Cathode ray tube

A cathode ray tube and shadow mask technology is applied in the field of improving the curved surface retention strength of the shadow mask, and can solve the problems of reducing image quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

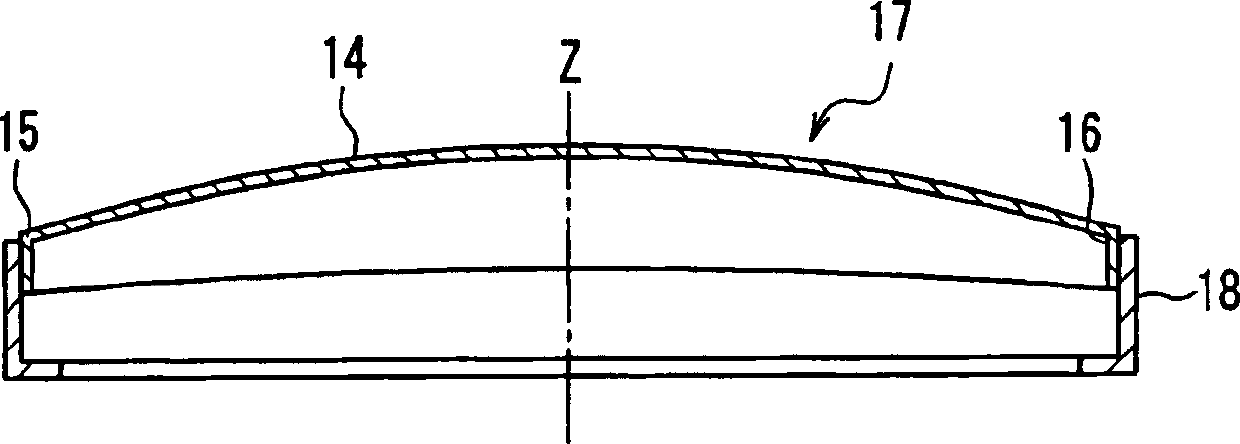

[0025] By satisfying the several formulas of the present invention given above, it is possible to increase the curved surface holding strength of the shadow mask main body, thereby reducing the deviation of electron beam landing and preventing the degradation of color purity.

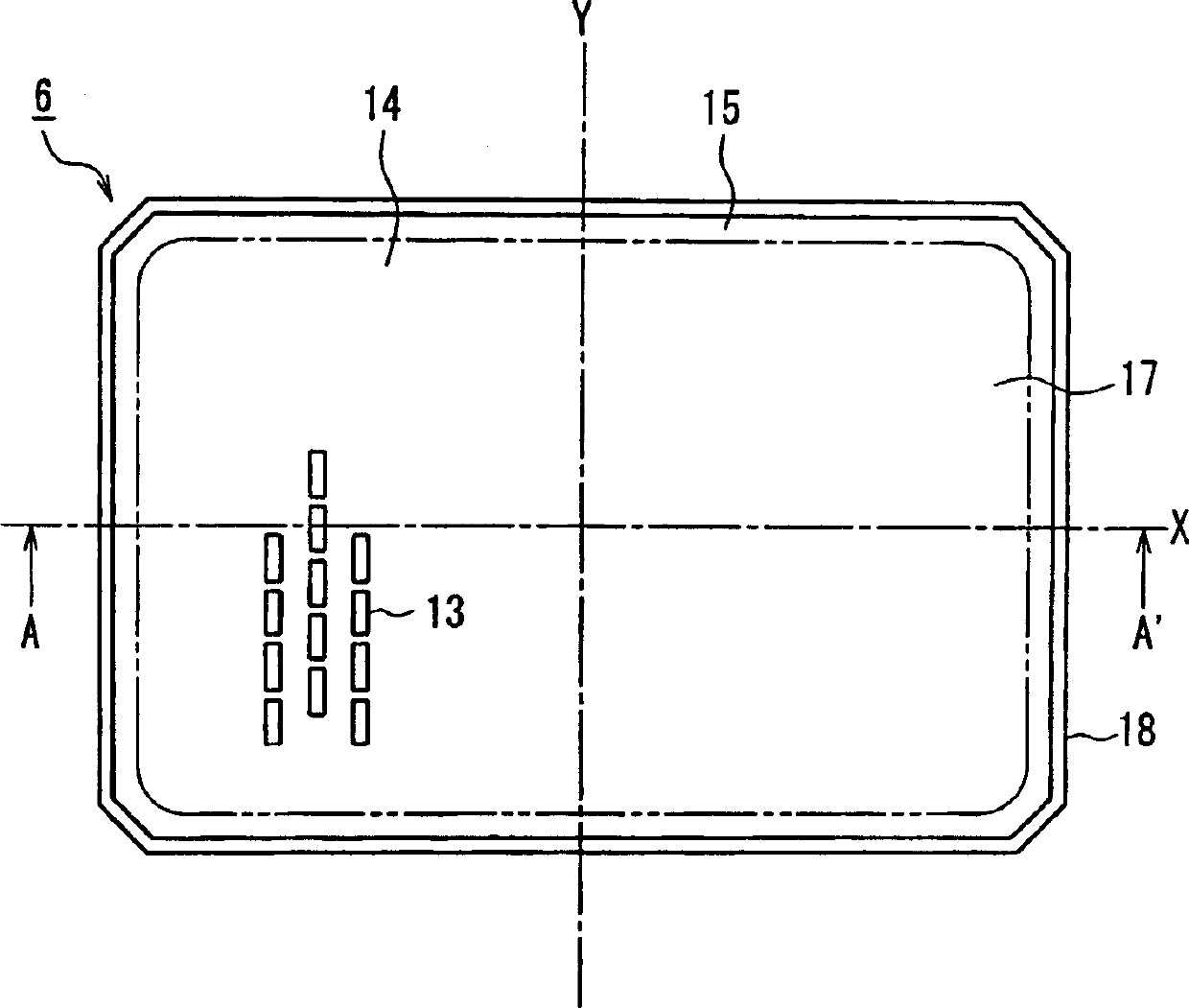

[0026] In the present invention, it is preferred that the effective surface has the horizontal axis as one side thereof and the 30 mm wide band-shaped range extending from the horizontal axis end point to the tube axis side includes a portion in which the radius of curvature of the effective surface in the vertical axis direction is The distribution is a concave radius of curvature distribution with a minimum value.

[0027] In addition, it is preferable that the effective surface has the horizontal axis as its one side and the 30mm-width band-shaped range extending from the horizontal axis end point to the pipe axis side includes a portion in which the effective surface has a distribution of curvature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com