Preparation method and preparation device of porous medium composite phase-change material

A technology of composite phase change materials and porous media, which is applied in the field of preparation methods and preparation devices of porous media composite phase change materials, can solve the problems of poor encapsulation effect, unsuitability for mass production, and low filling amount of phase change matrix, and achieve Improved encapsulation effect, strong durability, and enhanced encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

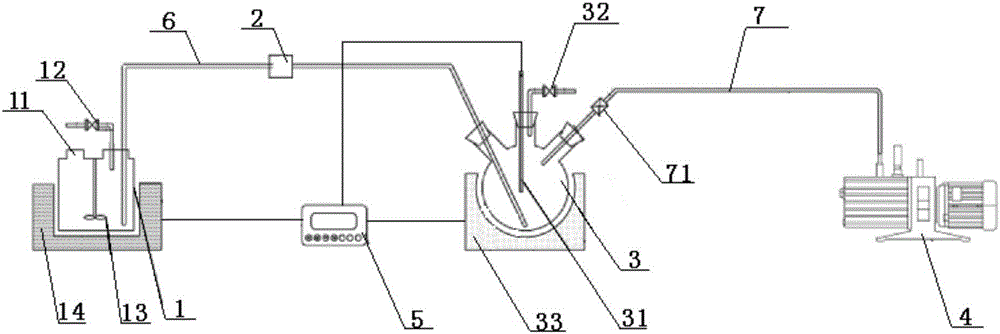

[0040] In order to solve the problems of low filling amount of phase change matrix and poor encapsulation effect of existing methods for preparing composite phase change materials, this embodiment provides a method for preparing porous media composite phase change materials, which specifically includes the following steps:

[0041] 1) Vacuum treatment: the porous support material is placed in the packaging composite container and sealed by a stop valve, and then the packaging composite container is evacuated by a vacuum pump. When the internal pressure of the packaging composite container is lower than 0.05Mpa, the Heating the porous support material, raising the temperature to 40-70°C, keeping it for 40-60 minutes, then closing the vacuum pump and stop valve and stopping heating to obtain the processed porous support material;

[0042] 2) Preparation of organic precursor solution: mix organic solvent, oleylamine and epoxy resin at a volume ratio of 3-8:1-1.5:1 to obtain an org...

Embodiment 1

[0057] Using the preparation device of the porous media composite phase change material provided by the present invention, the porous media composite phase change material is prepared by the following method:

[0058] (1) Weigh 5g of expanded graphite (density 0.005g / mL), place it in a packaged composite container, open the electromagnetic stop valve after sealing, turn on the vacuum pump, evacuate until the pressure in the packaged composite container is lower than 0.05MPa, and then turn on the temperature control instrument, heat the packaged composite container through the second heating jacket, raise the temperature to 40°C, keep it for 50 minutes, then turn off the vacuum pump and shut-off valve, and turn off the temperature controller;

[0059] (2) Measure 1000mL of petroleum ether, slowly add 250mL of oleylamine and 250mL of epoxy resin (EP-16), stir evenly, and make an organic precursor;

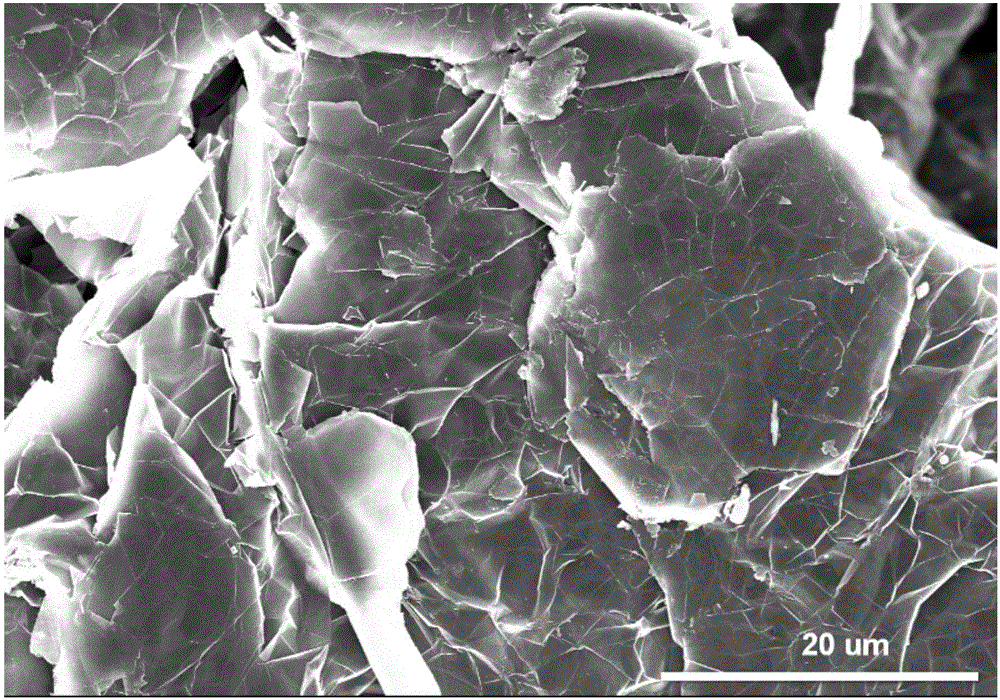

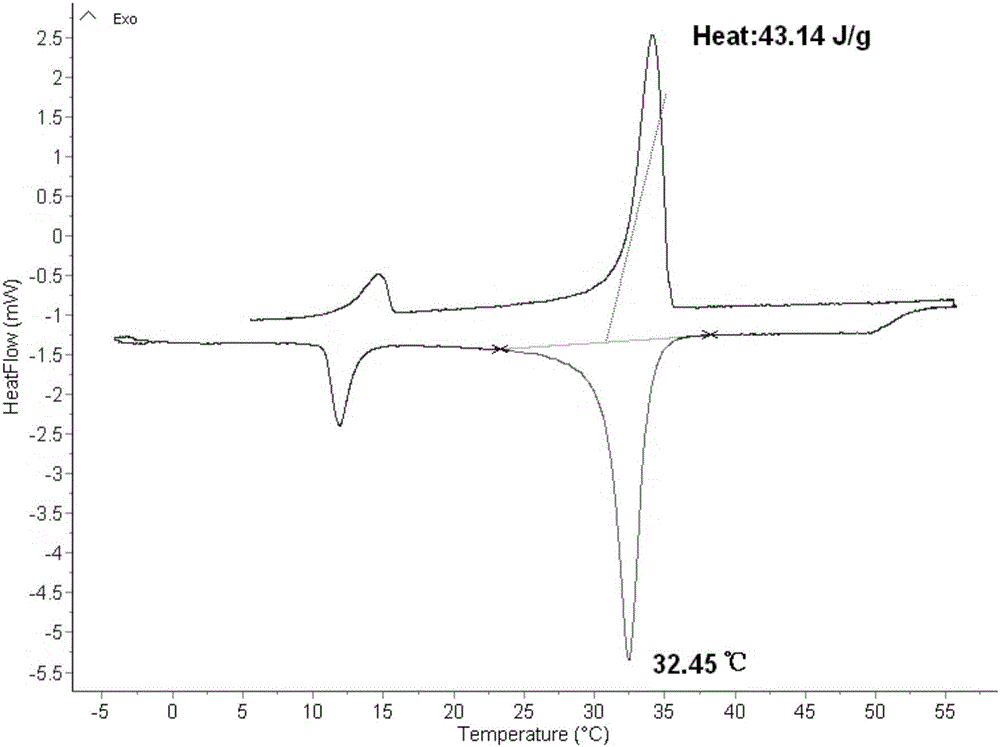

[0060] (3) Weigh 5g of paraffin wax with a phase change temperature of 30-40°C, ...

Embodiment 2

[0065] Using the preparation device of the porous media composite phase change material provided by the present invention, the porous media composite phase change material is prepared by the following method:

[0066] (1) Weigh 20g of carbon fiber (density 0.08g / mL) and place it in a packaging composite container. After sealing, open the electromagnetic stop valve, turn on the vacuum pump, and vacuum until the pressure in the packaging composite container is lower than 0.05MPa, then turn on the temperature controller. , heat the packaged composite container through the second heating jacket, raise the temperature to 40°C, keep it for 50 minutes, then turn off the vacuum pump and the shut-off valve, and turn off the temperature controller;

[0067] (2) Measure 400mL of dichloromethane, slowly add 50mL of oleylamine and 50mL of epoxy resin (EP-16), stir evenly, and make an organic precursor;

[0068] (3) Weigh 30g of paraffin wax with a phase change temperature of 30-40°C, place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com