Apparatus for testing cement-based material deformation under multiple environmental conditions

A cement-based material, deformation testing technology, applied in the direction of mechanical solid deformation measurement, material inspection products, etc., can solve the problem that the volume deformation of cement-based materials cannot be correctly evaluated, the early deformation test of cement-based materials cannot be performed, and the influence of engineering environmental factors is not considered and other problems, to achieve the effect of fast measurement, small quantity, and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

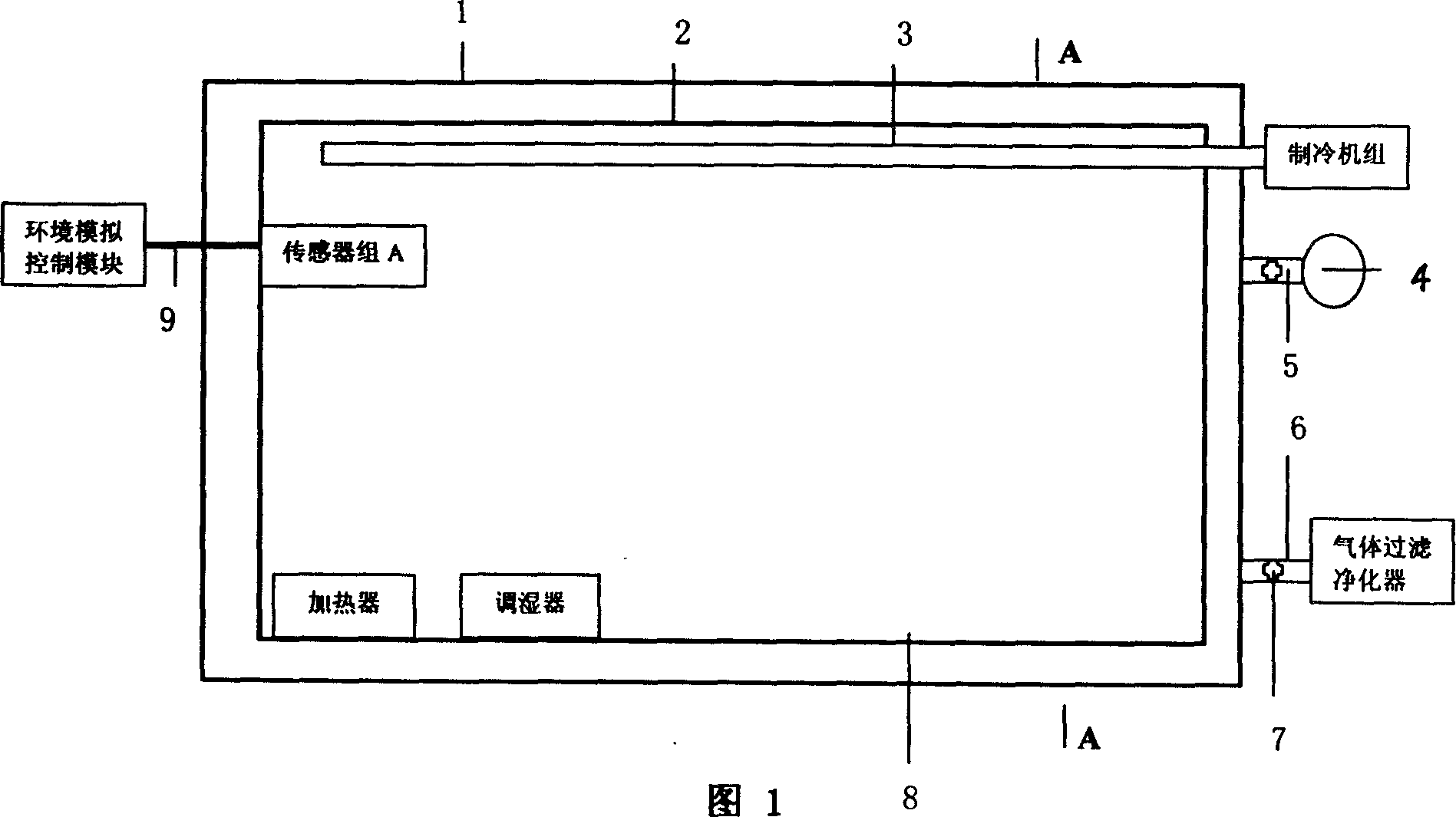

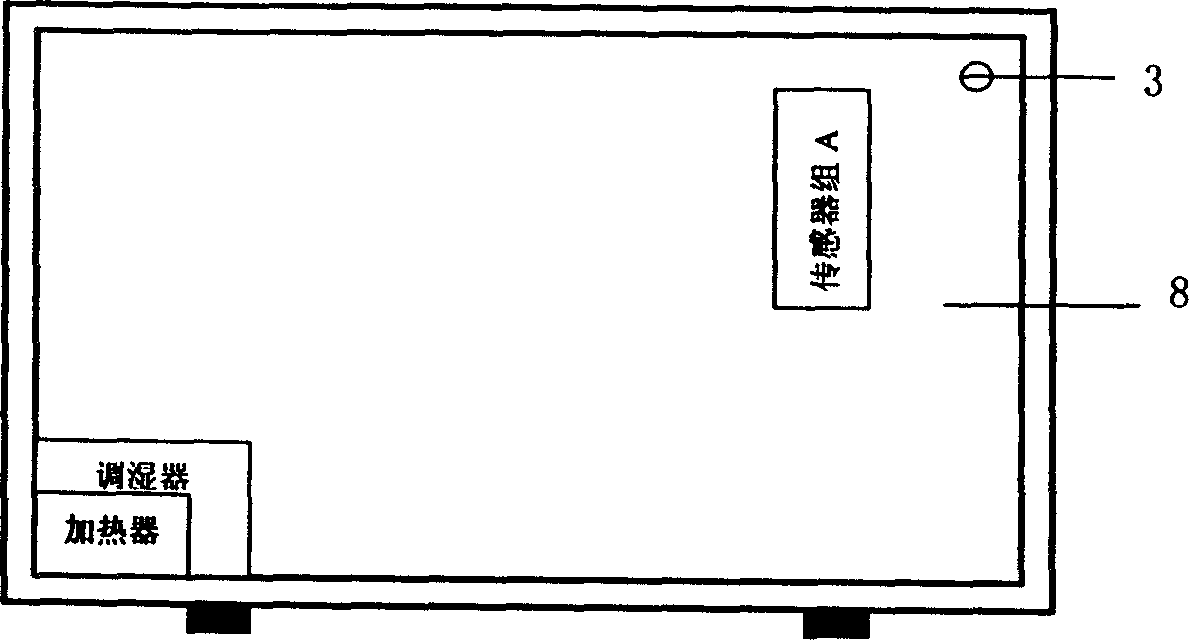

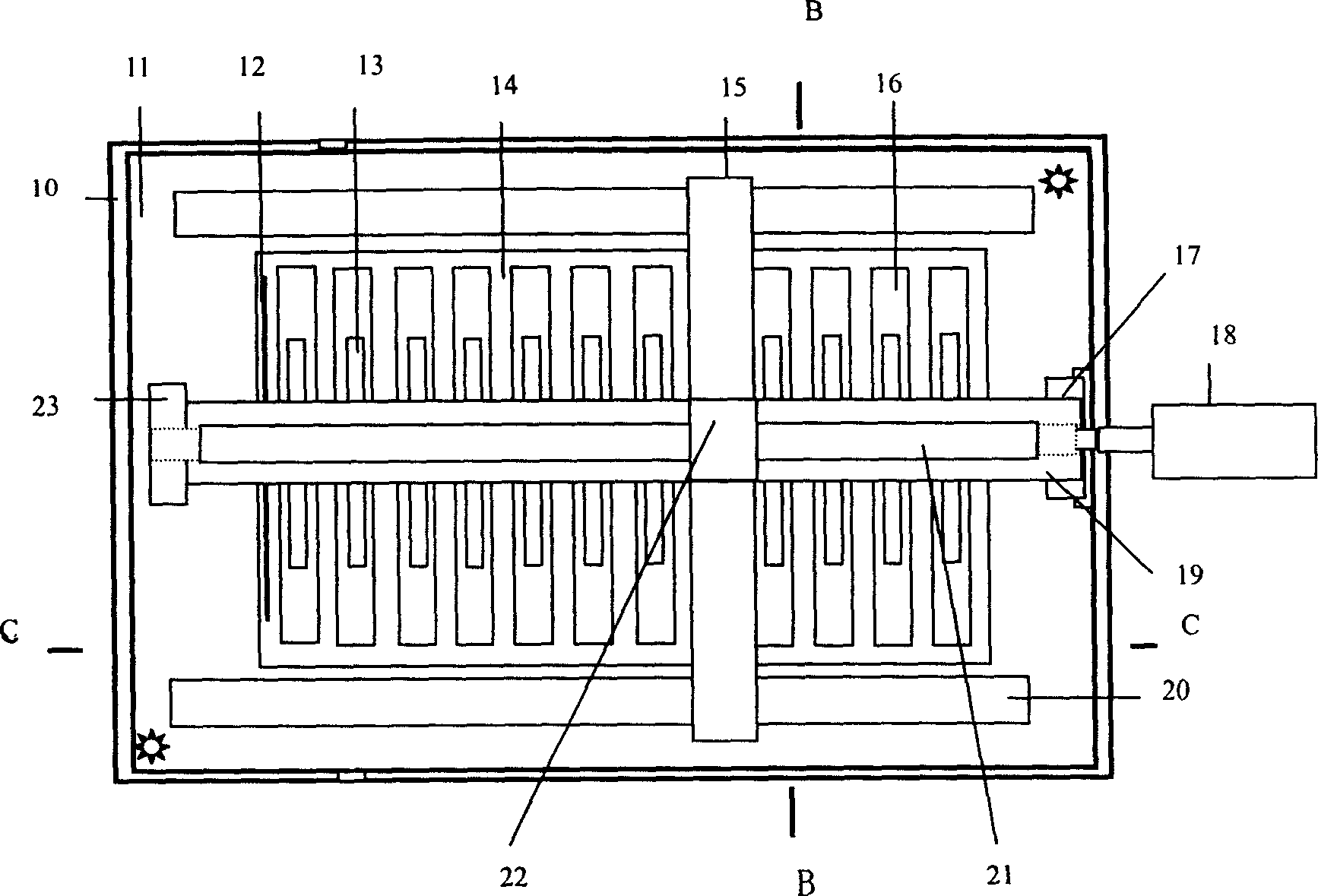

[0025] like image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7, Figure 9 As shown, a cement-based material deformation testing device under multiple environmental conditions, it includes an environmental simulation box 10, a pedestal 14, a displacement sensor, a temperature sensor, a computer, a copper measuring head 34, a pedestal 14, a displacement sensor measuring head 25, a temperature sensor The measuring head 35 is located in the simulation chamber 8 of the environmental simulation box 10, the bottom of the pedestal 14 is located on the steel floor 11 in the environmental simulation box 10, and the upper part of the pedestal 14 is respectively provided with 12 small dark grooves 13 and 12 large dark grooves. Groove 16, 12 test pieces are located on the pedestal 14, copper probes 34 are pre-embedded at both ends of the test pieces. Temperature sensor comprises temperature sensor measuring head 35 and temperature sensor control module, and temperature sensor measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com