Outlet device for a container or vessel

A nozzle device and nozzle technology are applied in the field of pump action nozzles, and the field of manufacturing such nozzle devices can solve problems such as easy actuation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0170] In the following description of the drawings, the same reference numerals in different drawings are used to designate the same or corresponding parts where appropriate.

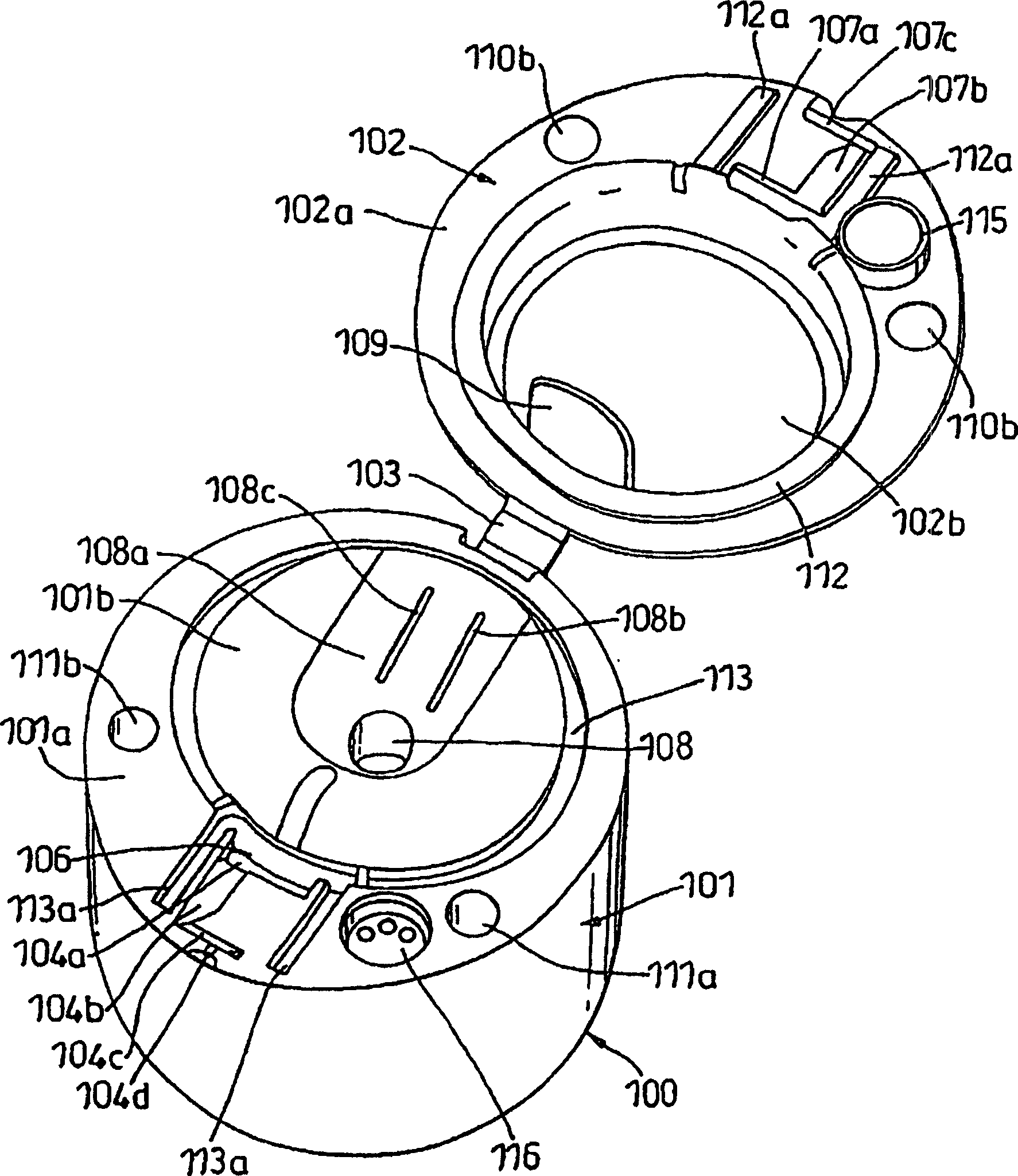

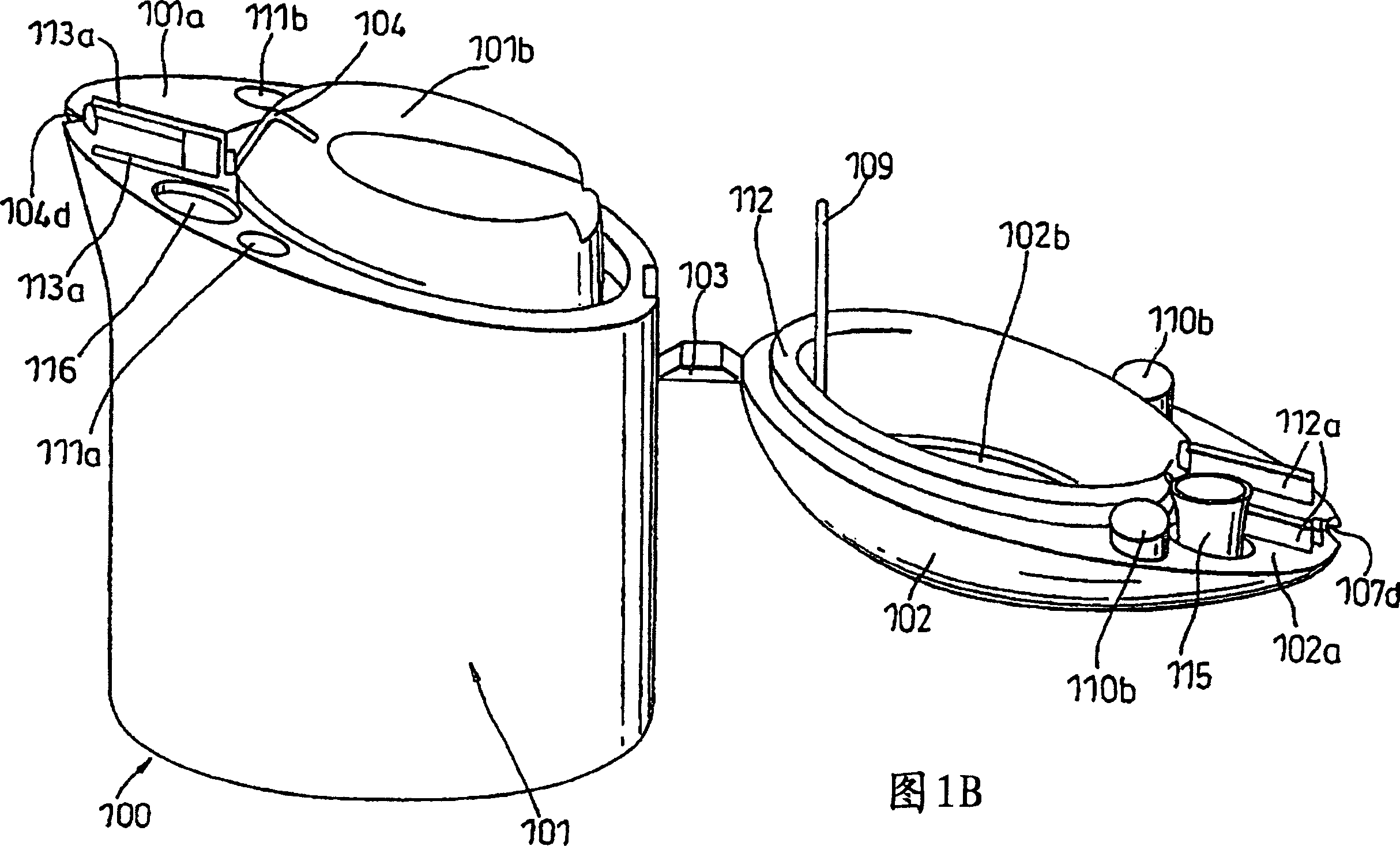

[0171] attached Figure 1A The nozzle device shown in and 1B comprises a main body 100 comprising two parts, namely a base 101 and an upper part 102 , which are interconnected by foldable connectors 103 .

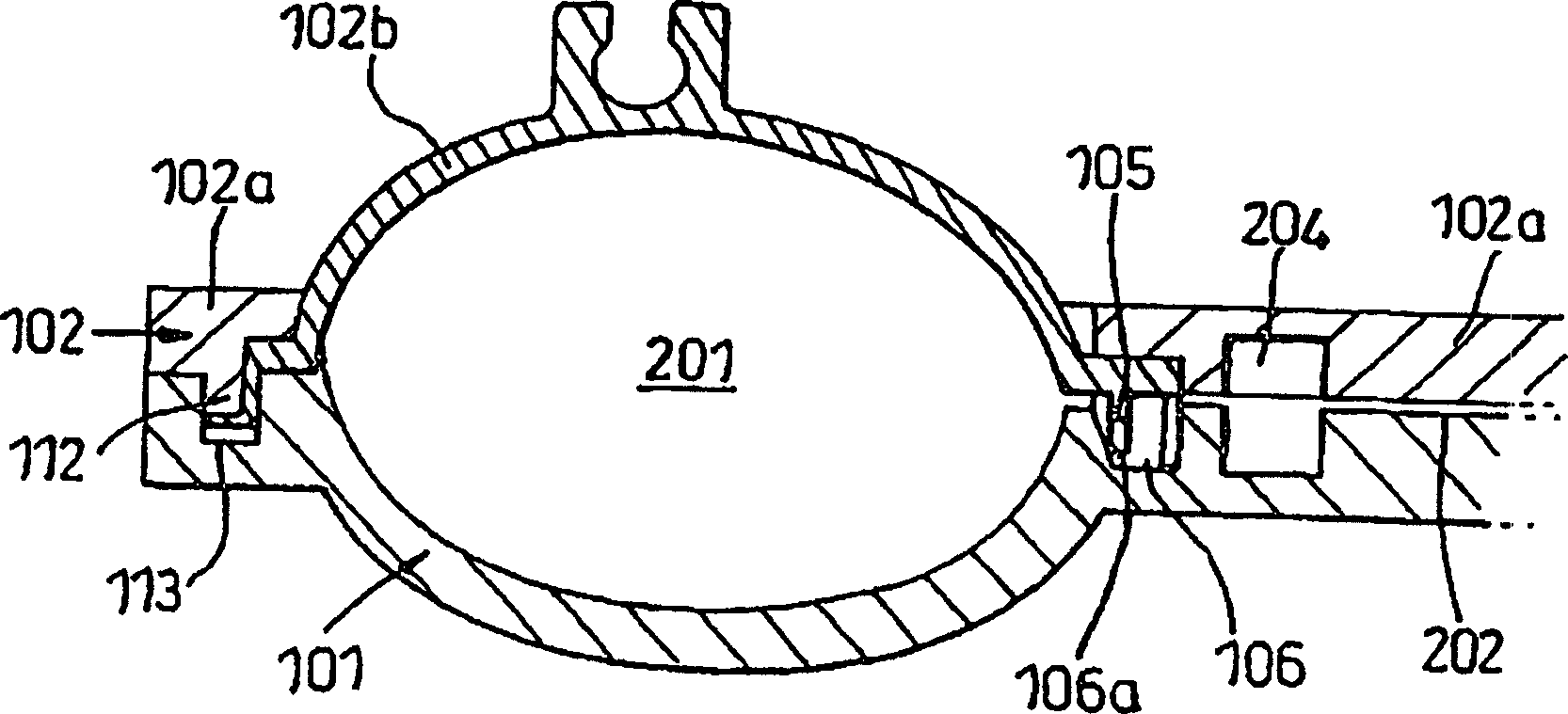

[0172] Body 100 is formed from a single rigid plastic in a single molding operation. The device is accompanied by Figure 1A and 1B, the upper part 102 is then folded around the connector 103 and fitted onto the upper surface of the base 101 to form an assembled nozzle structure. Once the base 101 and upper part 102 are fitted together, a portion 102a of the lower surface of the upper part 102 abuts an adjoining portion / surface 101a of the upper surface of the base 101 . The raised portion 101b of the upper surface of the base 101 is received in a groove 102b formed in the lower surface of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com