Cathode ray tube

A technology for cathode ray tubes and tube shells, applied in the direction of cathode ray/electron beam tube shells/containers, cold cathode manufacturing, electrode system manufacturing, etc., which can solve problems such as weight increase, panel 3 price increase, long time, etc. Achieve the effect of reducing weight, reducing material cost and reducing heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

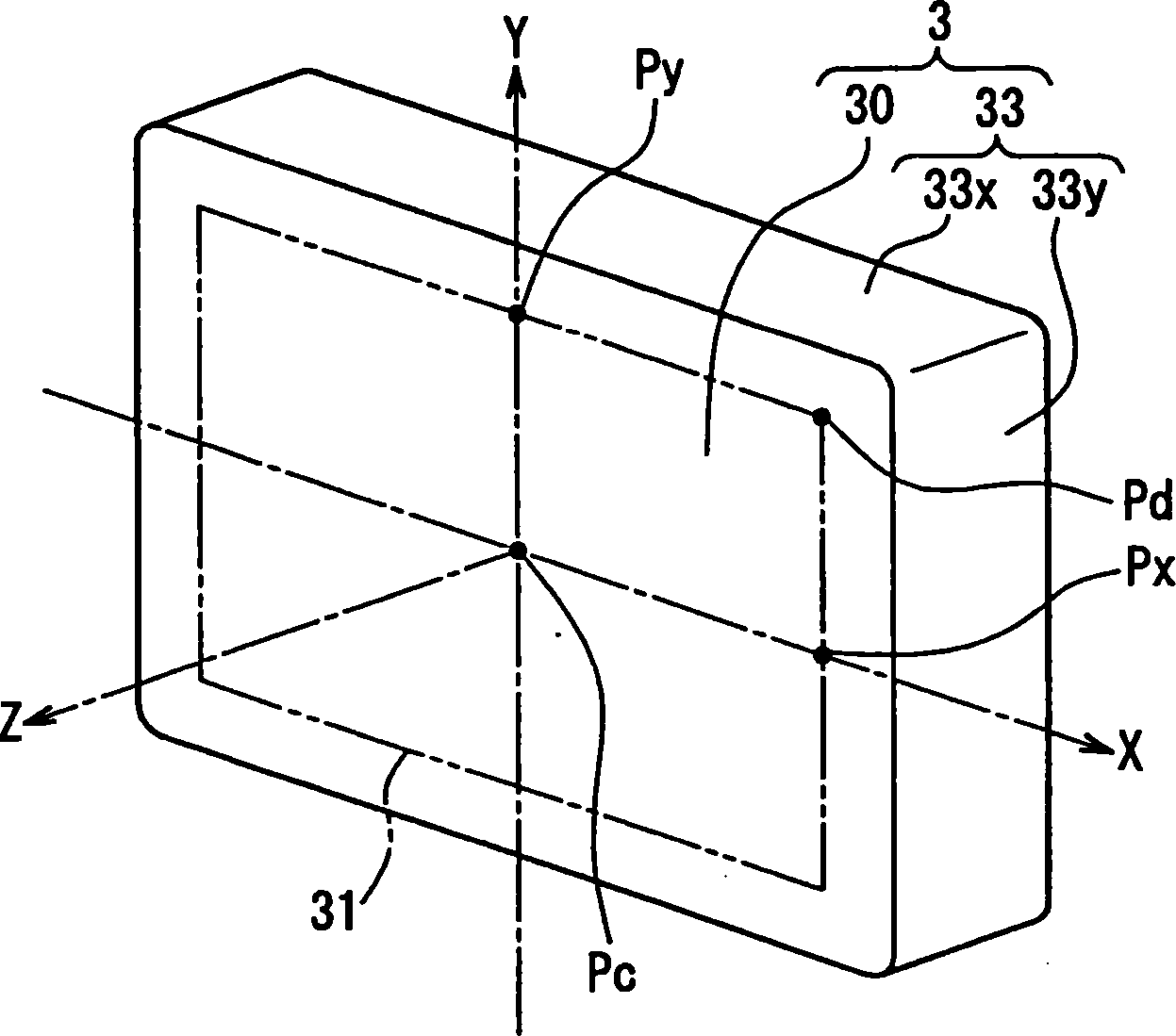

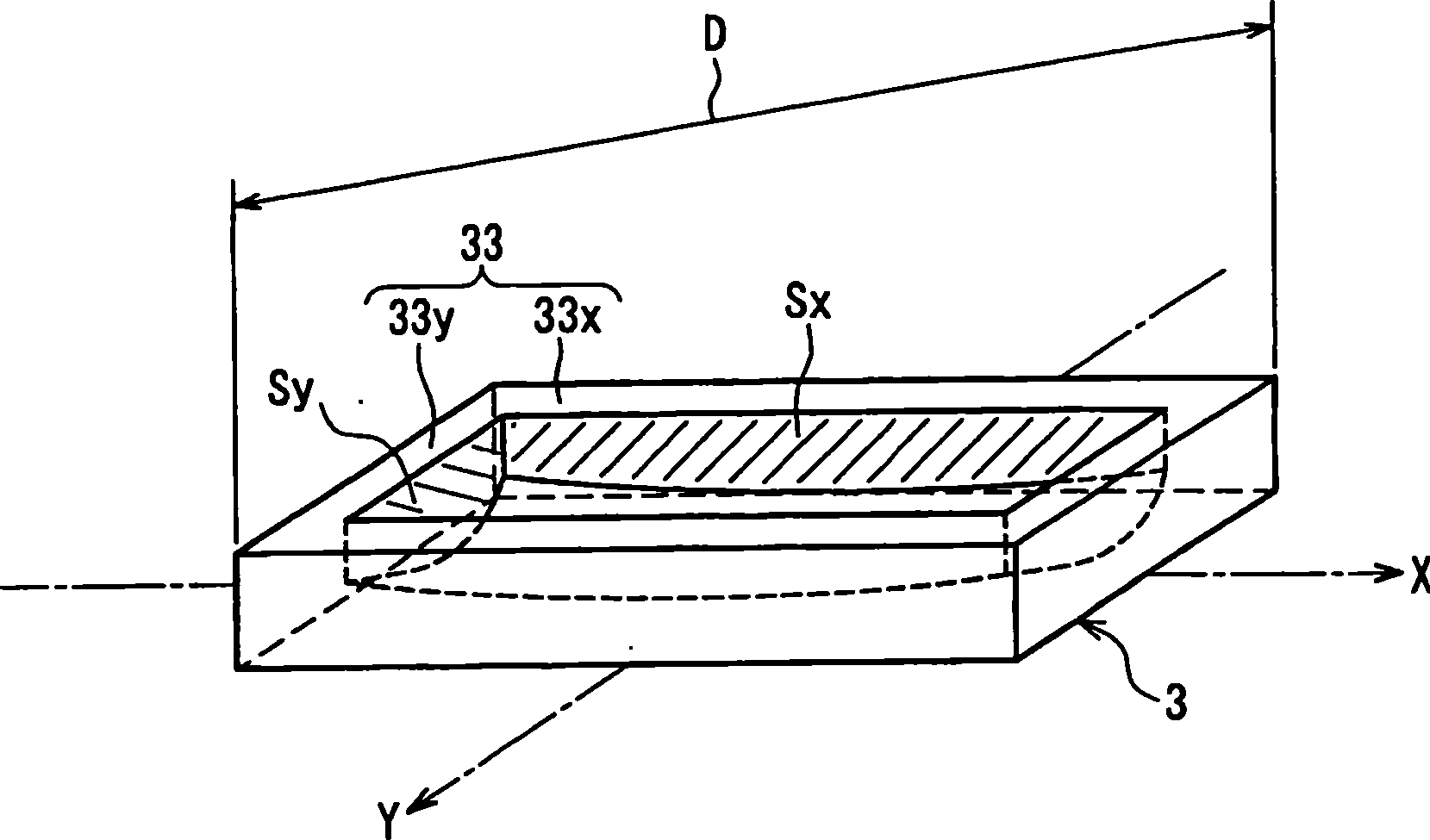

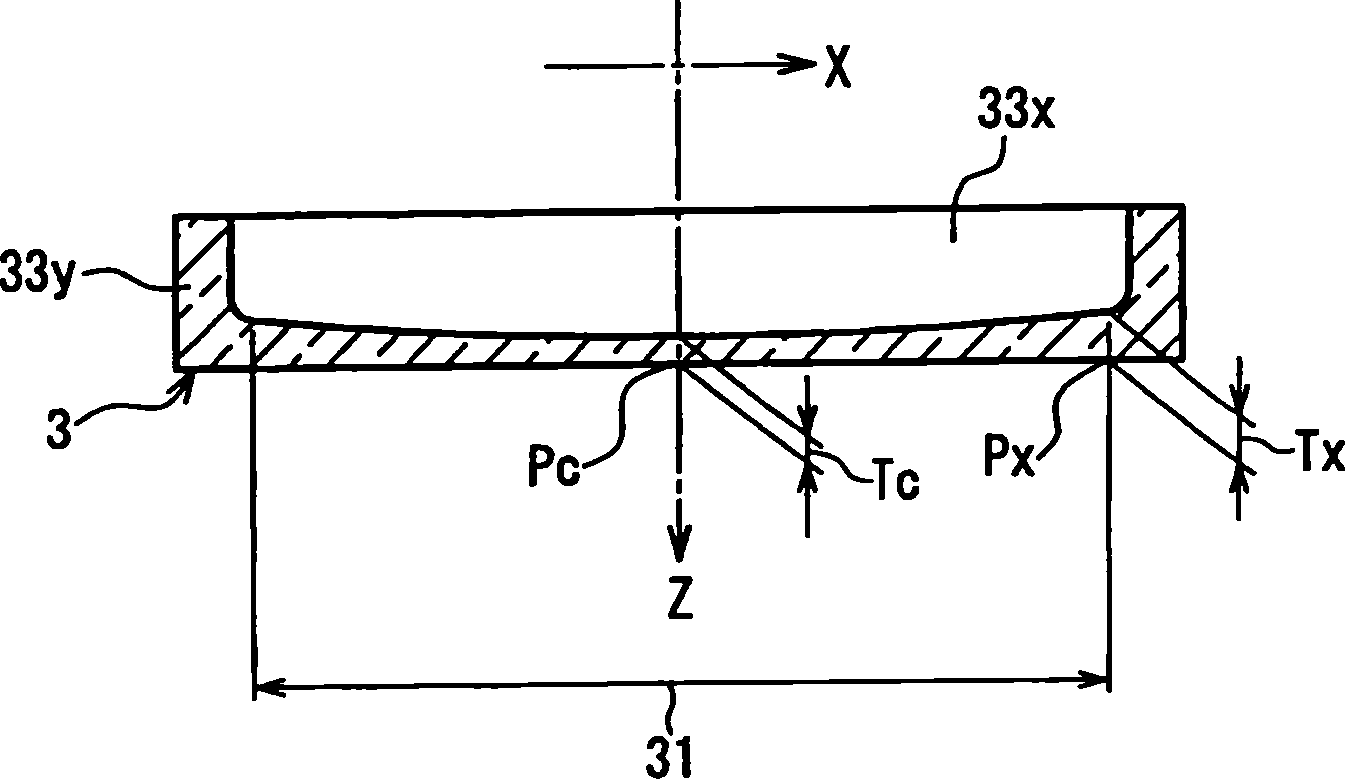

[0027] The above-mentioned cathode ray tube of the present invention further includes a metal tape mounted on the outer peripheral surface of the skirt portion of the panel, and a resin sheet pasted so as to cover at least the outside of the effective portion, preferably satisfying the following formula (3):

[0028] 0.012≤Tc / D≤0.016…………………………(3)

[0029] Therefore, even if the casing of the cathode ray tube is crushed, the glass sheet of the panel can be prevented from splashing to the front of the panel. As a result, it can fully meet the Electrical Appliances and Materials Regulations, UL (Underwriters Laboratories Inc. Underwriters Laboratories) standards, CSA ( Canadian Standards Association Canadian Standards Association) standards and other strict safety standards. In addition, there is no need to increase the thickness of the panels in order to meet these safety standards. Therefore, not only sufficient safety can be ensured, but also the weight and cost of the panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com