fluid, the positive electrode current collector and / or the negative electrode current collector are composed of a conductive film base layer and a metallized film layer, the thickness of the conductive film base layer is 5 to 20 μm, and the conductivity of the conductive film base layer is 1 to 100 s / cm, the thickness of the metallized film layer is 0.2-2 μm, the metallized film layer of the positive electrode current collector is an aluminum layer or a nickel layer, and the metallized film layer of the negative electrode current collector is a copper layer, an iron layer and a tungsten layer one of the layers. In the present invention, the positive electrode current collector and / or the negative electrode current collector are composed of a conductive film base layer and a metallized film layer, wherein the conductive film base layer is prepared from a polymer substrate, so as to effectively reduce the current collector while realizing the current collector function. The quality of the collector achieves the purpose of reducing the weight of the current collector.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Conic-body for cathode-ray tube

InactiveCN1264188CNo loss of mechanical strengthDoes not reduce formabilityCathode-ray/electron-beam tube vessels/containersStructural engineeringUltimate tensile strength

Wall thickness on a major axis L is set to the same value as before to prevent mechanical strength from being impaired. Furthermore, the wall thickness of a region from a major axis L to a diagonal axis D is made almost the same in molding the funnel with the wall thickness difference of 0.3 mm or less between the wall thickness on the major axis L and that on the diagonal axis D, and a uniform wall thickness area of almost the same wall thickness in molding the funnel with the wall thickness difference of 0.3 mm or less from the wall thickness on a minor axis S is formed over the range of the minor axis S from 90 DEG -(d+alpha ) DEG. The weight can thereby be reduced.

Owner:NIPPON ELECTRIC GLASS CO LTD

A preparation method of a liquid oxygen-compatible composite resin system copolymerized with silicon dioxide and epoxy resin

Owner:DALIAN UNIV OF TECH

A kind of halogen-free flame retardant resin and preparation method thereof

ActiveCN110903642BNo loss of mechanical strengthImprove flame retardant performancePolymer sciencePolyamide

The invention provides a halogen-free flame-retardant resin and a preparation method thereof. The halogen-free flame-retardant resin comprises the following components in parts by weight: 100 parts of polyamide 56, 5-20 parts of organic halogen-free flame retardant, and 5-20 parts of glass fiber 40 parts, lubricant 0.05-0.5 part, antioxidant 0.05-0.5 part. The halogen-free flame-retardant resin of the present invention not only adopts renewable substances as main raw materials, is environmentally friendly, but also has good flame-retardant properties and mechanical properties.

Owner:CATHAY R&D CENT CO LTD +1

Spray shaping special-purpose powdered iron

InactiveCN101157135APrecise process parametersGood density and other propertiesCoatingsNanometreIron powder

The invention relates to nanometer scale iron powder, in particular to spray molding special purpose iron powder. The invention solves the problem existing in the prior art that the particle diameter of metal powder material and the powder particle surface can not reach 0.5 to 20 micron. Through utilizing the cutting manufacturing process of the zero zone particles of the nanometer powder body under the circumstance of 10 DEG C to 25 DEG C and the circumstance of setting the high frequency cutting times to be in 5000 times to 6000 times per minute, nanometer iron powder particles are produced, powder materials with D3=51nm, 125.1nm=D25, D50=200nm and =D75=273.2nm, and D97 = 317.3nm particles which are distributed more dispersedly are graded, the anti-oxidization coating is performed to the iron powder particles. The invention breaks through the 0.5 to 20 micron range of the international spray molding technology metal powder material at present, and the nanometer scale iron powder can be arbitrarily produced and processed between the micron and the nanometer.

Owner:王惠民

Composite aluminum-plastic film as well as preparation method and application thereof

PendingCN112318965AImprove heat resistanceImprove flame retardant performanceLamination ancillary operationsSynthetic resin layered productsPlastic filmProtection layer

The invention relates to a composite aluminum-plastic film as well as a preparation method and application thereof. The composite aluminum-plastic film comprises a protective layer, a metal layer anda polymer heat-seal layer which are arranged in sequence, and the protective layer is obtained by blending nylon fibers treated by a flame retardant and high-temperature-resistant fibers. The selectedfibers in the protective layer have the advantages of high strength, high heat resistance, no combustion in flame, no shrinkage and the like; and due to the existence of the flame retardant, the flame retardance of the protective layer can be further improved, and the safety of a soft package battery is further improved. The composite aluminum-plastic film disclosed by the invention can help to construct a soft package battery with high safety and high strength.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

Artificial grain spraying method for solid wood board

InactiveCN102173276BNo loss of mechanical strengthIncrease added valueLiquid surface applicatorsCoatingsCoated surfaceSolid wood

The invention discloses an artificial grain spraying method for a solid wood board, which comprises the following steps of: (1) manufacturing a template; (2) engraving a mold; (3) selecting a base board; (4) mixing color; (5) pressing the mold and spraying; (6) removing the mold and curing the coating; and (7) spraying transparent paint on the surface of the coating. The solid wood board painted with the artificial grain through the steps can be widely applied to decoration of indoor floor boards, wall boards and roofs. The artificial grain spraying method disclosed by the invention has a simple and convenient process and high applicability, does not influence the mechanical strength of the base board body, can be used for spraying various grains on the surface of the base board, ensures that the bonding strength between the sprayed pattern grains and the base board is high, overcomes the deficiency of simplex property of the traditional floor pattern, enlarges the using range of woodof trees with simplex grains, and improves the additional value of products.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Flame-retardant plastic shell for capacitor

ActiveCN106366586BImprove mechanical propertiesImprove flame retardant performancePolytetramethylene terephthalatePolyethylene terephthalate

The invention discloses a flame retardant plastic shell for a capacitor. The flame retardant plastic shell is prepared from, by weight, polybutylene terephthalate, ABS plastic, a filling agent, color master batch, dimethyl trimethylsilylmethylphophonate, polyvinyl chloride resin, a lubricant and a flame retardant. The prepared plastic shell for the capacitor is good in mechanical performance, high in flame retardance, good in processability and low in cost and melt viscosity.

Owner:ANHUI FEIDA ELECTRICAL TECH CO LTD

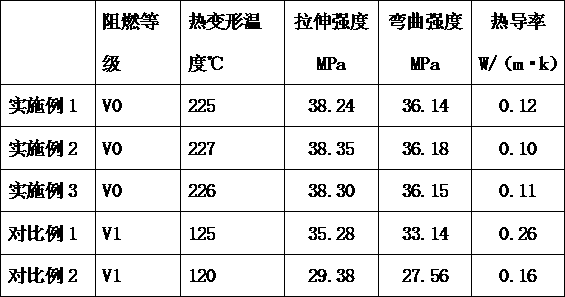

A non-toxic, harmless, high-strength, high-heat-resistant hemicellulose foam composite material and its preparation method

The invention discloses a nontoxic and harmless hemicellulose foam composite material and a preparation method thereof. The method comprises the following steps: (1) dissolving hemicellulose in water, heating and stirring until dissolved to obtain a hemicellulose solution, dissolving a crosslinking agent and citric acid in the hemicellulose solution to obtain a mixed solution; (2) dissolving PVA Dissolving in water, heating and stirring to dissolve to obtain a PVA solution; (3) mixing and stirring the mixed solution and the PVA solution to obtain a cross-linked product, cooling and forming, washing and drying to obtain the foam composite material. The foam composite material is easy to process, has excellent mechanical properties, good recovery, and high heat resistance, and has broad application prospects in functionalized materials based on foam porous materials, such as shock-resistant and compression-resistant materials. In addition, the foam material has no residue of toxic and harmful substances, so it also has great application potential in materials related to human health, such as tissue engineering materials and biomedical materials.

Owner:SOUTH CHINA UNIV OF TECH

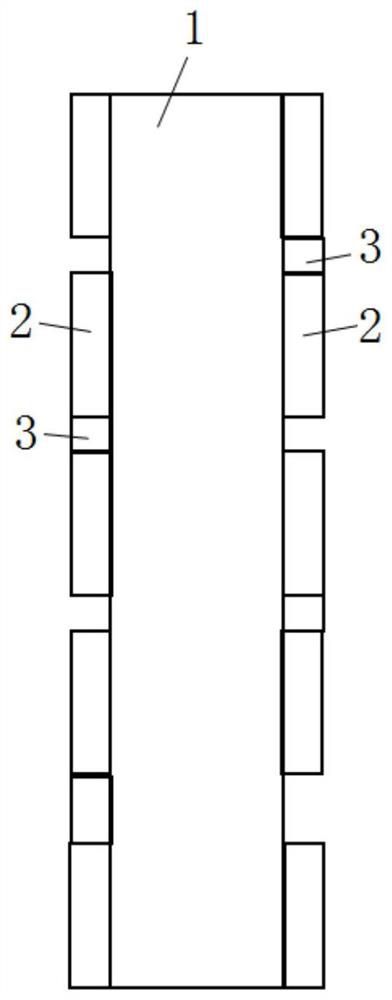

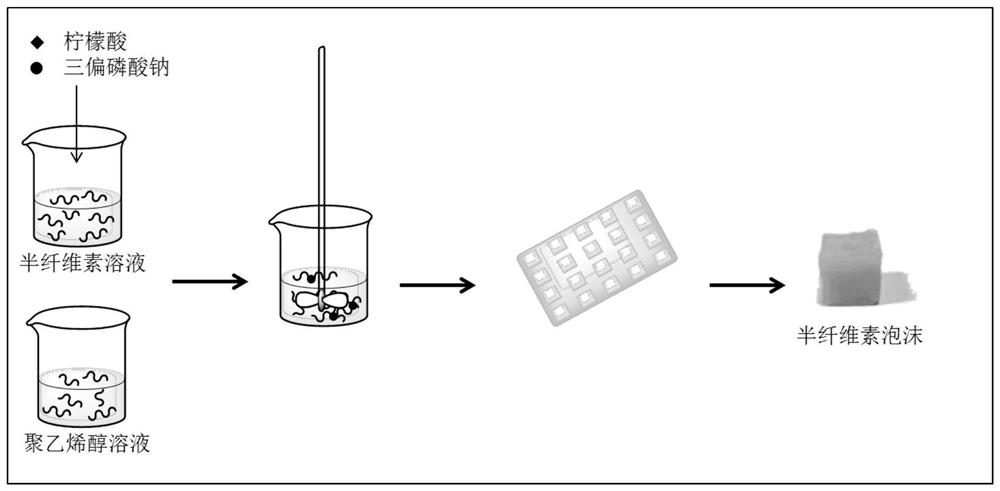

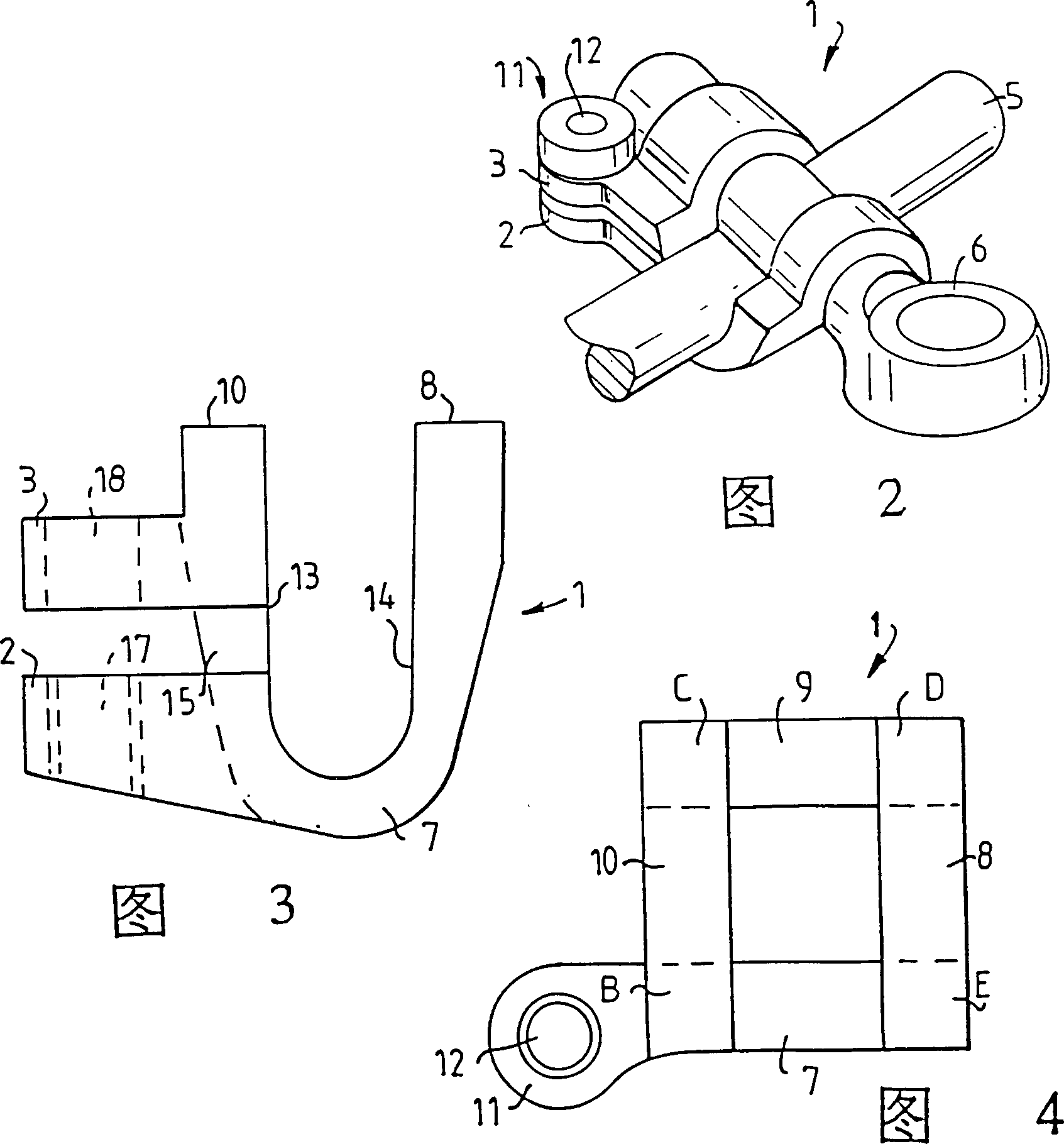

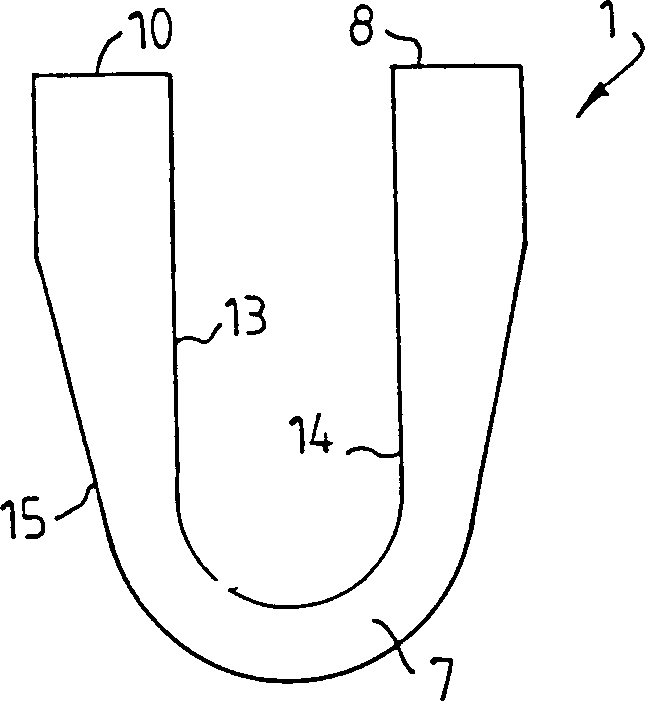

Device for fixating and adjusting the positions of vertebrae in vertebral surgical operations

InactiveCN1200649CEasy to operateNo loss of mechanical strengthInternal osteosythesisSurgical operationFixed position

The present invention relates to a device for fixing and adjusting the position of the spine in spinal surgery, which comprises two interdigitated substantially rod-shaped implant elements. In order to lock the implant elements together, the device (1) also includes four generally parallel elongated elements (B, C, D, E) extending into a plane passing through two of them, their The ends are generally located at the corners of a parallelogram, preferably a square. The ends of the elongated elements are joined to each other in pairs by means of mutually parallel partial hoops (7, 9; 8, 10) bent outwards from the ends of the elongated elements, wherein at the ends of the elongated elements A pair of partial hoops (7, 9) at one end are perpendicular to the pair of partial hoops (8, 10) at the other end of the elongated element, wherein each pair of partial hoops attaches the rod-shaped implant element (5, 6, 11a, 17) and each adjacent intersecting rod-shaped member, wherein those sides (13, 14, 13', 14'; 15, 16, 15', 16 ′) are substantially flat and substantially parallel to respective opposing sides of adjacent elongate members when fixing and adjusting the position of the spine.

Owner:斯文·奥勒鲁德

Plated fiber, carbon fiber, wire harness and plating method

ActiveCN108221369AAvoid breakingImprove precipitation effectCarbon fibresConductive materialFiberCarbon fibers

The invention provides a plated fiber, a carbon fiber, a wire harness and a plating method. The plated fiber is obtained by applying a metal plating onto a fiber having an elongation percentage whichis more than or equal to 1% and less than or equal to 10%. An elongation percentage of the metal plating is higher than the elongation percentage of the fiber. A carbon fiber wherein the surface oxygen amount as a value obtained by dividing an O1S peak intensity measured by X-ray photoelectron spectroscopy by a C1S peak intensity measured by the spectroscopy is more than or equal to 0.097 and lessthan or equal to 0.138.

Owner:YAZAKI CORP

Implant material for promoting bone wound healing and preparation method thereof

InactiveCN108030960BGood biocompatibilityLarge specific surface areaMicrocapsulesProsthesisSalvianolic acid BOrthopedic department

The invention discloses an implant material for promoting bone wound healing and a preparation method thereof, and relates to the technical field of medical materials. The orthopedic implant material consists of a polylactic acid matrix and a medical magnesium alloy skeleton suspended in the polylactic acid matrix. The medical magnesium alloy The skeleton is composed of multi-layered wavy network structures made of medical magnesium alloy wires. The surface of the polylactic acid matrix is decorated with a porous hydroxyapatite layer, and the micropores of the hydroxyapatite layer are filled with Dan Phenolic acid B microcapsules and vancomycin microcapsules. The orthopedic implant material of the present invention has good biocompatibility, large specific surface area and high porosity, is suitable for the growth of new bone cells, promotes the bridging and healing of broken ends of fractures, and has the stability of fixation force during the bridging and healing of broken ends of fractures Strong, can prevent secondary fractures; in addition, it can maintain the effective concentration of salvianolic acid B and vancomycin in the drug receiving system for a long time, play a role in continuous anti-inflammatory and promote the bridging and healing of fracture ends.

Owner:AFFILIATED YONGCHUAN HOSPITAL OF CHONGQING MEDICAL UNIV

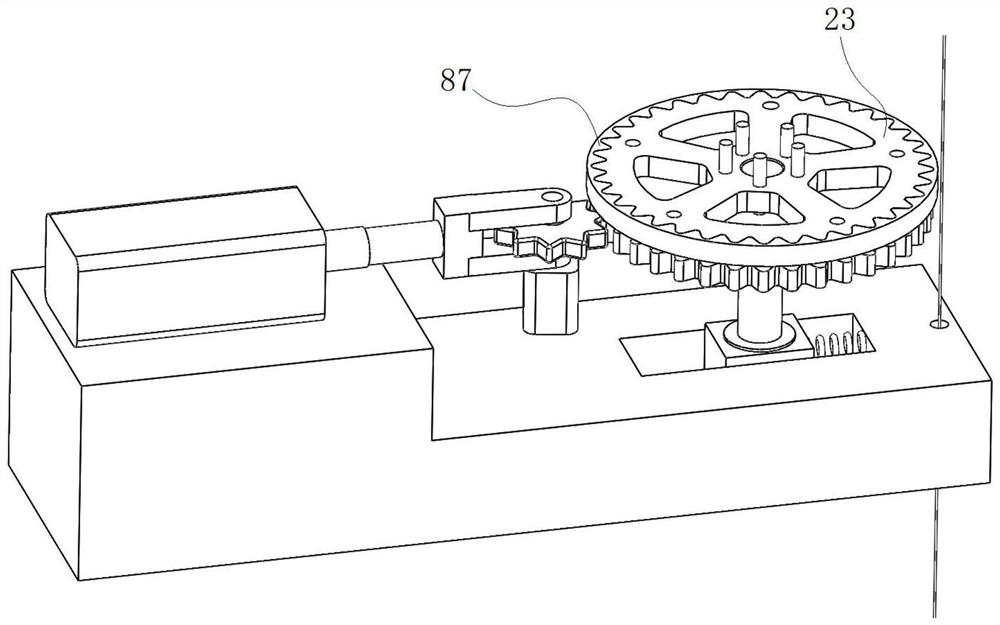

A kind of automobile wheel hub, processing device and technology thereof

The invention discloses an automobile hub machining device. The automobile hub machining device comprises linear cutting equipment, the linear cutting equipment comprises a working platform, a horizontal sliding groove is formed in the working platform, and a sliding block is arranged inside the sliding groove in a sliding mode; the linear cutting equipment further comprises a supporting verticalrotating shaft, and the lower end of the vertical rotating shaft is rotationally arranged on the sliding block; the top pf the vertical rotating shaft is fixedly connected with a linear cutting platform in a horizonal posture in a supporting mode; the contour of the linear cutting platform is a gear contour, and the gear contour of the linear cutting platform is consistent with the contour of an outer ring of a rim disc after the linear cutting is completed; and a plurality of limiting columns are vertically arranged on the upper surface of the linear cutting platform, and the plurality of limiting columns are distributed in a circumferential array mode. The rim disc to undergo linear cutting is of a rotary body structure with a simple structure, the heat treatment and other processes of the rim disc are simple, carrying out linear cutting forming on the basis of the rim disc to undergo linear cutting belongs to cold machining, so that the deformation of other parts does not occur, themachining precision is high, and the mechanical strength of a material of the rim disc cannot be damaged in the process.

Owner:ZHEJIANG PDW IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com