Blade machine bucket height automatic adjusting method and device thereof

An automatic adjustment and road grader technology, which is applied to mechanically driven excavators/dredgers, etc., can solve problems such as difficulty in clearing obstacles and affecting work efficiency, and achieve the effect of ensuring construction quality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

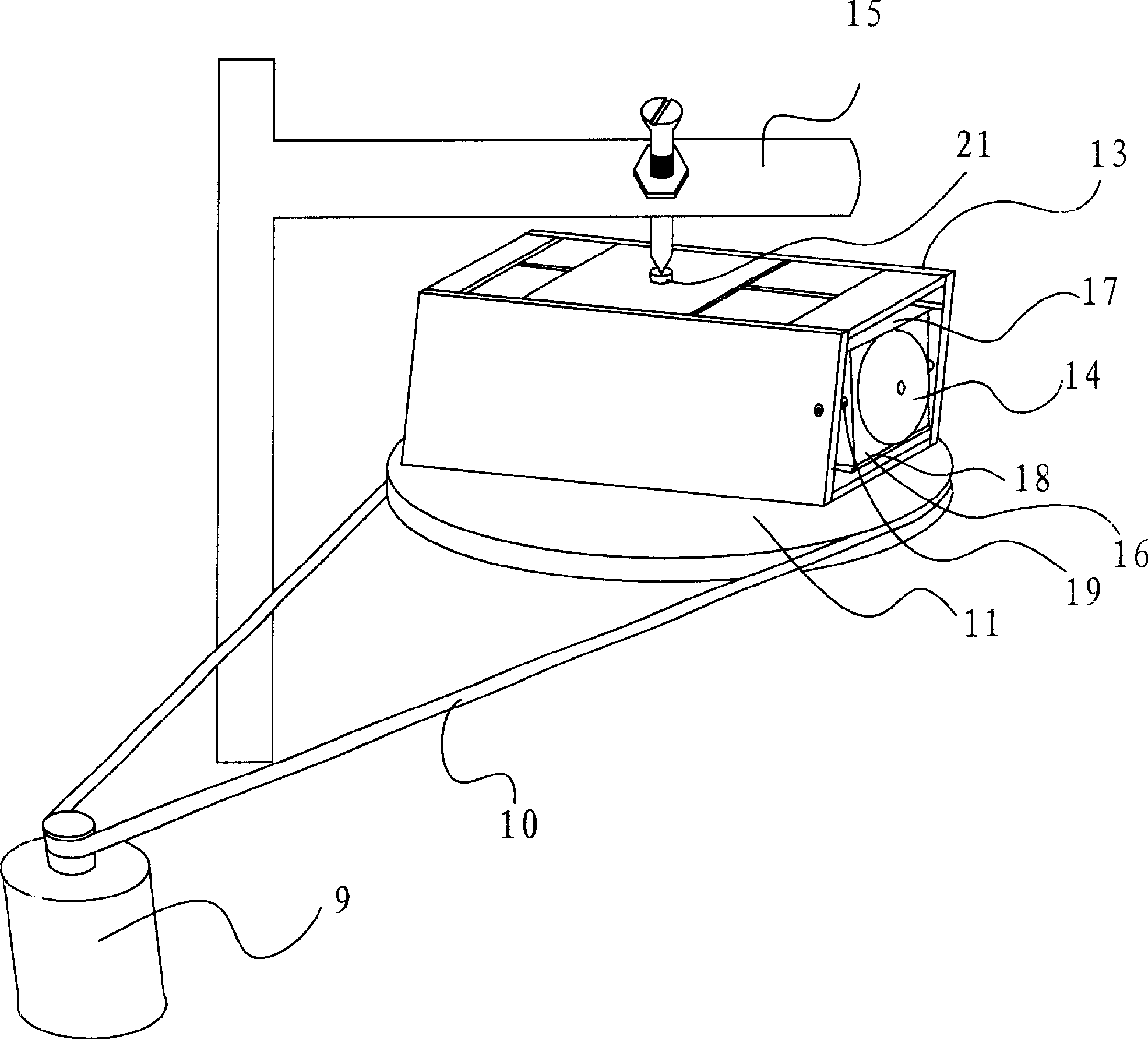

[0020] The present invention will be further described below in conjunction with accompanying drawing:

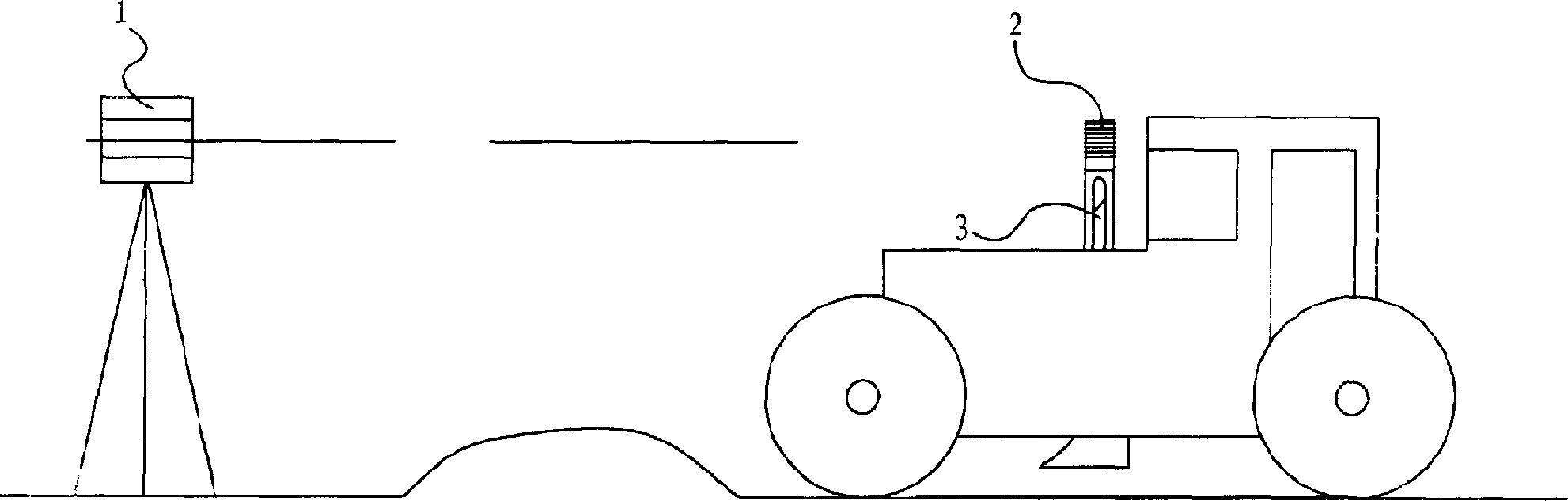

[0021] The invention mainly aims at improving the defects existing in the construction process of the existing grader. The construction road surface is often uneven, and the height of the bucket on the road grader needs to be adjusted continuously during the road leveling process in order to remove obstacles on the road surface. The effect of the road is always not very ideal, and repeated construction is often required, resulting in low work efficiency and low construction quality.

[0022] In the present invention, the following method is proposed to solve this problem, and the concrete steps are:

[0023] (1) Place a laser emitter that can emit a rotating laser line in front of the road grader. The laser transmitter is selected here because the laser has high intensity and good directionality, and is not easy to scatter; the laser is required to be rotated and emitted,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com