Wing rudder driving device of flap type rudder

A technology of driving device and flap rudder, which is applied in directions such as rudder steering and steering, and can solve the problems of inconvenient installation of rudder bushings on the wing rudder, reducing the mechanical strength of the wing rudder, increasing the wing rudder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

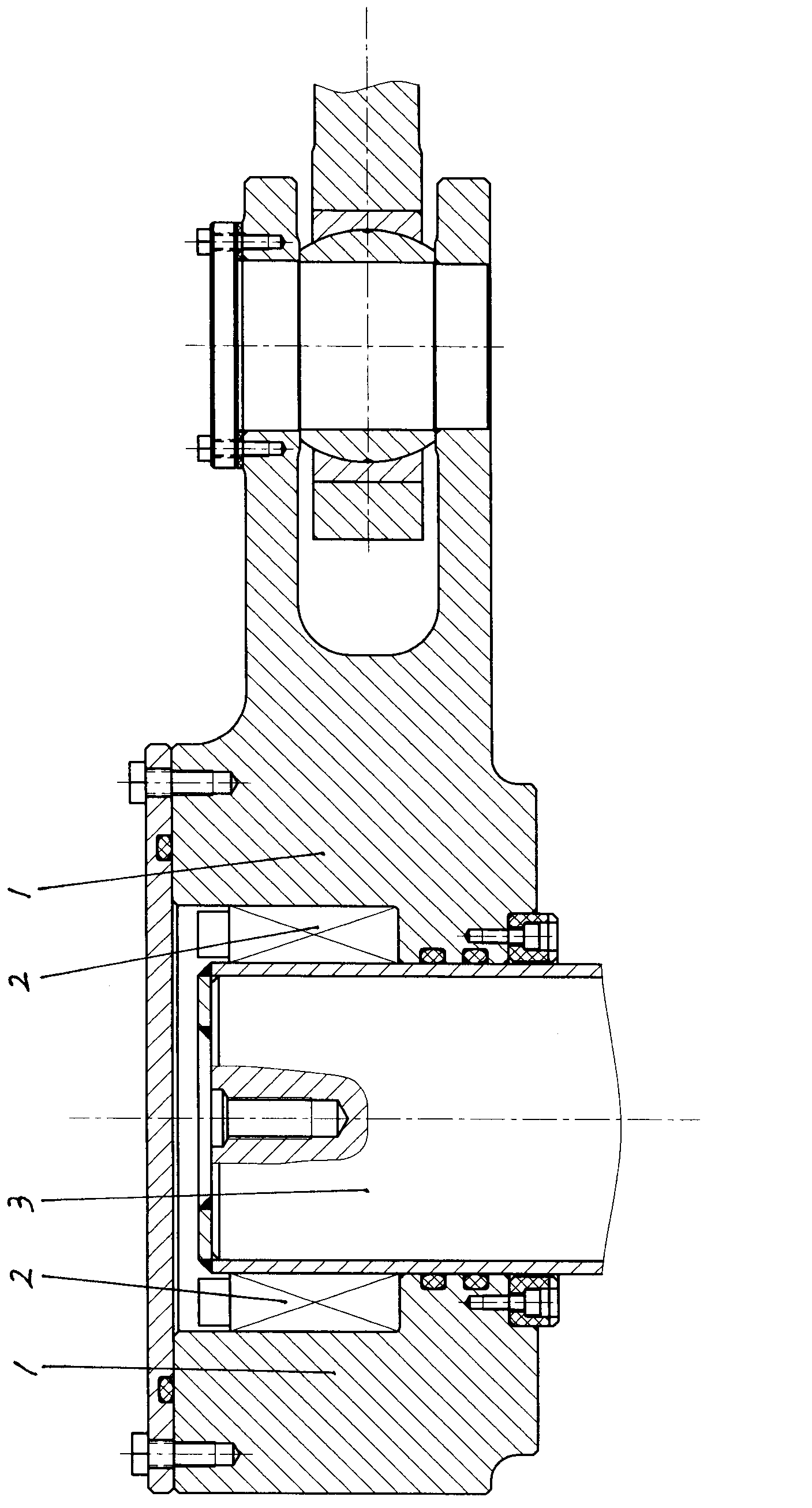

[0008] figure 1 Among them, the flap rudder wing rudder driving device is composed of wing rudder blades (not shown in the figure of wing rudder blades), wing rudder stock 3 and rudder stock cover 1, and the lower part of wing rudder stock 3 is fixedly installed on the top of wing rudder blades. The top of the wing rudder stock 3 is covered with a rudder stock cover 1, and an expansion joint sleeve 2 is installed between the wing rudder stock 3 and the rudder stock cover 1, and the wing rudder stock 3 and the rudder stock cover 1 are fixed by the expansion joint sleeve 2 Connected together, compared with the key connection, this connection method does not need to make grooves on the surface of the wing rudder stock 3 and the rudder stock 1, which reduces the metal processing accuracy and processing cost of the flap rudder, and does not affect the wing rudder stock. To improve the mechanical strength, a rudder cover can also be installed on the wing rudder to prevent seawater f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com