Automatic flip method and flip device

An automatic and semi-automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of materials falling into improper positions and unable to return materials to the correct position, so as to improve the flipping effect and efficiency, improve cooking quality, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

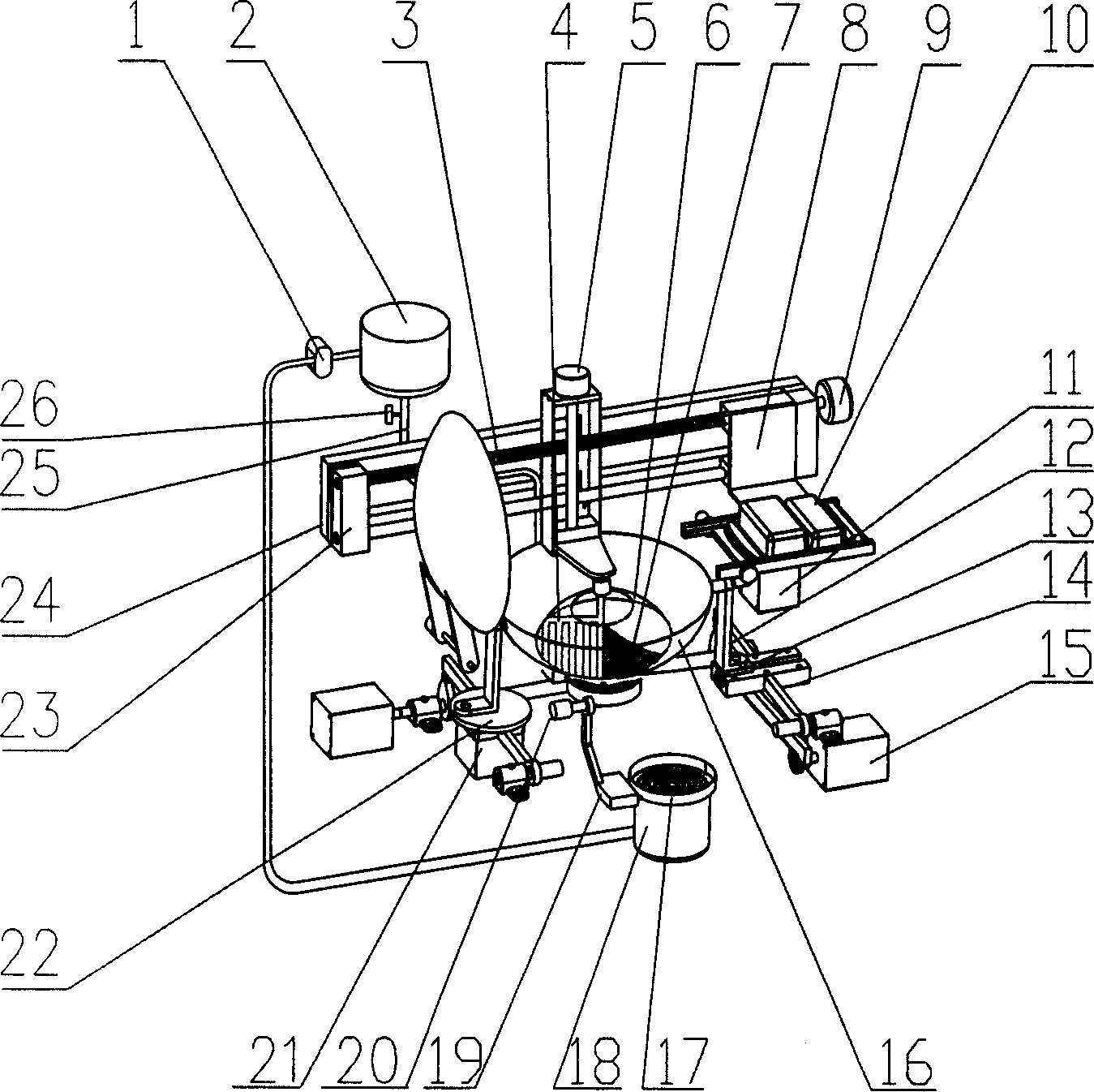

[0025] Please refer to figure 1 , is an automatic cooking machine that adopts the turning method and turning device of the present invention. Among them, 16 is a pot; 17-20 constitutes a lubricating oil system; 21, 22, 12-14 are a crank slider mechanism that drives the pot to shake the pot; 11 is a driving motor and a reducer that drives the pot to turn over; 15 is 8-10 are material packaging and feeding mechanisms; 23, 24 and 3 are; 1, 2, 25 and 26 are cooking oil recovery and feeding systems; 4-7 are turning devices, Wherein 6 is a limit device, 4 is a comb-shaped turning tool, and 7 is a shovel-like turning tool, 4 and 7 are installed on the same rotating shaft, and the motor 5 drives the turning device to rise and fall; 23, 24 and 3 are to make the turning device and The screw mechanism for the translation of the feeding mechanism.

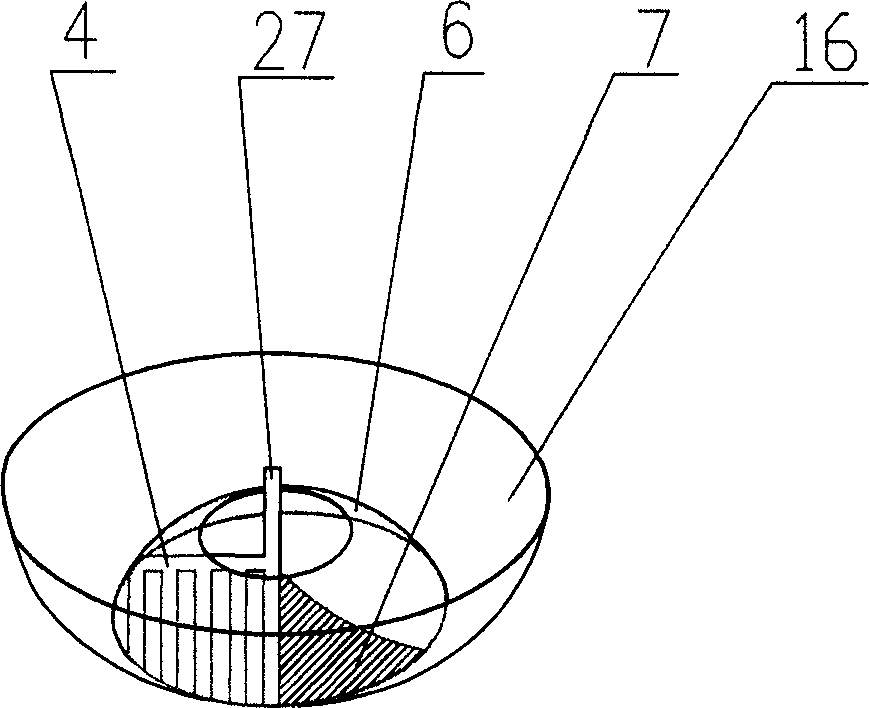

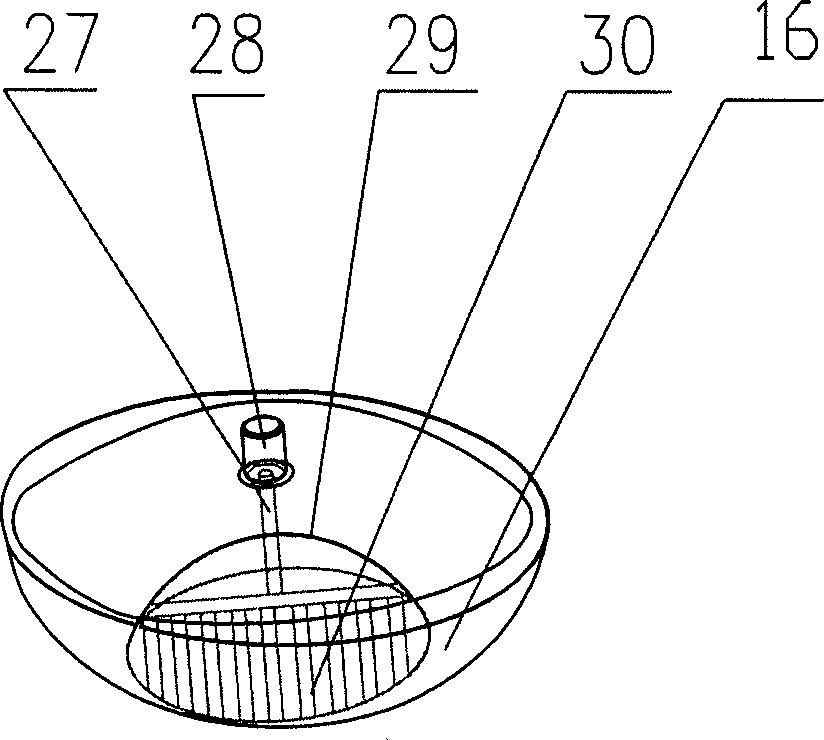

[0026] figure 2 One embodiment of the invention is shown. 16 among the figure is a pot; 6 is a ring-shaped limiting device, and its bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com