Patents

Literature

45results about How to "Avoid extensive cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Weight and Density Fire-Resistant Gypsum Panel

InactiveUS20110195241A1Small expansionReduce Shrinkage ProblemsSolid waste managementWood layered productsThermal insulationVolumetric Mass Density

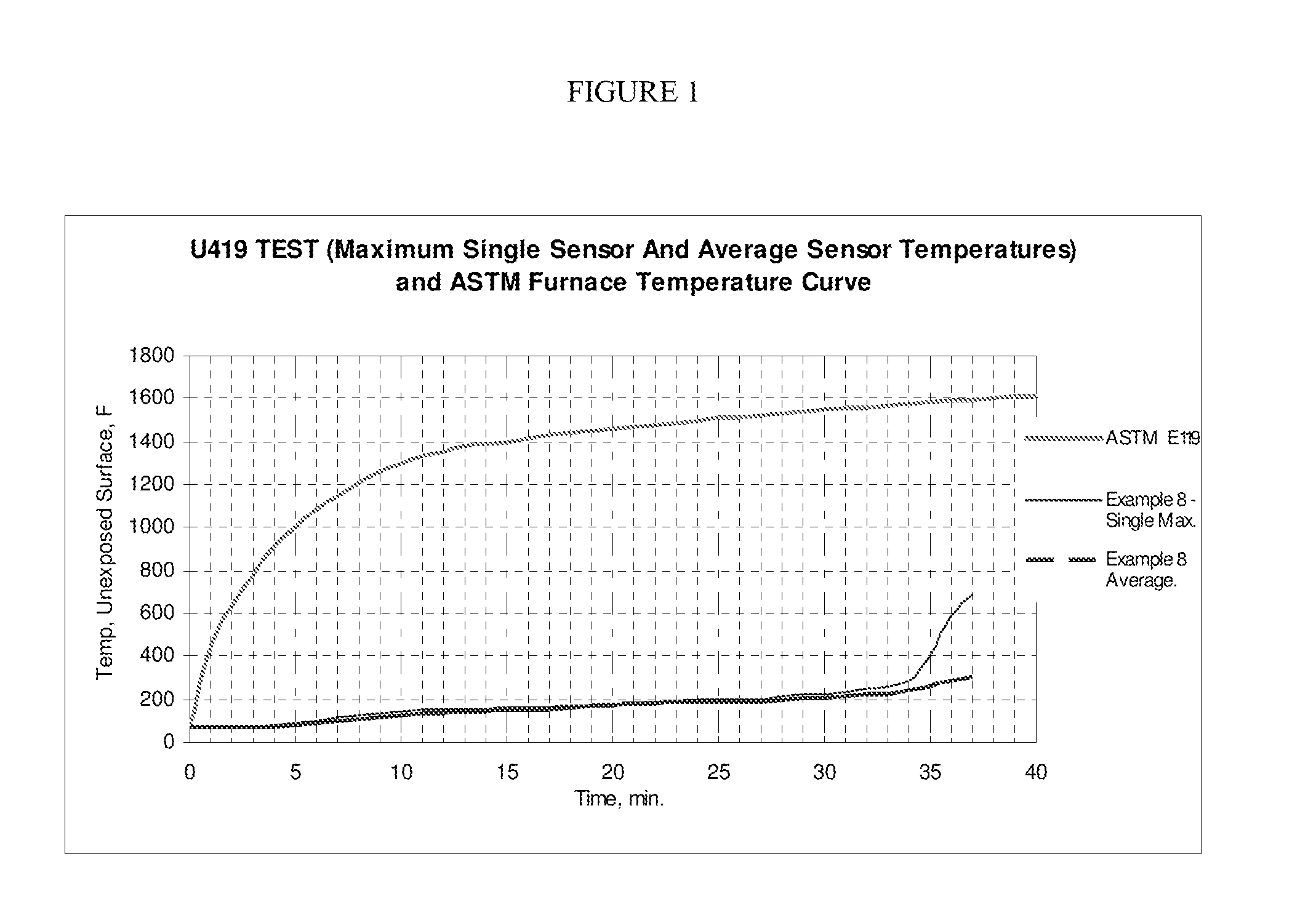

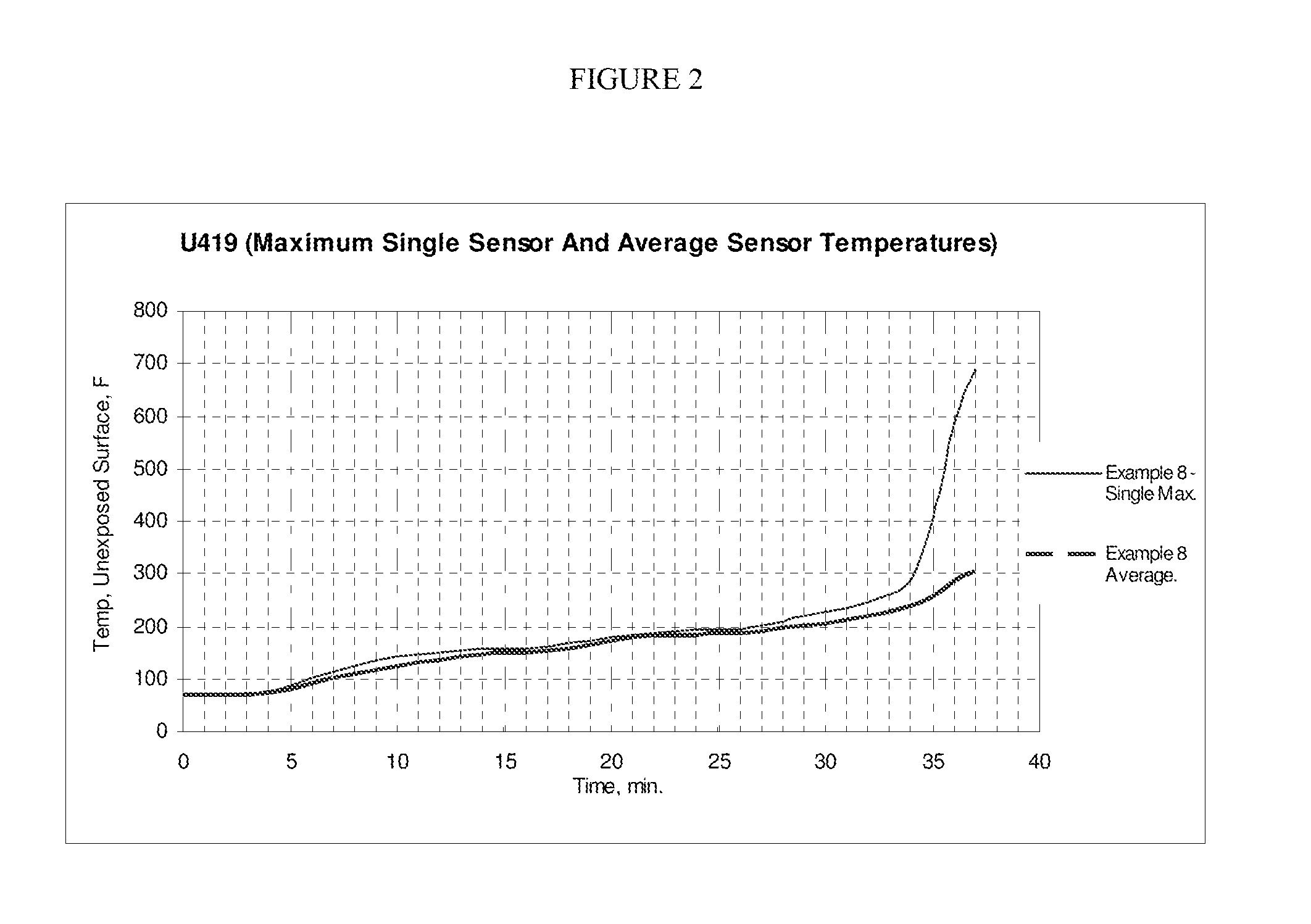

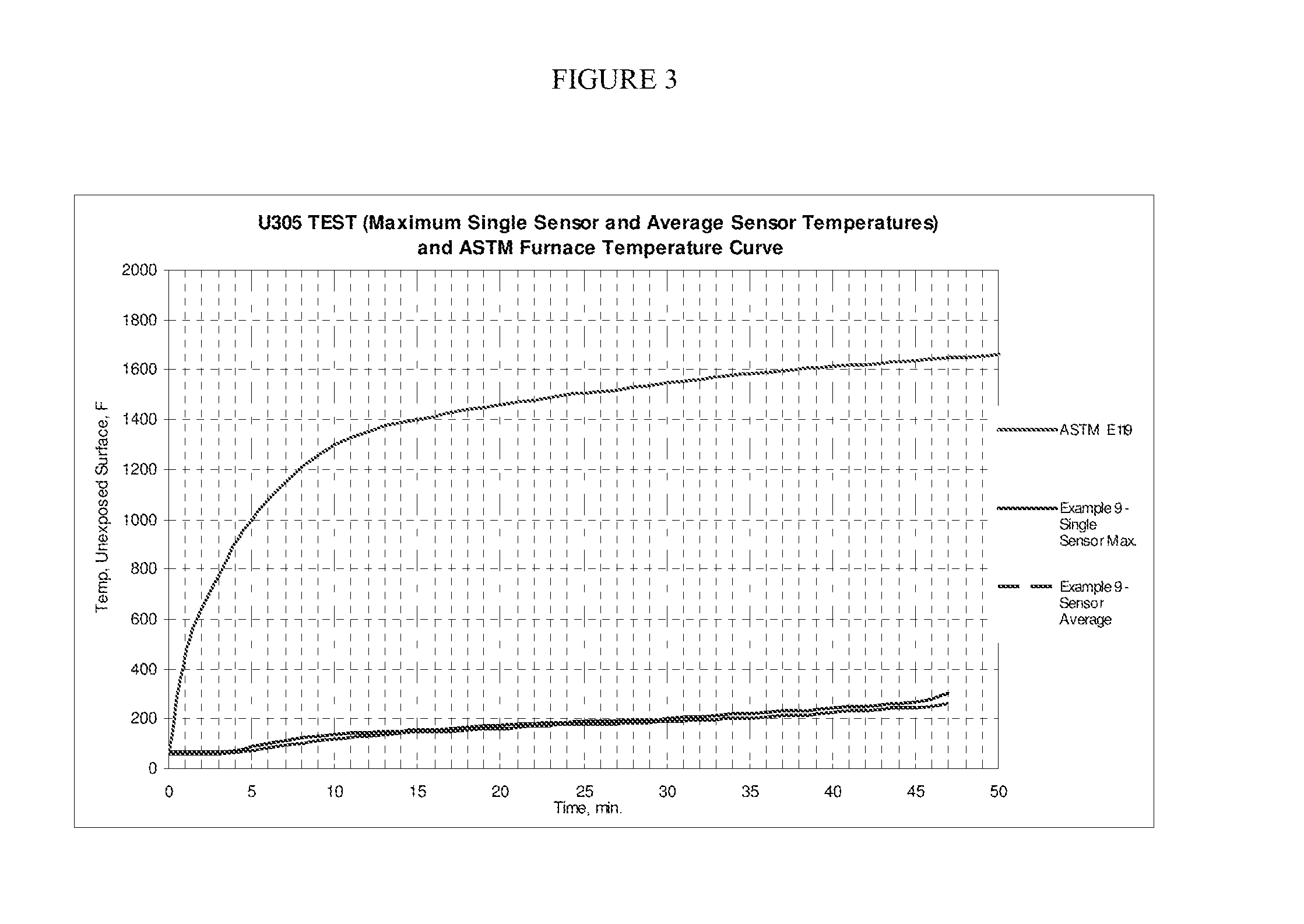

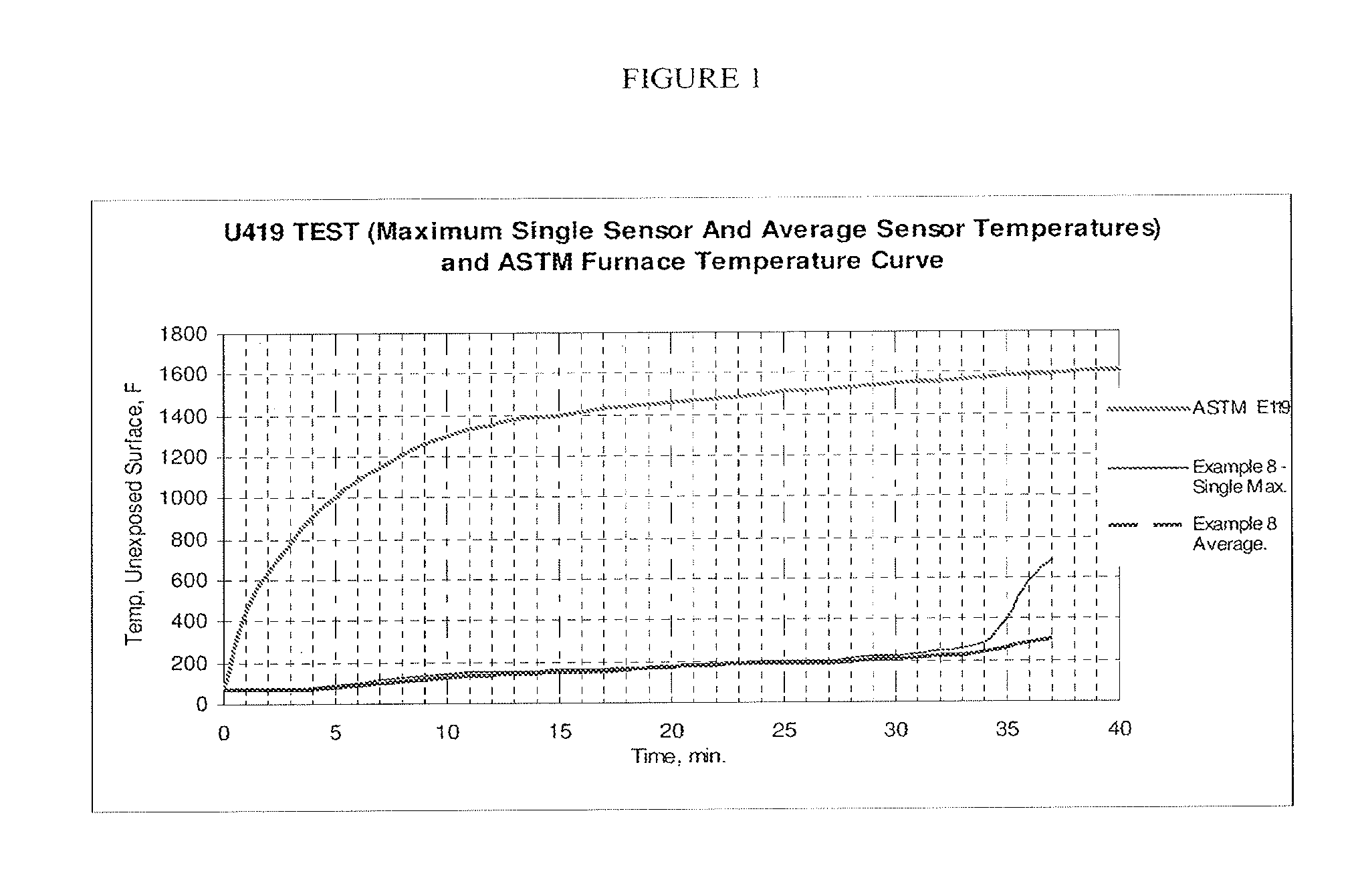

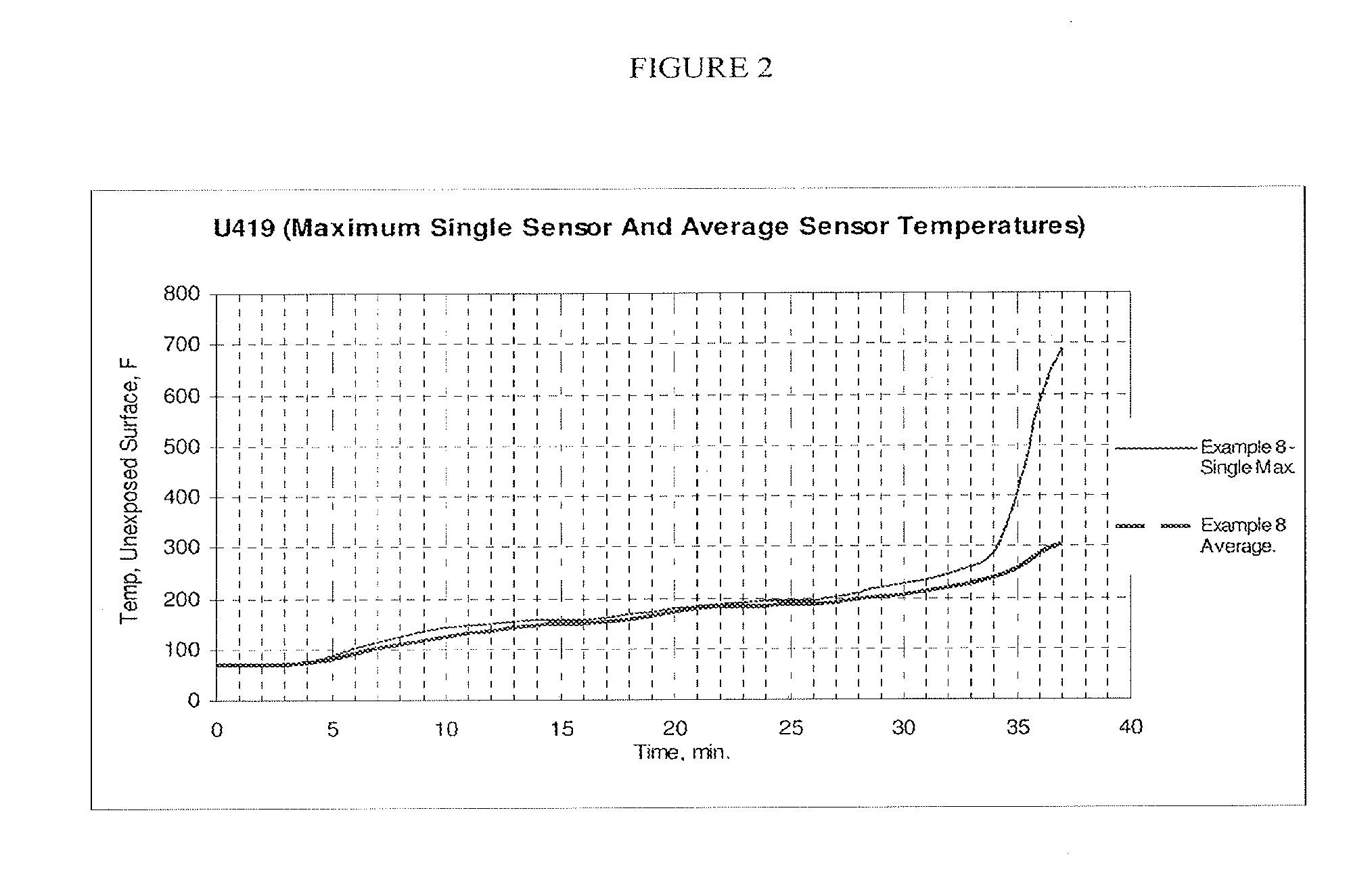

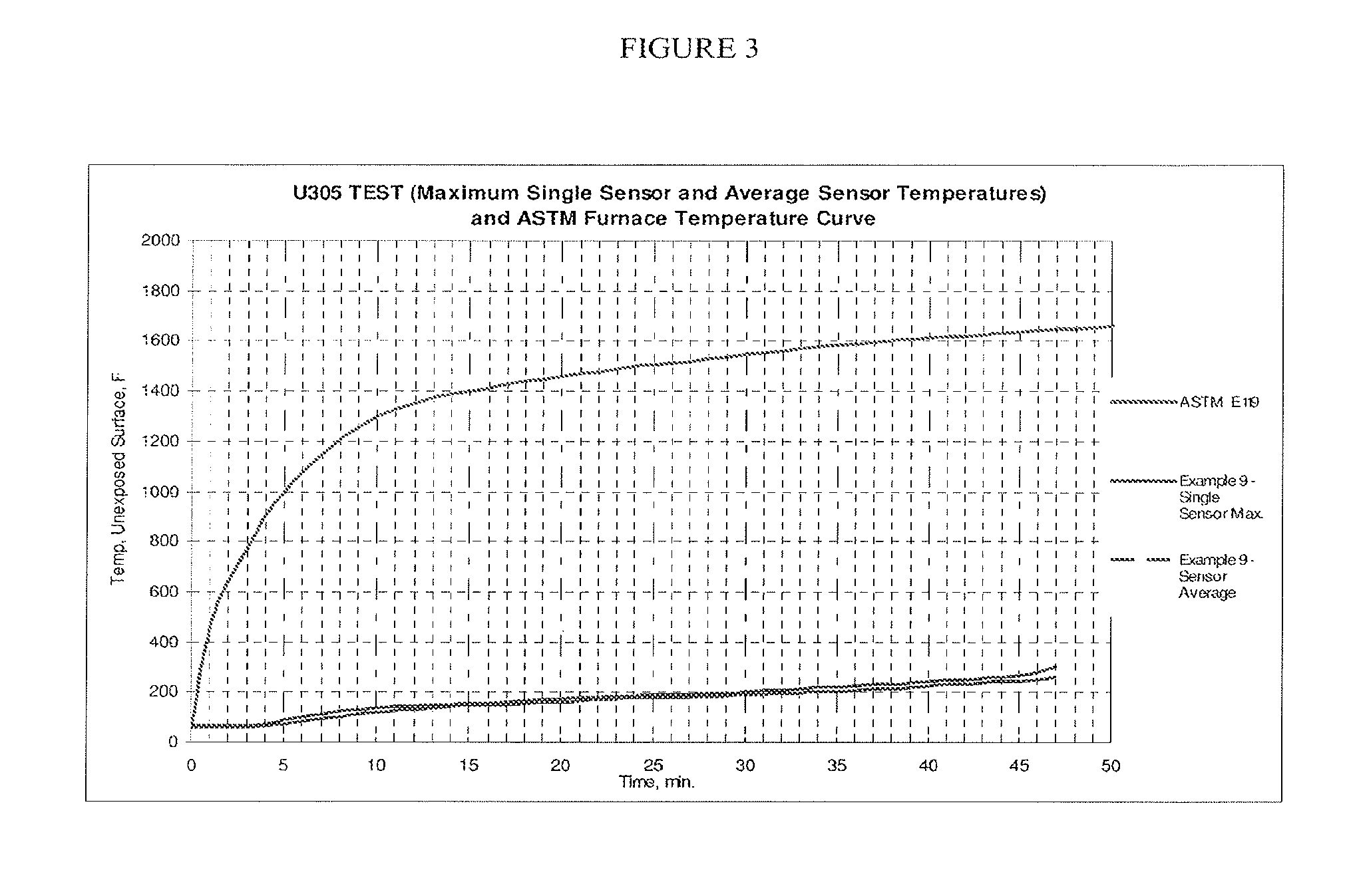

An about ⅝ inch to ¾ inch thick low weight, low density gypsum panel with fire resistance capabilities sufficient to provide a Thermal Insulation Index of at least 17.0 minutes which when subjected to U419 test procedures will not fail for at least 30 minutes and, in selected embodiments, also has outstanding water resistance properties.

Owner:UNITED STATES GYPSUM CO

Fiber reinforcement material, products made thereform, and method for making the same

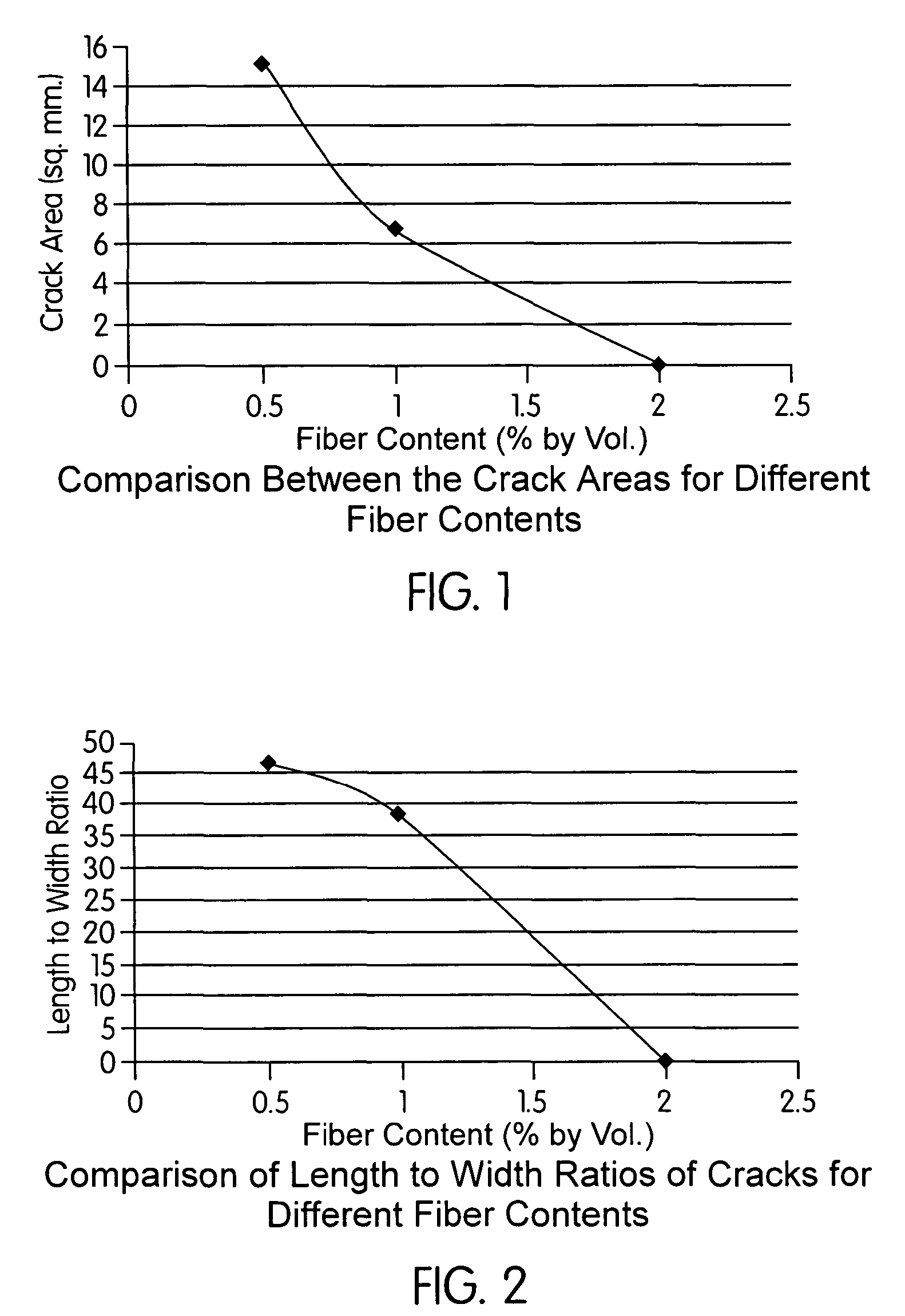

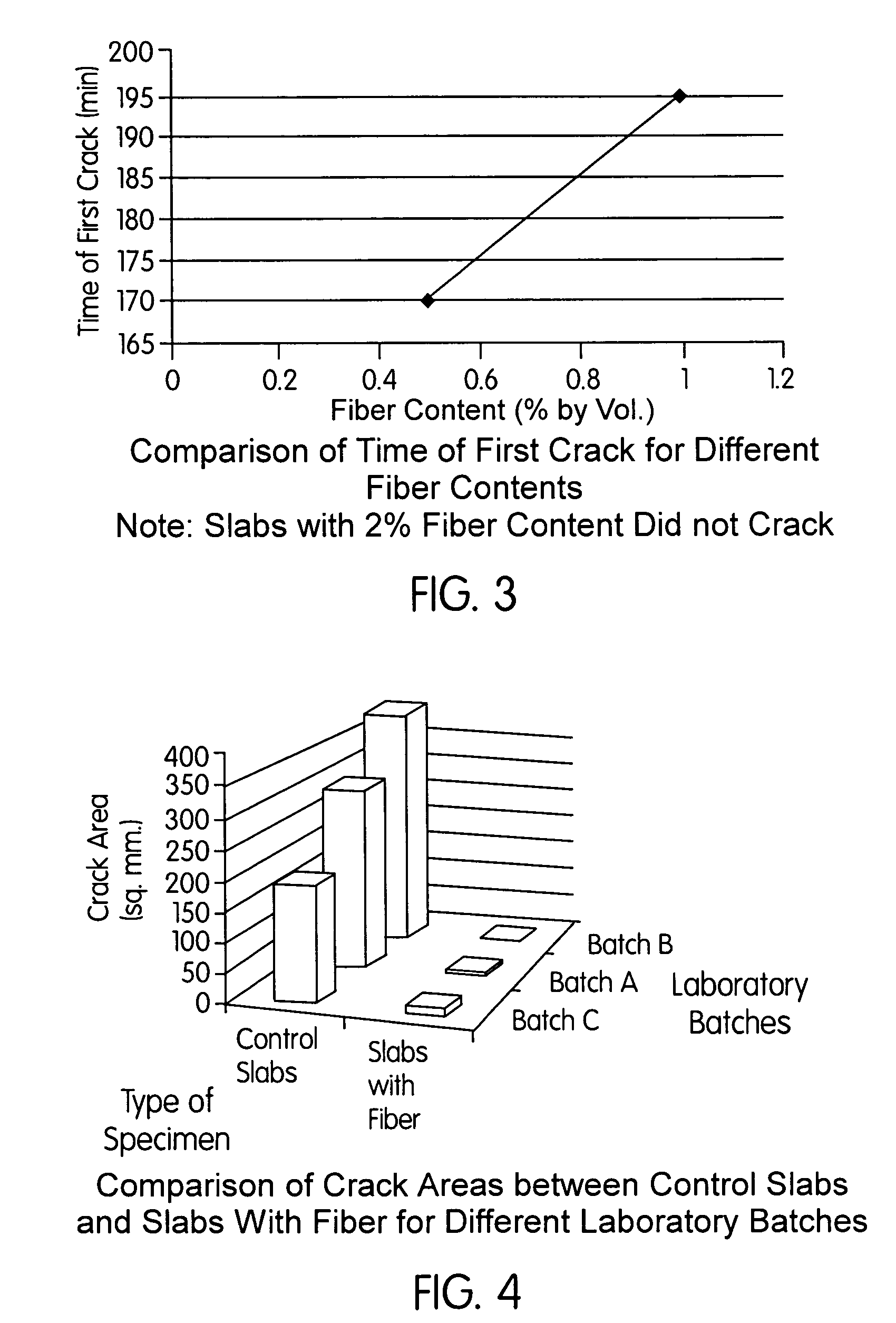

InactiveUS7168232B2Crack in areaDecrease their propagationCeramic layered productsGlass/slag layered productsSynthetic fiberEngineering

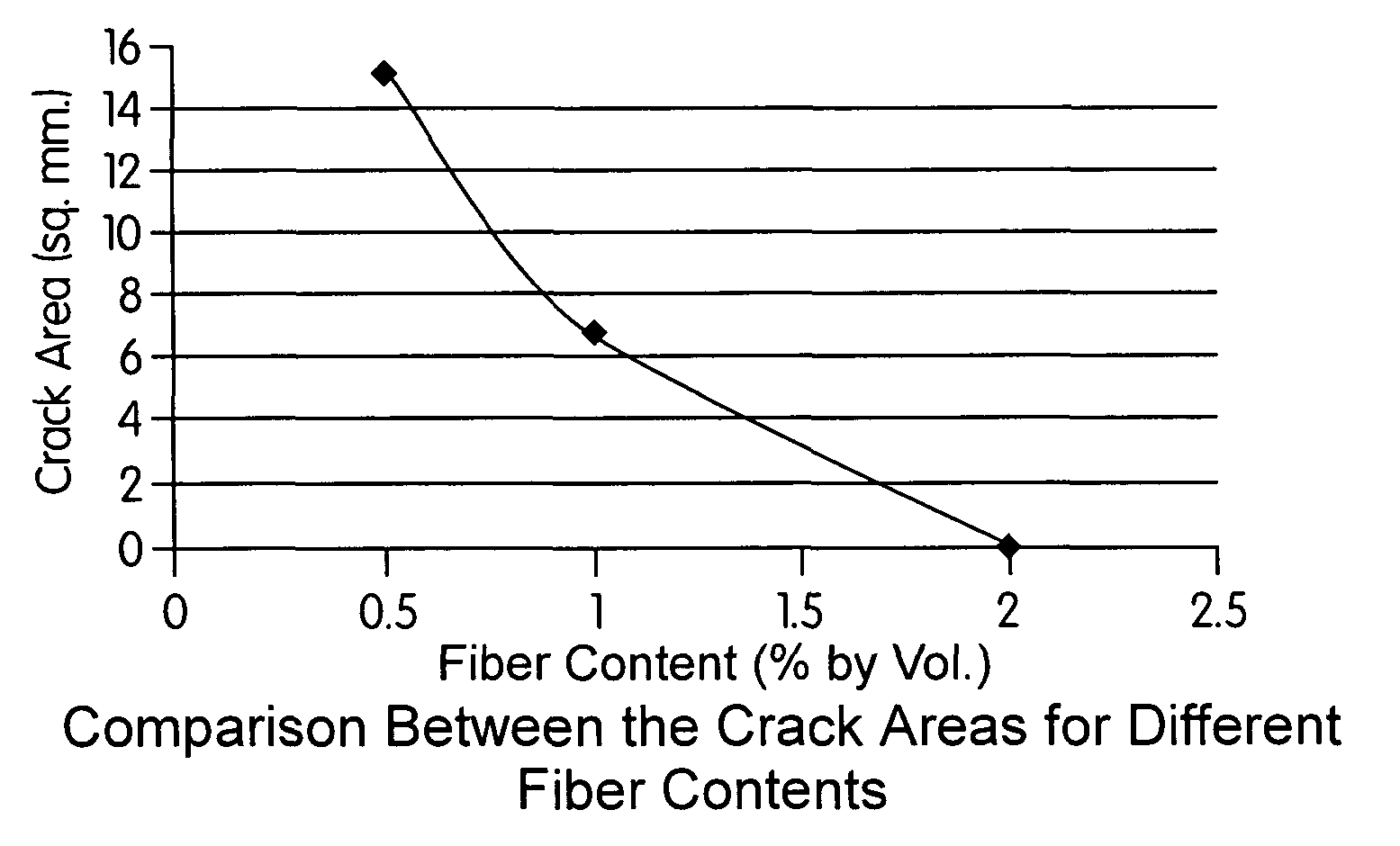

The present invention provides a synthetic fiber and methods for its use and formation. The present invention may comprise a fiber component that is a twisted bundle comprised of multiple strands of a nonfibrillating monofilament, the degree of twist being greater than about 0.9 turns / inch (about 0.36 turns / cm). The present invention may further comprise another fiber component, discrete from the twisted fiber component, that is fibrillated.

Owner:FORTA LLC

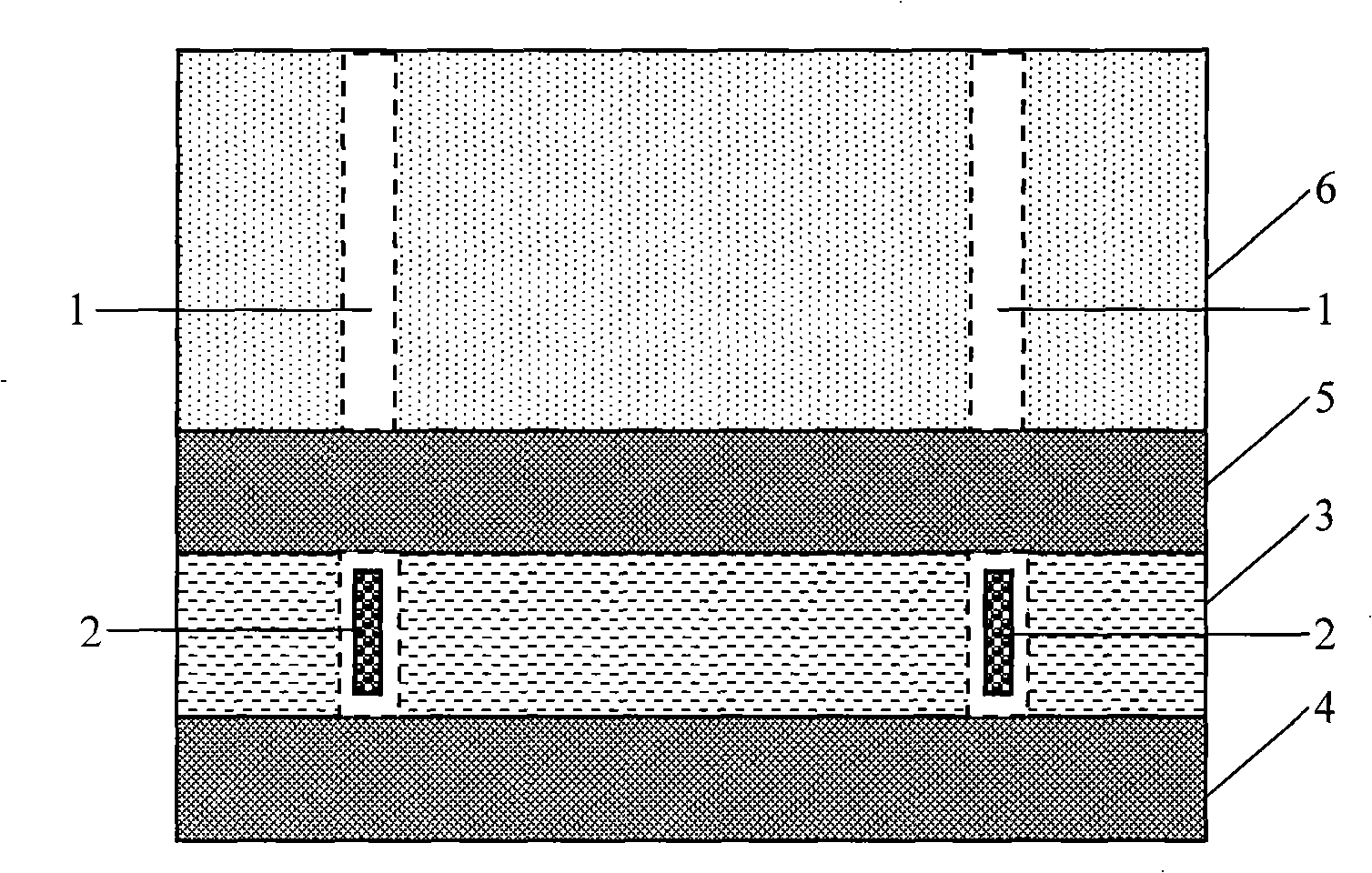

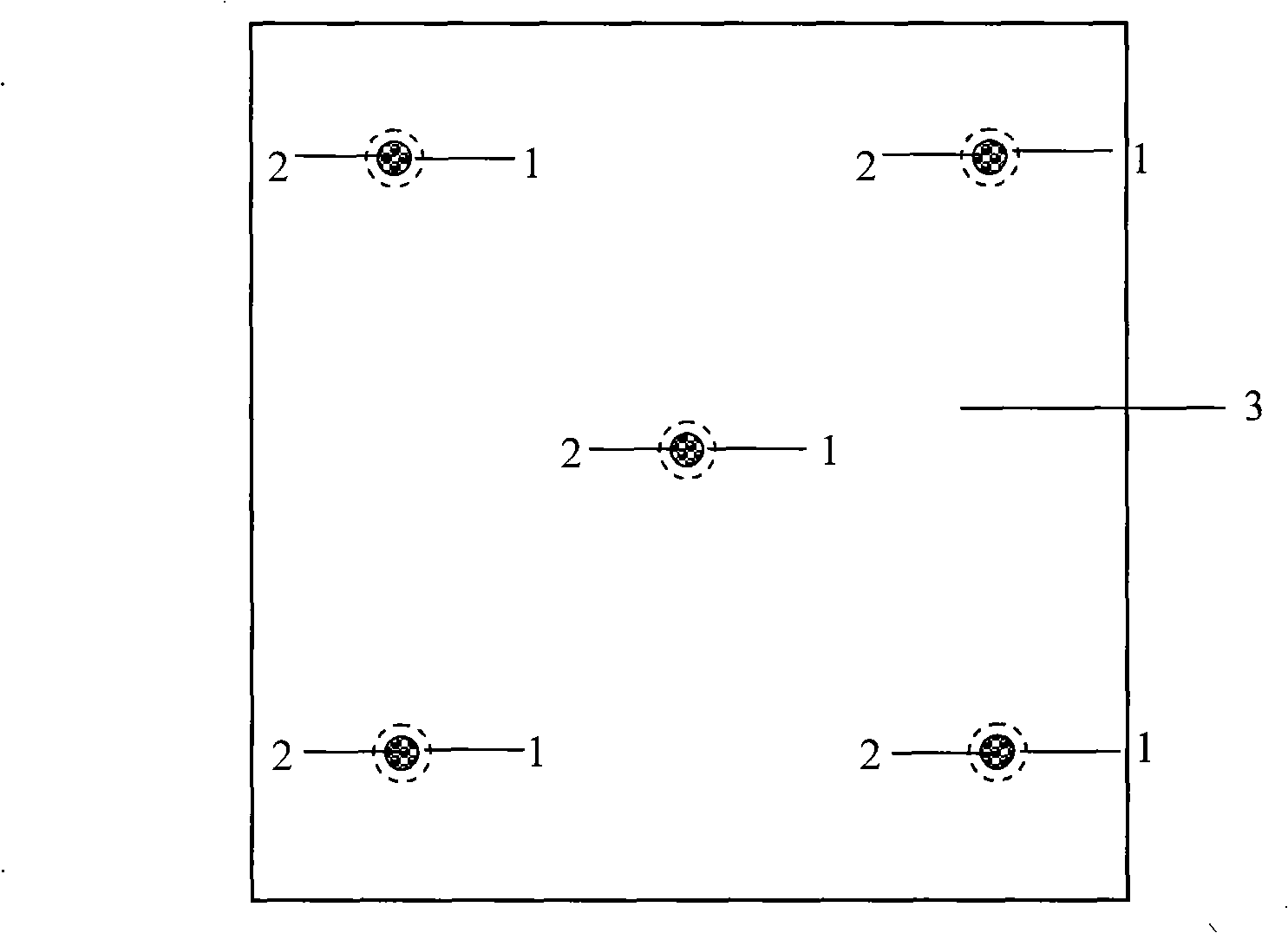

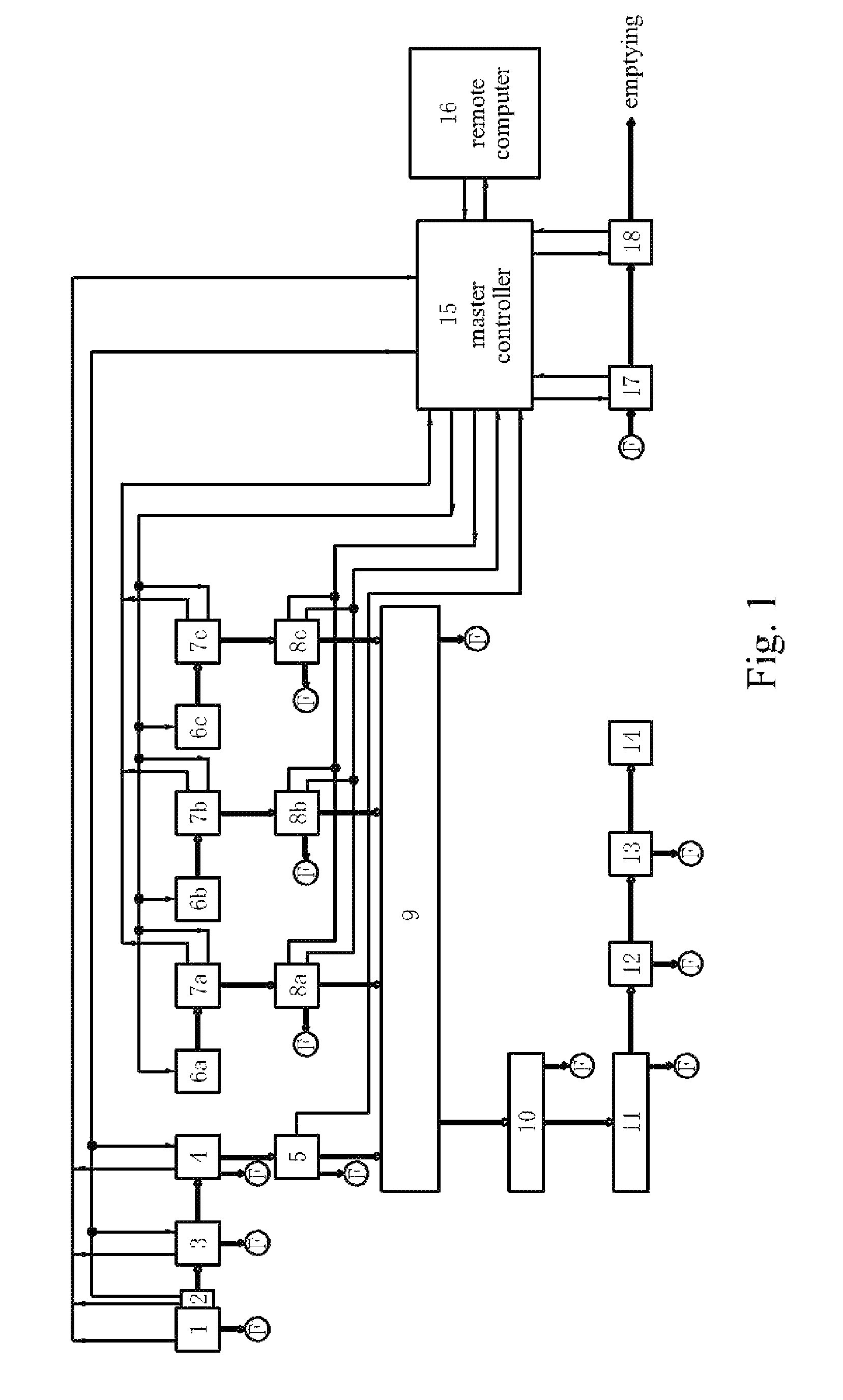

Method for blasting seepage enhancement for low infiltration sandrock -type uranium deposit

The invention discloses a method for explosion and leakage increase of a low permeability sandstone uranium deposit, which includes steps as follows: A. blast holes are drilled through the overburden, the top rock of occurrence terrane to the proper position of the occurrence terrane from surface. An underreamer is used to locally ream the blast holes at the occurrence terrane to meet charging requirement; B. blasting cartridges are arranged in the blast holes in an uncoupling way; the detonator is waterproof; uncoupling charge for explosion comprises radial uncoupling charge and axial uncoupling charge; C. after the blasting cartridges are arranged properly, hole seal measures shall be taken to build up the blast holes; D. the blasting cartridges are initiated through short delay blasting which comprises short delay blasting inside the blast holes and short delay blasting between the blast holes. The recovery factor and the yield per unit of in-situ Uranium leaching are improved; the uranium deposit resource of low permeability sandstone type is used completely, thus alleviating the shortages of uranium resources.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

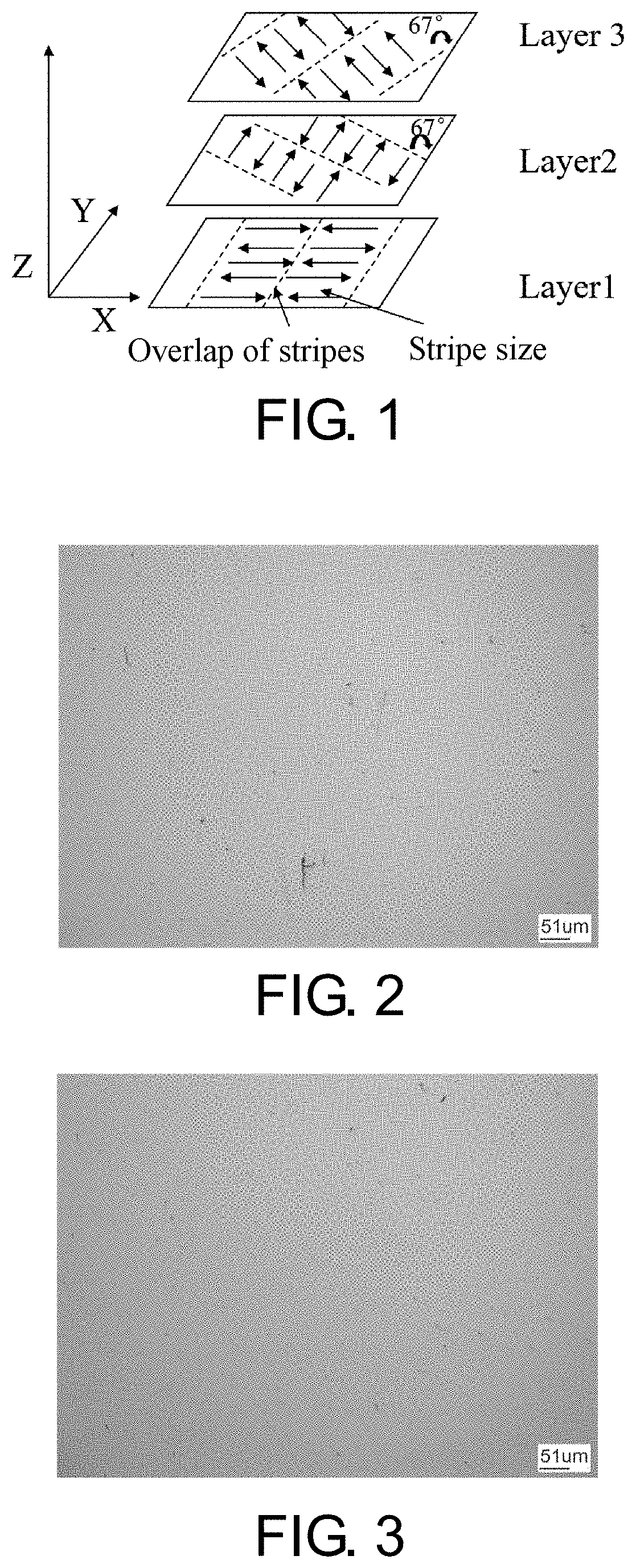

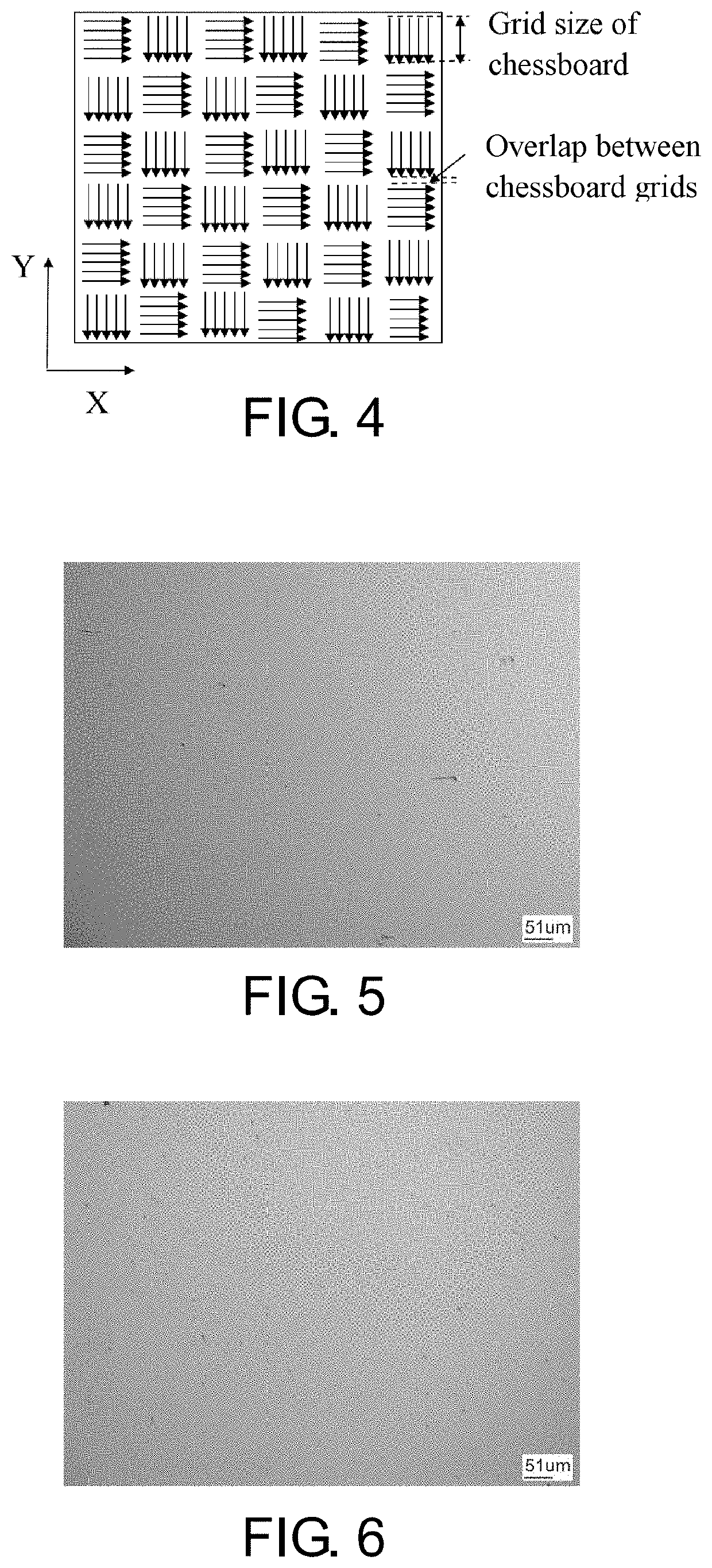

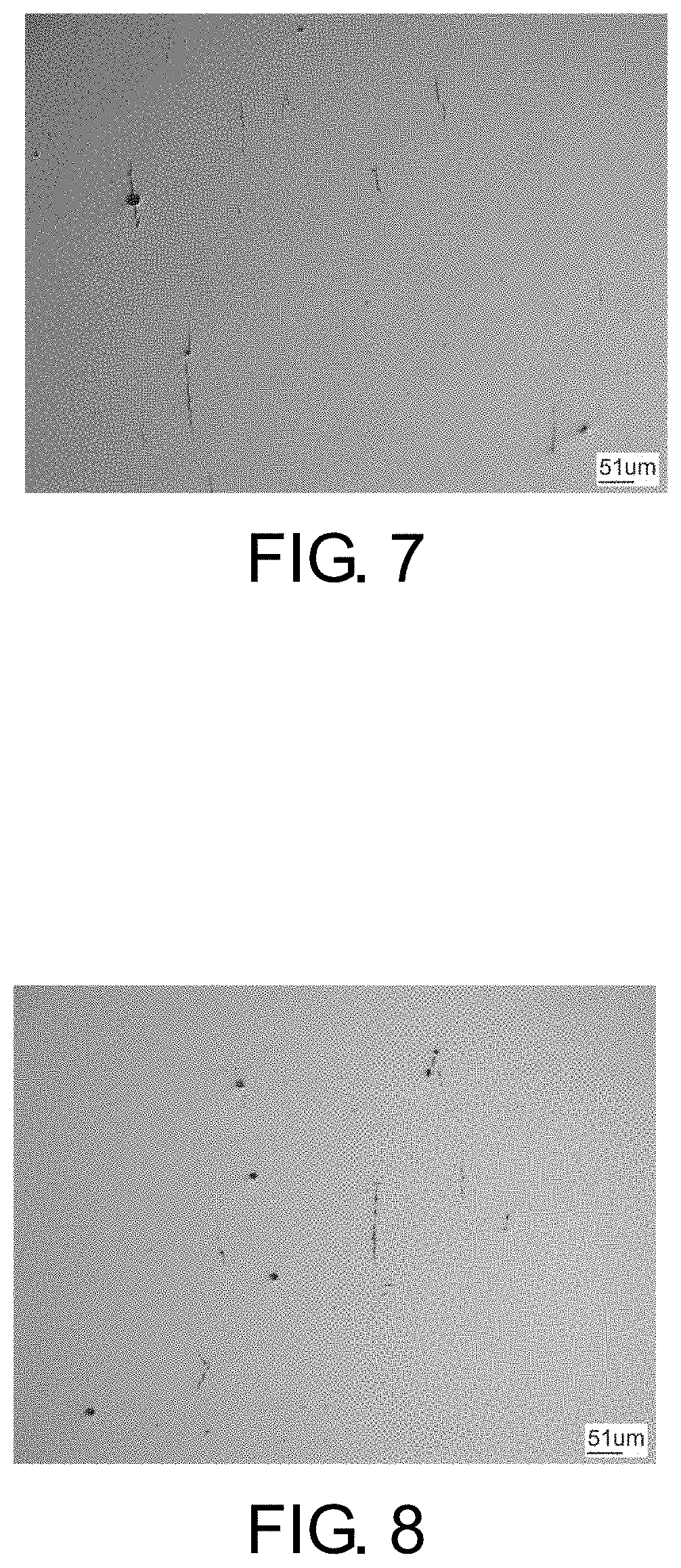

Method for eliminating cracks in rené 104 nickel-based superalloy prepared by laser additive manufacturing

PendingUS20210170487A1Inhibition formationHigh contentAdditive manufacturing apparatusTransportation and packagingCrazingStress relief

The present disclosure relates to the field of additive manufacturing and superalloys, particularly to a method for eliminating cracks in René 104 nickel-based superalloy prepared by laser additive manufacturing. For solving the problem that cracks are easily generated during laser additive manufacturing of René 104 nickel-based superalloy with high content of Al and Ti (Al+Ti>5 wt. %), generation of large-size cracks inside a fabricated part is suppressed by means of designing laser forming parameters and a partition scanning strategy; then stress relief annealing is performed to completely eliminate residual stress inside the fabricated part; and a spark plasma sintering process is performed to eliminate cracks inside the fabricated part and suppress the growth of grains during the sintering process.

Owner:CENT SOUTH UNIV

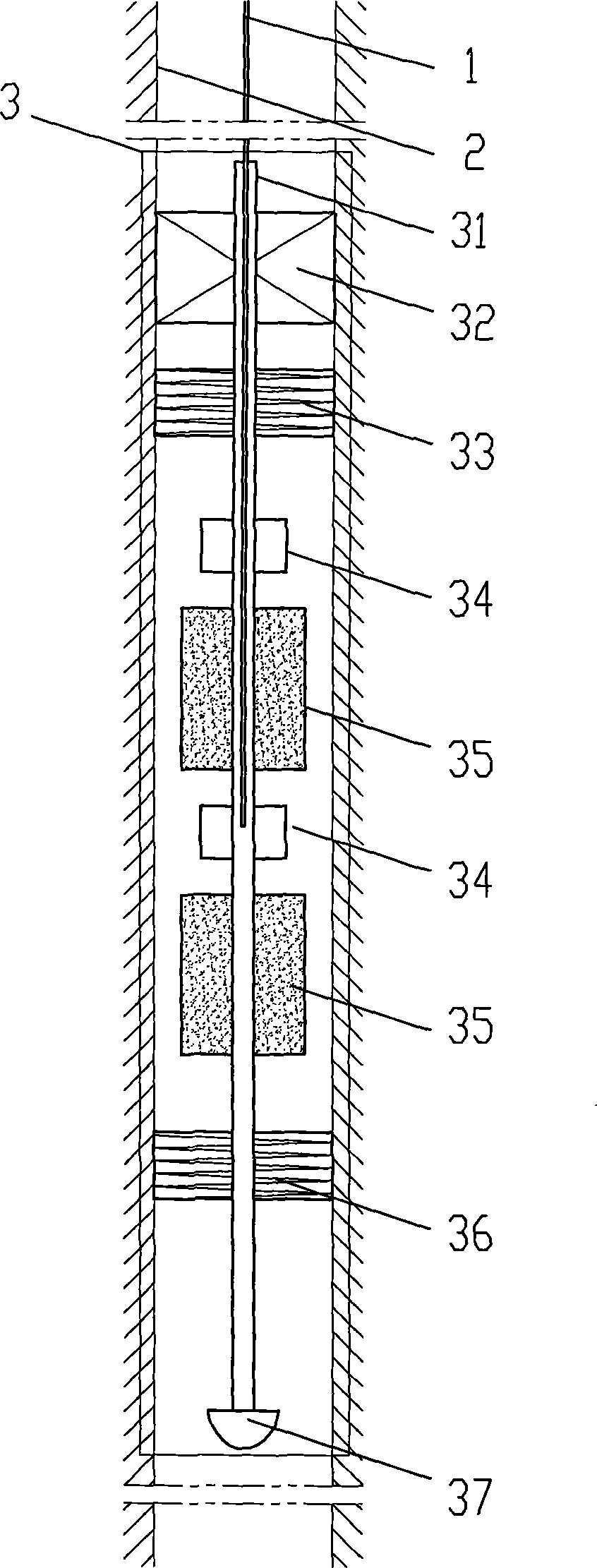

Ground-dipping ore bed continuous high-energy gas fracturing seepage increasing method and specific high-energy gas generator

ActiveCN101440704AImprove permeabilityIncrease penetrationFluid removalTime delaysDischarge pressure

The invention relates to a continuous high-energy gas fracturing and penetration increasing method for an in-situ leachable ore layer and a special high-energy gas generator and belongs to the technical field of improving penetrability of an ore-bearing terrane. In the continuous high-energy gas fracturing and penetration increasing method for the in-situ leachable ore layer, the high-energy gas generator is transported to the ore-bearing terrane through cable for a producing well to ignite a deflagration shell in the high-energy gas generator; and continuous high-energy gas acts on the ore-bearing terrane and discharges pressure for the ore layer in order that high-energy gas, a gas-water mixture and groundwater form rapid seepage under the action of hydraulic gradient produced instantaneously, thereby completing continuous high-energy gas fracturing and penetration increasing. The high-energy gas generator for the method is characterized in that the structure of the generator comprises: a connecting pipe is sequentially connected with a plugging device, an upper buffer, a time delay igniter, the deflagration shell, a lower buffer and a head tip from top to bottom. The method can improve the permeability of the in-situ leachable ore layer, further improve the mining yield and unit output of situ leaching and mining and improve the utilization efficiency of resource of the in-situ leachable ore layer.

Owner:SHIJIAZHUANG RAILWAY INST

Low weight and density fire-resistant gypsum panel

InactiveUS20130101838A1Small expansionReduce Shrinkage ProblemsConstruction materialSolid waste managementThermal insulationTest procedures

An about ⅝ inch to ¾ inch thick low weight, low density gypsum panel with fire resistance capabilities sufficient to provide a Thermal Insulation Index of at least 17.0 minutes which when subjected to U419 test procedures will not fail for at least 30 minutes and, in selected embodiments, also has outstanding water resistance properties.

Owner:UNITED STATES GYPSUM CO

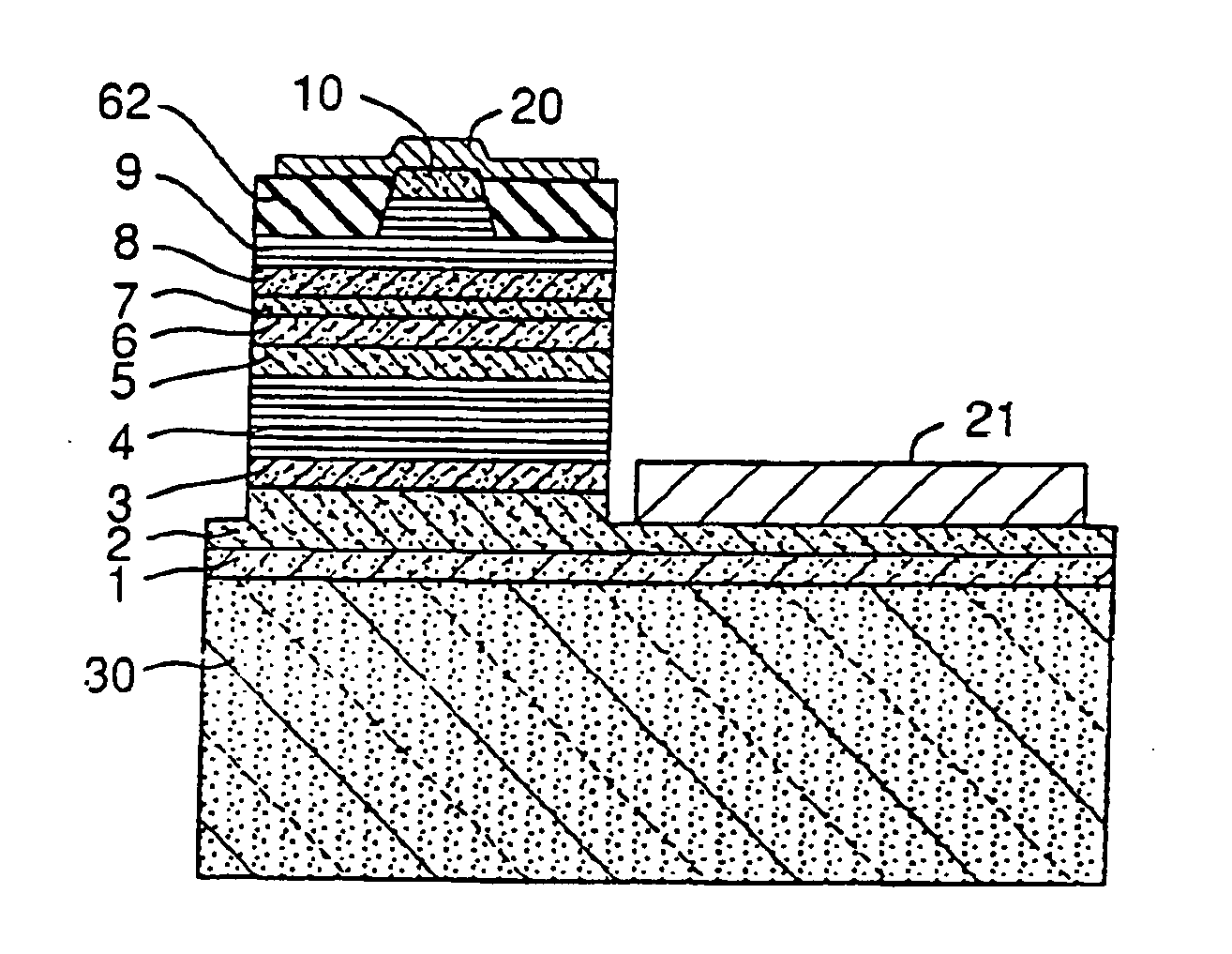

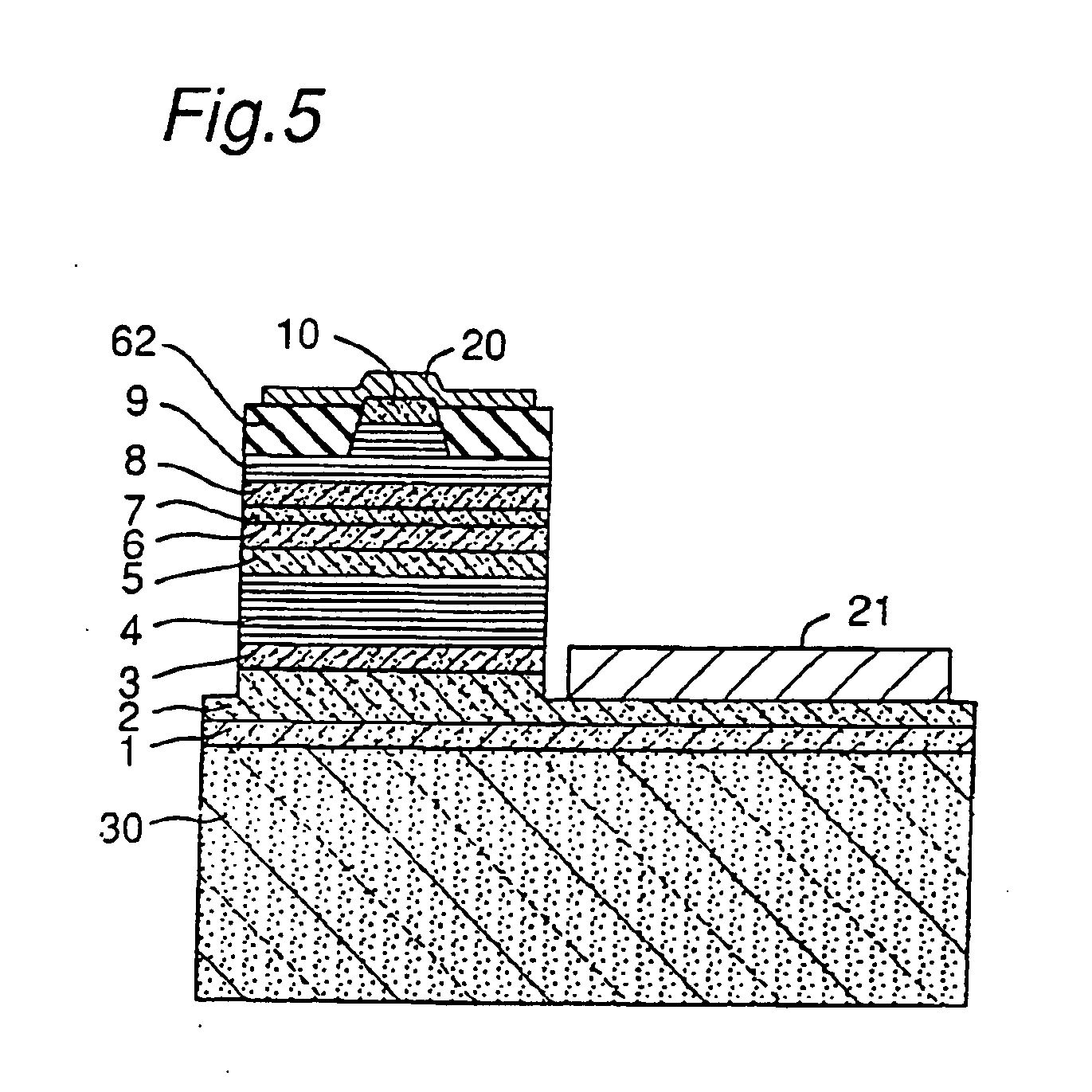

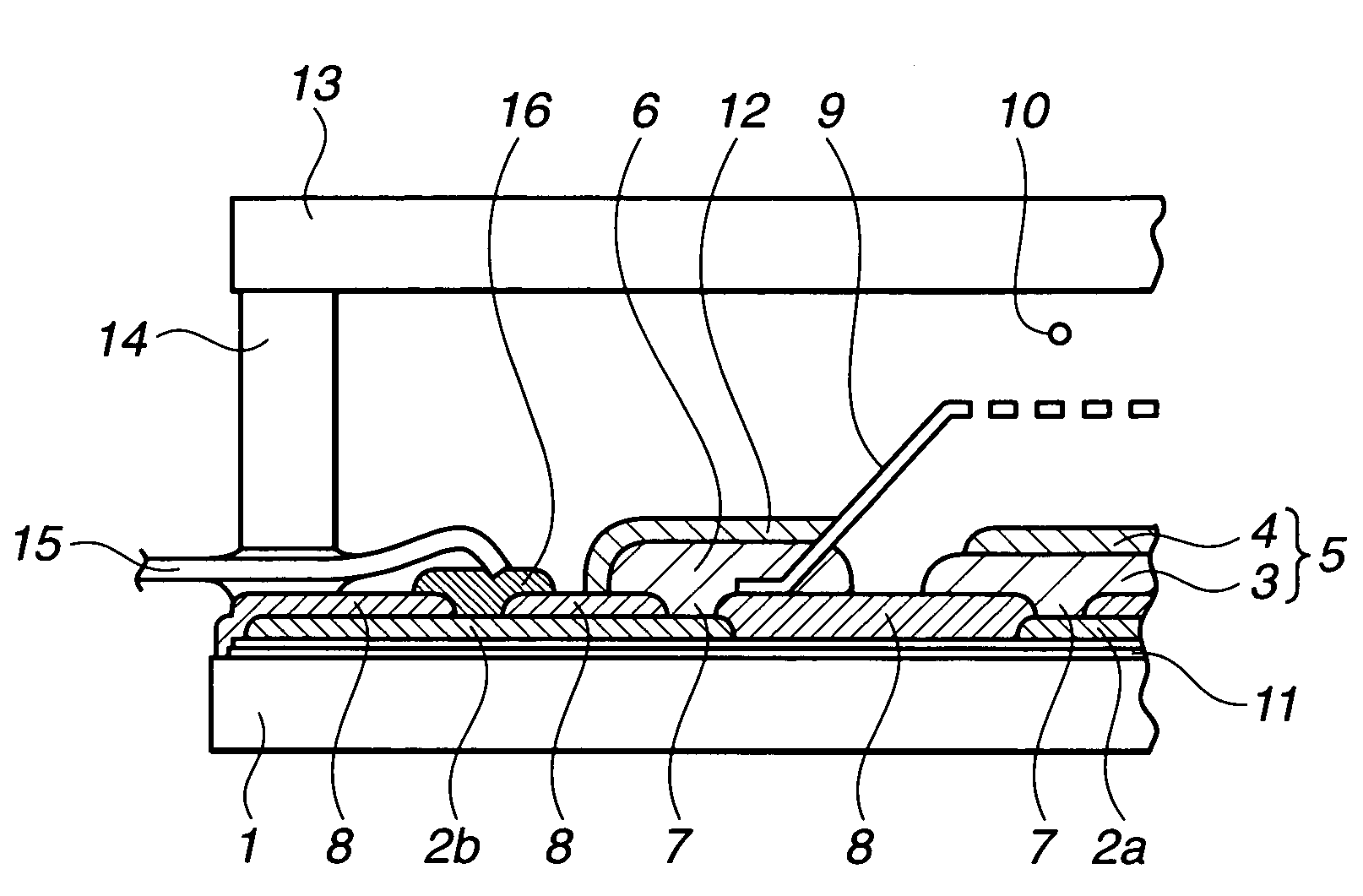

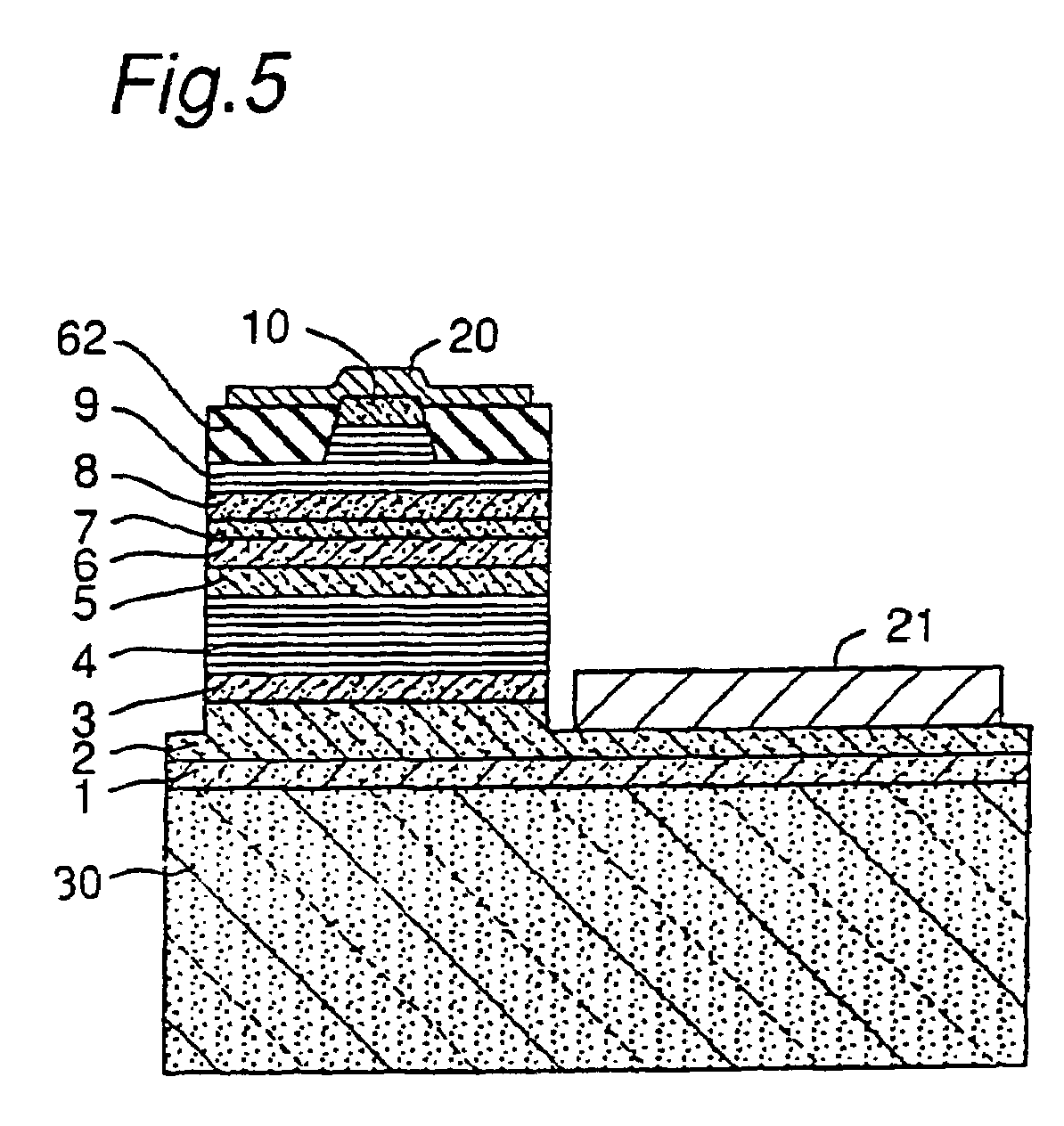

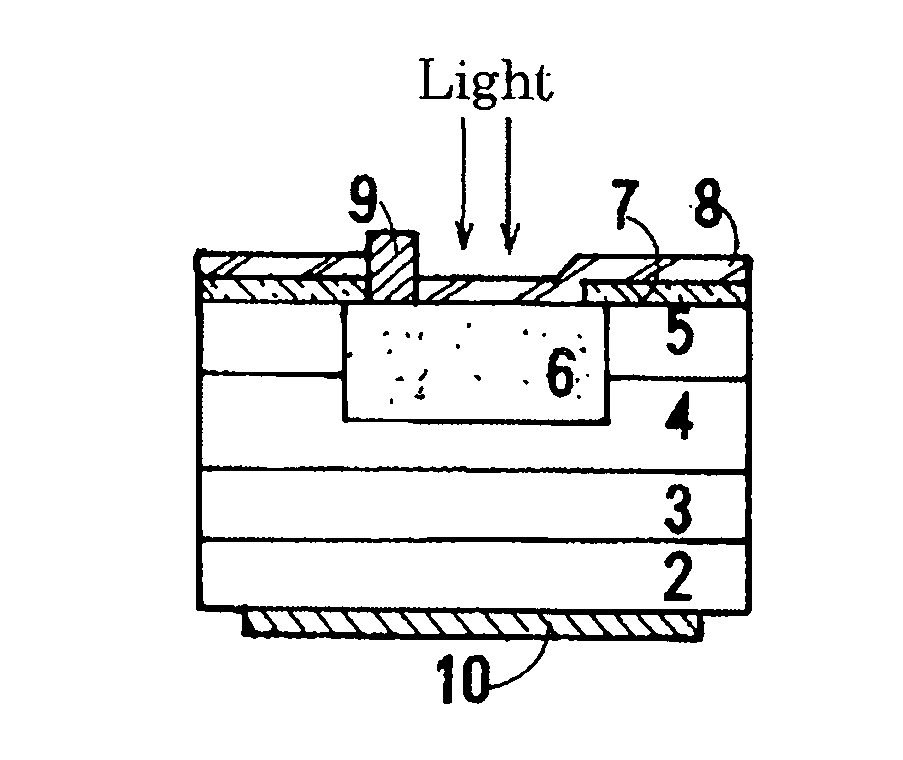

Nitride semiconductor device and manufacturing method thereof

InactiveUS20050054132A1Easy to operateAvoid breakingPolycrystalline material growthLaser detailsDevice formThermal expansion

A nitride semiconductor device includes a GaN substrate having a single-crystal GaN layer at least on its surface and plurality of device-forming layers made of nitride semiconductor. The device-forming layer contacting the GaN substrate has a coefficient of thermal expansion smaller than that of GaN, so that a compressive strain is applied to the device-forming layer. This result in prevention of crack forming in the device-forming layers, and a lifetime characteristics of the nitride semiconductor device is improved.

Owner:NICHIA CORP

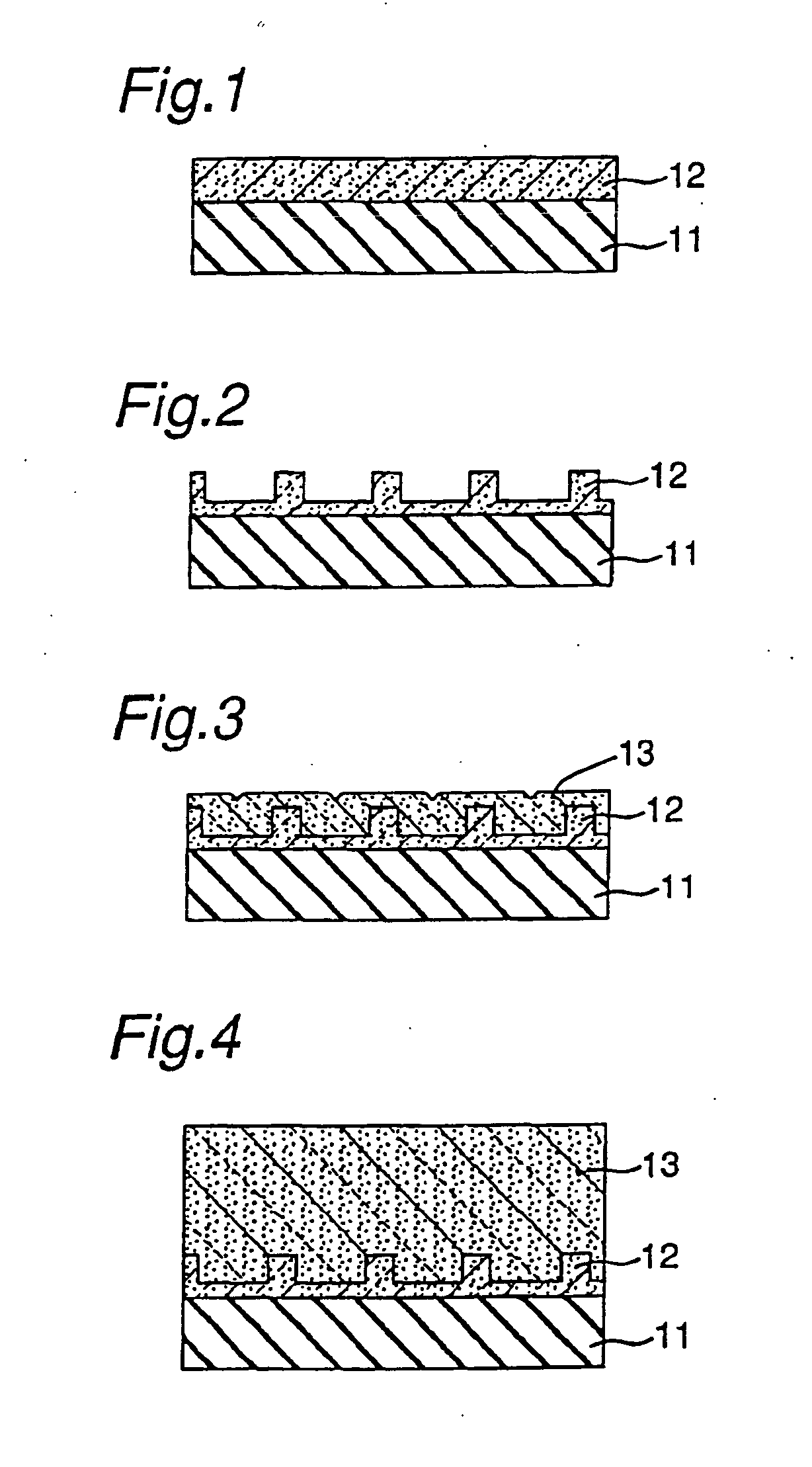

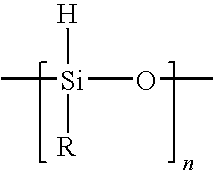

Siloxane polymerization in wallboard

ActiveUS20090239087A1Small expansionDimensional stabilitySolid waste managementLaminationSlurryWater resistant

Owner:UNITED STATES GYPSUM CO

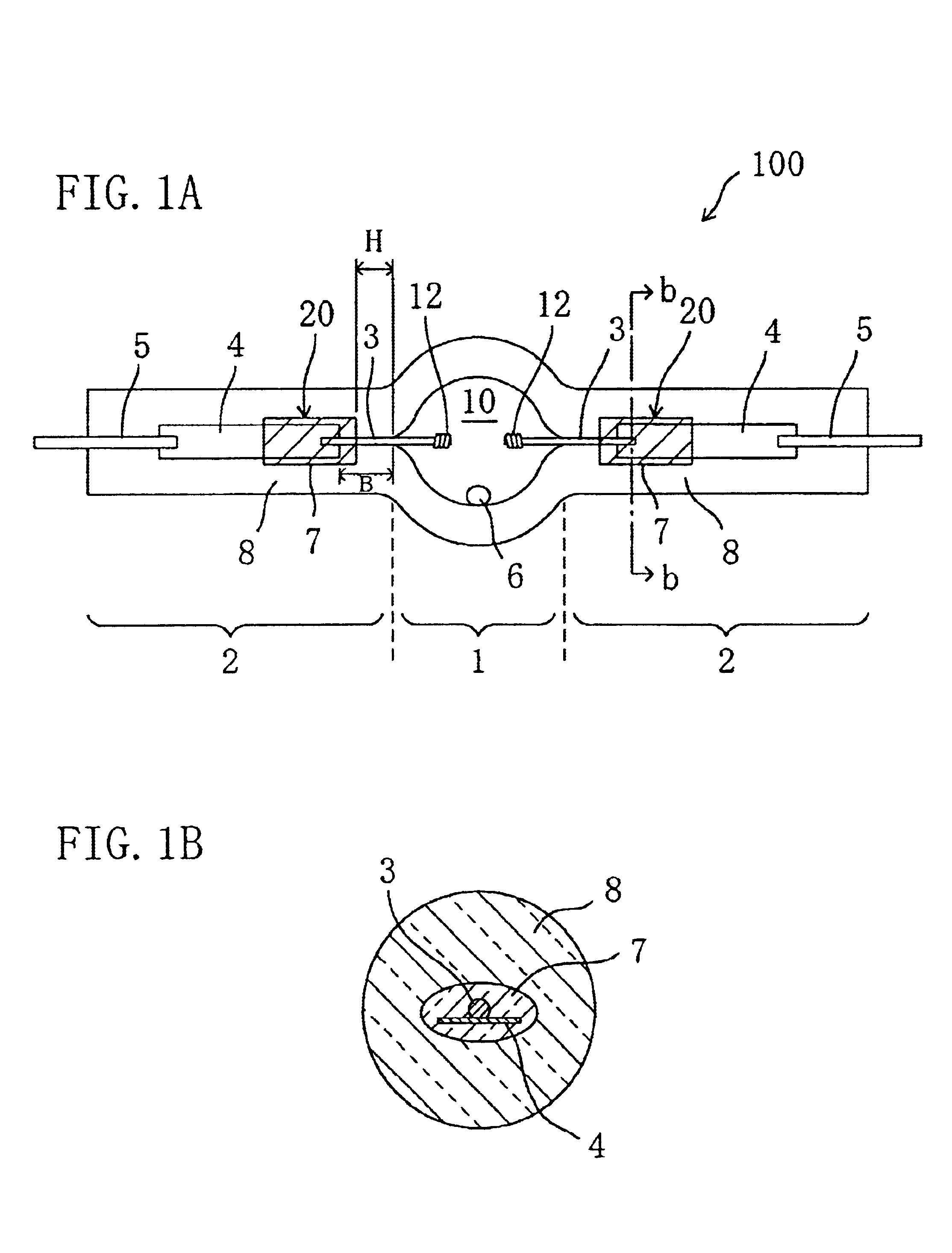

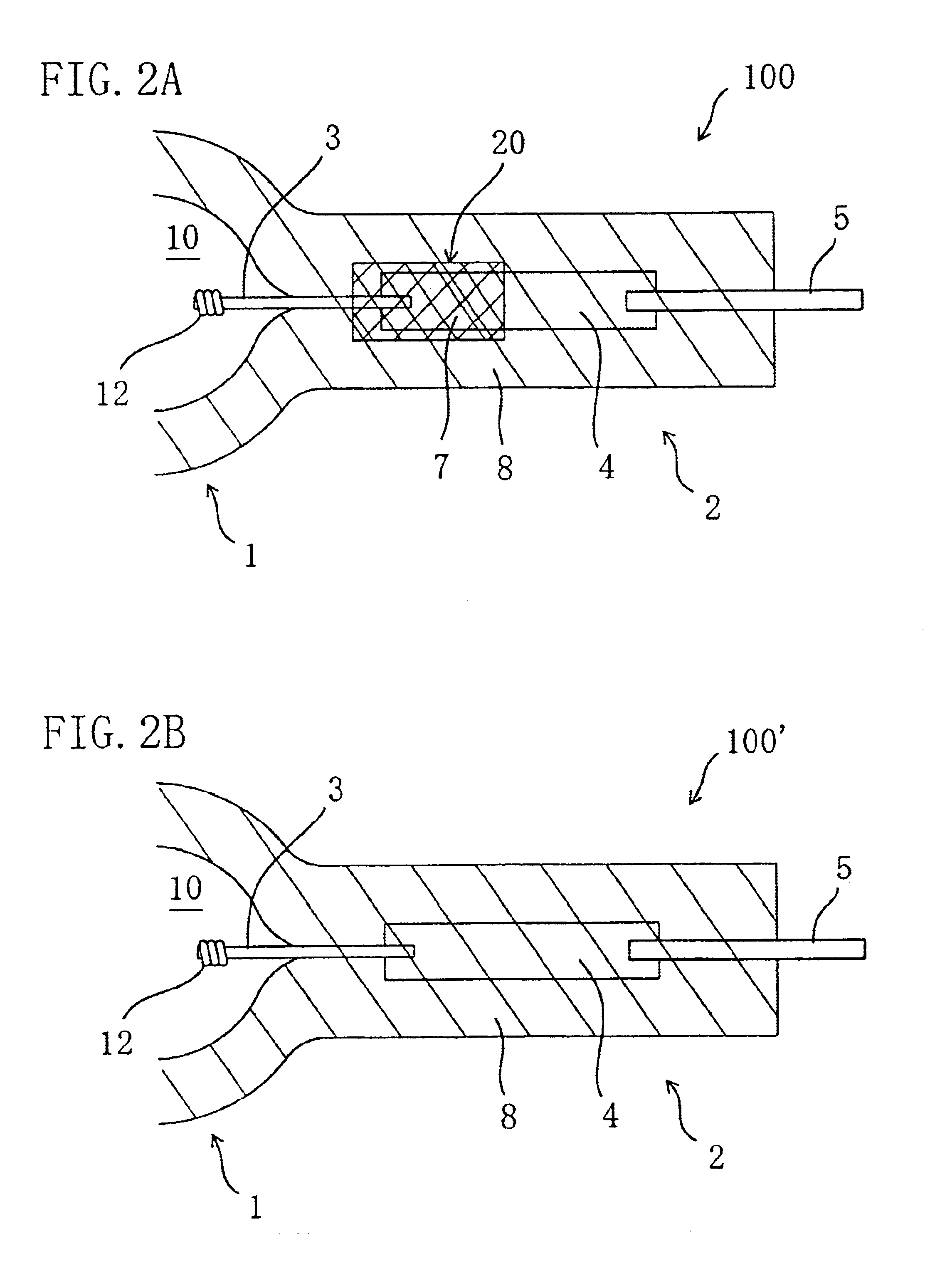

High pressure discharge lamp and lamp unit

InactiveUS6965202B2High compressive strengthEasy to separateElectroluminescent light sourcesSolid cathode detailsEngineeringHigh pressure

A high pressure discharge lamp includes a luminous bulb enclosing a luminous substance therein; and a sealing portion for retaining airtightness of the luminous bulb. The sealing portion has a first glass portion extending from the luminous bulb and a second glass portion provided at least in a portion inside the first glass portion, and the sealing portion has a portion to which a compressive stress is applied.

Owner:PANASONIC CORP

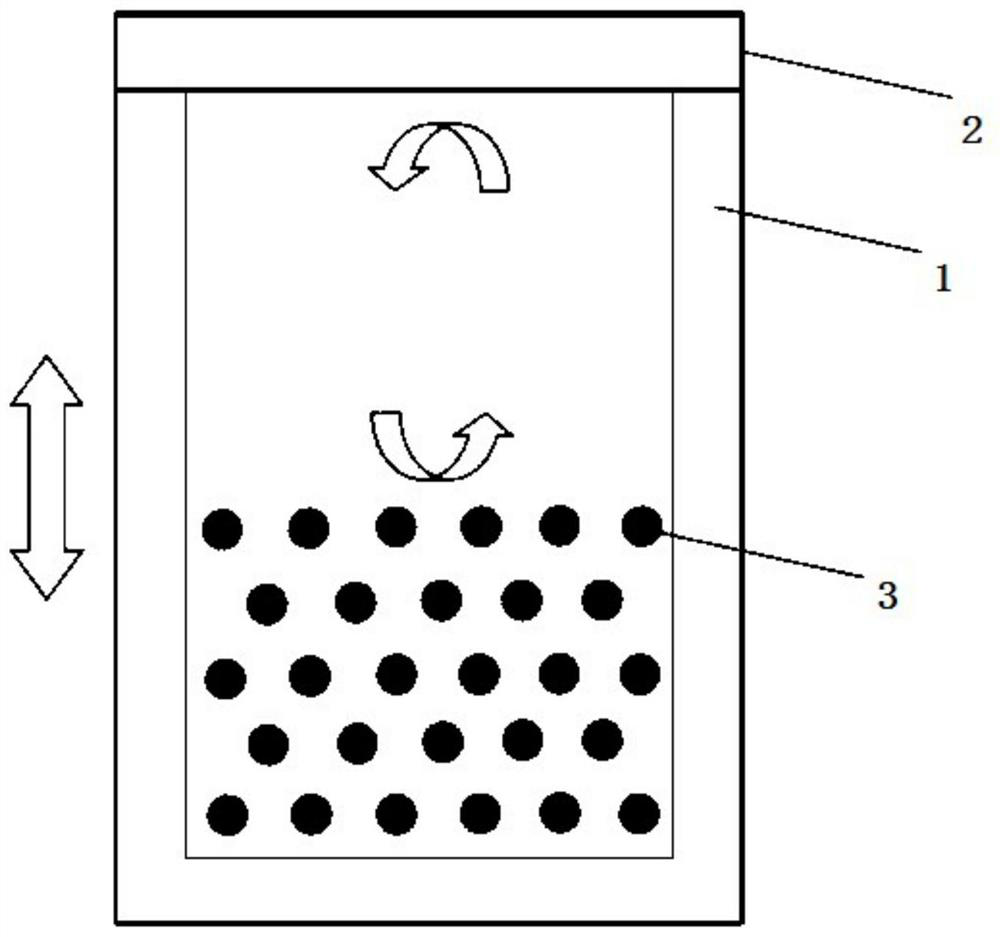

Preparation method of nano gradient magnesium alloy

InactiveCN113373329AAvoid extensive crackingObtaining a grain-refined structureUltimate tensile strengthContinuous casting

The invention relates to a preparation method of a nano gradient magnesium alloy, and belongs to the technical field of high-strength magnesium alloy preparation. The method comprises the steps of: carrying out homogenization treatment on a semi-continuous casting blank and then extruding the semi-continuous casting blank into a bar, wherein the extrusion temperature ranges from 430 DEG C to 480 DEG C, the extrusion ratio ranges from 13:1 to 16:1; and firstly, carrying out peak aging treatment on an extruded alloy, carrying out heat preservation for 16-20 h at the temperature of 225 DEG C, and then carrying out surface mechanical grinding treatment SMAT at the room temperature to prepare a disc-shaped nano gradient magnesium alloy plate with the thickness ranging from 2.5 mm to 5 mm and the diameter of 49 mm, wherein the total grinding time ranges from 60 min to 120 min. According to the preparation method, the alloy strength is effectively improved, and good strength and plasticity combination is obtained.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

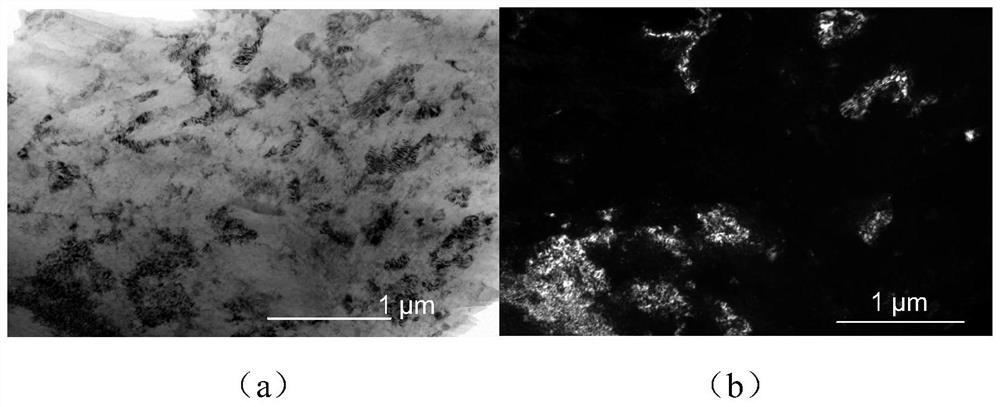

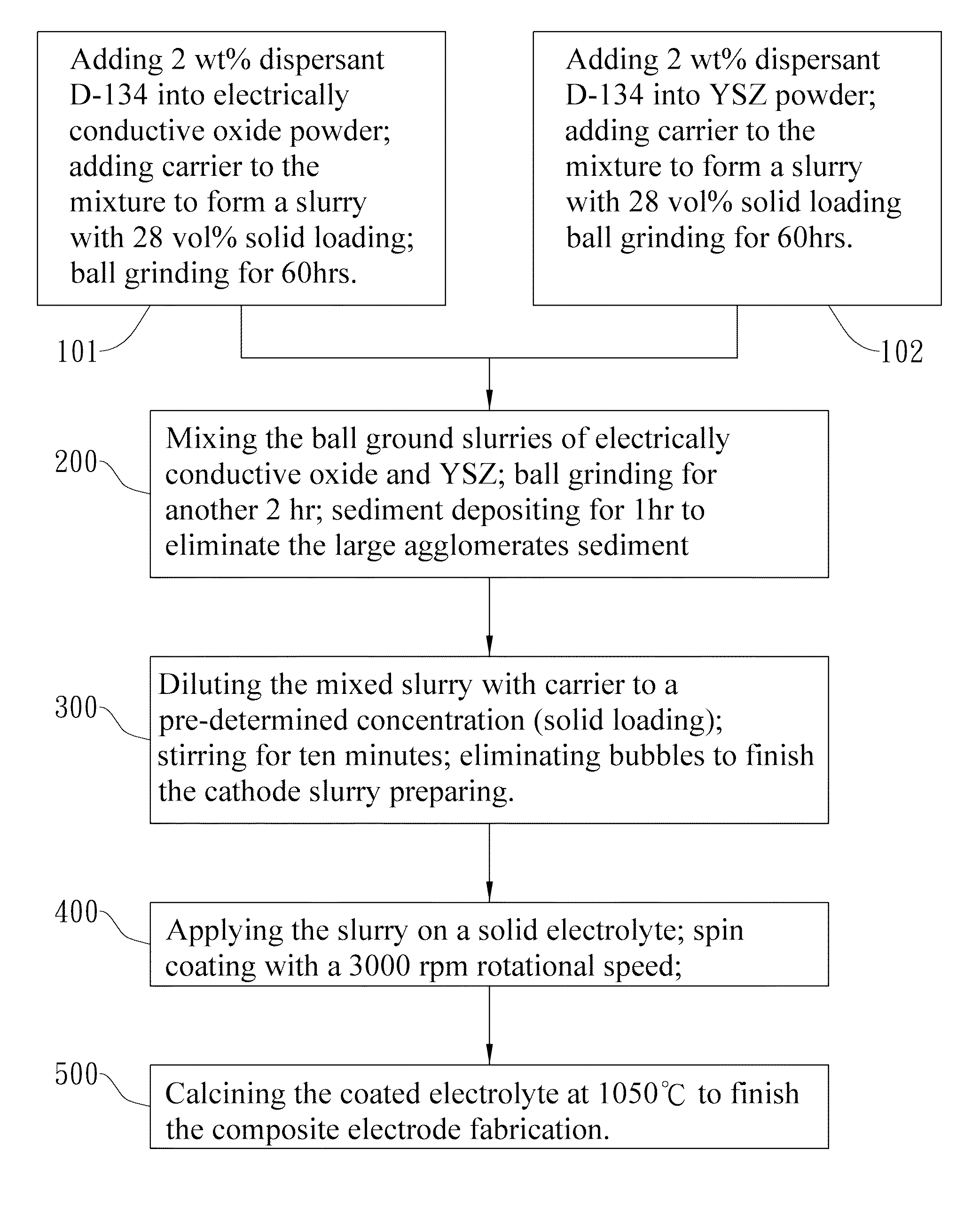

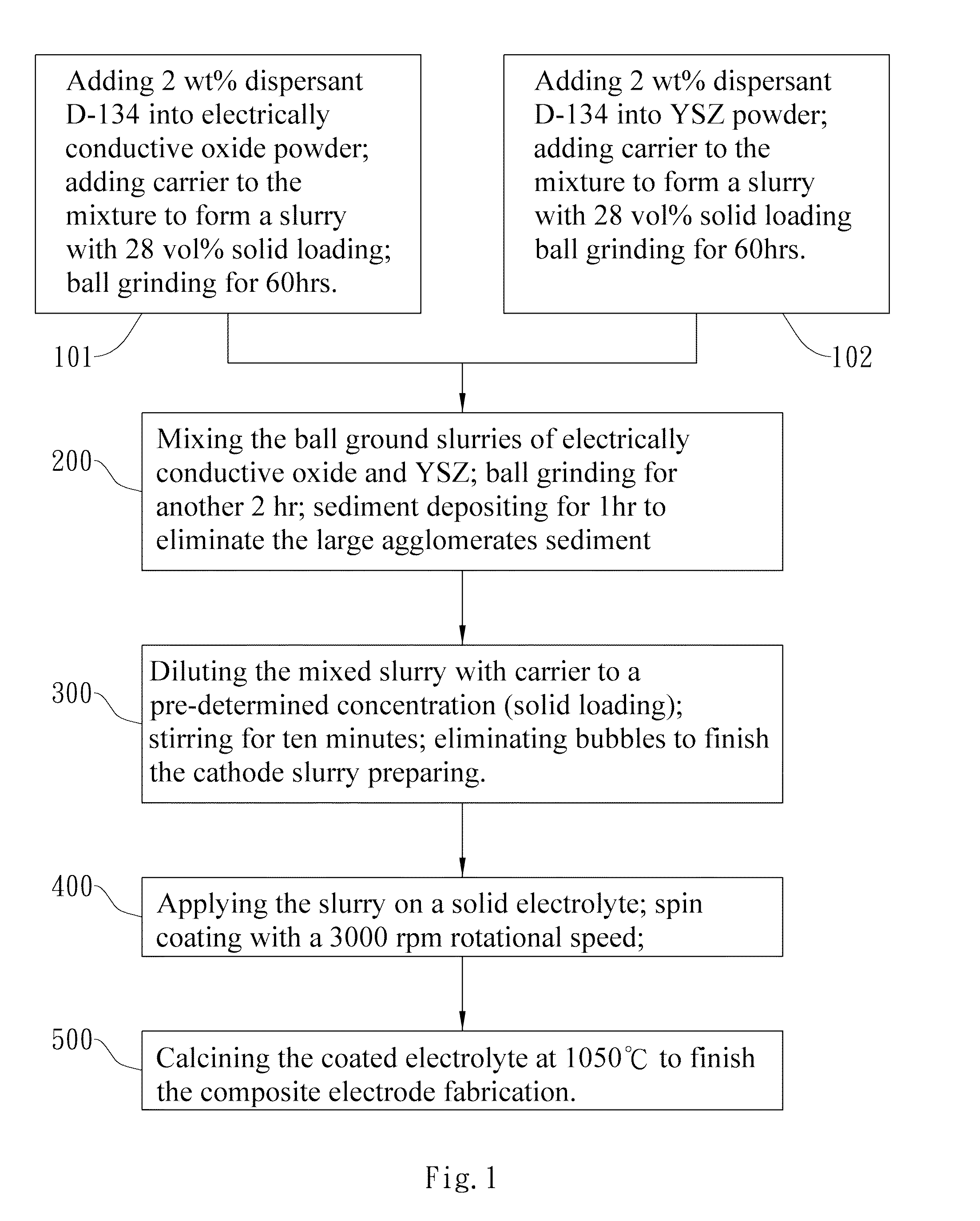

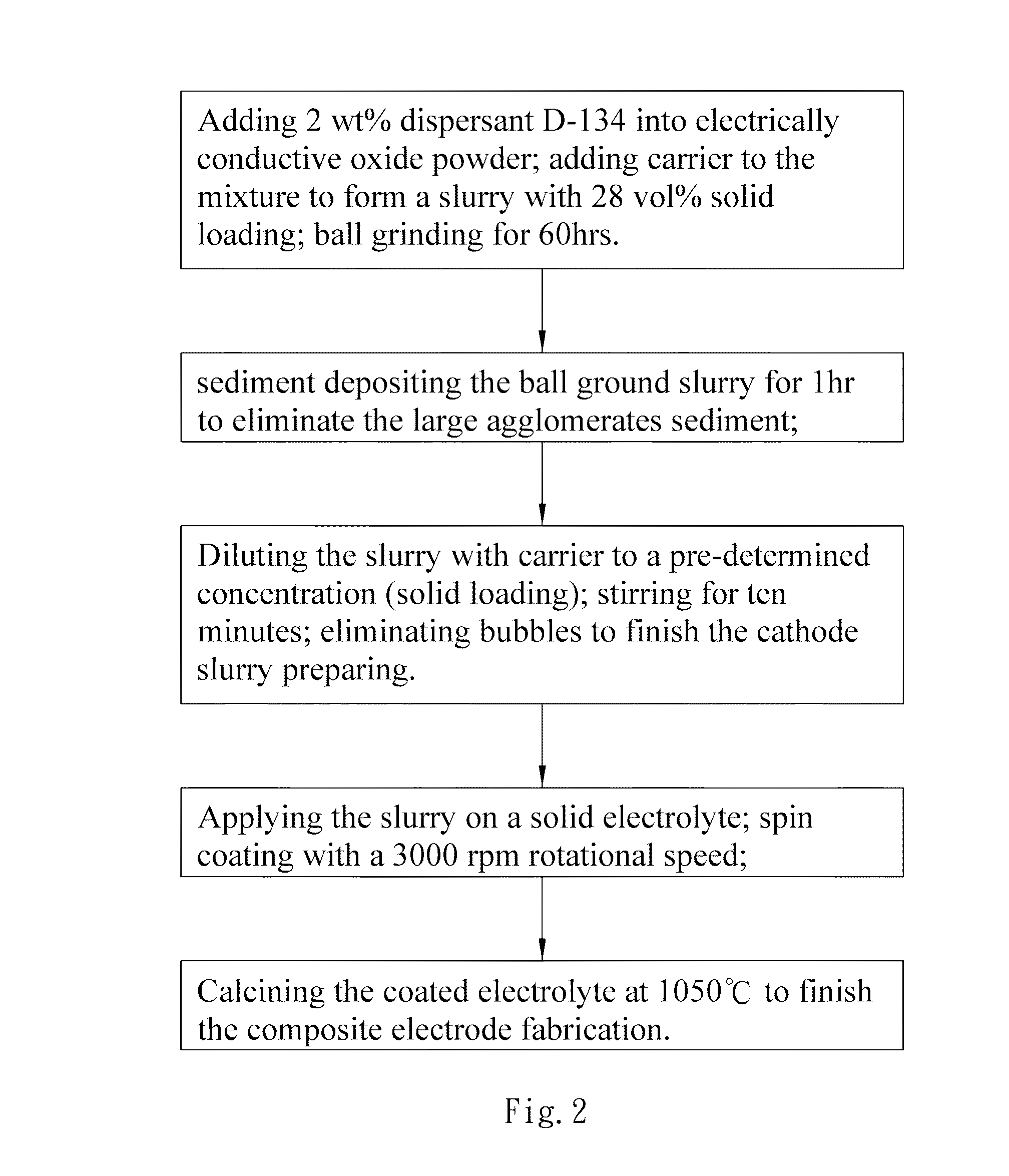

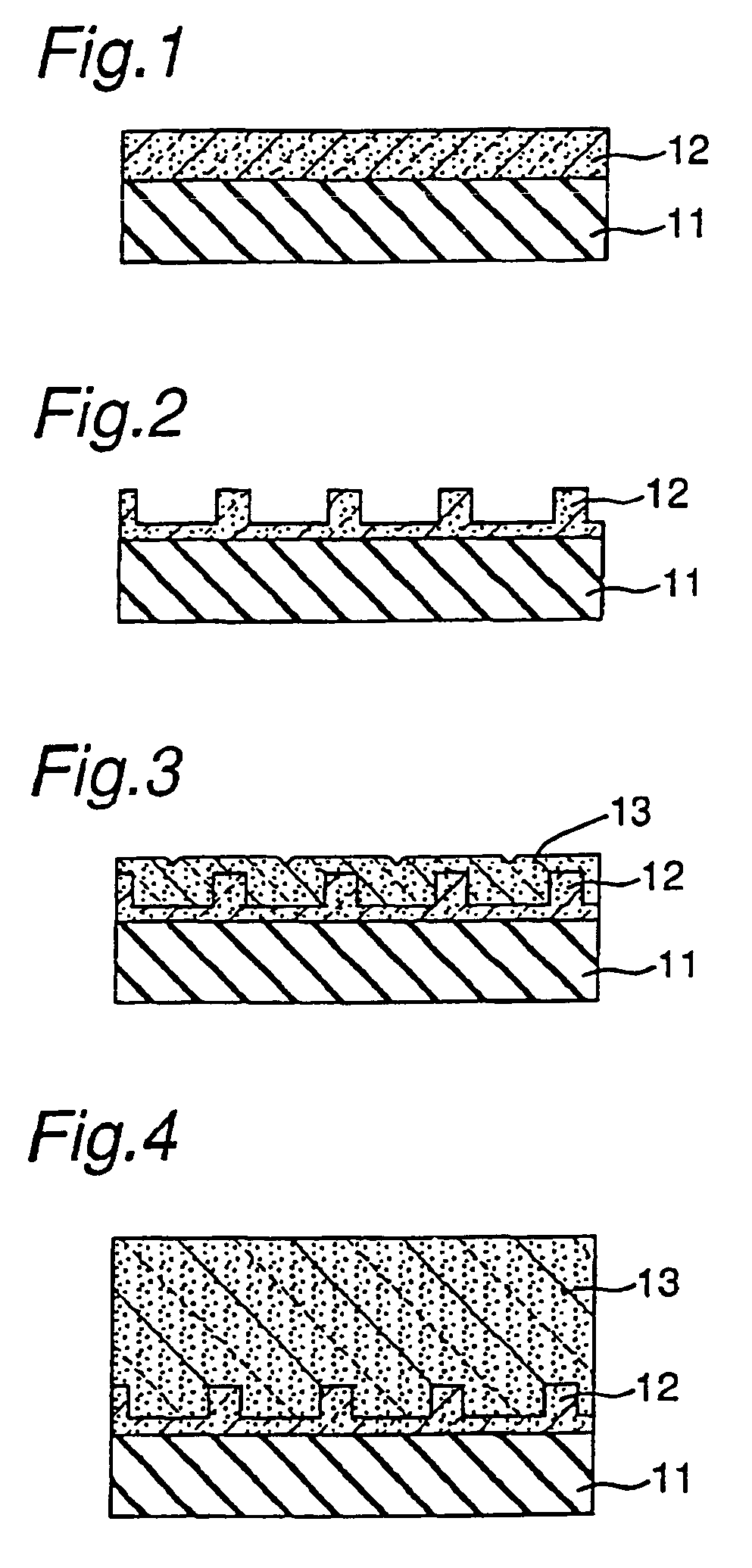

Porous oxide electrode layer and method for manufacturing the same

InactiveUS20140113213A1Reduce crackingImprove conductivityCell electrodesSolid electrolyte fuel cellsPorous substrateSlurry

This invention provides a method for manufacturing porous oxide electrode layer, comprising: preparing an electrode slurry containing an electrically conductive oxide material powder, a dispersant, water and a moisture agent; spin coating the electrode slurry on a surface of a thin electrolyte or a porous substrate and simultaneously controlling the thickness and uniformity of the electrode layer on the fine electrolyte or the porous substrate; and calcining the electrode layer on the fine electrolyte or the porous substrate to form a porous electrode.

Owner:NAT TAIWAN UNIV

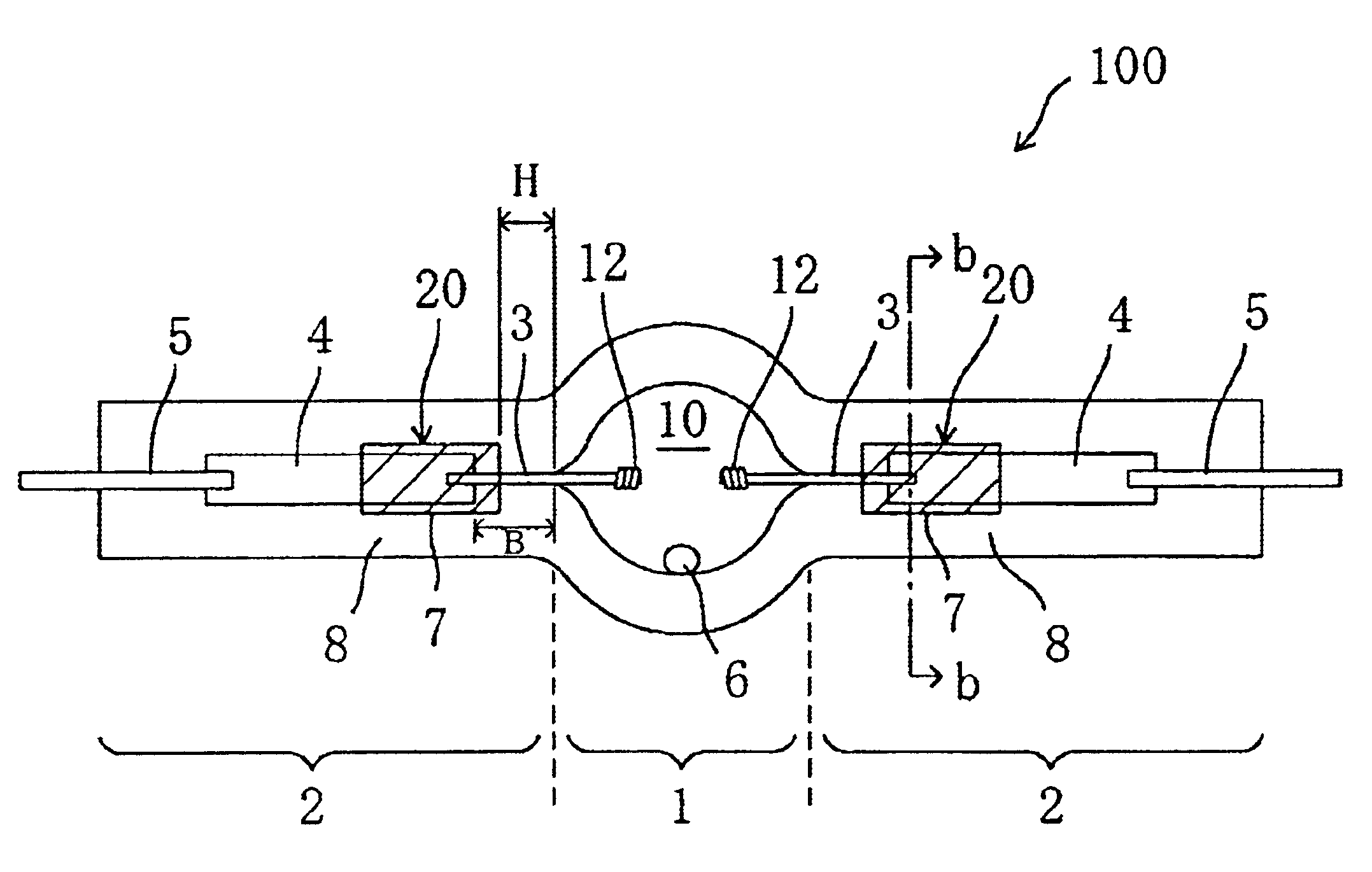

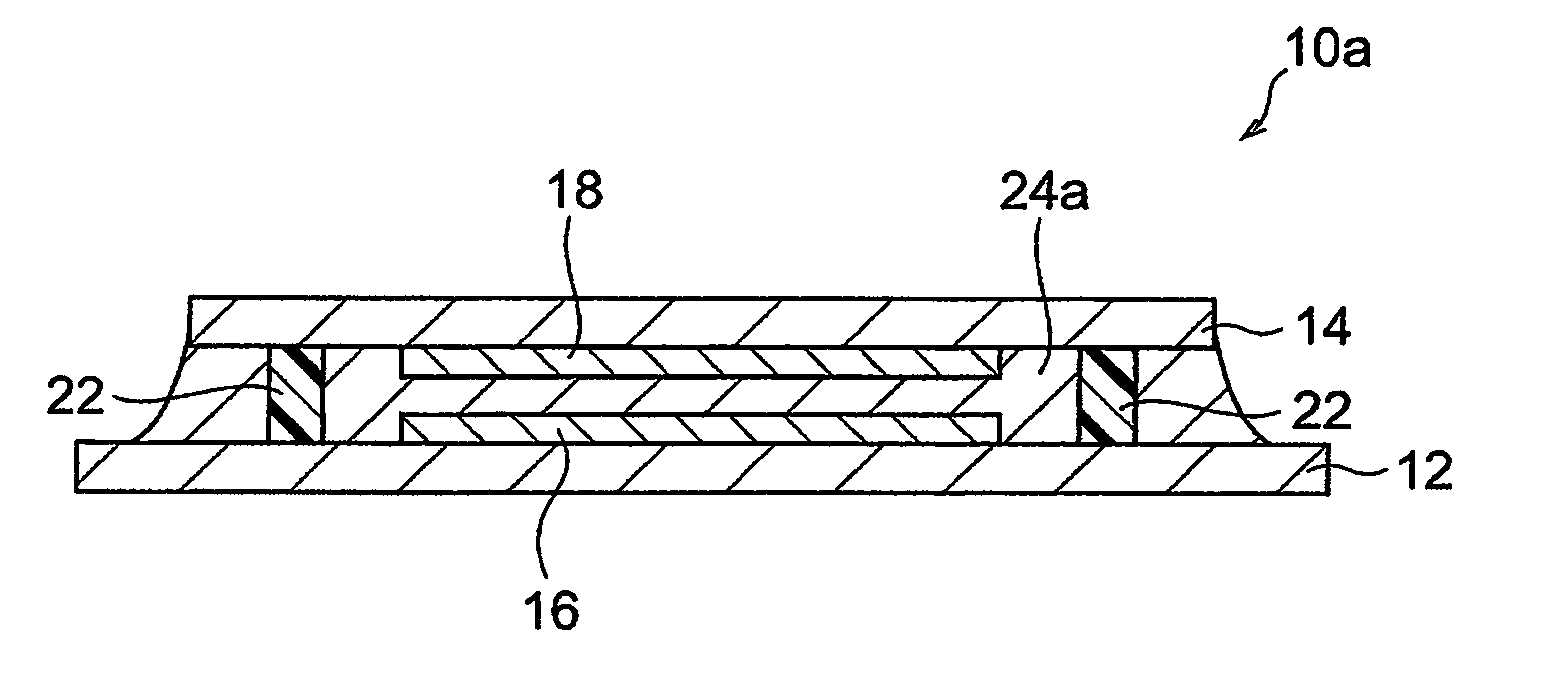

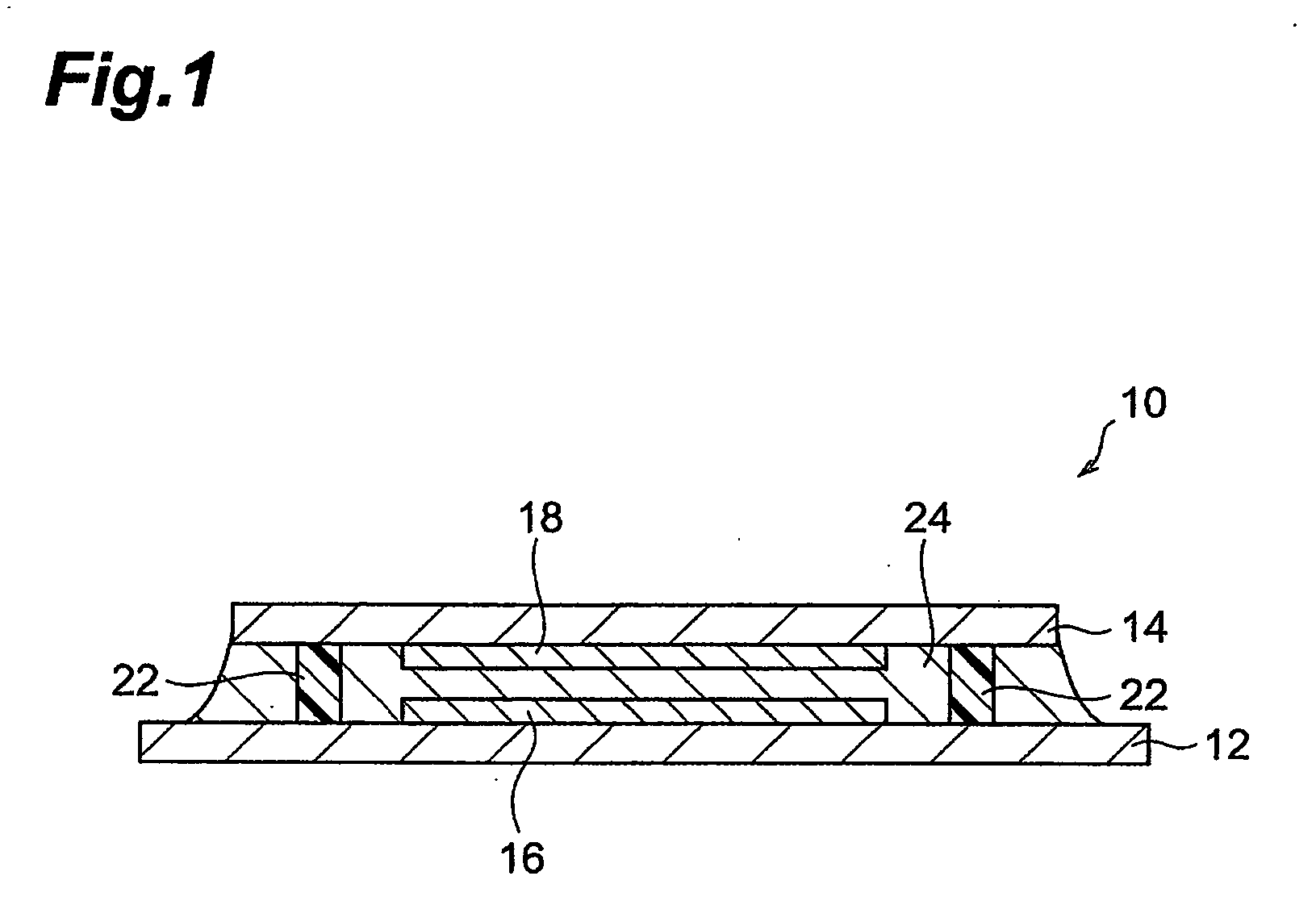

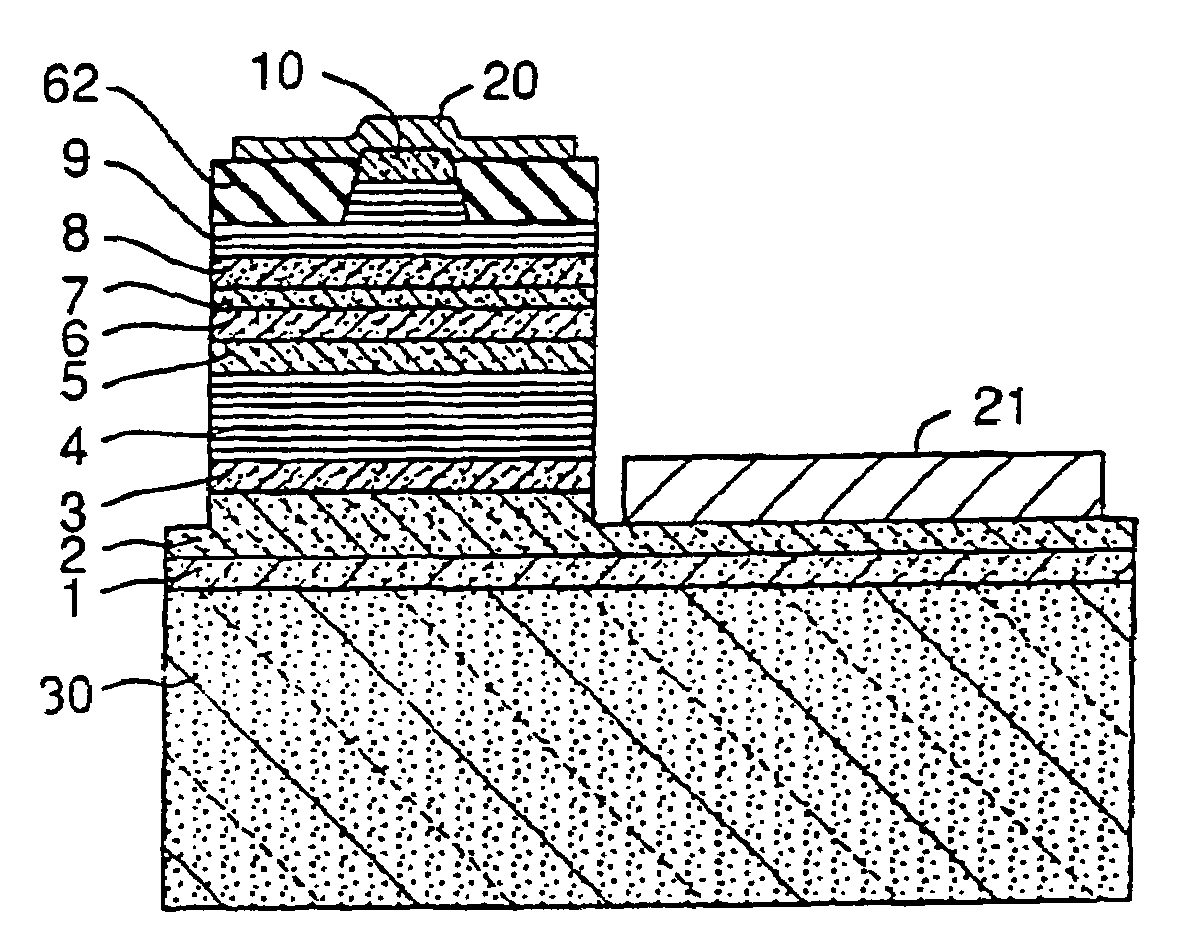

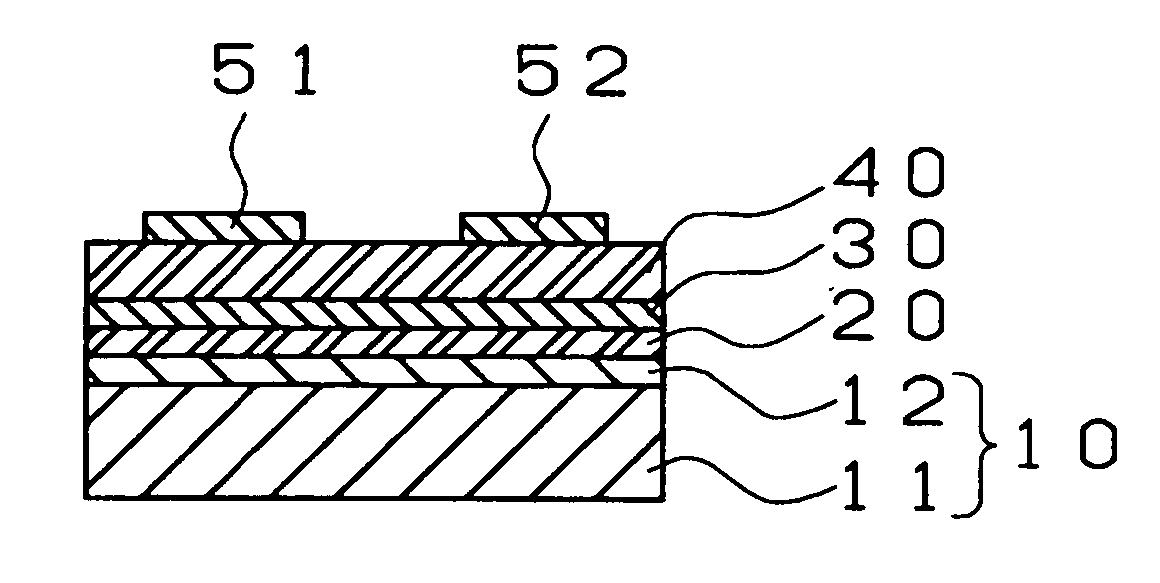

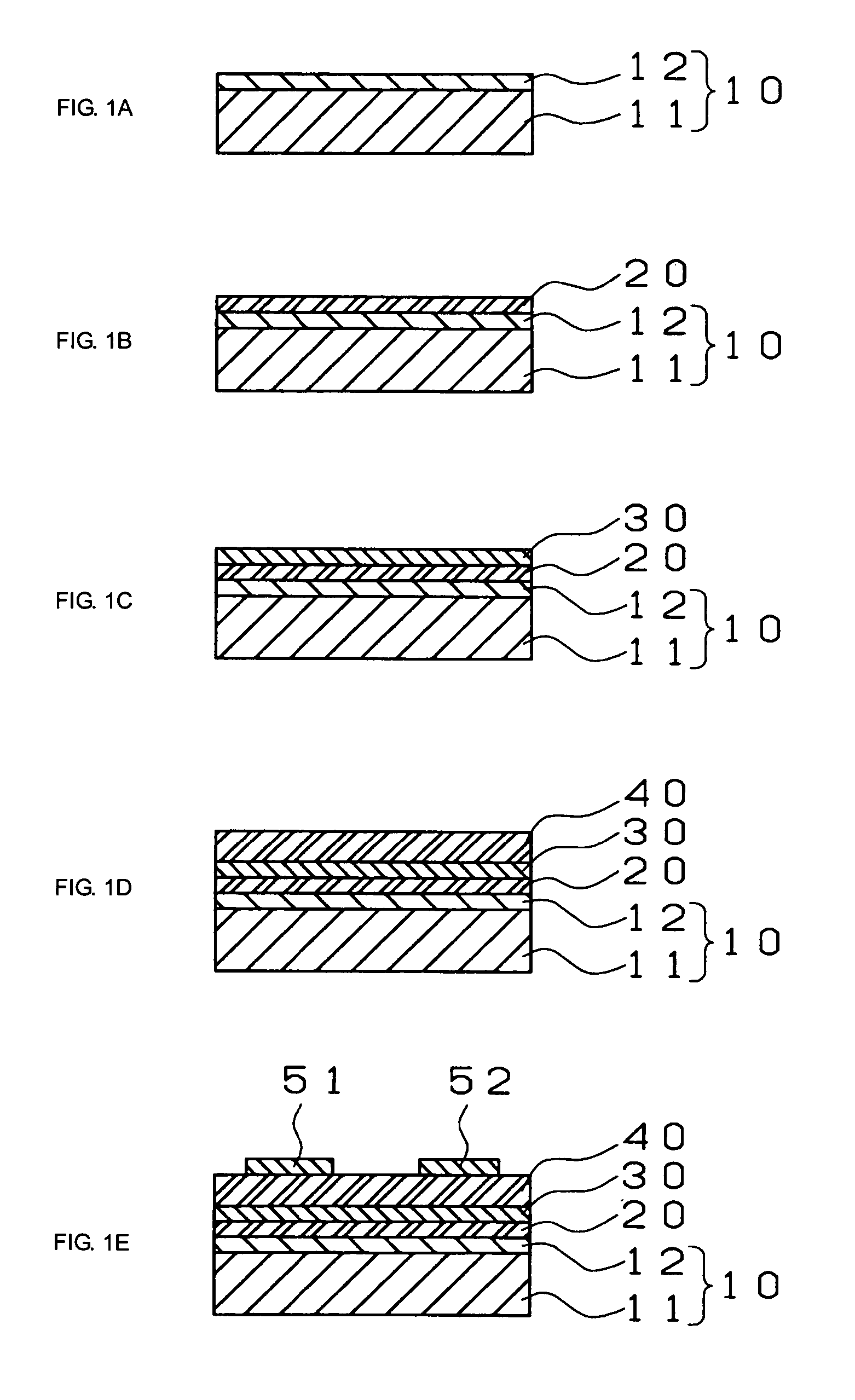

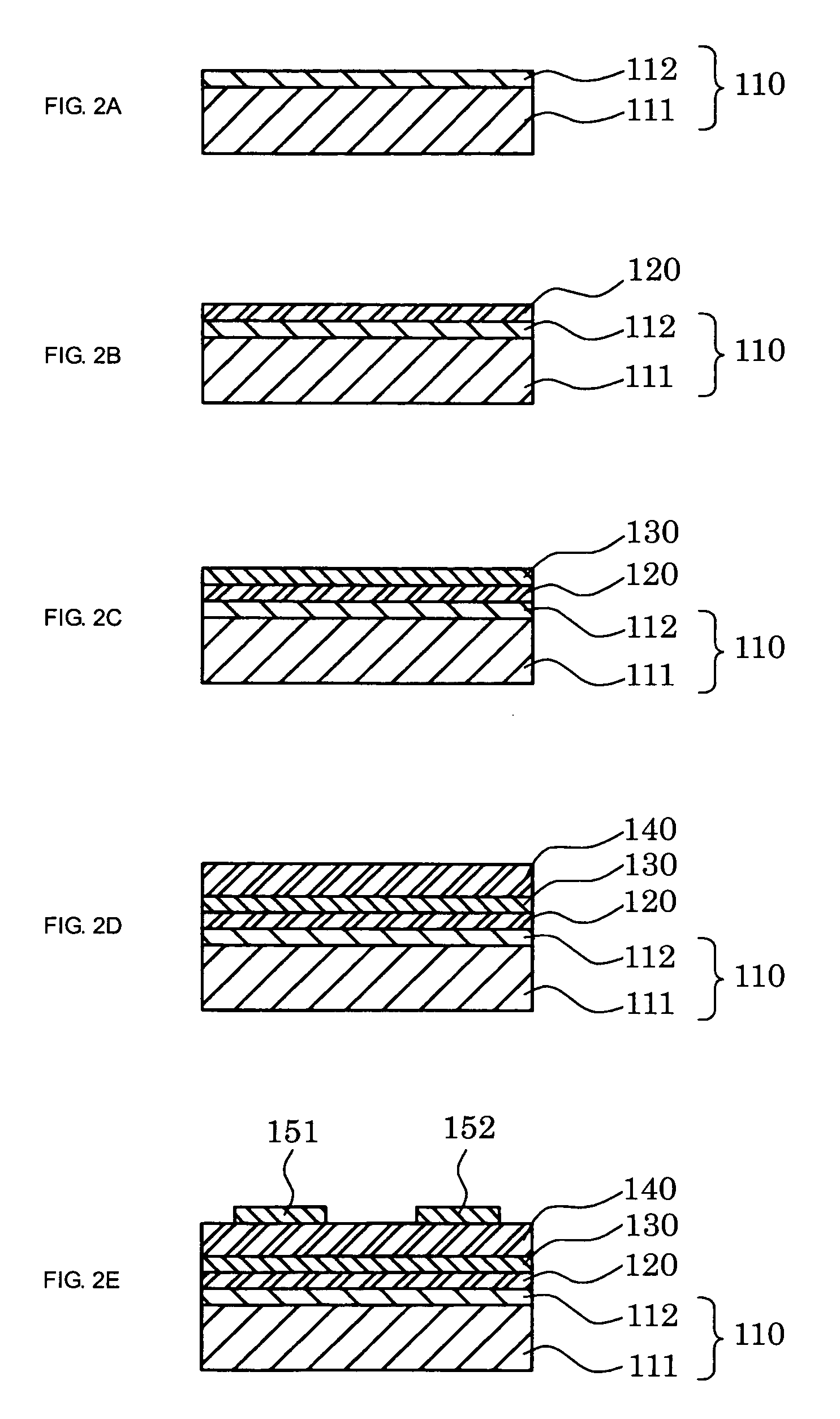

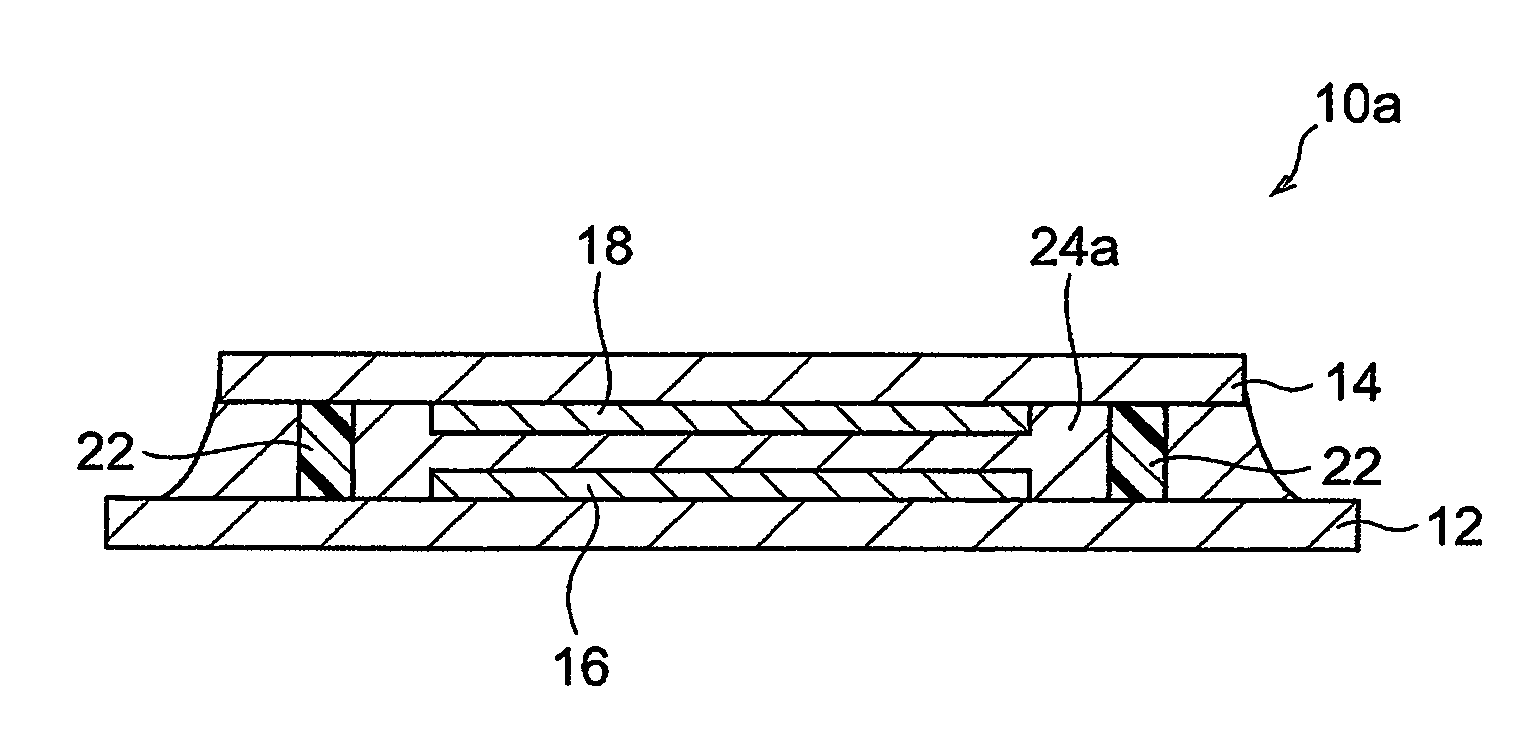

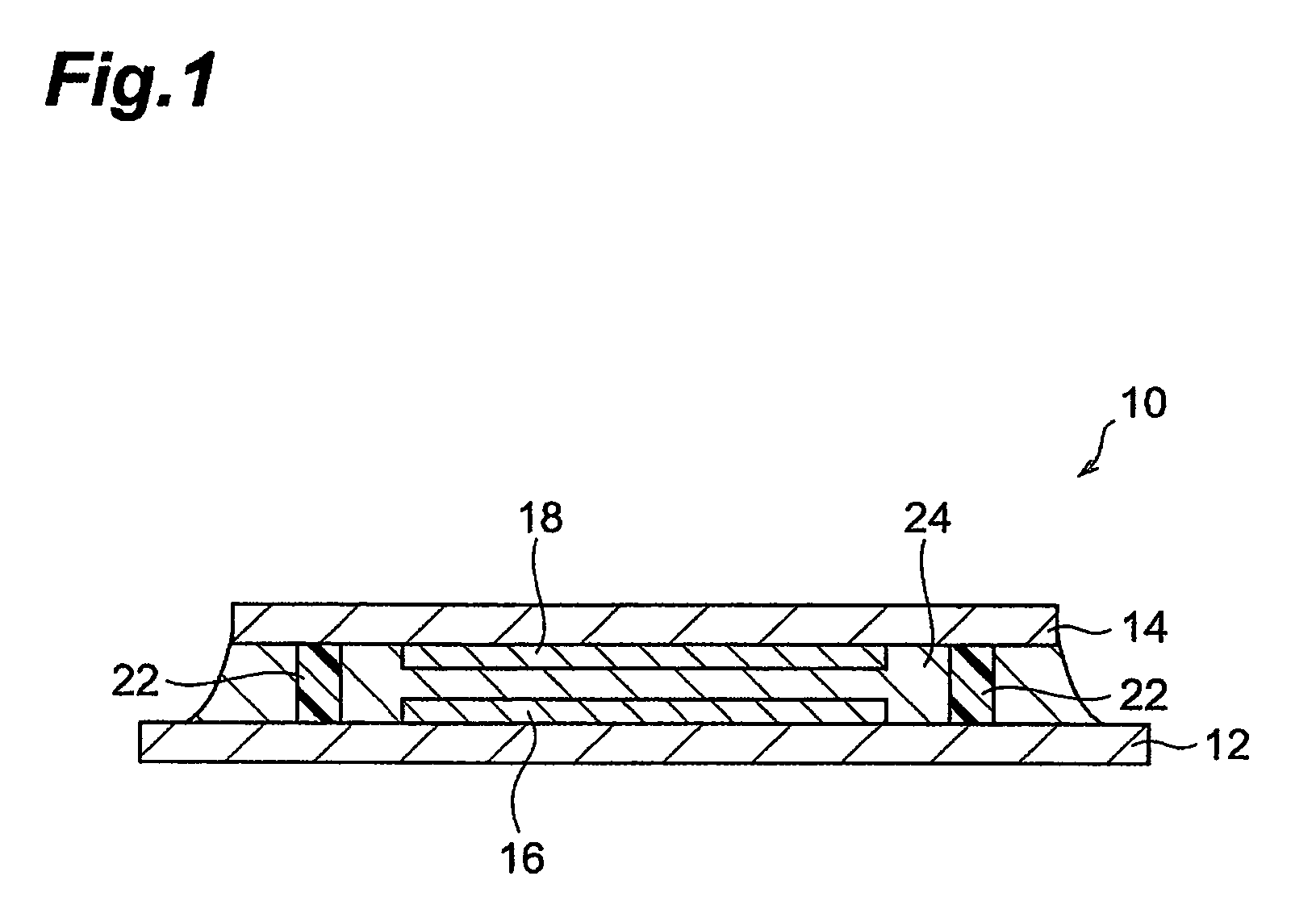

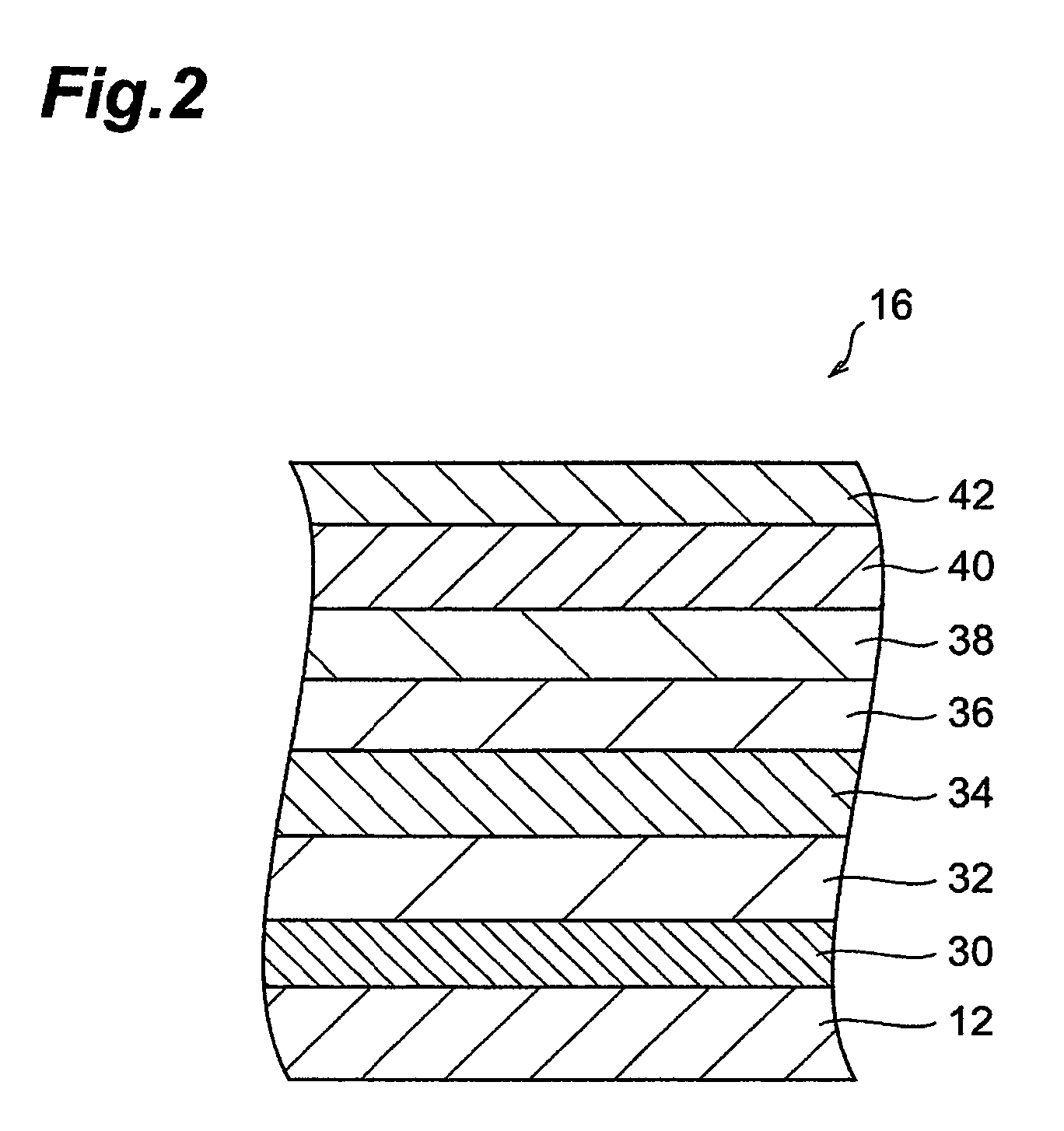

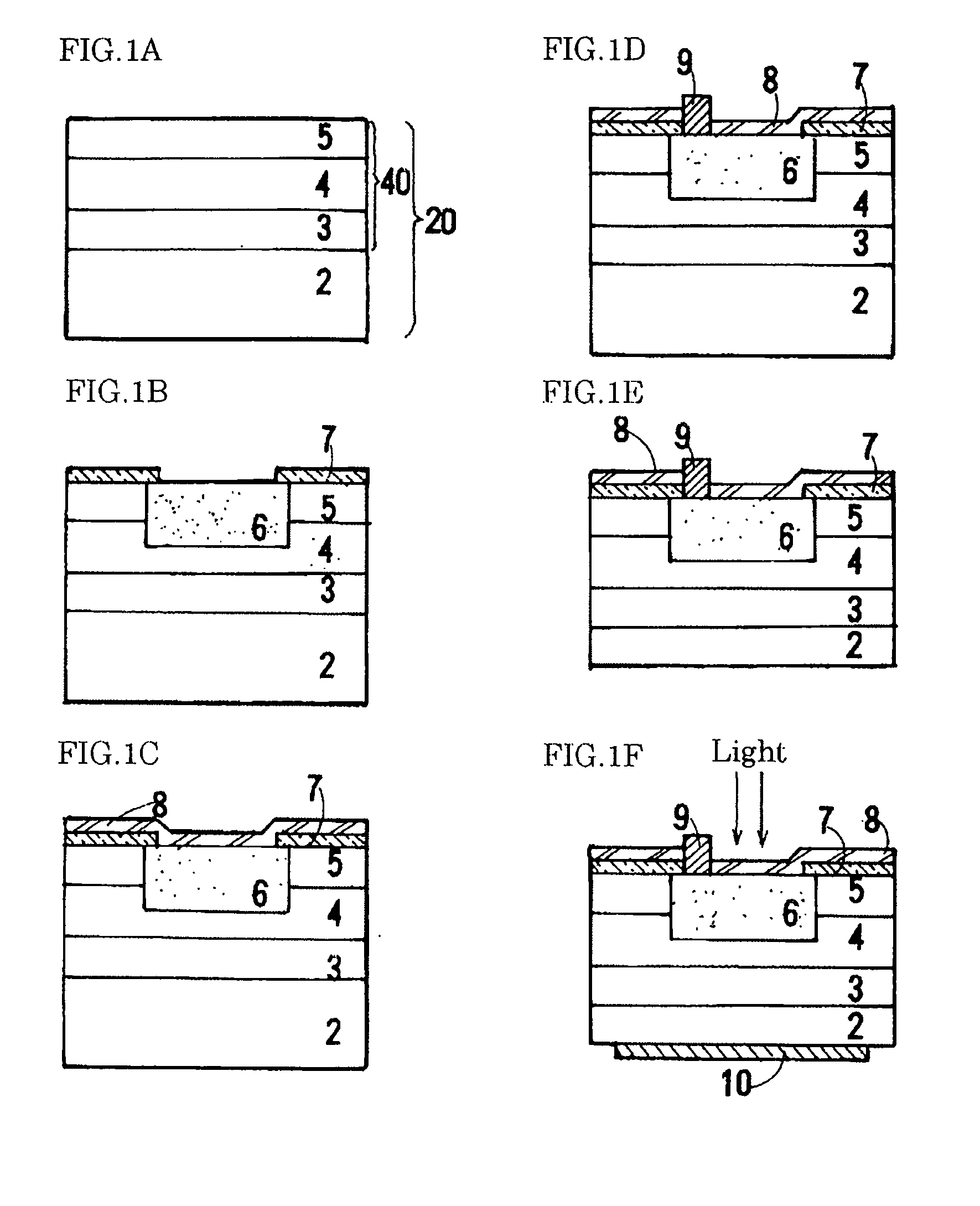

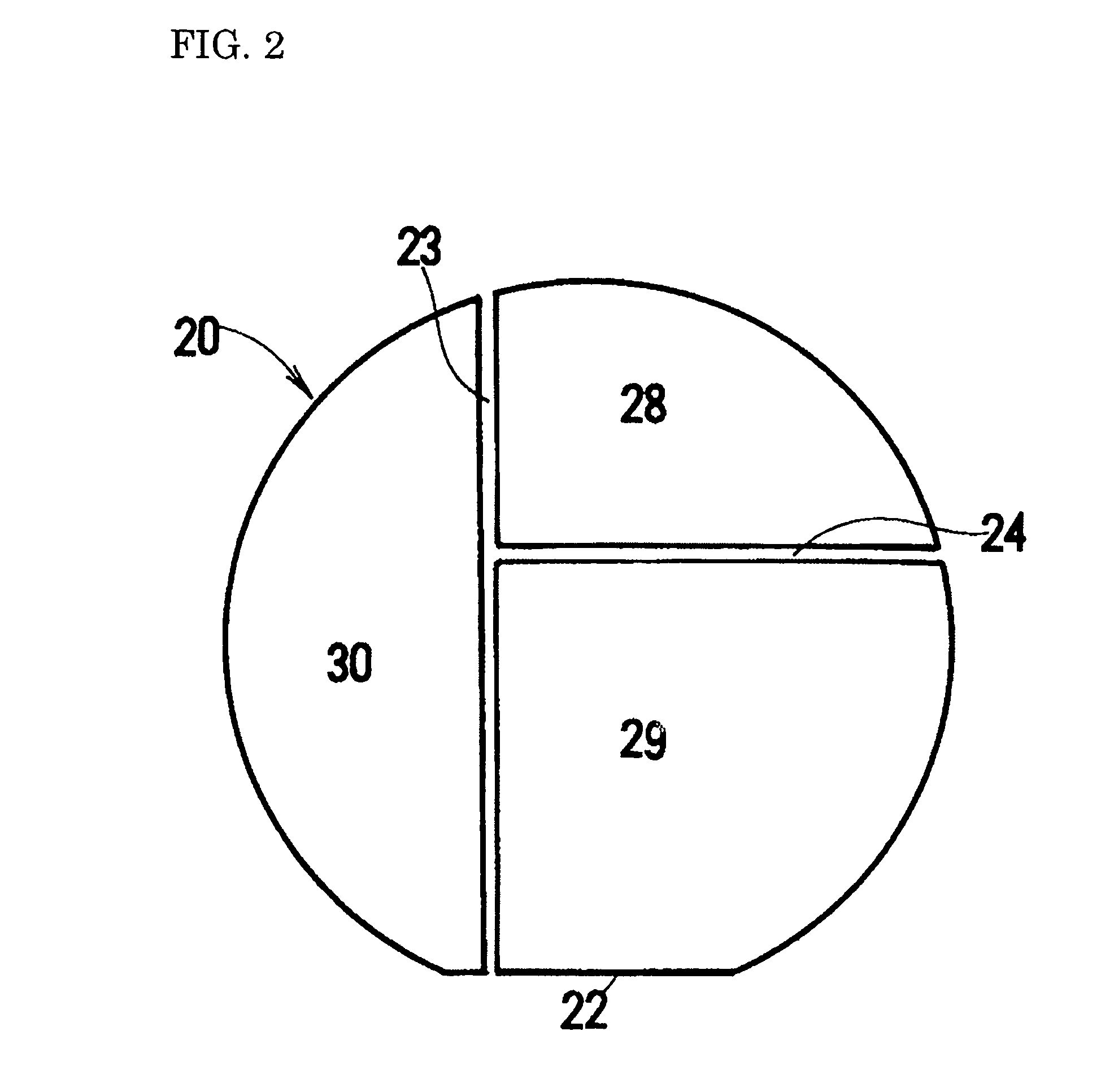

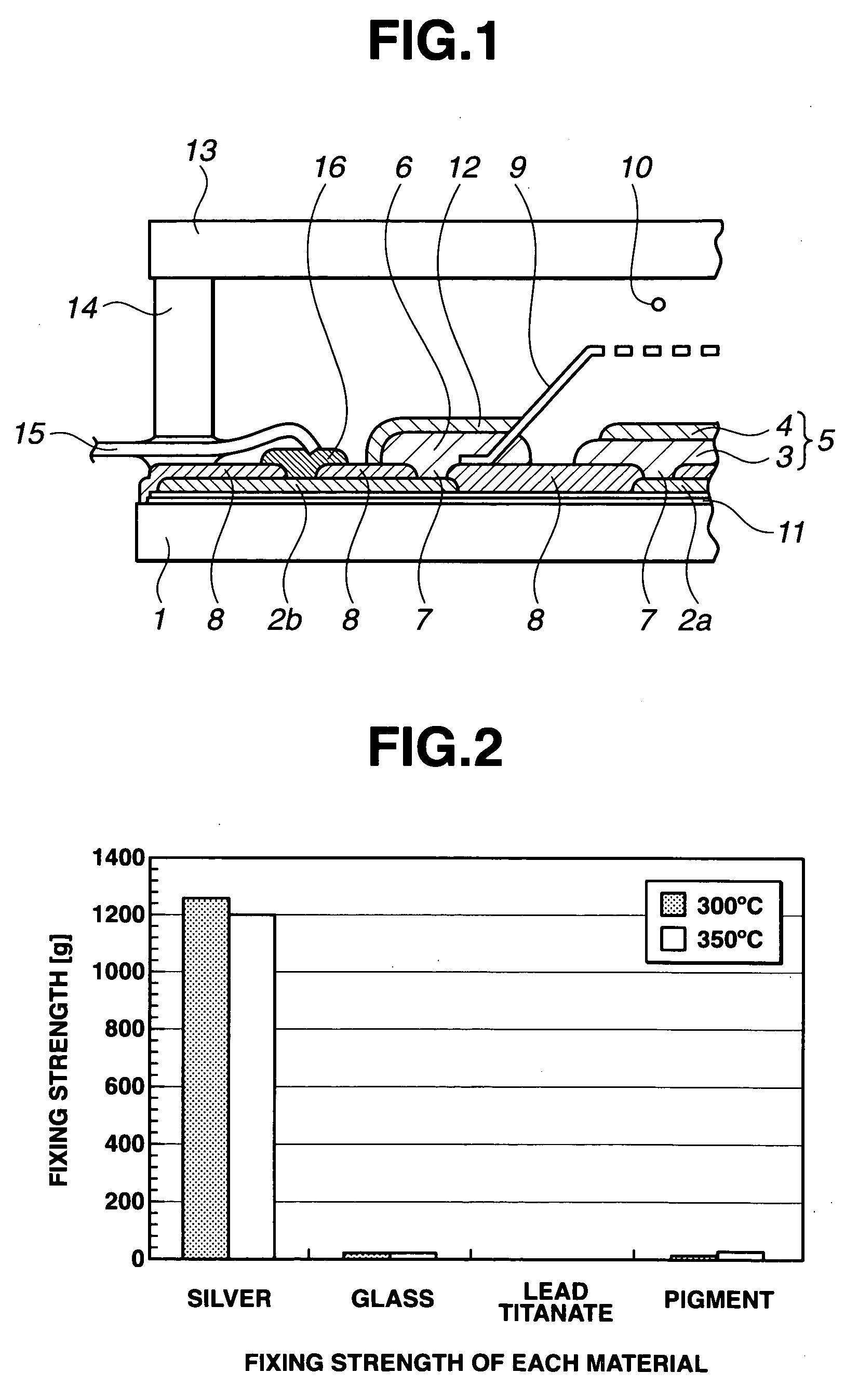

Method of manufacturing EL panel

InactiveUS20060178073A1Low volume rateAvoid high pressureElectroluminescent light sourcesSolid-state devicesEngineeringSurface plate

The preferable method of manufacturing the EL panel comprises a panel precursor formation step of forming a panel precursor comprising a substrate, a sealing plate disposed facing the substrate, an EL device (EL device portion) provided on a surface of the substrate facing the sealing plate, and a sealant comprising a curable adhesive composition filled between the substrate and the sealing plate; a first curing step of irradiating the sealant with light so as to partially cure the curable adhesive composition; and a second curing step of heating the sealant after the irradiation with the light so as to further cure the curable adhesive composition.

Owner:FUTABA CORPORATION

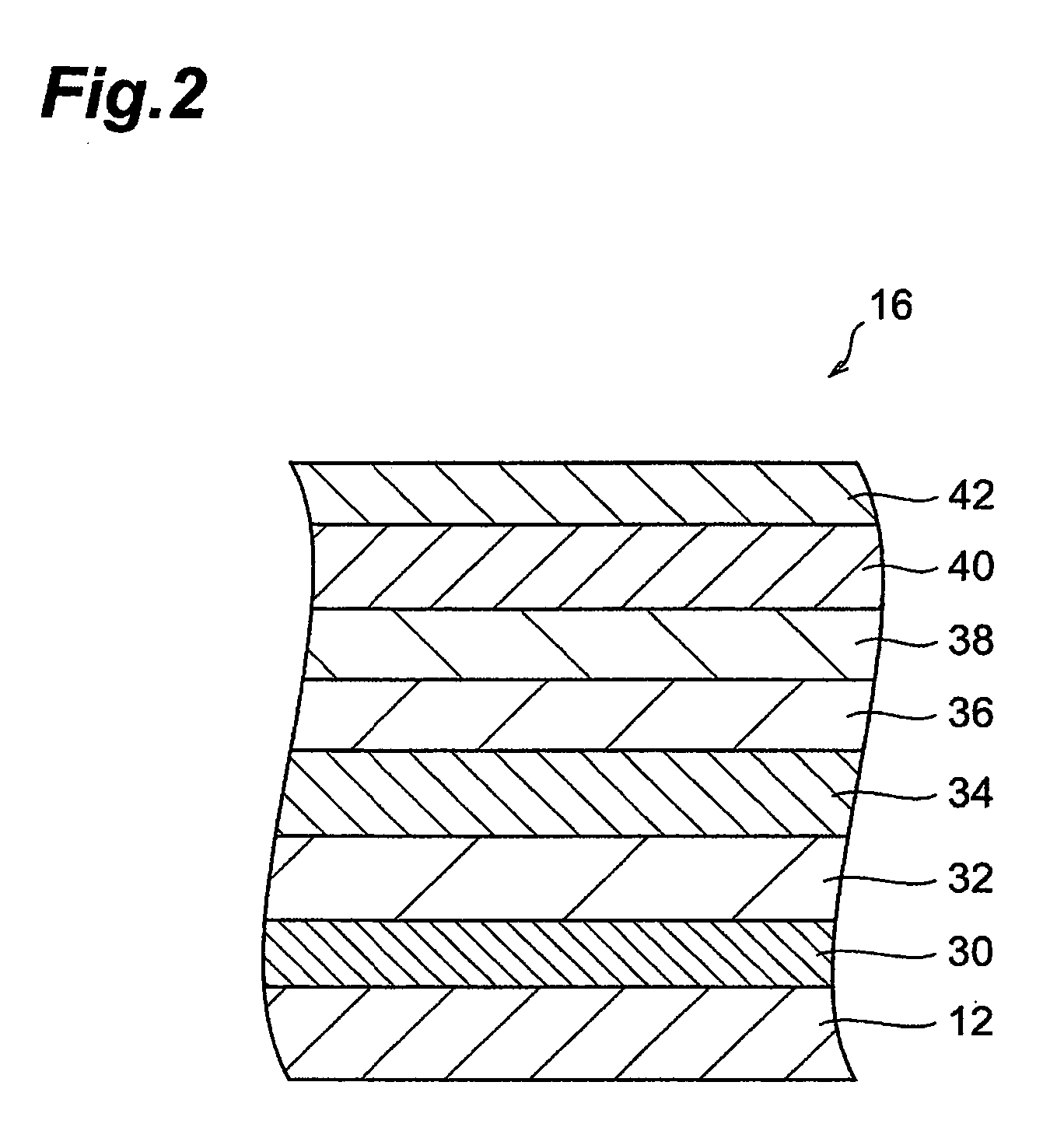

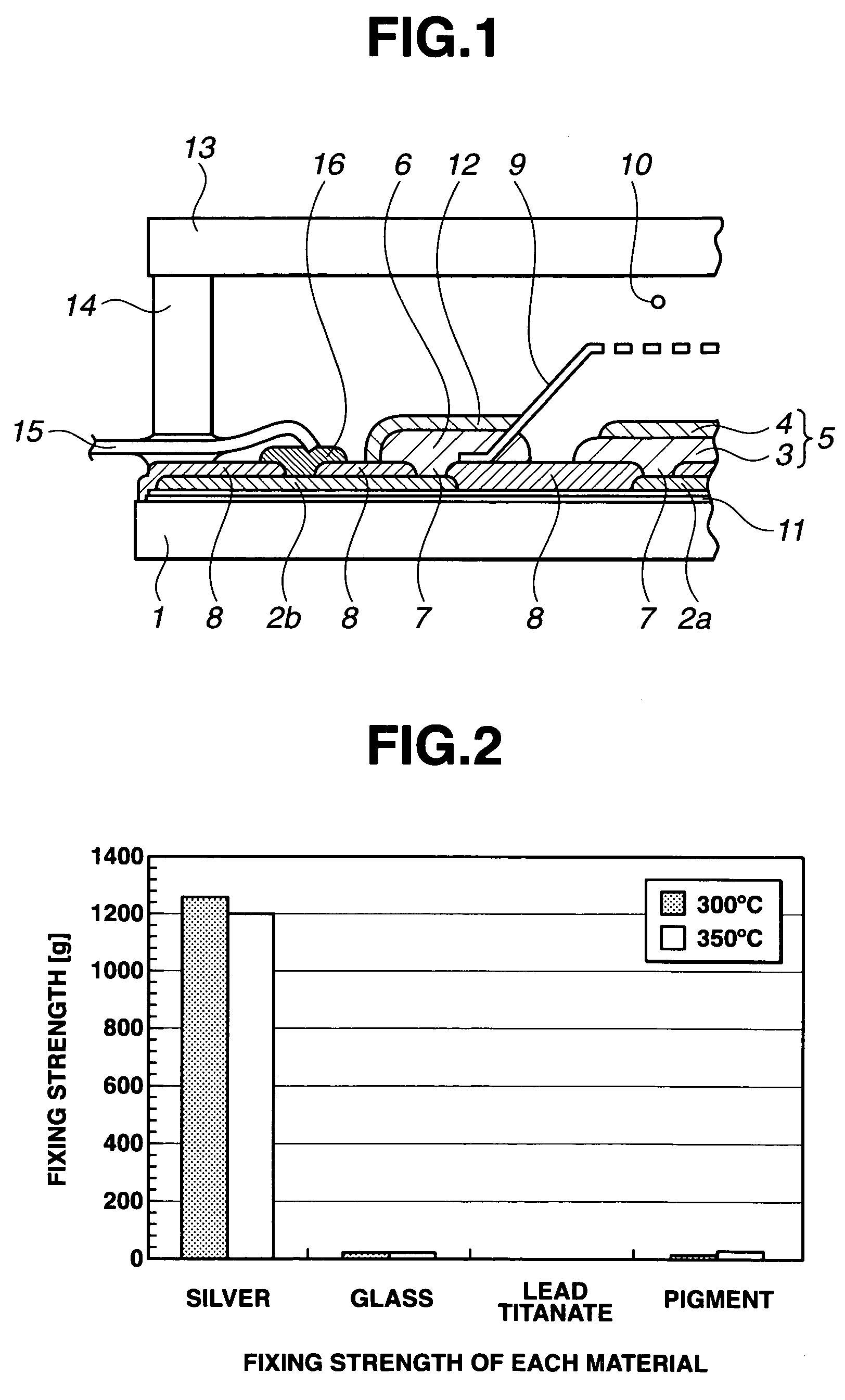

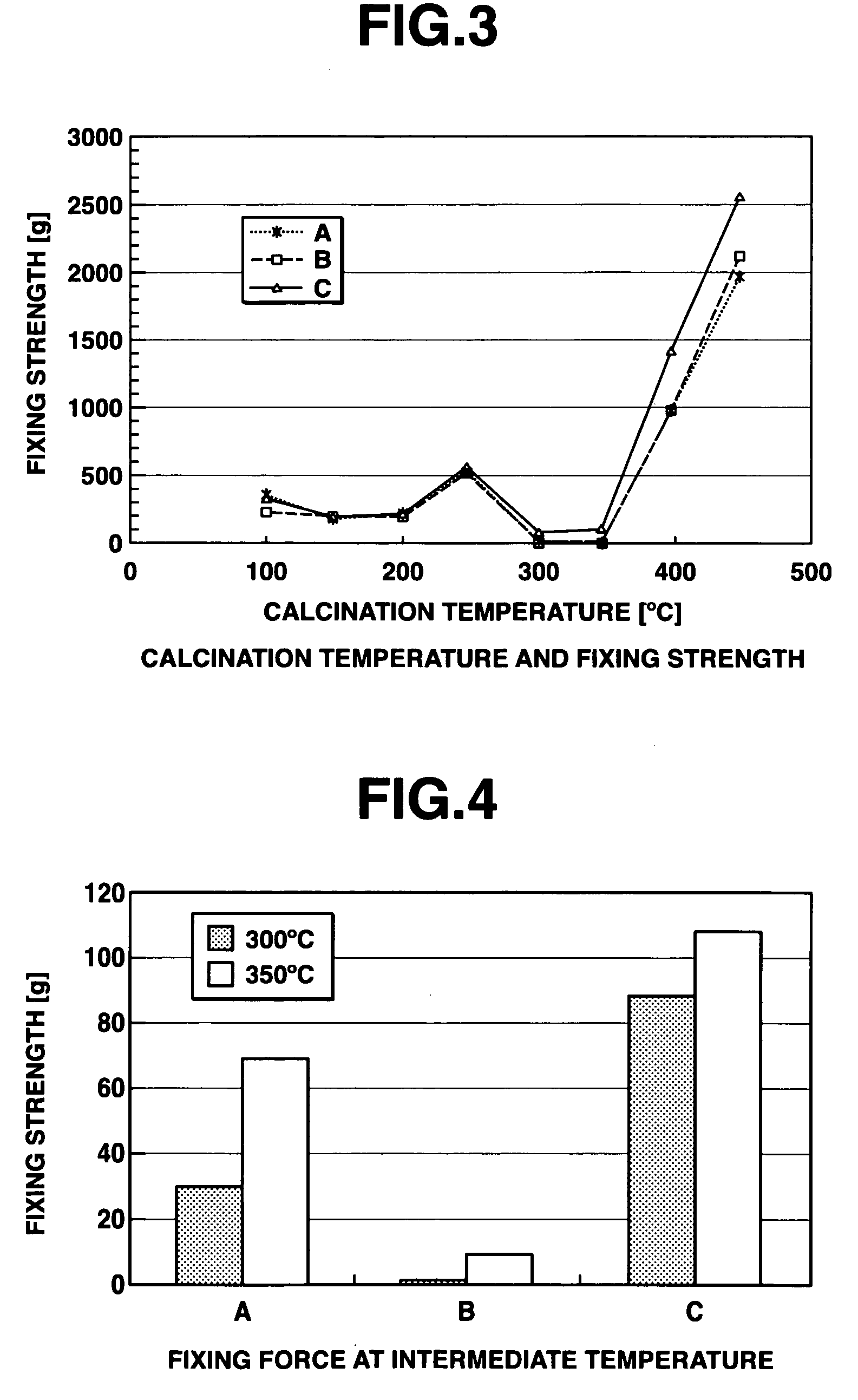

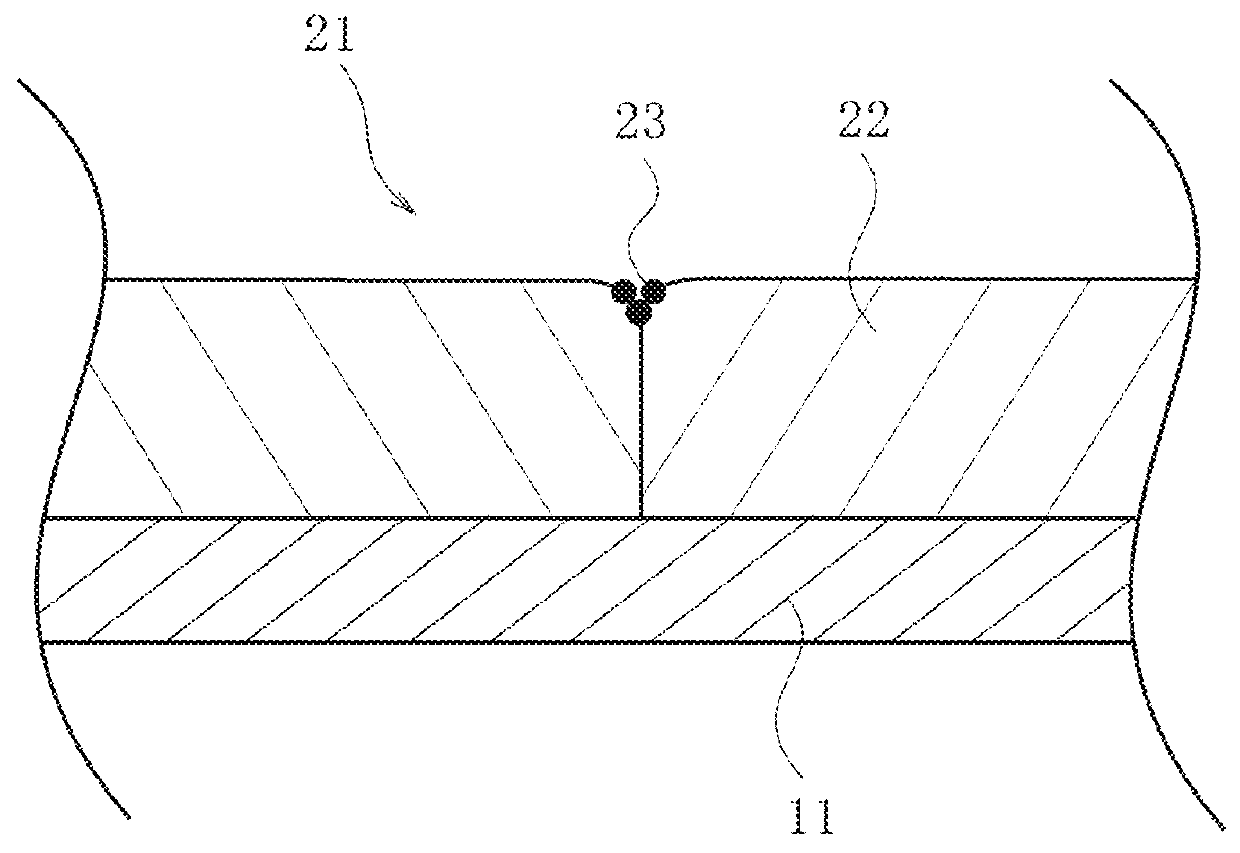

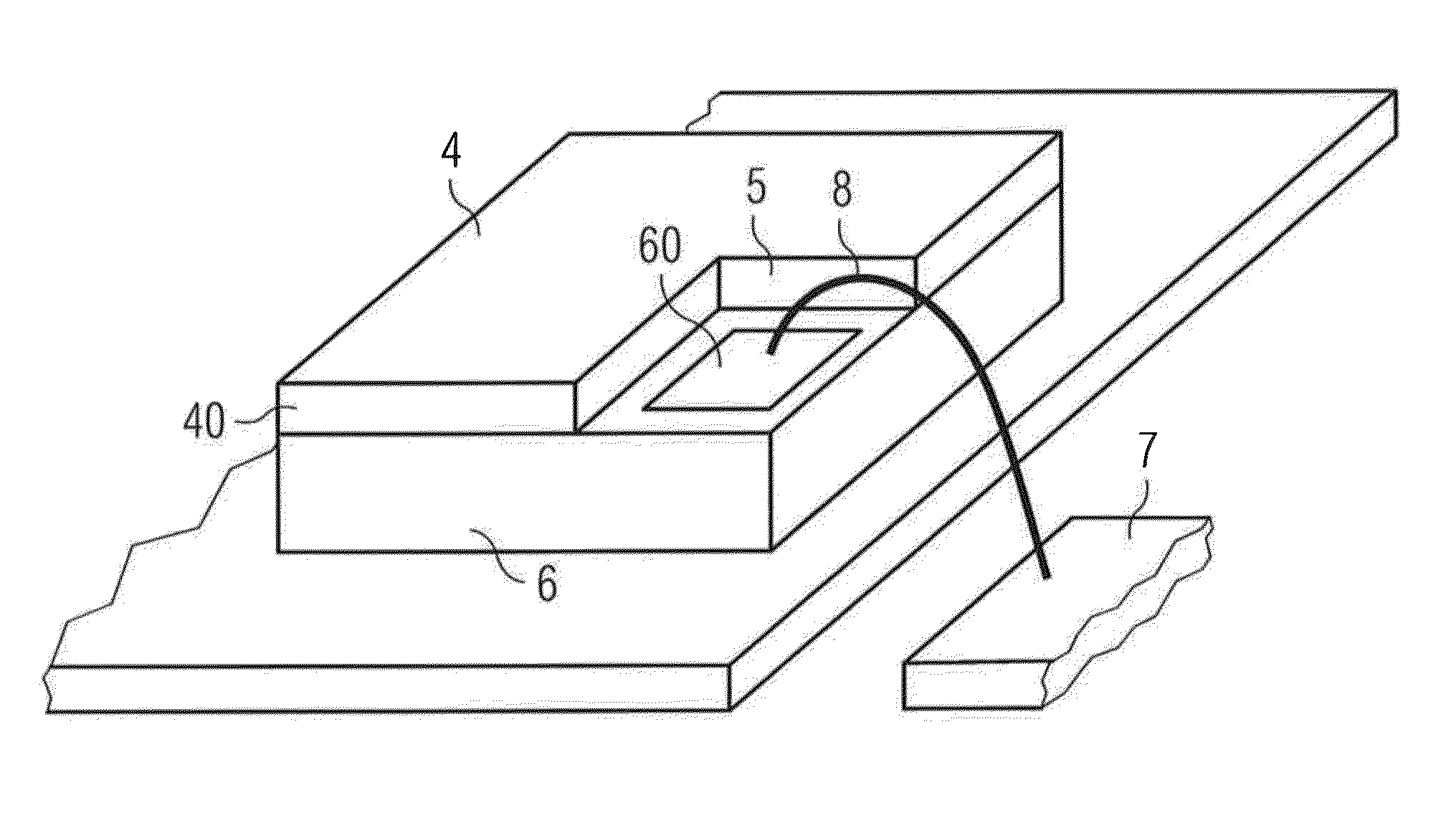

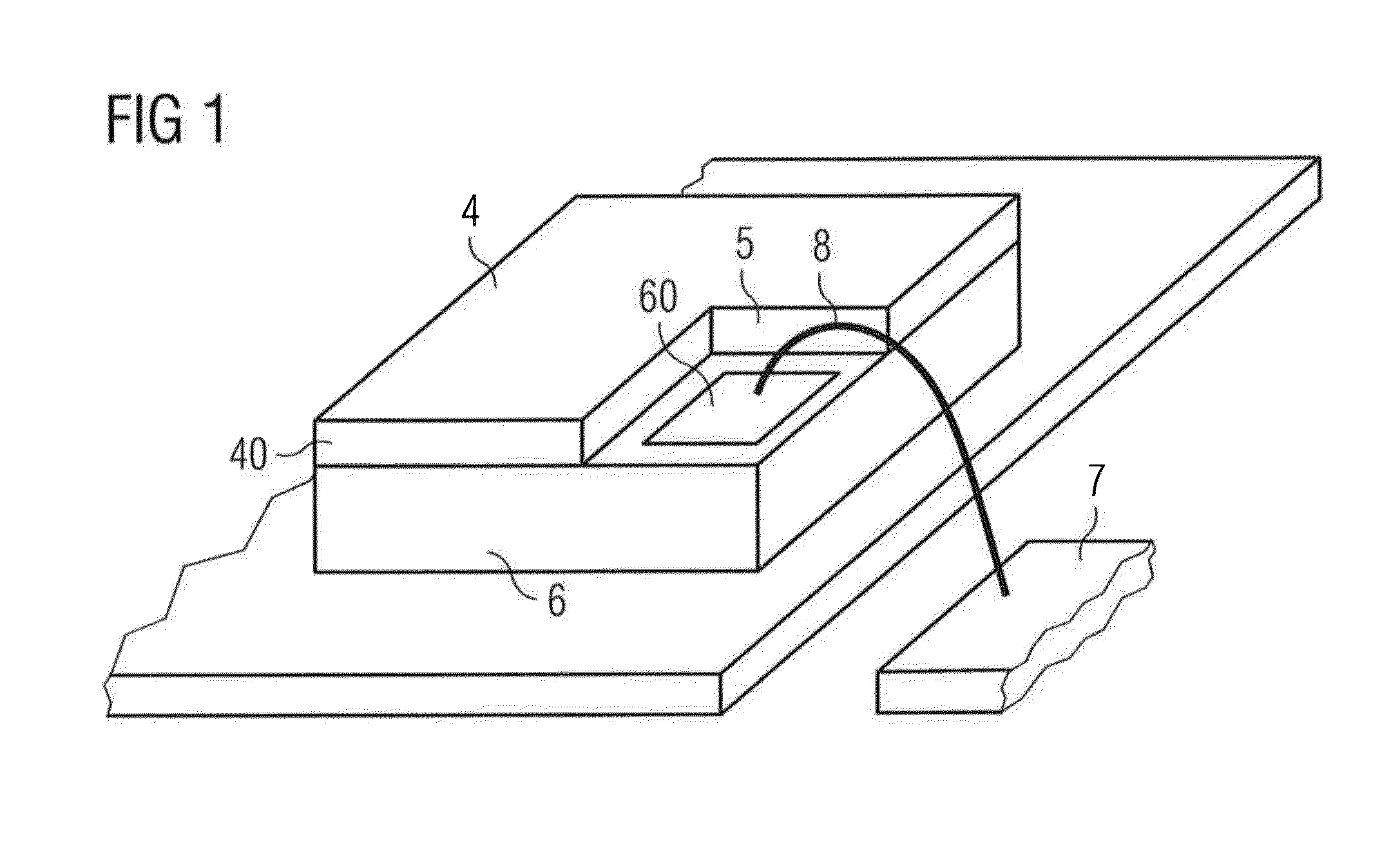

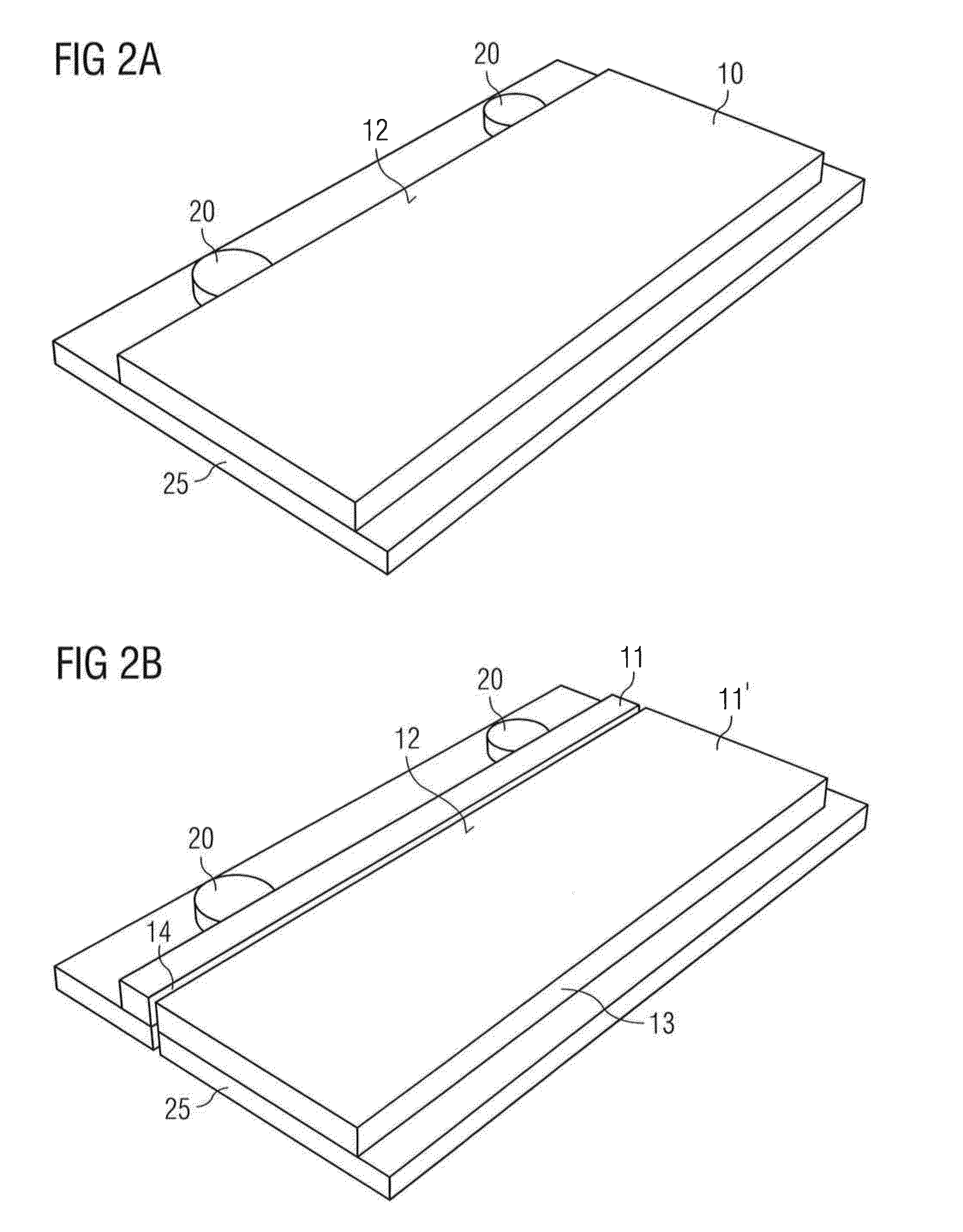

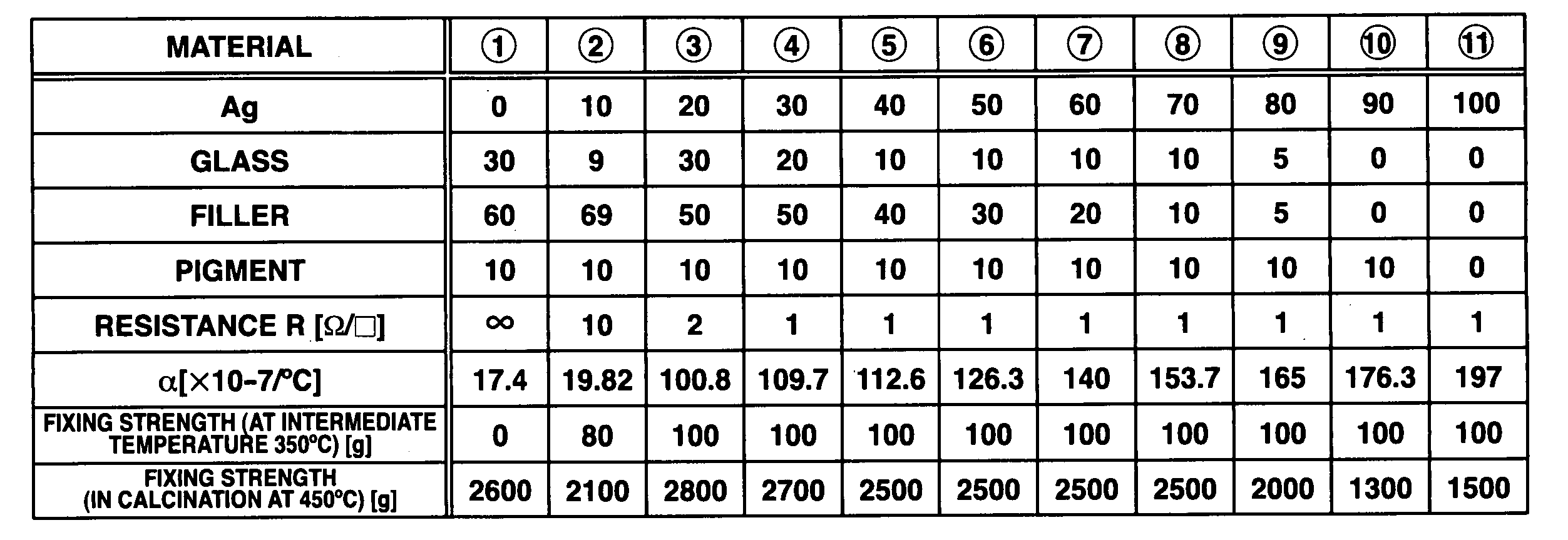

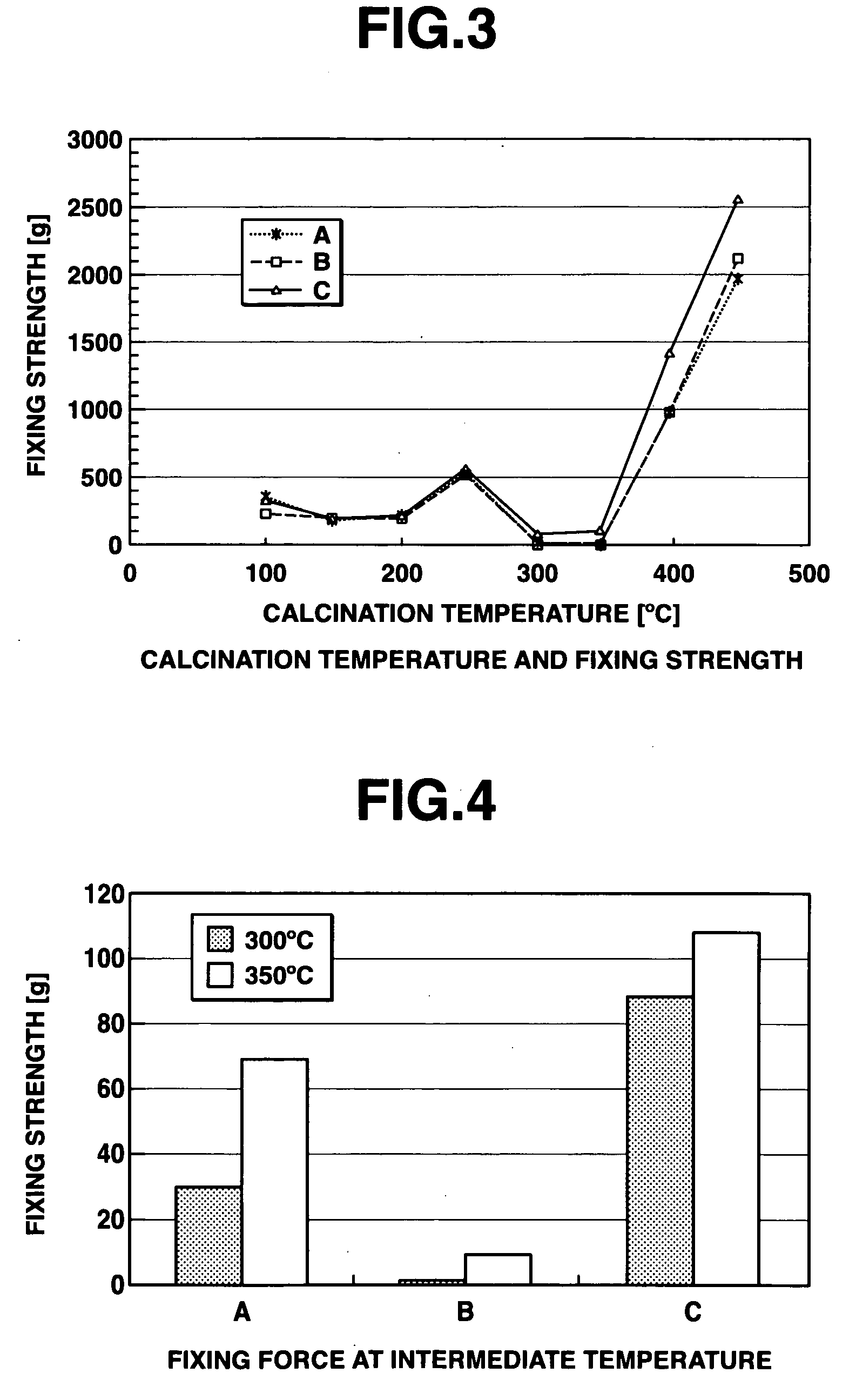

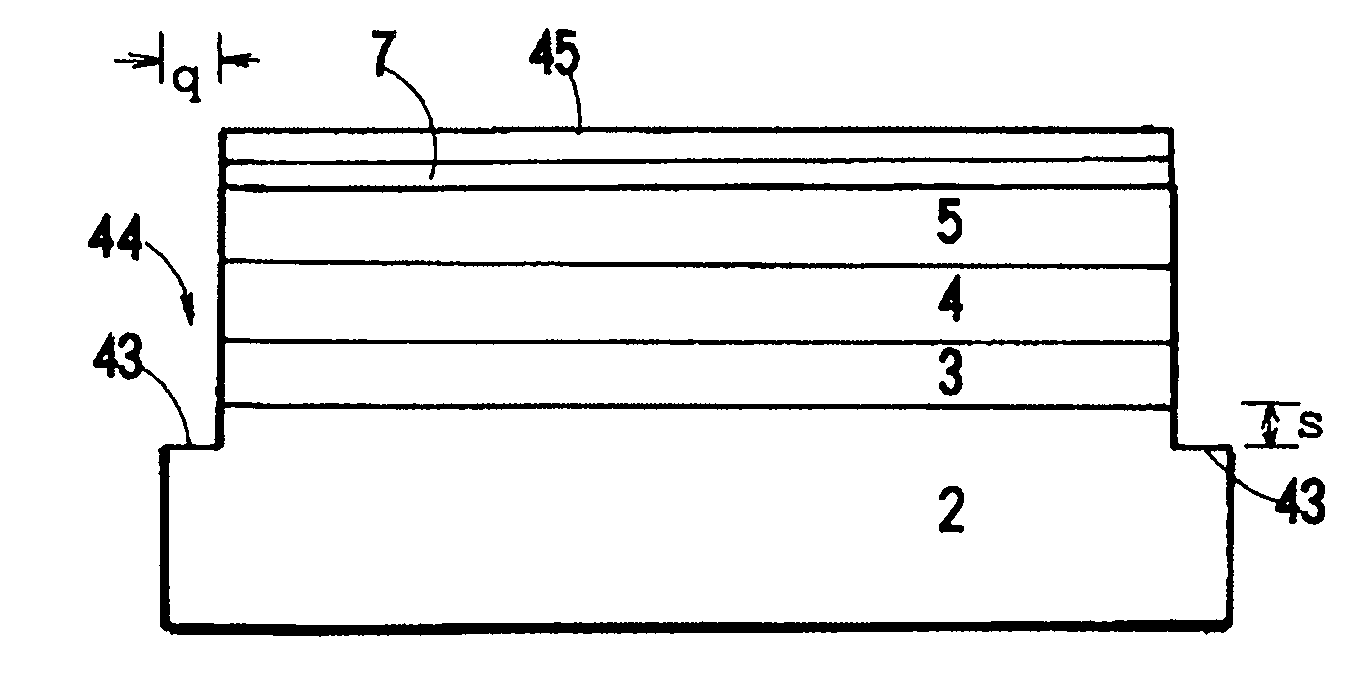

Conductive sintered compact for fixing electrodes in electronic device envelope

InactiveUS7300607B2Not impair fixing strength and electrical characteristicAvoid extensive crackingLiquid surface applicatorsSemiconductor/solid-state device detailsMetallurgyMaterials science

A conductive sintered compact for fixing electrodes inside an electronic device envelope is provided. The sintered compact is made of a conductive composition calcined. The conductive composition includes at least 10 vol % to 60 vol % of Ag particles, a low melting-point glass containing 10 vol % to 80 vol % of B2O3, 0 vol % to 70 vol % of ceramic particles, and a metal oxide series pigment. The total amount of the ceramic particles and the metal oxide series pigment is at least 10 vol % or more.

Owner:FUTABA CORPORATION

Nitride semiconductor device and manufacturing method thereof

InactiveUS7083996B2Avoid extensive crackingExtended service lifePolycrystalline material growthLaser detailsDevice formThermal expansion

A nitride semiconductor device includes a GaN substrate having a single-crystal GaN layer at least on its surface and plurality of device-forming layers made of nitride semiconductor. The device-forming layer contacting the GaN substrate has a coefficient of thermal expansion smaller than that of GaN, so that a compressive strain is applied to the device-forming layer. This result in prevention of crack forming in the device-forming layers, and a lifetime characteristics of the nitride semiconductor device is improved.

Owner:NICHIA CORP

Method for manufacturing dielectric thin film capacitor

ActiveUS20050079670A1Surface deteriorationAvoid crackingDischarge tube luminescnet screensThin/thick film capacitorLiquid stateCapacitor

A method for manufacturing a dielectric thin film capacitor of the present invention includes the steps of coating a liquid raw material on a substrate and performing a first heat treatment to form an adhesive layer, forming a lower electrode on the adhesive layer, coating a liquid raw material on the lower electrode and performing a second heat treatment to form a dielectric thin film by crystallization, forming an upper electrode on the dielectric thin film, and performing a third heat treatment at a temperature higher than those of the first and second heat treatments. The adhesive layer and the dielectric thin film are formed by using materials having the same composition system or using the same material.

Owner:MURATA MFG CO LTD

Method of manufacturing EL panel including two curing steps

InactiveUS7491106B2Relaxation stressLow viscositySolid-state devicesCold cathode manufactureEngineeringSealant

The preferable method of manufacturing the EL panel comprises a panel precursor formation step of forming a panel precursor including a substrate, a sealing plate disposed facing the substrate, an EL device (EL device portion) provided on a surface of the substrate facing the sealing plate, and a sealant comprising a curable adhesive composition filled between the substrate and the sealing plate; a first curing step of irradiating the sealant with light so as to partially cure the curable adhesive composition; and a second curing step of heating the sealant after the irradiation with the light so as to further cure the curable adhesive composition.

Owner:FUTABA CORPORATION

Cementitious capillary crystalline waterproof material with an eka-molecular sieve structure and its manufacturing method

In this invention a cementitious capillary crystalline waterproof material with an eka-molecular sieve structure and its manufacturing method is disclosed. The major ingredient of this material is Portland cement; the accessories include silicon dioxide, alumina, magnesia, calcium sulphonate, methlycellulose, quick-setting agent and sodium aluminate, etc. Put separately major ingredient and accessories premixed in given proportion separately into the major ingredient bin and the accessory bins. The major ingredient passing through an impulse flowmeter is carried to the dosing machine; and in the same time, the premixed accessories are automatically weighed by the weighing device using gewichtsabnahme method when they are carried to the above dosing machine; they are mixed in the premixing machine and the refine-mixing machine and prepared to the product. The product is mixed with water and forms slurry. After setting, it becomes coating layer with an eka-molecular sieve structure which is water-tight and breathes freely. The coating has high compressive strength, resistance to very high and low temperatures, and resistant to acid, chlorides, and Sulphates so on. It also has self-healing ability to small crack when meet with water. It is non-toxic, odorless, with long service life, and convenient to application. The material can be used at wide range in underground facilities, tunnel, cave depot, bridge, swimming pool, toilet, sewage treating reservoir, dam, etc.

Owner:ZHANG HUIDONG

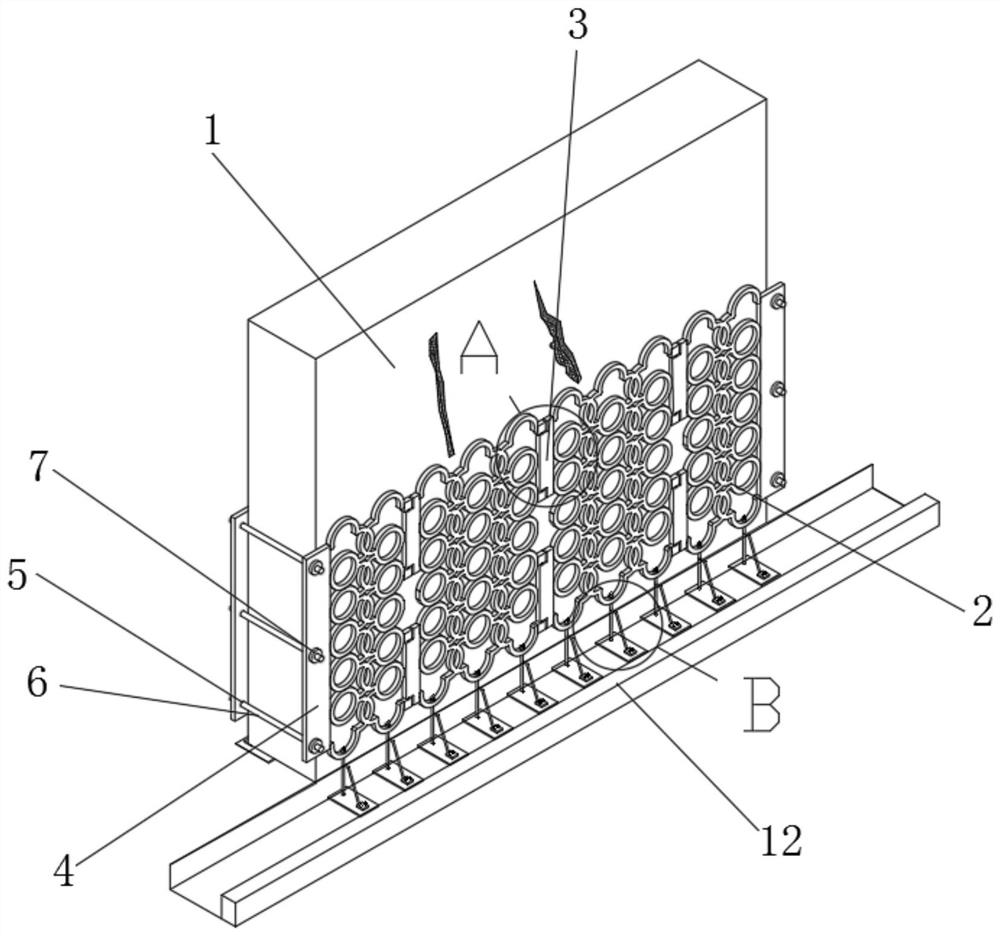

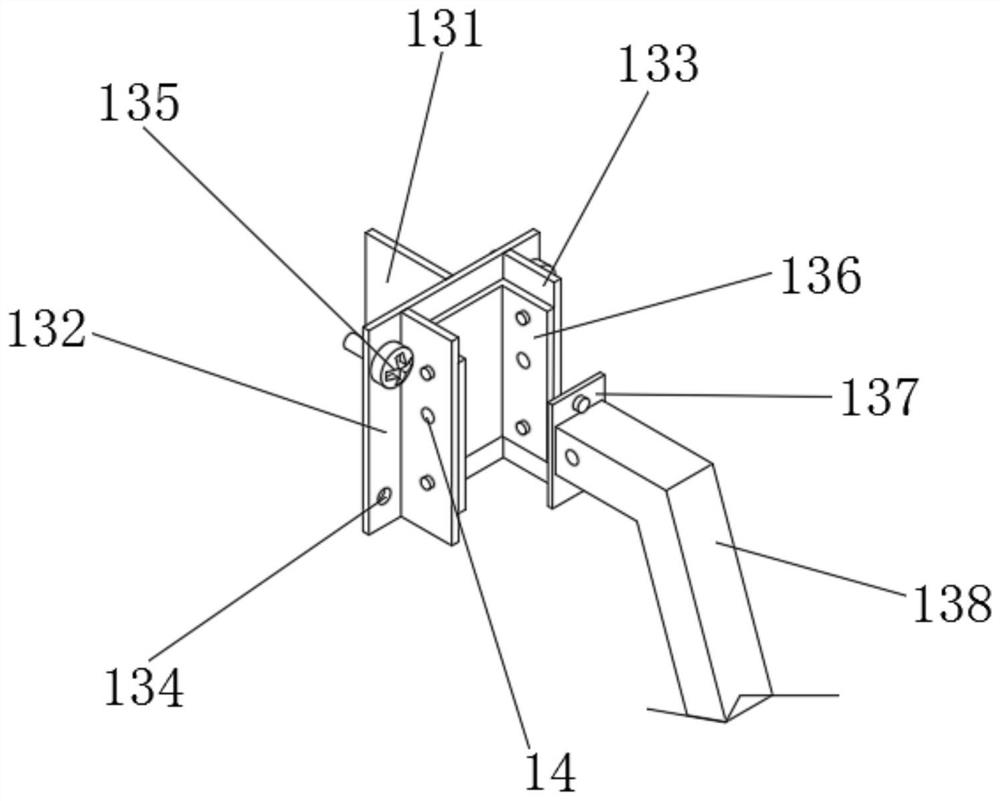

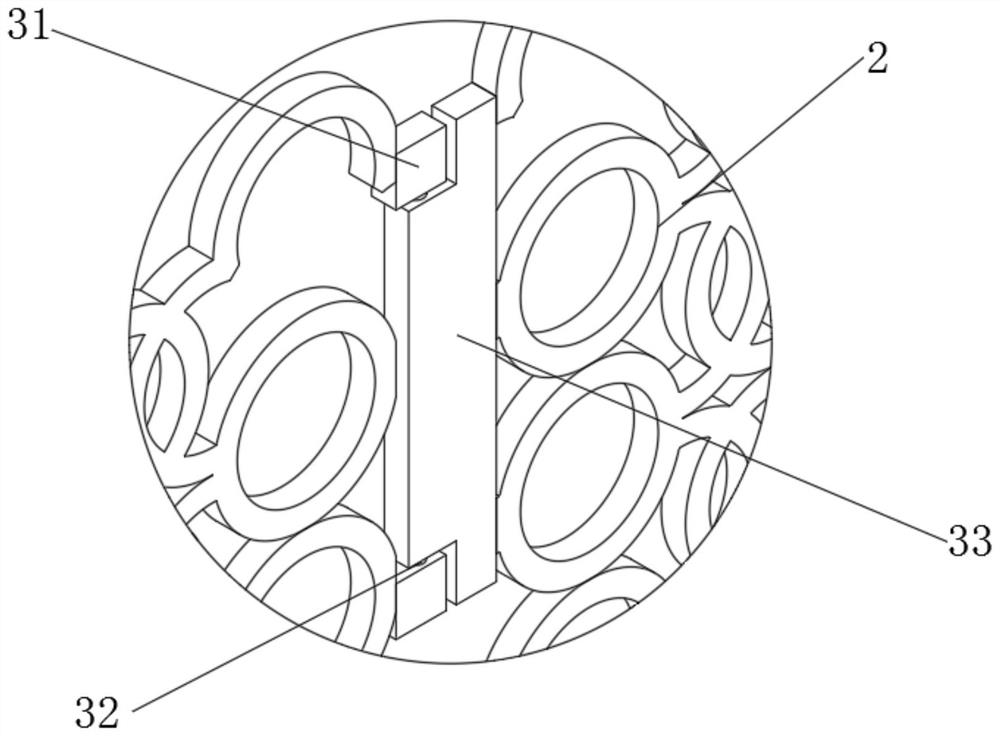

Reinforcing structure for ancient building rammed earth wall construction

PendingCN112443172AImprove toughnessIncrease binding forceBuilding repairsArchitectural engineeringRammed earth

The invention discloses a reinforcing structure for ancient building rammed earth wall construction. The reinforcing structure comprises a wall body, steel wire pulling nets are arranged on the two faces of the wall body, folding mechanisms are arranged at the connecting positions of the steel wire pulling nets, and connecting blocks are fixedly connected to the two sides of the steel wire pullingnets. The two ends of screw rods fixedly connect two connecting blocks through fixing nuts, vertical rods are fixedly connected to the bottoms of the steel wire pulling nets, and pull rods are fixedly connected to the outer walls of the vertical rods. An embedded part is fixedly connected to the bottoms of rectangular metal blocks, a reinforcing structure body is fixedly connected to a crack inner cavity of the wall body, an embedded steel plate is nailed into cracks of the wall body, outer wall fixing blocks are fixedly connected to the front face of the embedded steel plate, side plates arefixedly connected to the two sides of the front face of the outer wall fixing blocks, threaded holes are formed in inner cavities of the outer wall fixing blocks, screws are fixedly connected to inner cavities of the threaded holes, and the outer wall fixing blocks are fixed to the wall through the screws, so that the cracks are prevented from becoming larger during construction.

Owner:SHANGHAI JIANWEI CULTURAL HERITAGE CONSERVATION TECH CO LTD

Wood impregnation

InactiveUS7056557B2Increase moisture contentHigh hardnessSynthetic resin layered productsCellulosic plastic layered productsPolymer compositesOrganic compound

The present invention relates to a wood-polymer composite, particularly wood which has been impregnated with a mixture containing polymerizable organic compounds, and more particularly to a method for preparing a wood-polymer-composite by impregnating wood material and / or wood-based material with a mixture containing polymerizable organic compounds, and most particularly uses thereof.

Owner:KEBONY

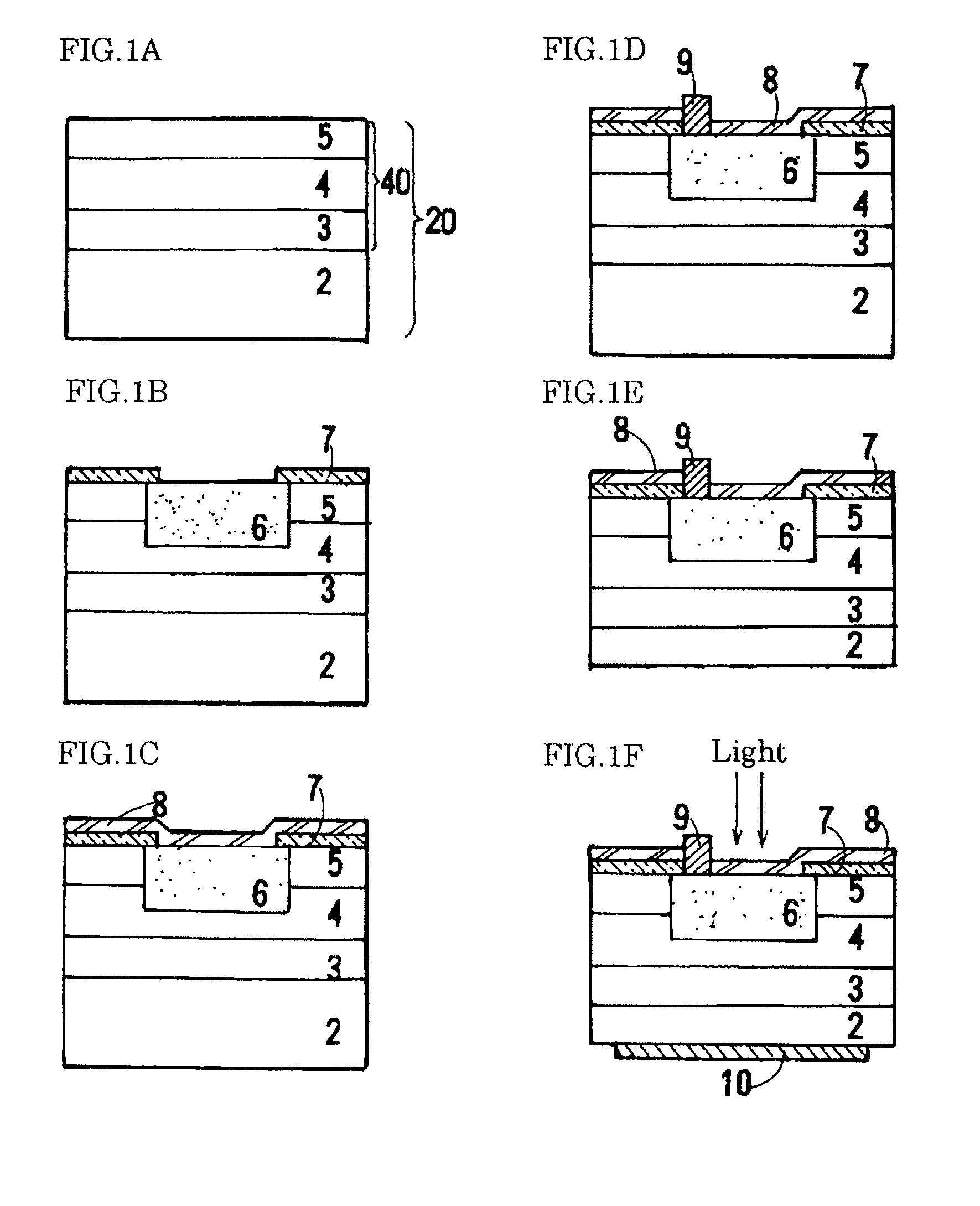

Manufacturing method of electronic element

ActiveUS20080188078A1Little crackingPrevent crackingFinal product manufactureDecorative surface effectsOptoelectronicsMaterials science

A circumferential portion of an epitaxial wafer is removed to remove an anomalously grown elevated portion formed in a circumferential chamfer. An epitaxial layer in the circumferential portion is removed with a width q=t to 5t wherein t is the thickness of the epitaxial layer so that the surface of a substrate is exposed. Therefore, cracking of the epitaxial layer in processing steps can be prevented.

Owner:SUMITOMO ELECTRIC IND LTD

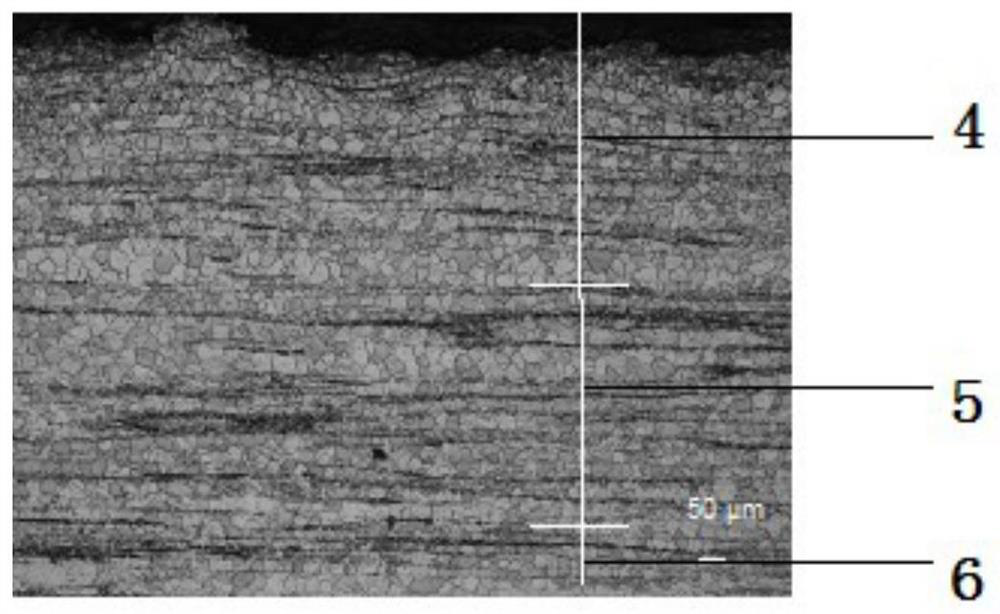

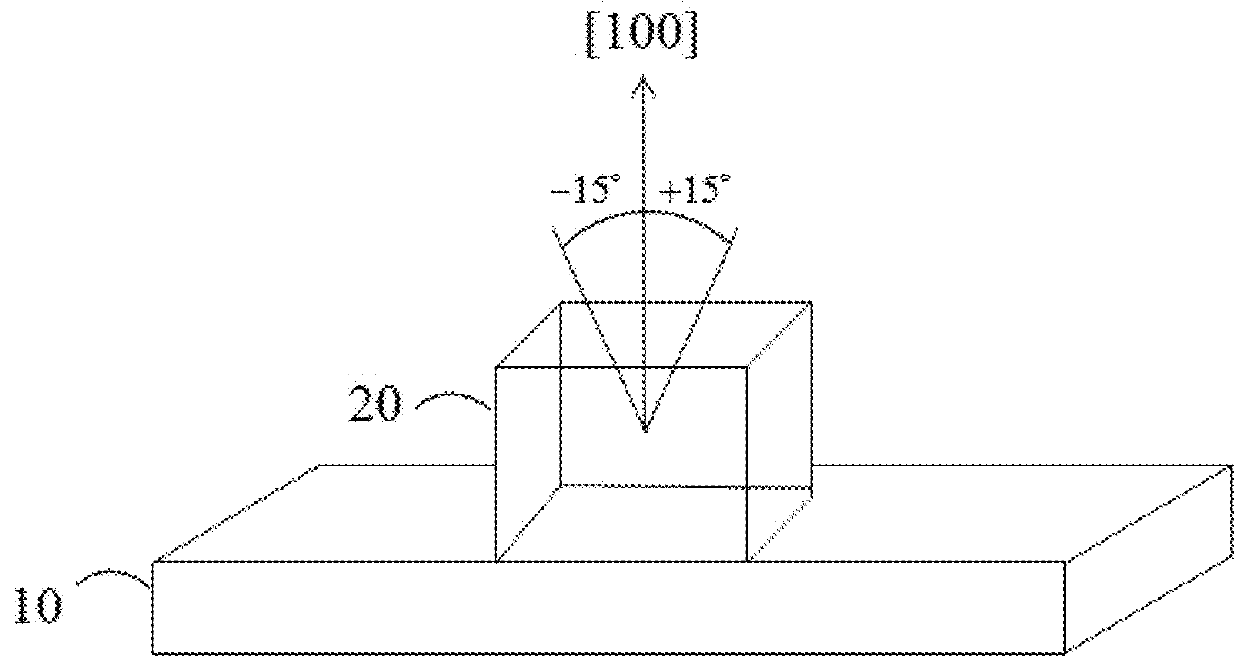

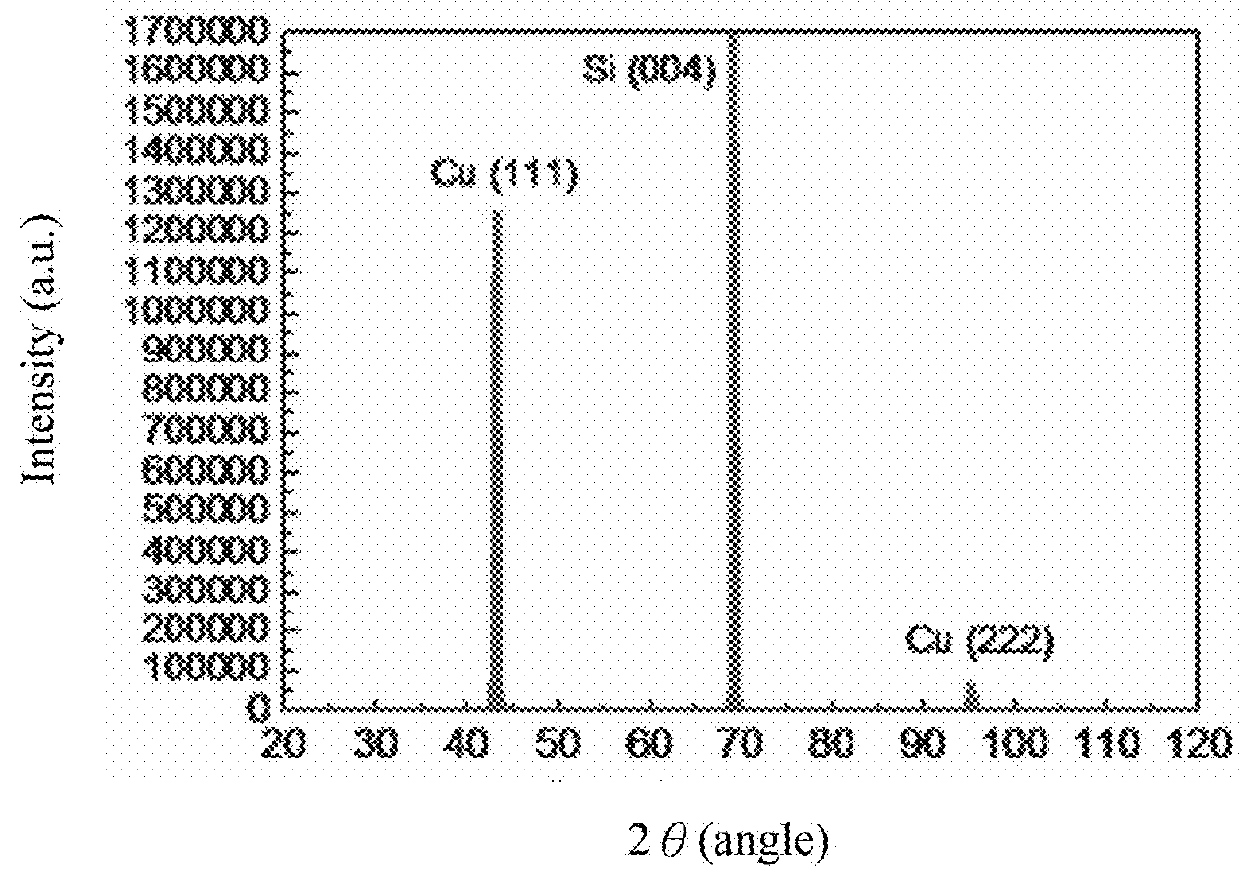

Copper film with large grains, copper clad laminate having the same and manufacturing method of copper clad laminate

ActiveUS9994967B2Improve ductilityGood flexibilitySuperimposed coating processThin material handlingCopper foilAverage size

Owner:NAT CHIAO TUNG UNIV

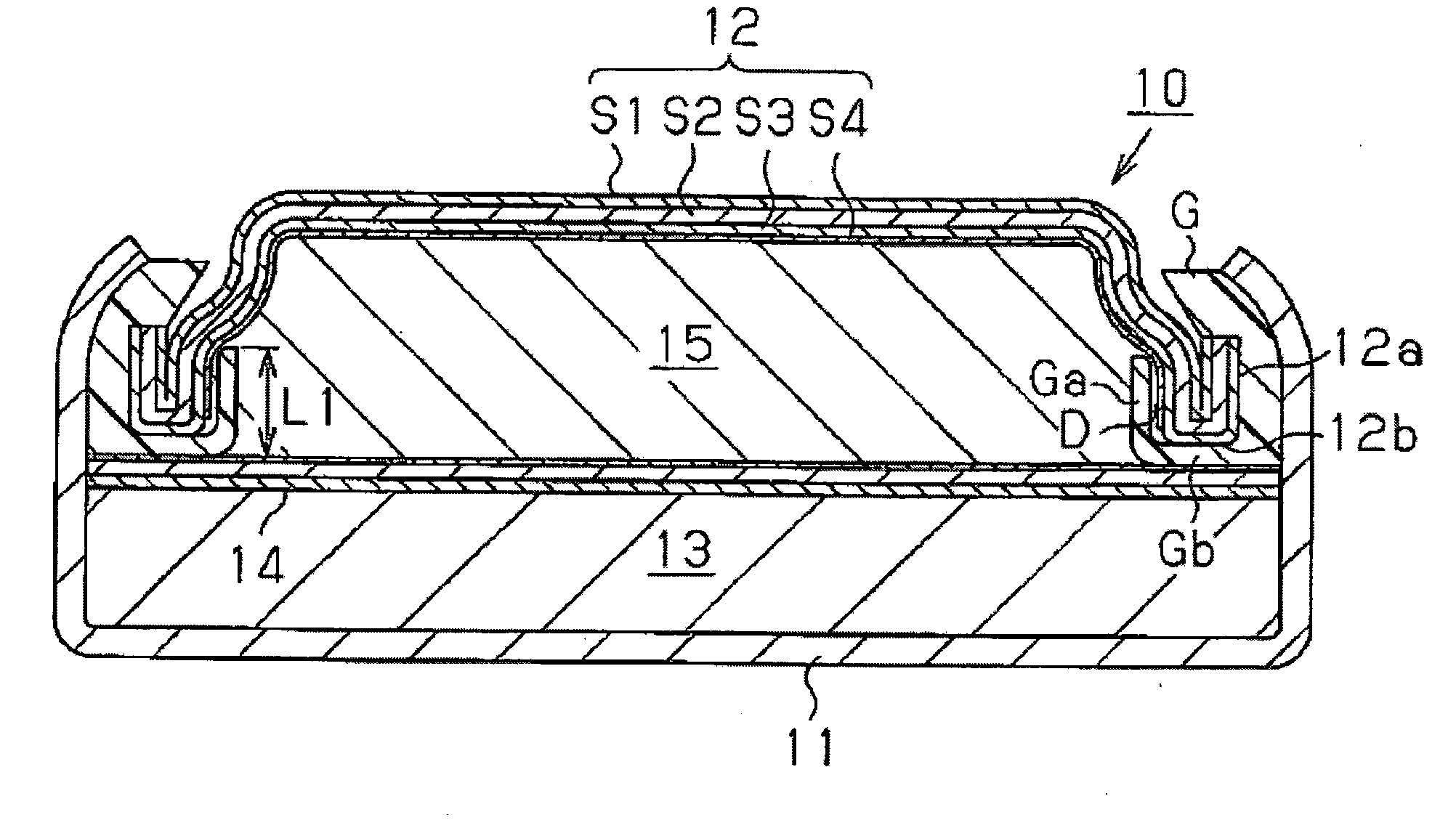

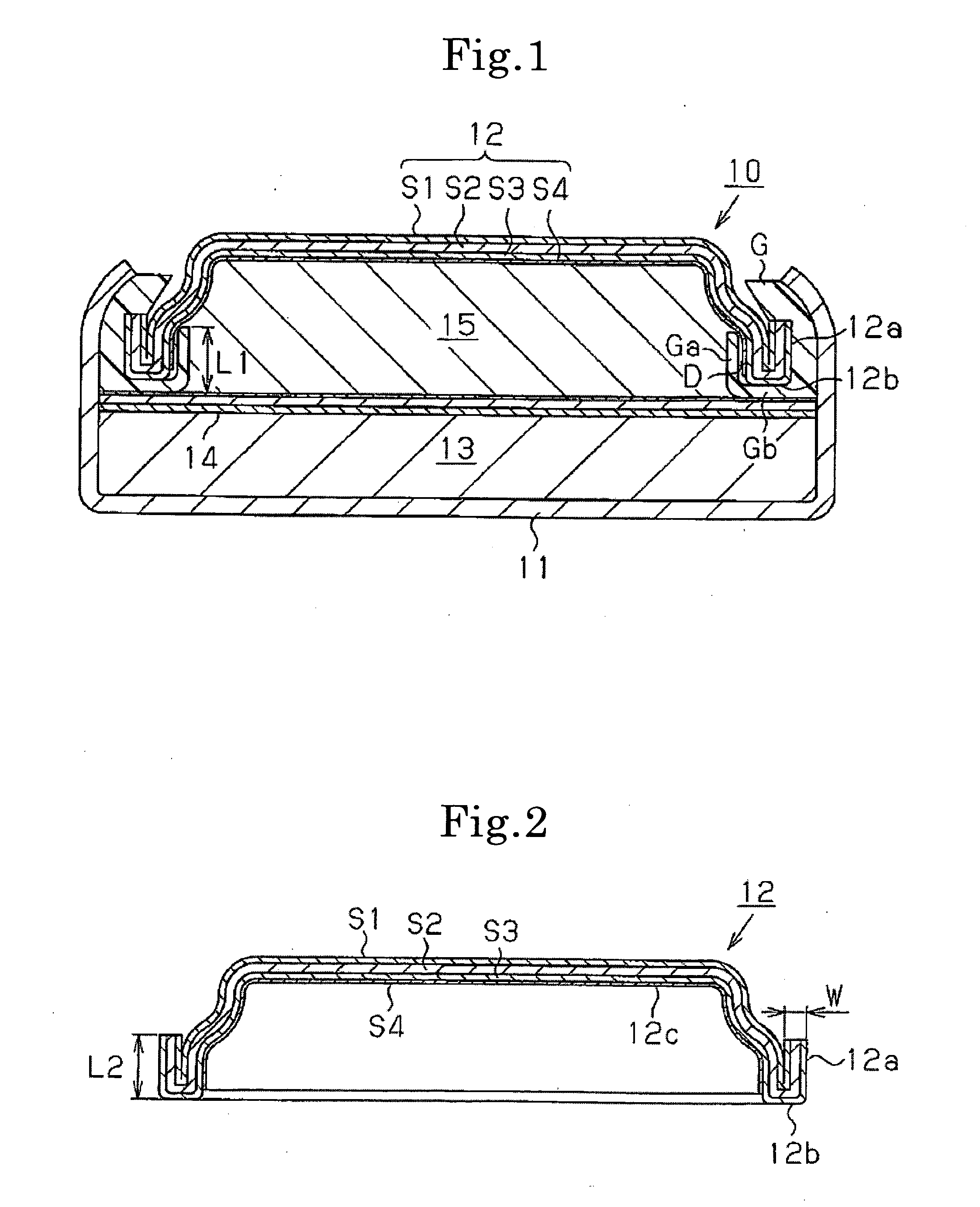

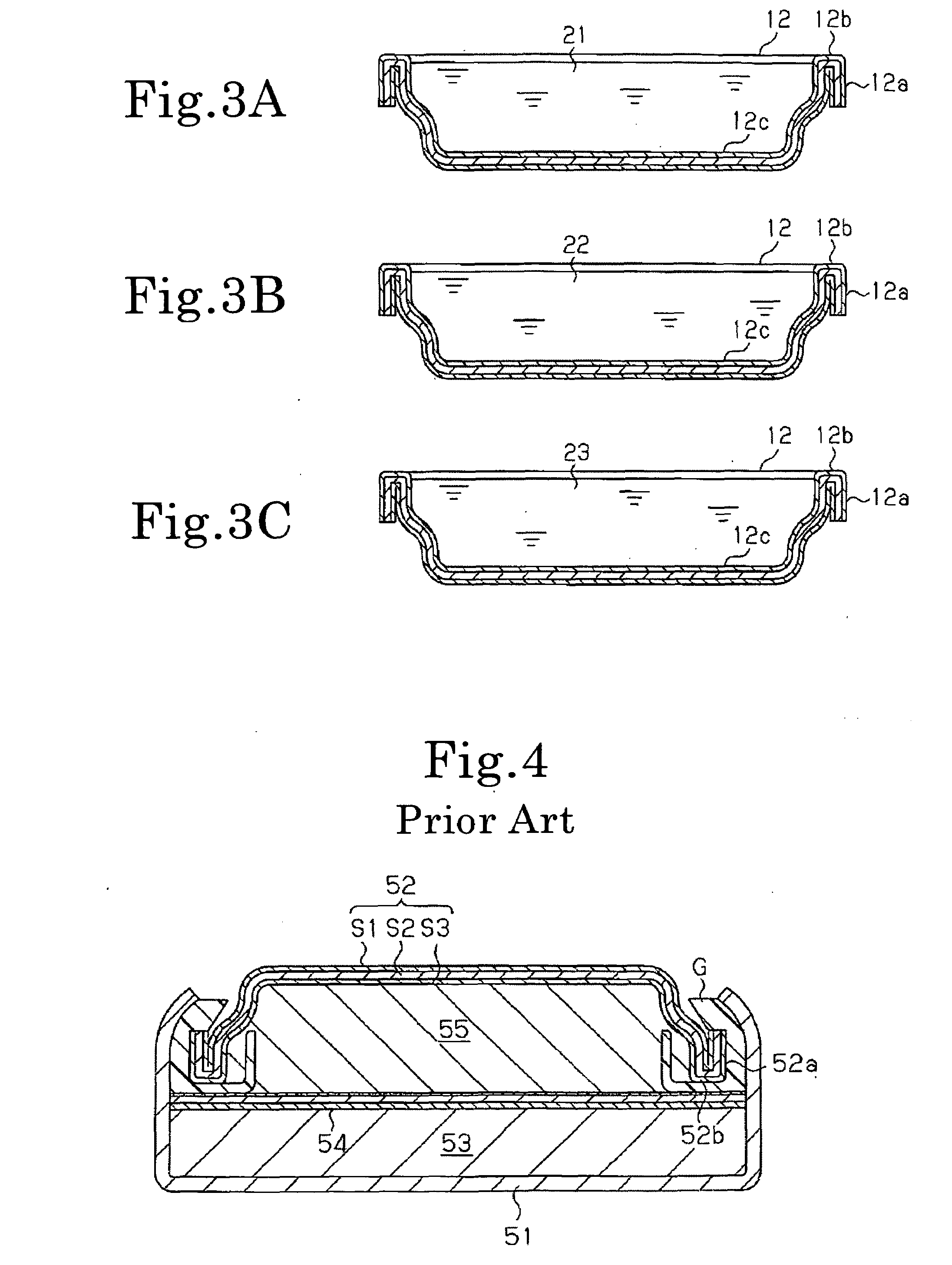

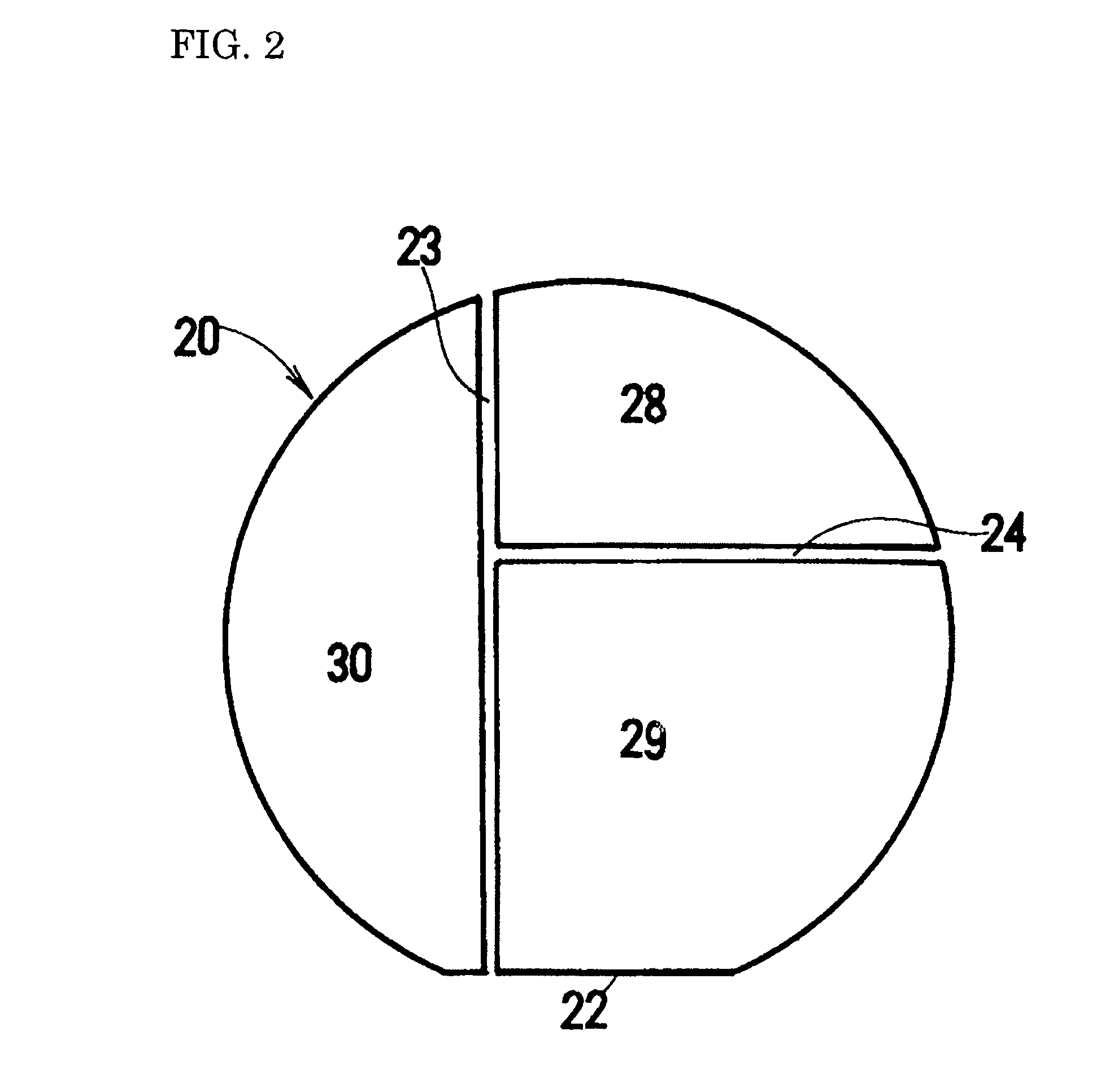

Method for producing alkaline battery, and alkaline battery

InactiveUS20090220861A1Higher hydrogen overpotentialAvoid extensive crackingFinal product manufactureElectrode carriers/collectorsHydrogenConductive polymer

The invention provides an alkaline battery that does not allow generation of hydrogen gas. An alkaline battery comprises a positive electrode mixture, a negative electrode mixture containing zinc alloy powder, a separator that separates the positive electrode mixture from the negative electrode mixture, an alkaline electrolyte, a positive electrode can that accommodates the positive electrode mixture, and a negative electrode can that accommodates the negative electrode mixture and has a tin coating layer formed after chemical polishing with a mixed acid and surface treatment with a conductive polymer. The opening edge of the negative electrode can has a folded portion formed along the outer peripheral surface thereof to have a U-shaped cross section, and a gasket has a protruding portion formed on the central side and having a J-shaped cross section. The space formed between the inner peripheral surface of the folded portion of the negative electrode can and the central-side protruding portion of the gasket is no wider than the thickness of the negative electrode can, and the length of the protruding portion is at least ½ the length of the folded portion.

Owner:SEIKO INSTR INC

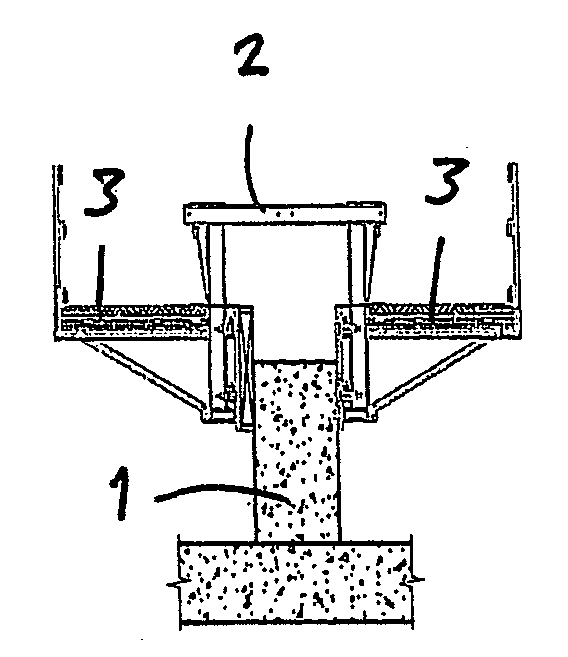

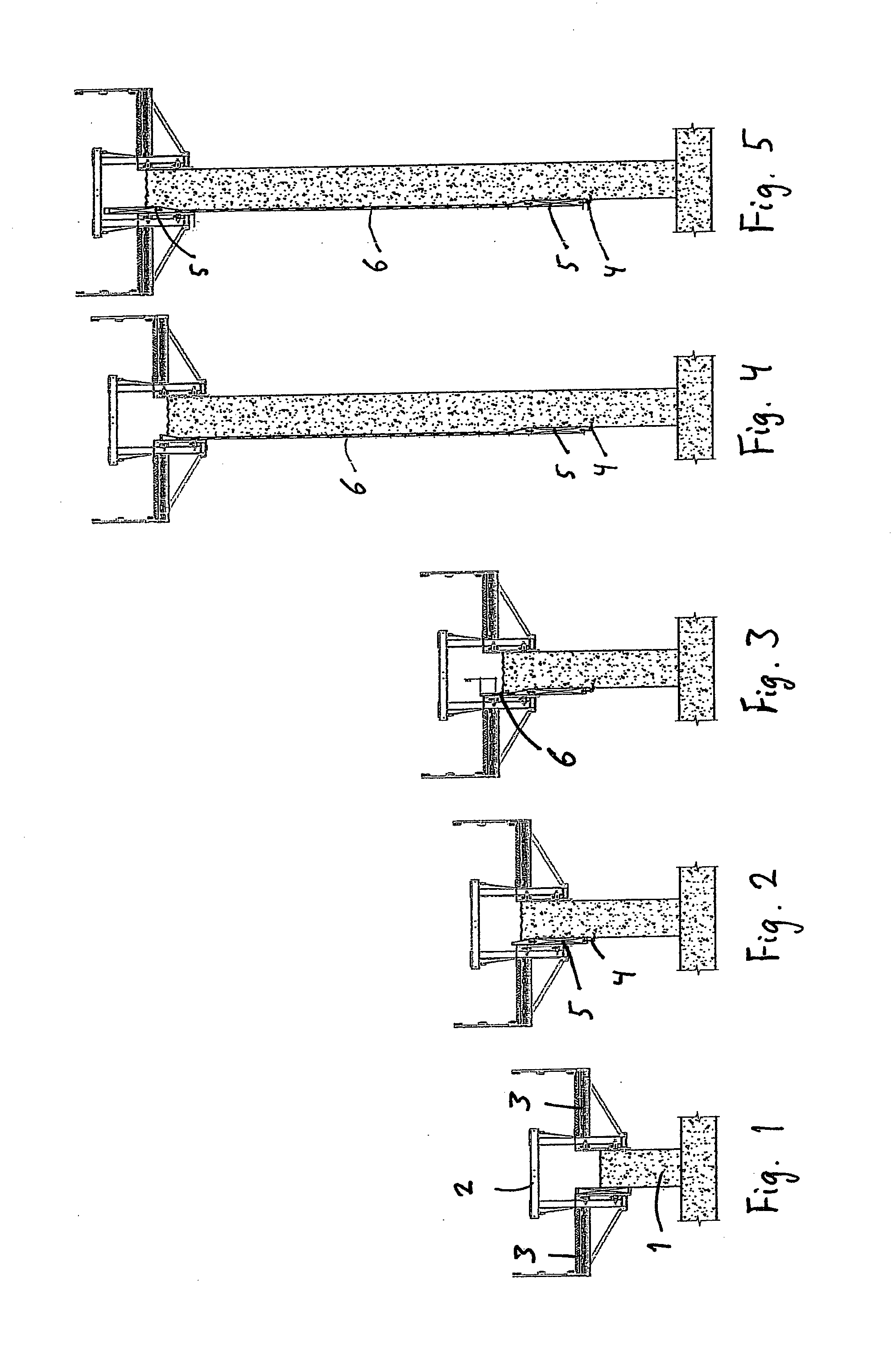

Slip formed concrete structure

InactiveUS20130183102A1Eliminates and reduces irregularityReduced service lifeForms/shuttering/falseworksExcavationsEngineeringFace sheet

Owner:KVAERNER AS

Gap-filling adhesive of stone

ActiveUS20110301263A1Improve breathabilityWell mixedOrganic compound preparationCarboxylic acid esters preparationAdhesive cementGap filling

An adhesive for filling in gaps between stones, the adhesive including at least 100 weight parts of an unsaturated polyester resin suitable for air-drying, between 1 and 5 weight parts of hydrogenated castor oil, between 0 and 60 weight parts of micron silica, and between 1 and 15 weight parts of an anti-shrinking agent. The adhesive overcomes the disadvantages of conventional marble glue, such as, poor air-drying property, poor shrinkage resistance, and poor permeability. The adhesive of the invention has good permeability, strong shrinkage resistance, and high brightness after being polished, and is not sticky after curing. The invention solves the difficulty of gap-filling of stone by providing a new category of marble glue.

Owner:WUHAN KEDA MARBLE PROTECTIVE MATERIALS

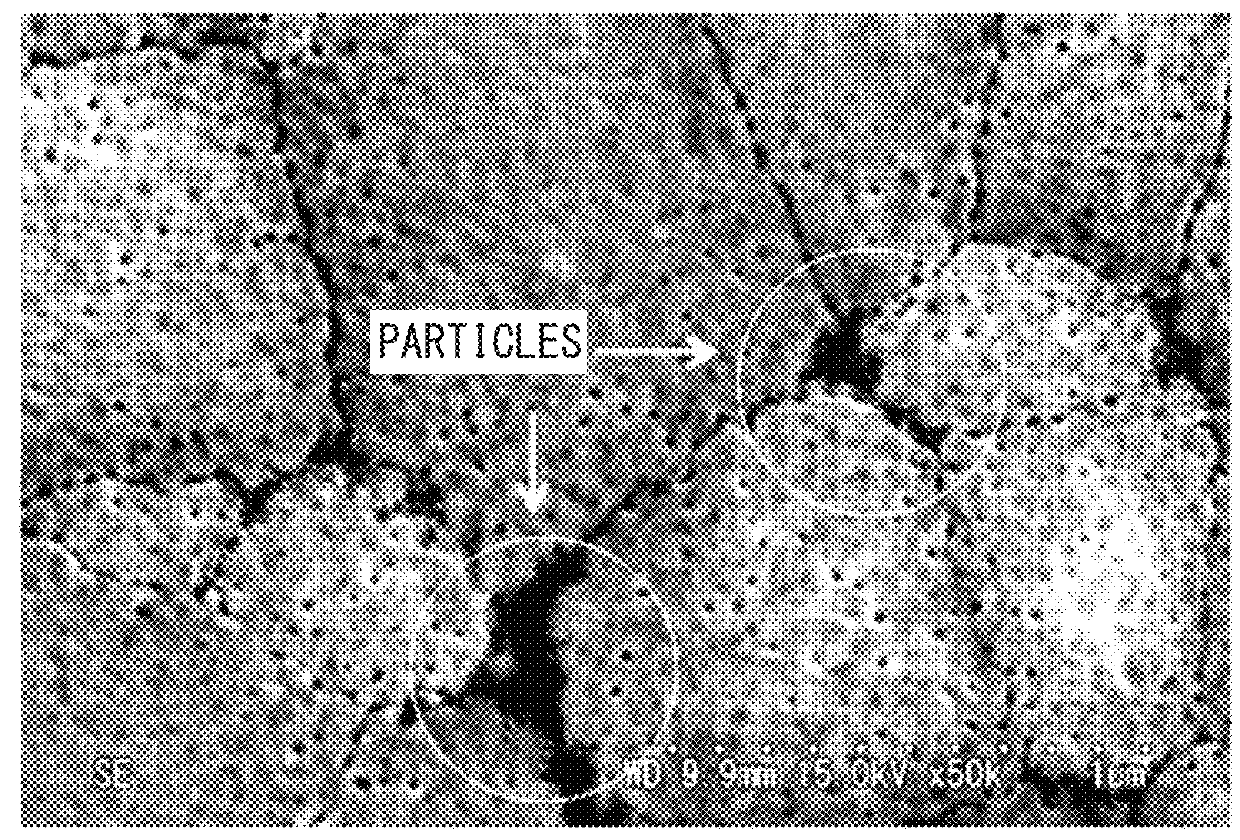

PZT-based ferroelectric thin film and method of forming the same

ActiveUS9251955B2Reduce crackingCompact structureFixed capacitor dielectricStacked capacitorsFerroelectric thin filmsGrain boundary

A PZT-based ferroelectric thin film is formed by coating a PZT-based ferroelectric thin film-forming composition on a lower electrode of a substrate one or two or more times, pre-baking the composition, and baking the composition to be crystallized, and this thin film includes PZT-based particles having an average particle size in a range of 500 nm to 3000 nm when measured on a surface of the thin film, in which heterogeneous fine particles having an average particle size of 20 nm or less, which are different from the PZT-based particles, are precipitated on a part or all of the grain boundaries on the surface of the thin film.

Owner:MITSUBISHI MATERIALS CORP

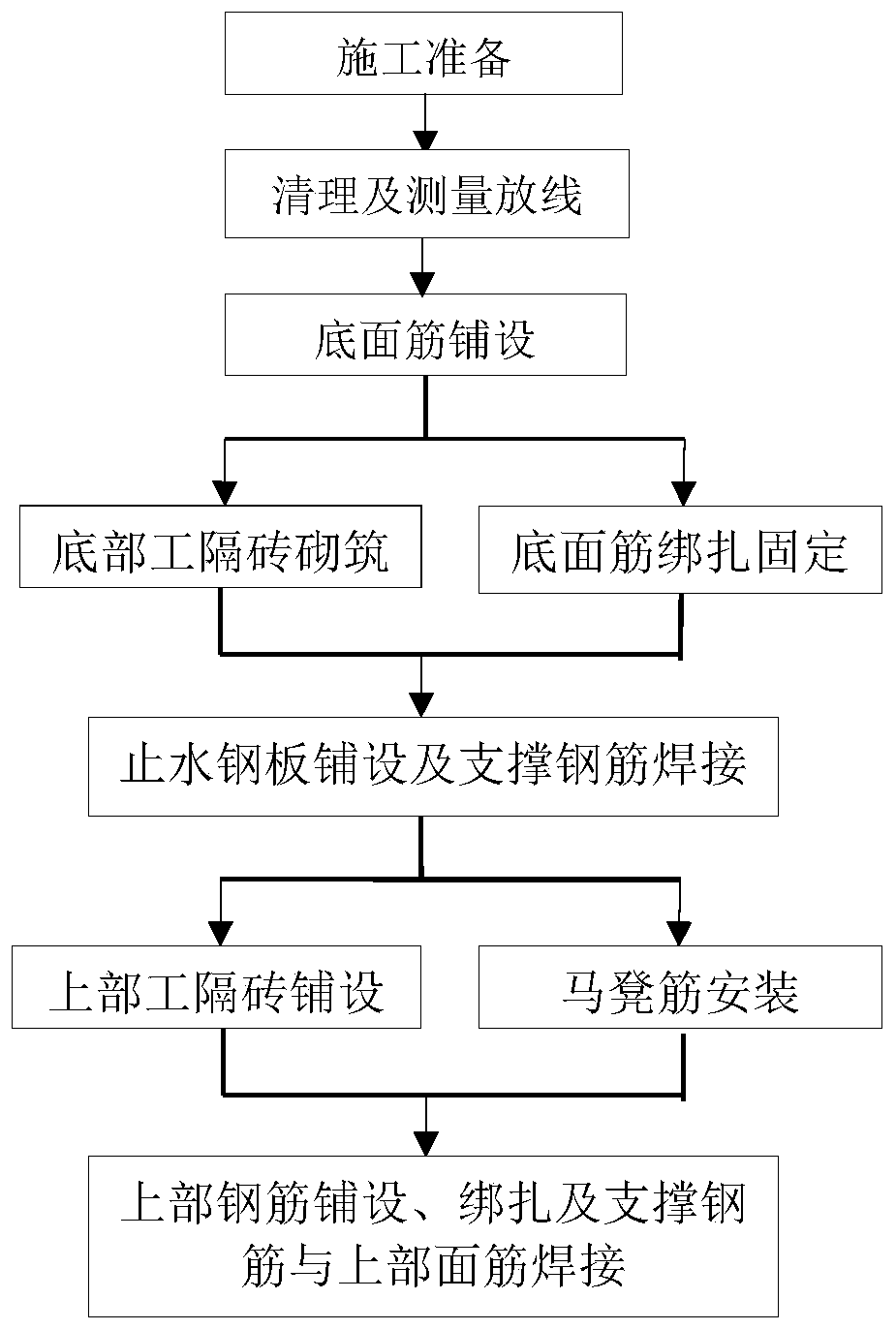

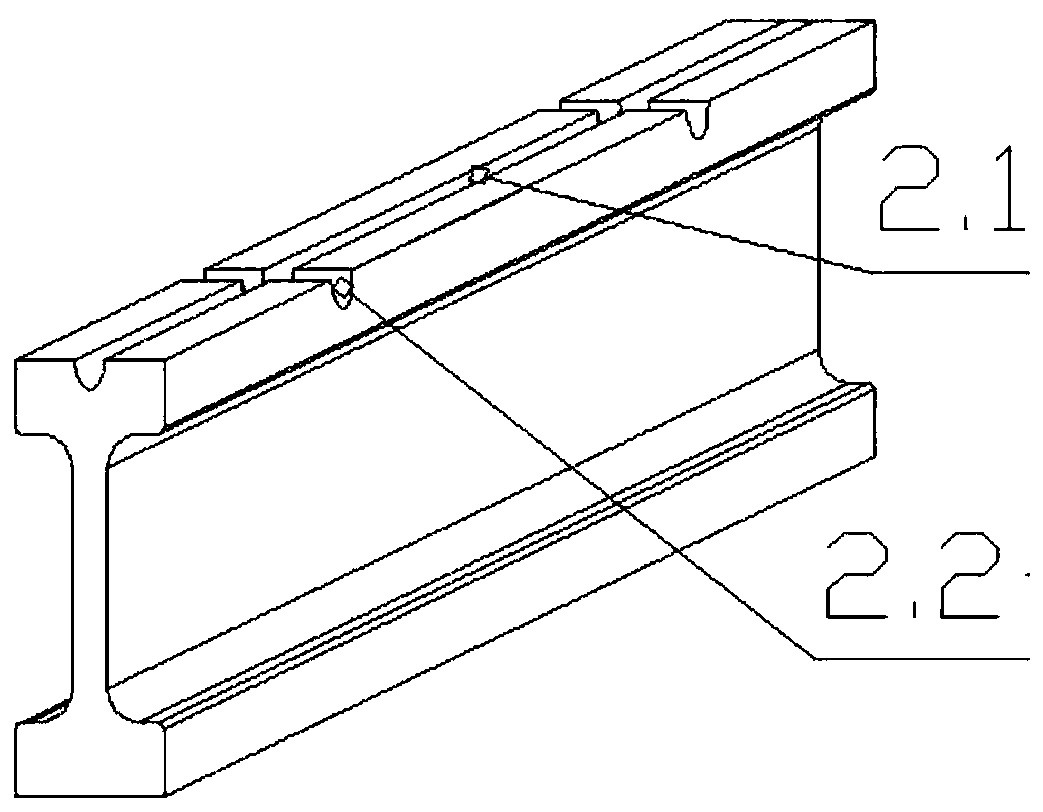

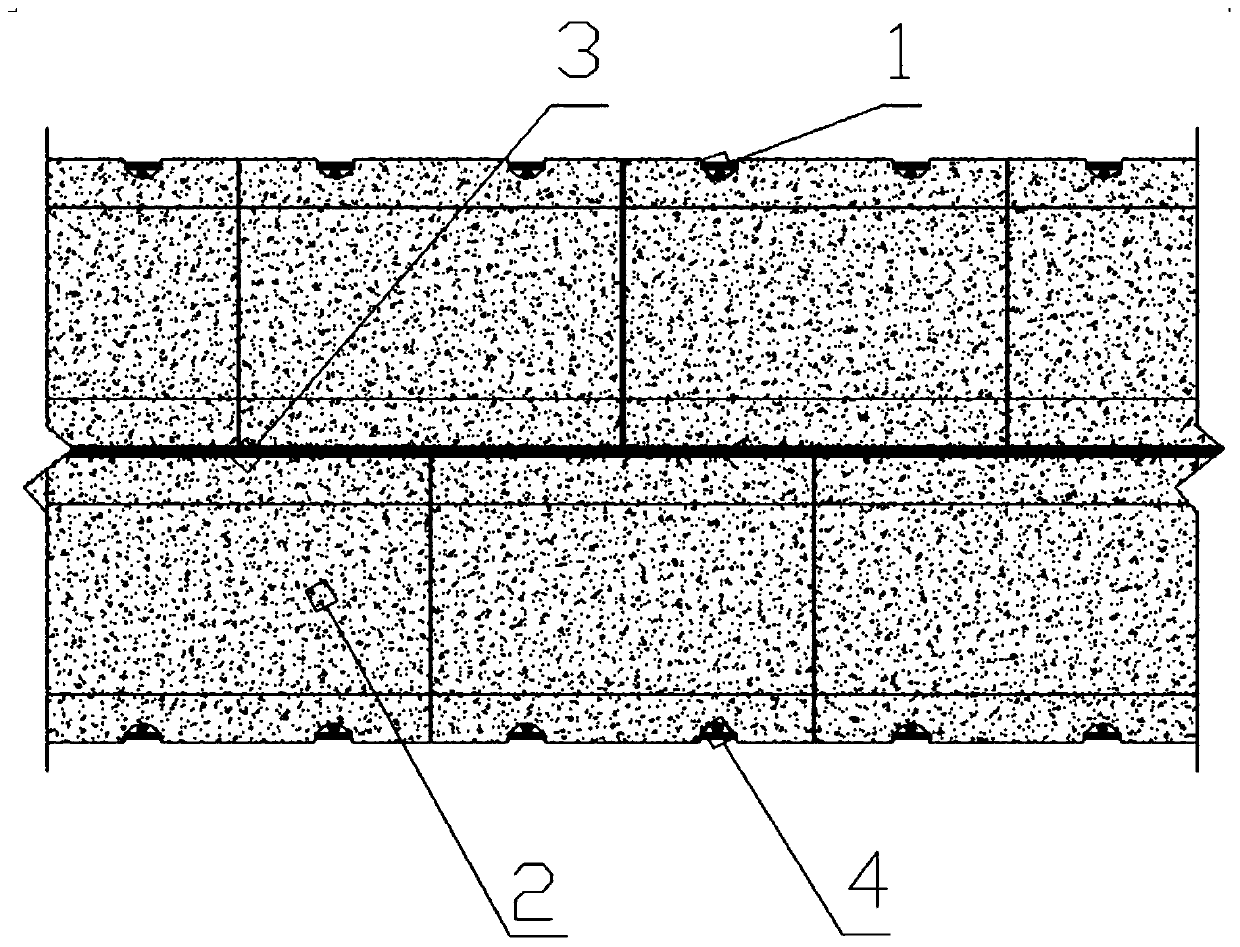

Post-cast strip blocking brick structure and construction method thereof

InactiveCN111501851AGuarantee stabilityGuaranteed cleanlinessArtificial islandsProtective foundationBrickArchitectural engineering

The invention provides a post-cast strip blocking brick structure and a construction method thereof. The structure comprises I partition bricks, a water stop steel plate, a supporting rib, upper faceribs and bottom face ribs. Each I partition brick is in an I shape, wherein the bottom face is a plane, the top face is provided with a longitudinal groove and transverse grooves, and the longitudinalgroove communicates with the transverse grooves. The grooves are used for containing the upper and bottom face ribs. The bottom faces of the two I partition bricks are stacked vertically to form a supporting pillar structure, and the water stop steel plate is arranged between the two I partition bricks. The water stop steel plate is perpendicularly connected to the supporting rib which is vertically arranged. The upper face ribs are arranged in the grooves of the upper I partition brick, and the bottom face ribs are arranged in the grooves of the lower I partition brick. The I partition bricks a plate and post-cast strip interface, and the water stop steel plate extends into a post-cast strip from a plate. The structure is firm and high in stability, and construction time can be greatly shortened. The invention further provides a construction method of the above post-cast strip blocking brick structure, and the construction quality and the construction efficiency are greatly improved.

Owner:CHINA FIRST METALLURGICAL GROUP

Luminescence Conversion Element, Method for the Manufacture Thereof and Optoelectronic Component Having a Luminescence Conversion Element

InactiveUS20130299862A1Prevent manufactureSusceptible to mechanical damageLayered productsElectroluminescent light sourcesMaterials scienceMachining

A method for manufacturing a ceramic luminescence conversion element includes providing a shaped body having a first main surface, a second main surface and a first lateral surface. The shaped body includes a ceramic material and a luminescence conversion substance. The first main surface and / or the second main surface of the shaped body is / are machined using a patterning method, so that at least one first machined area and at least one unmachined area are formed. The first machined area extends essentially parallel to the first lateral surface. Singularization is performed to produce a plurality of luminescence conversion elements by means of cuts that are made in the machined main surface of the machined shaped body essentially at right angles to the first lateral surface.

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

Conductive sintered compact for fixing electrodes in electronic device envelope

InactiveUS20050161811A1Well formedNot impair fixing strength and electrical characteristicLiquid surface applicatorsSemiconductor/solid-state device detailsCeramic particleOxide

A conductive sintered compact for fixing electrodes inside an electronic device envelope is provided. The sintered compact is made of a conductive composition calcined. The conductive composition includes at least 10 vol % to 60 vol % of Ag particles, a low melting-point glass containing 10 vol % to 80 vol % of B2O3, 0 vol % to 70 vol % of ceramic particles, and a metal oxide series pigment. The total amount of the ceramic particles and the metal oxide series pigment is at least 10 vol % or more.

Owner:FUTABA CORPORATION

Manufacturing method of electronic element

ActiveUS8258061B2Avoid breakingReduce crackingFinal product manufactureDecorative surface effectsOptoelectronicsEpiwafer

A circumferential portion of an epitaxial wafer is removed to remove an anomalously grown elevated portion formed in a circumferential chamfer. An epitaxial layer in the circumferential portion is removed with a width q=t to 5t wherein t is the thickness of the epitaxial layer so that the surface of a substrate is exposed. Therefore, cracking of the epitaxial layer in processing steps can be prevented.

Owner:SUMITOMO ELECTRIC IND LTD

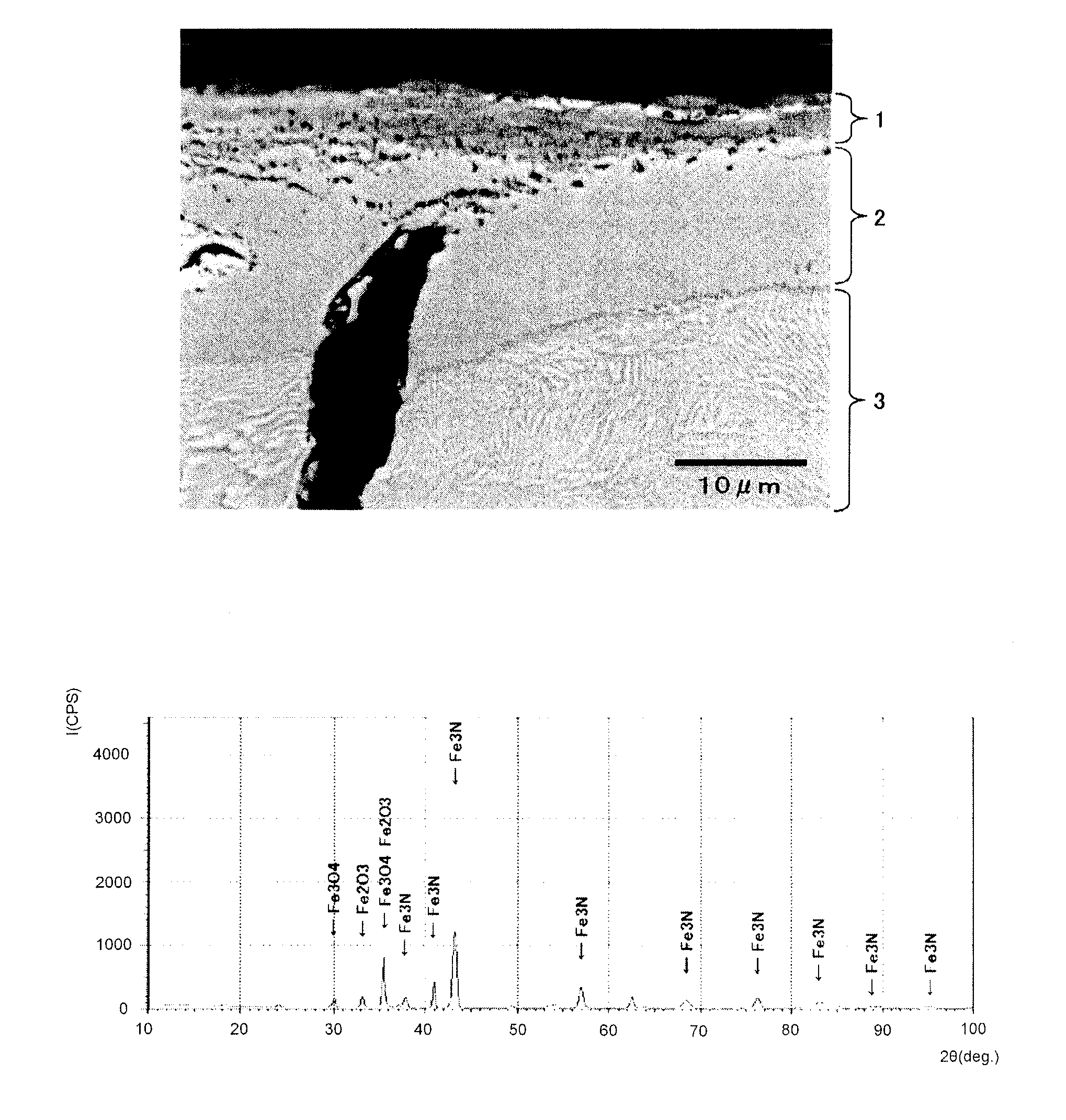

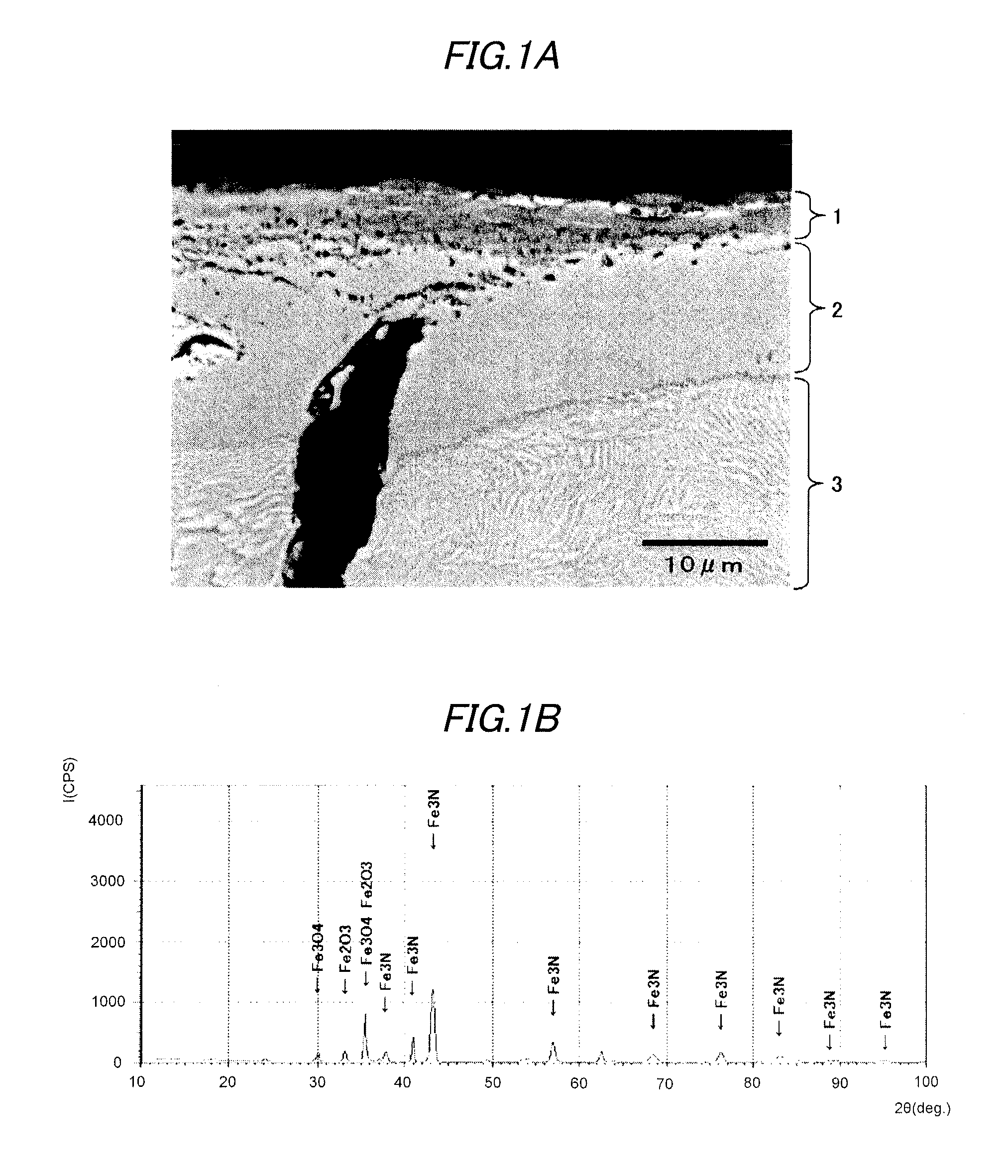

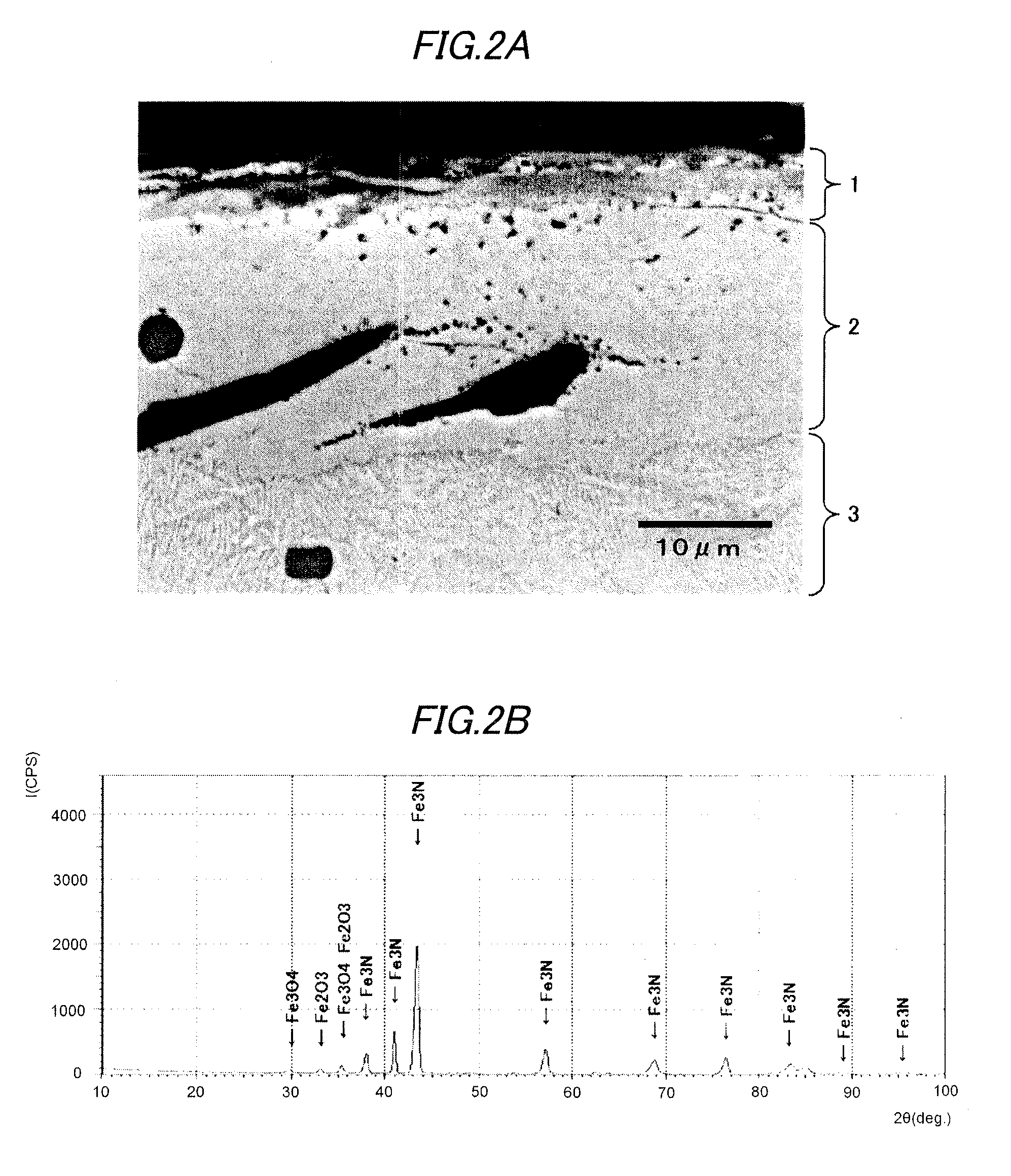

Manufacturing method of cast-iron friction member

ActiveUS20140060704A1Improve corrosion resistanceImprove wear resistanceBraking drumsBraking discsIron oxideCast iron

A cast-iron friction member is manufactured by: performing a nitrocarburizing treatment on a cast workpiece at a treatment temperature of 500° C. to 600° C. to thus form a nitrogen compound layer on a surface of the workpiece; and exposing the workpiece to an atmosphere when a temperature becomes 400° C. to 480° C. after the nitrocarburizing treatment so as to cool the workpiece to a room temperature while keeping a contact state with oxygen to thus form an iron oxide layer including Fe3O4 on a surface of the nitrogen compound layer.

Owner:AKEBONO BRAKE IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com