Scintillator member and manufacturing method thereof, and radiation measuring device

A measuring device and manufacturing method technology, which is applied in the field of shading technology and radiation measuring device, and can solve problems such as weak strength and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

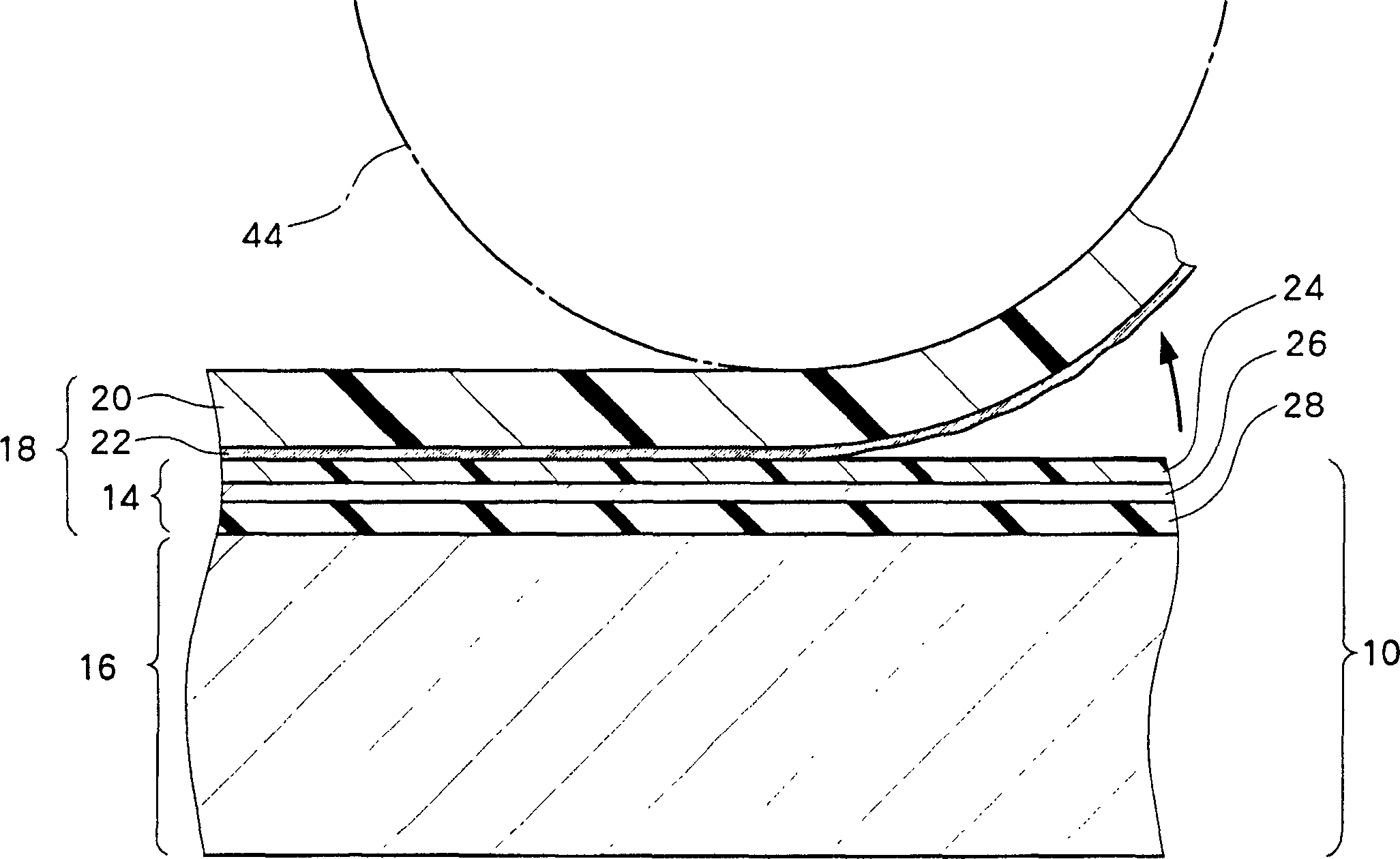

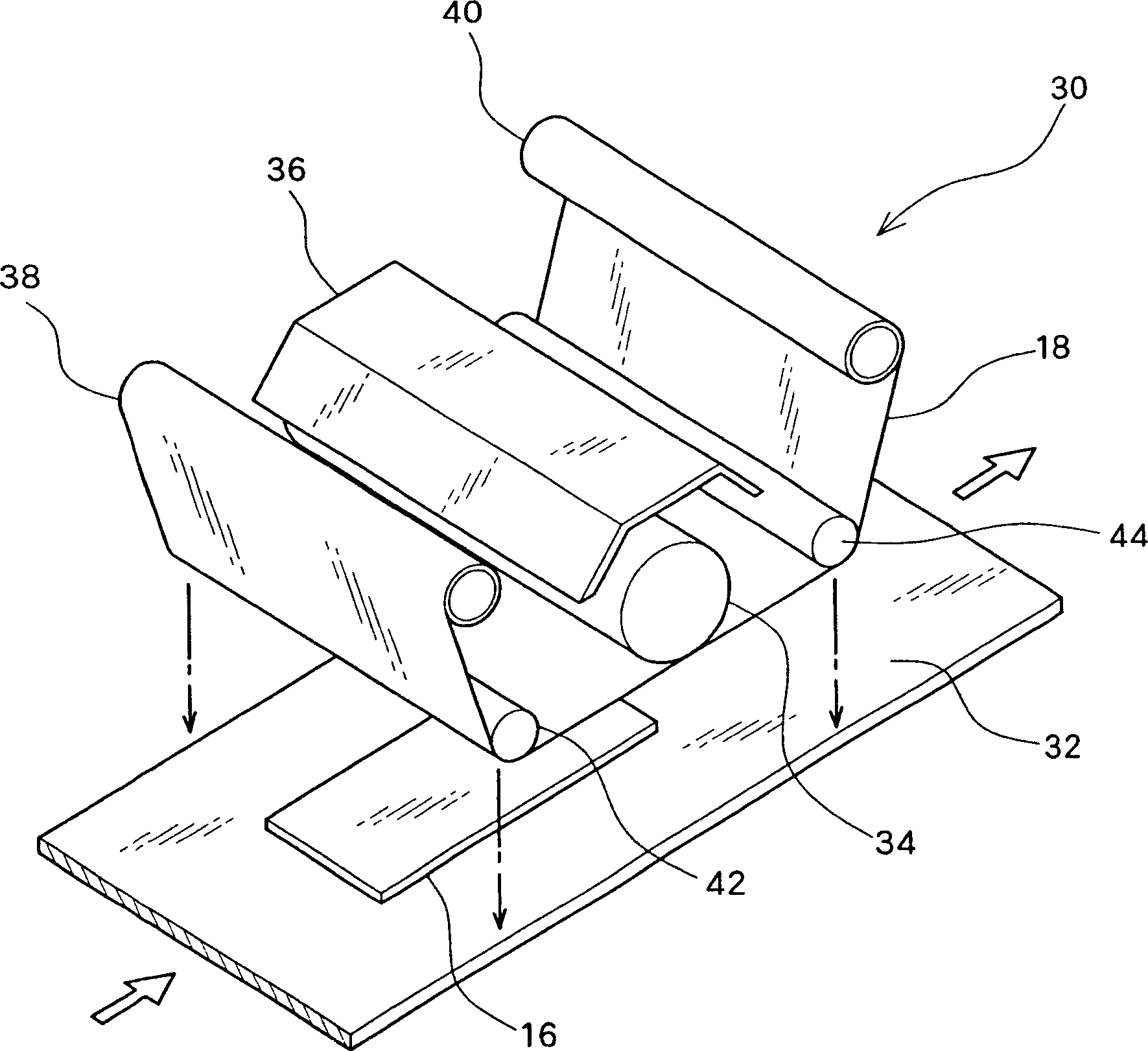

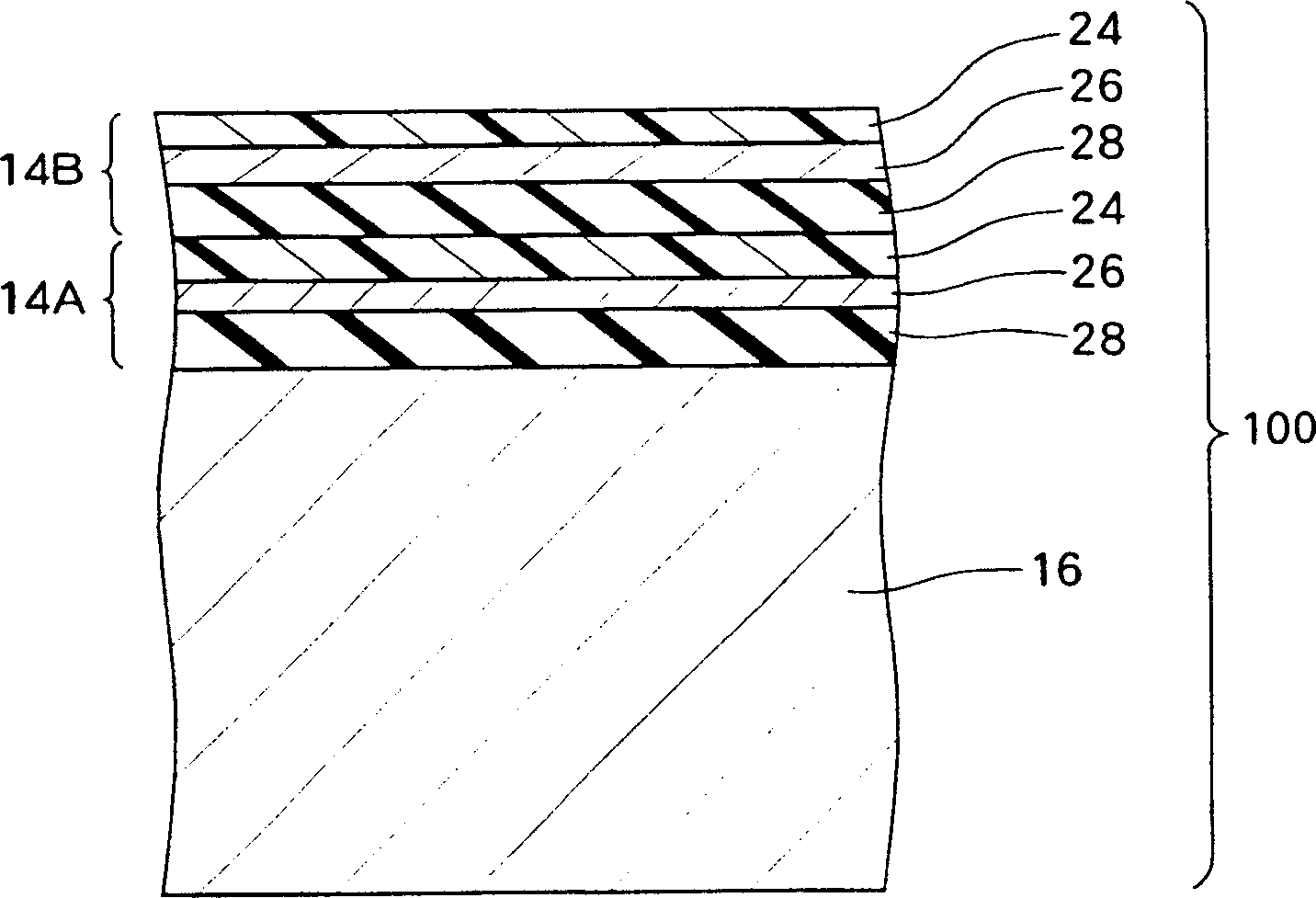

[0034] figure 1 A method for manufacturing the scintillator member 10 is shown. In the radiation measuring apparatus, the scintillator unit 10 is used as a radiation detector. The scintillator unit 10 is composed of a scintillator plate 16 and a film 14 .

[0035] figure 1 This is an embodiment in which one film is formed on the surface (radiation incident surface) of the scintillator plate 16 , but a plurality of films may be formed on the surface of the scintillator plate 16 .

[0036] The scintillator plate 16 is constructed of a plastic scintillator material. As is well known, when radiation enters the scintillator member 16, light is emitted, and the inner surface side of the scintillator plate detects the emitted light. Several types of radiation include X-rays (γ-rays), β-rays, and α-rays, and the scintillator member 10 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com