An automatic box sorting device

An automatic box-separating and box-separating technology, which is applied in packaging and other directions, to achieve the effects of preventing secondary pollution, improving filling materials, and uniform packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

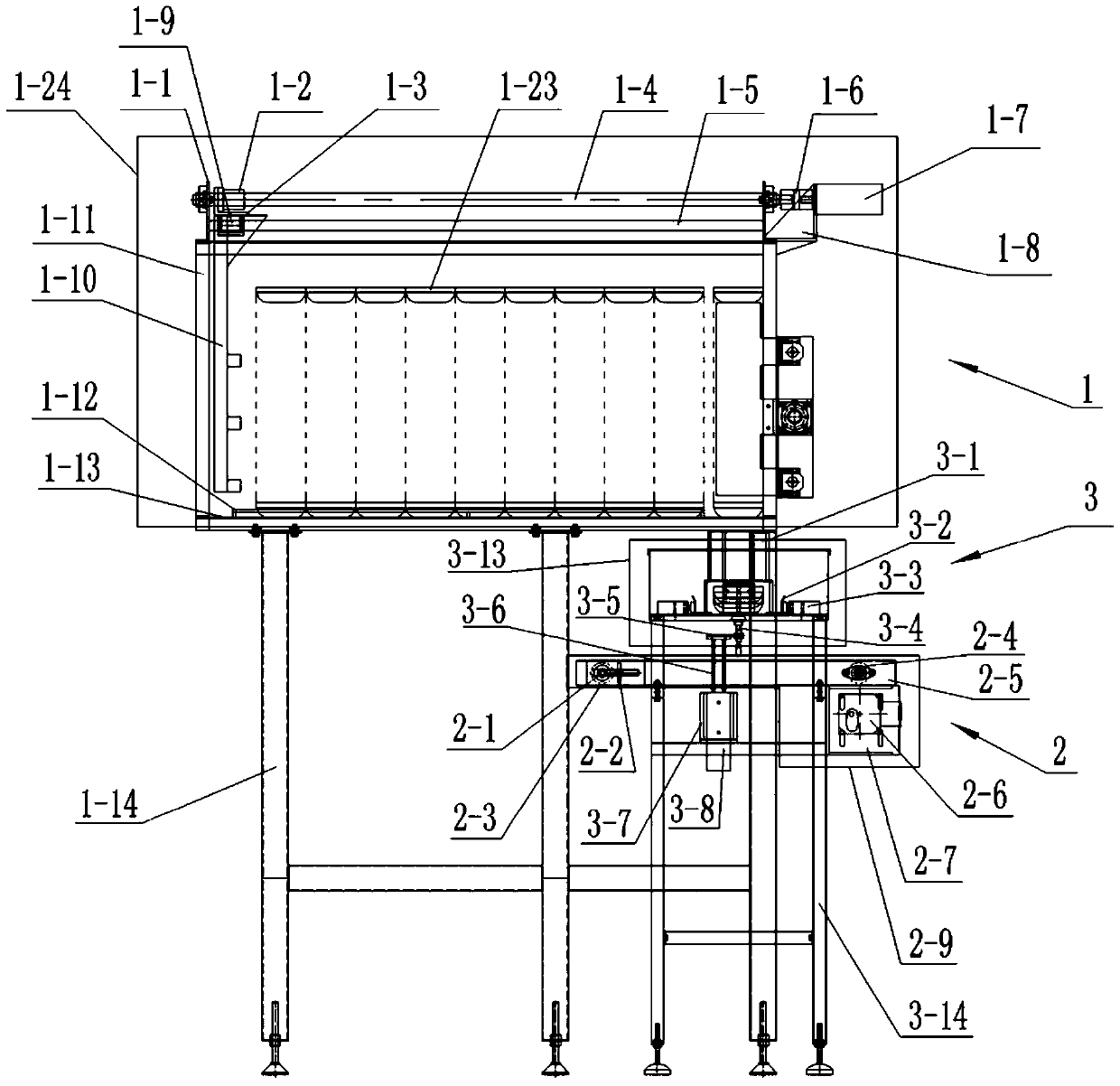

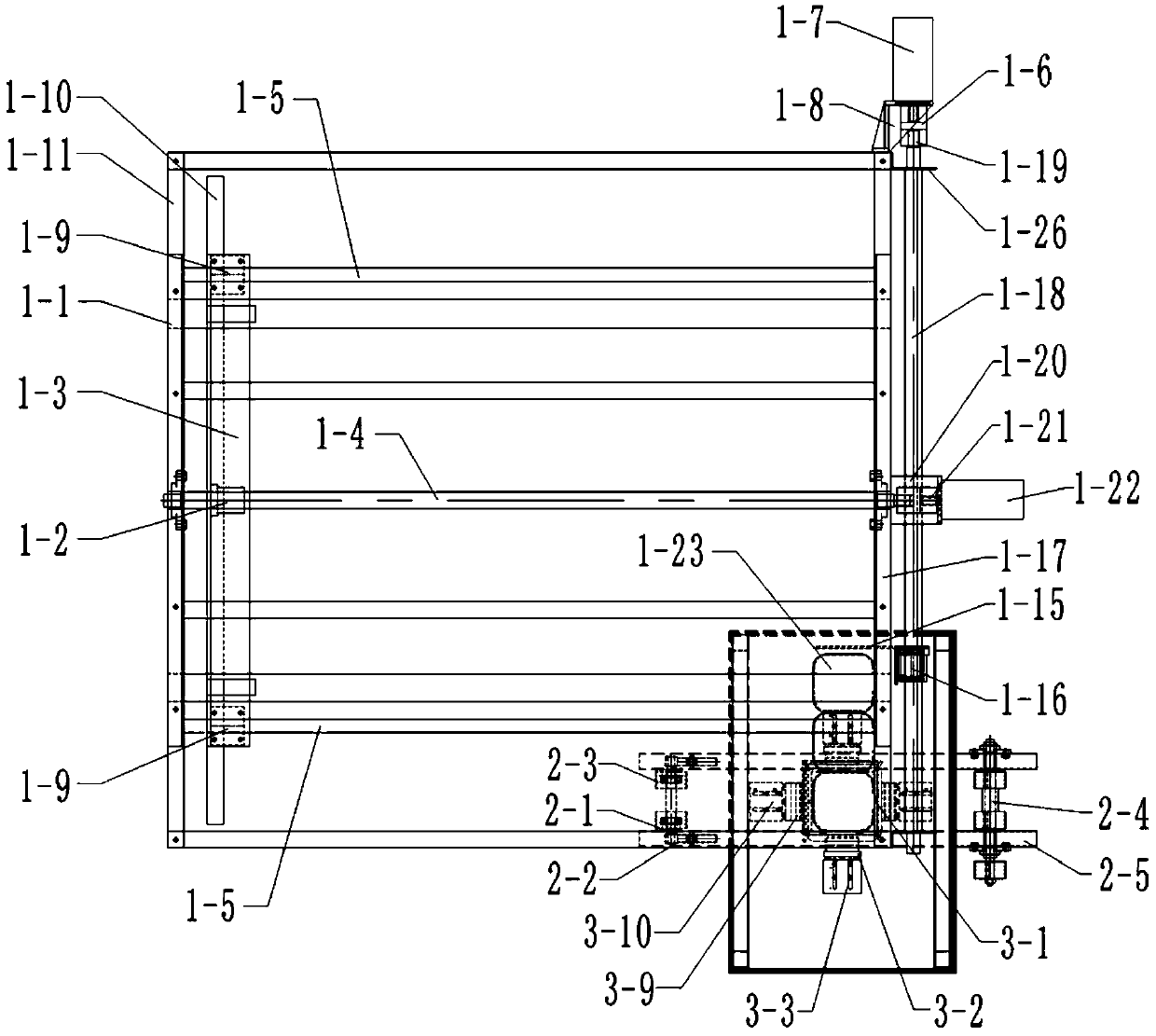

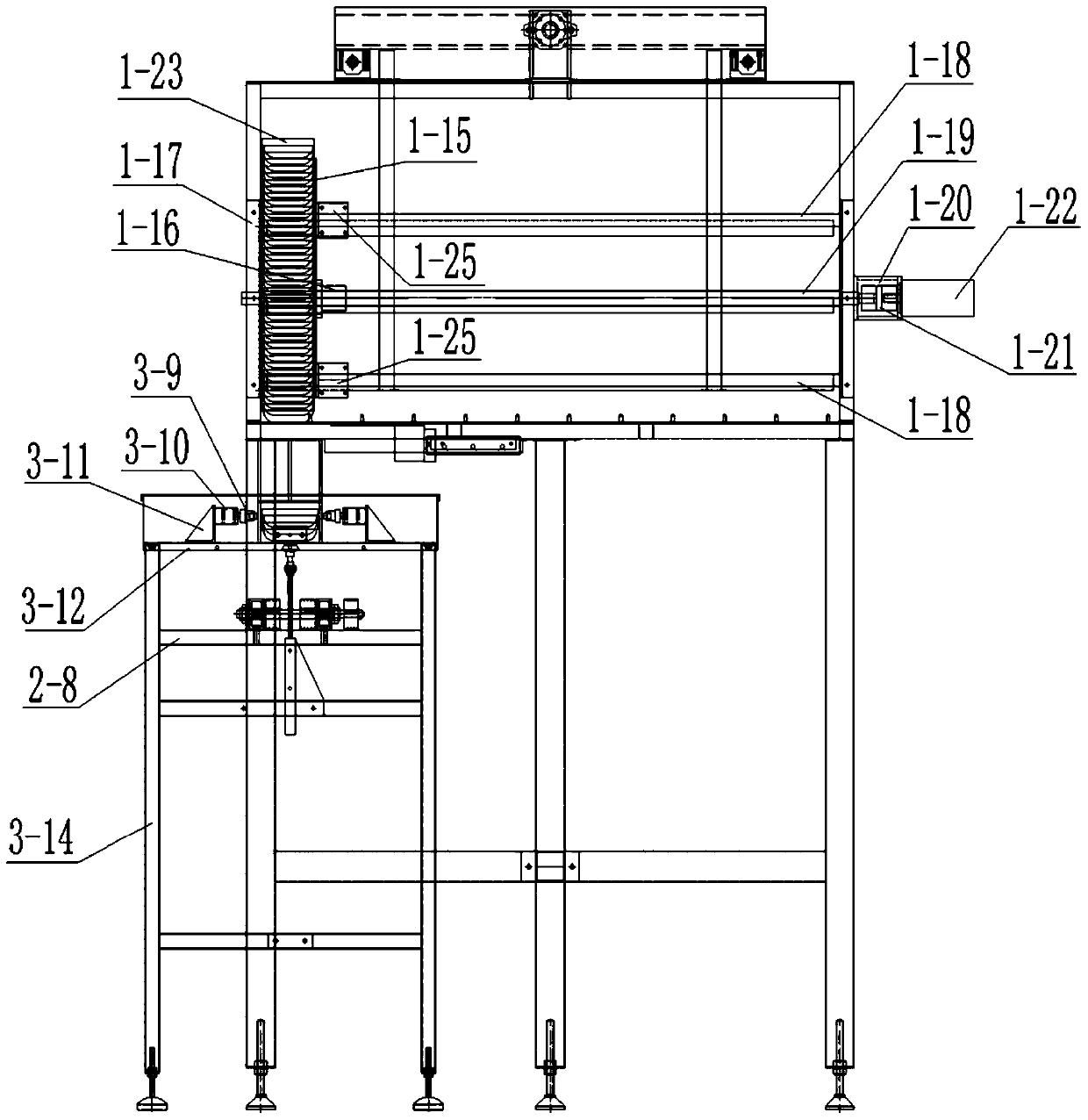

[0068] like Figure 1-9 As shown, an automatic box dividing device includes a hard box storage part 1, a hard box sub-box part 3 and a hard box conveying part 2, and the hard box storage part 1 is provided with a first frame 1-11, the first frame 1 The bottom of the -11 is provided with a first bottom plate 1-13, the first bottom plate 1-13 is provided with a third guide rail 1-12, and a number of hard boxes 1-23 are arranged on the third guide rail 1-12. The hard boxes 1-23 are arranged in a linear array in the horizontal and vertical directions, and the hard boxes in each stack are arranged in close contact with each other, and the first frame 1-11 is fixedly installed in the horizontal and vertical directions respectively. A lateral push box mechanism and a longitudinal push box mechanism, the lateral push box mechanism includes a first ball screw drive assembly and a first push rod slider assembly, the first ball screw drive assembly includes a first ball screw 1- 4. The ...

Embodiment 2

[0073] like Figure 10-15 As shown, an automatic box dividing device includes a soft box storage section 4, a soft box box section 5 and a soft box conveying section 6, and the soft box storage section 4 is provided with a second frame 4-1, the second frame 4 A third base plate 4-3 is fixedly installed on the bottom surface of the -1, and a third leg 4-4 is fixedly installed on the bottom surface of the third base plate 4-3. On the four sides and one top surface of the second frame 4-1 Five protective plates are fixedly installed, the top protective plate of the second frame 4-1 is provided with a soft box inlet, and the inner side of the second frame 4-1 is fixedly installed with a seventh fixing bracket 4-13, the seventh fixing bracket 4-13 is fixedly installed with a soft box storage box disk rotation mechanism, the soft box storage box disk rotation mechanism includes a turntable 4-2, the geometric center of the turntable 4-2 is provided with an installation hole, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com