Post-cast strip blocking brick structure and construction method thereof

A post-casting belt and brick structure technology, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the problems of post-casting belts such as difficult cleaning and post-casting belts, and achieve stable welding time saving, beautiful interface, and security Firm and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

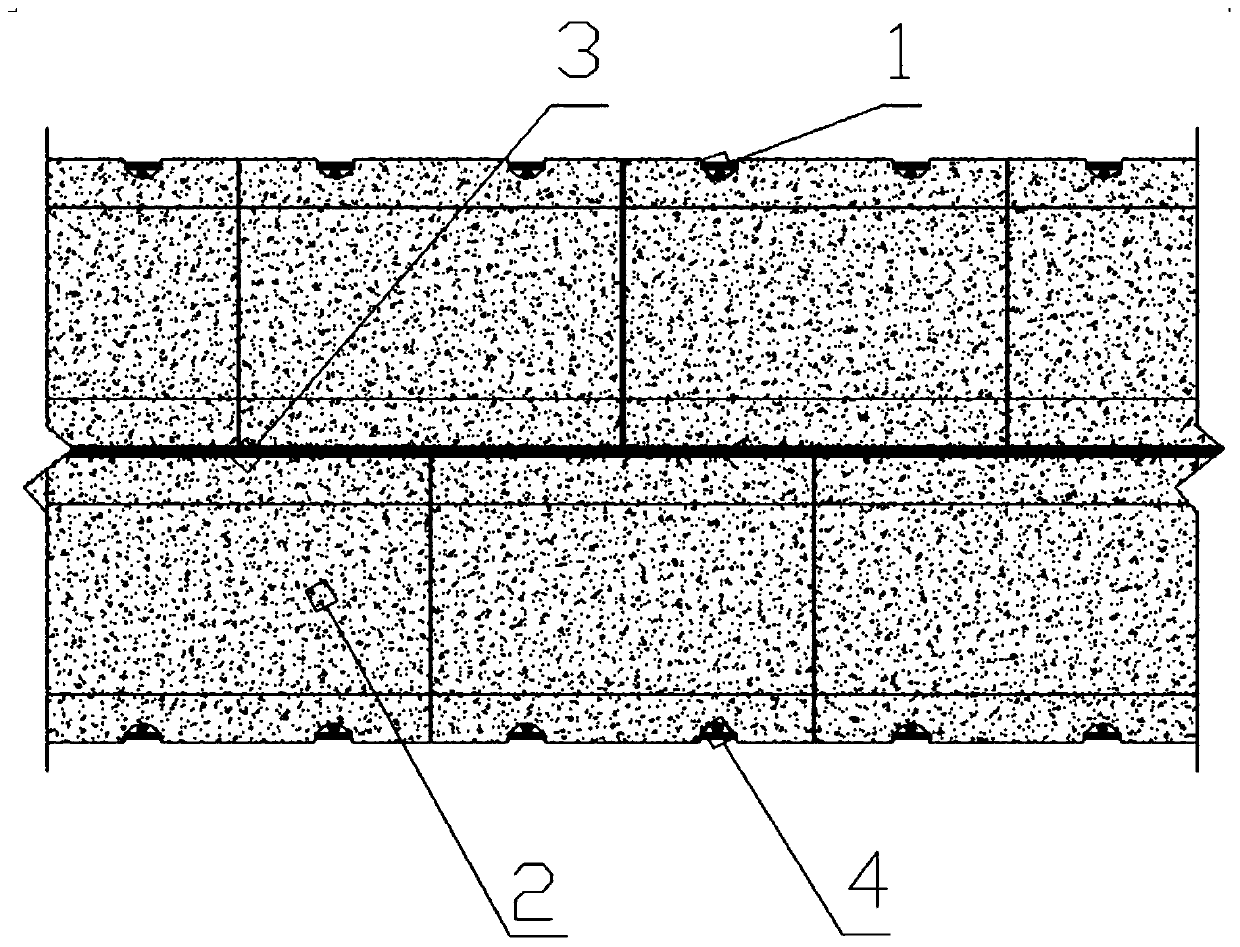

[0043] image 3 , Figure 4 The post-cast tape sealing brick structure provided by the present invention is shown. A post-casting strip-blocking brick structure, comprising work partition bricks 2, water-stop steel plates 3, support ribs 5, upper ribs 1 and bottom ribs 4.

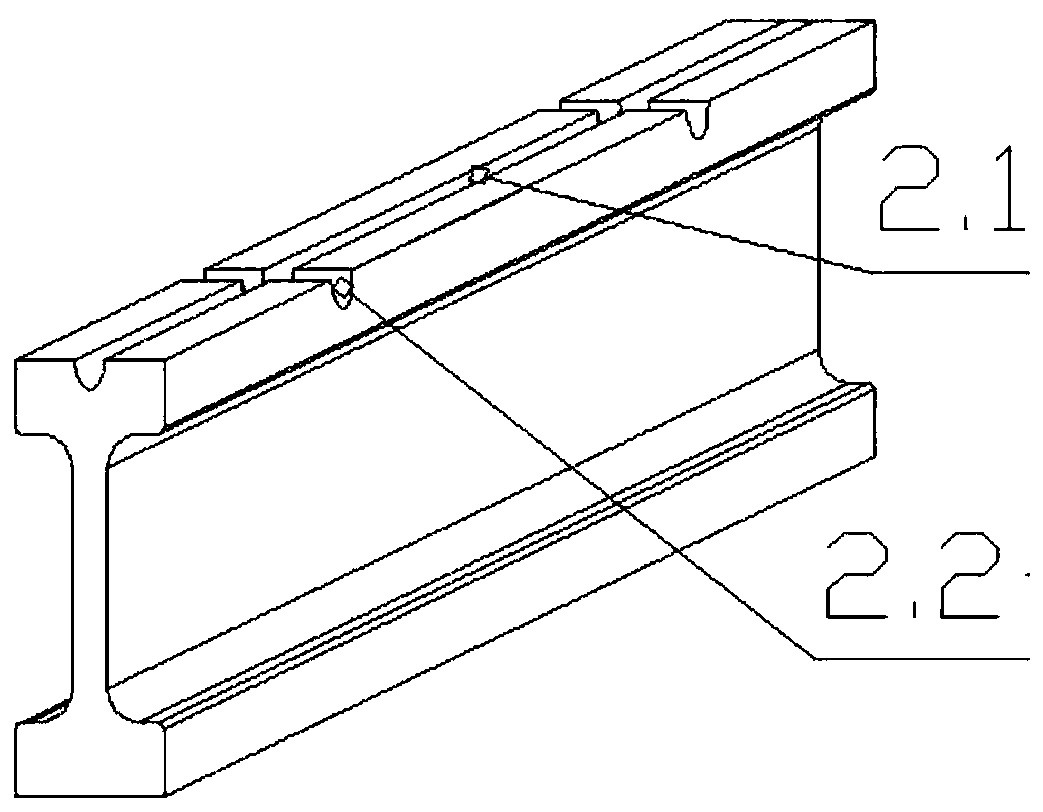

[0044] The work partition brick 2 is in the shape of "I", the bottom surface is flat, and the top surface is provided with through longitudinal grooves 2.1 and transverse grooves 2.2. The height of the partition brick is 1 / 2 of the thickness of the board, and the length of the top surface is more than twice the distance between the gluten in the transverse groove. The thickness of the partition brick is 3-4cm, preferably 3.5cm. The distance between the transverse groove of the work partition brick and the edge is 1 / 2 the gluten spacing in the transverse groove; the number of transverse grooves is 2. The material of the work partition brick is permeable concrete. figure 2 The structure of the work part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com