Preparation method for composite resin system copolymerized by silicon dioxide and epoxy resin and compatible with liquid oxygen

A technology of epoxy resin and silicon dioxide, which is applied in the field of preparation of organic polymer compounds, can solve problems such as unusable resin materials, and achieve the effects of improved toughness, high efficiency and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

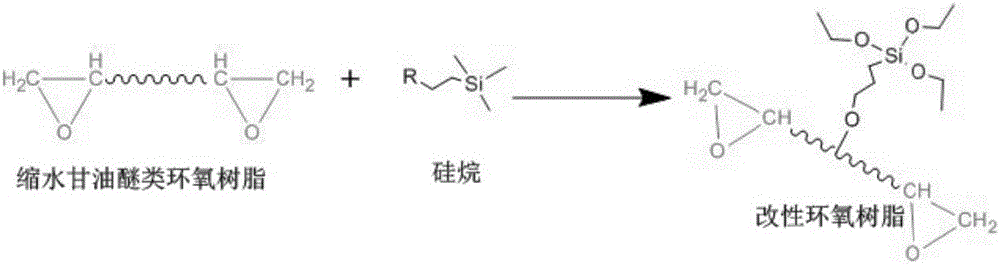

[0029] Step 1. Mix bisphenol F epoxy resin (epoxy value 0.51mol / 100g), 3-chloropropyltriethoxysilane in a molar ratio of 15:1, add 0.2% dibutyltin dilaurate of total mass (catalyst), and reacted at 50° C. for 2 hours to obtain a siloxane-modified glycidyl ether epoxy resin (a).

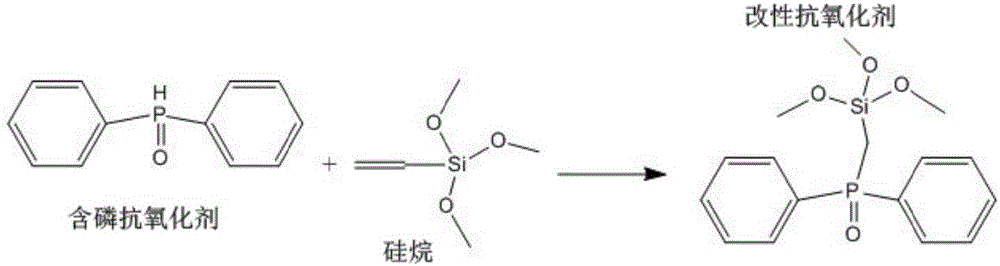

[0030] Step 2. Mix 21.6g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, 21g of allyltriethoxysilane, add 30ml of toluene solvent, heat up to 80°C, and Under the reflux condensing device, stir with a magnetic stirrer for 10 minutes to completely dissolve 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide, and add 0.2 g of azobisisobutyronitrile as a catalyst. Reaction 2h. Distill under reduced pressure to remove the solvent to obtain a light yellow viscous modified phosphorus-containing antioxidant (b).

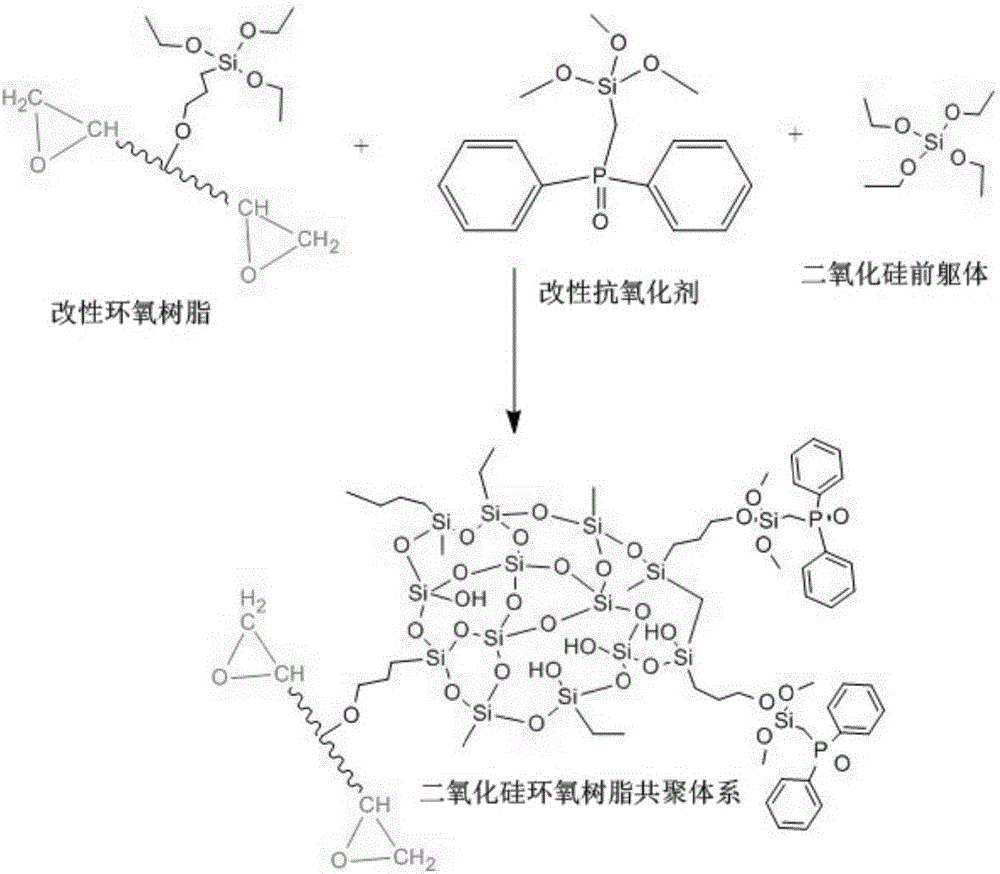

[0031] Step 3. Mix 46g of silane-modified epoxy resin (a), 4g of silane-modified antioxidant (b), and 2.1g of tetraethyl orthosilicate into 100ml of solvent acetone, and stir well to make th...

Embodiment 2

[0036] Step 1. Mix bisphenol F epoxy resin (epoxy value 0.51mol / 100g) and dichlorodimethylsilane at a molar ratio of 10:1, and react at 30°C for 2 hours to obtain siloxane-modified glycidol Ether epoxy resin (a).

[0037] Step 2. Mix 20g of diphenylphosphine and 21g of allyltriethoxysilane, add 30ml of toluene solvent, heat up to 80°C, and stir for 10min with a magnetic stirrer under the reflux condensing device to make diphenylphosphine Oxygen was completely dissolved, and 0.2 g of azobisisobutyronitrile was added as a catalyst for 2 hours of reaction. Distill under reduced pressure to remove the solvent to obtain a light yellow viscous modified phosphorus-containing antioxidant (b).

[0038] Step 3. Mix 40g of silane-modified epoxy resin (a), 4g of silane-modified antioxidant (b), and 2.4g of trimethoxysilane into 100ml of solvent acetone, and stir well to make the components evenly mixed.

[0039] Step 4. Add 1.5g deionized water and 0.1g acetic acid, react at 30°C for 3h...

Embodiment 3

[0043] Step 1. Mix bisphenol A epoxy resin (epoxy value 0.51mol / 100g), 3-chloropropyltriethoxysilane in a molar ratio of 15:1, add 0.2% dibutyltin dilaurate of total mass (catalyst), and reacted at 50° C. for 2 hours to obtain a siloxane-modified glycidyl ether epoxy resin (a).

[0044] Step 2. Mix 20g of diphenylphosphine and 21g of allyltriethoxysilane, add 30ml of toluene solvent, heat up to 80°C, and stir for 10min with a magnetic stirrer under the reflux condensing device to make diphenylphosphine Oxygen was completely dissolved, and 0.2 g of azobisisobutyronitrile was added as a catalyst for 2 hours of reaction. Distill under reduced pressure to remove the solvent to obtain a light yellow viscous modified phosphorus-containing antioxidant (b).

[0045] Step 3. Mix 46g of silane-modified epoxy resin (a), 4g of silane-modified antioxidant (b), and 2.1g of tetraethyl orthosilicate into 100ml of solvent acetone, and stir well to make the components evenly mixed.

[0046] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com