Method of feeding tire structure member

A technology for tires and parts, applied in the supply field of tire components, which can solve the problems of complicated intermediate product management operations, obstacles to productivity improvement, and many winding frame replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, the same constituent elements are denoted by the same reference numerals, and repeated explanations are omitted.

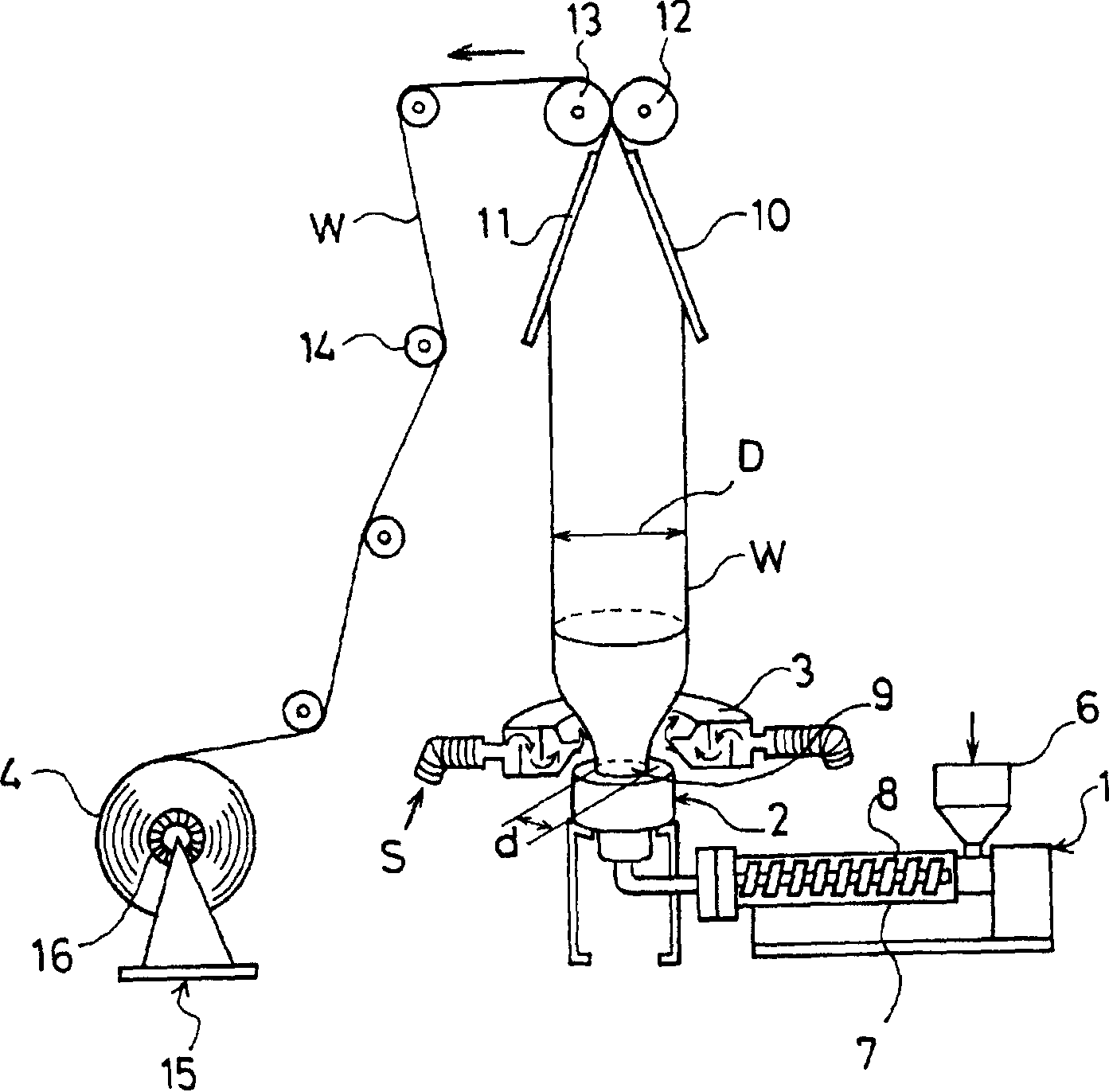

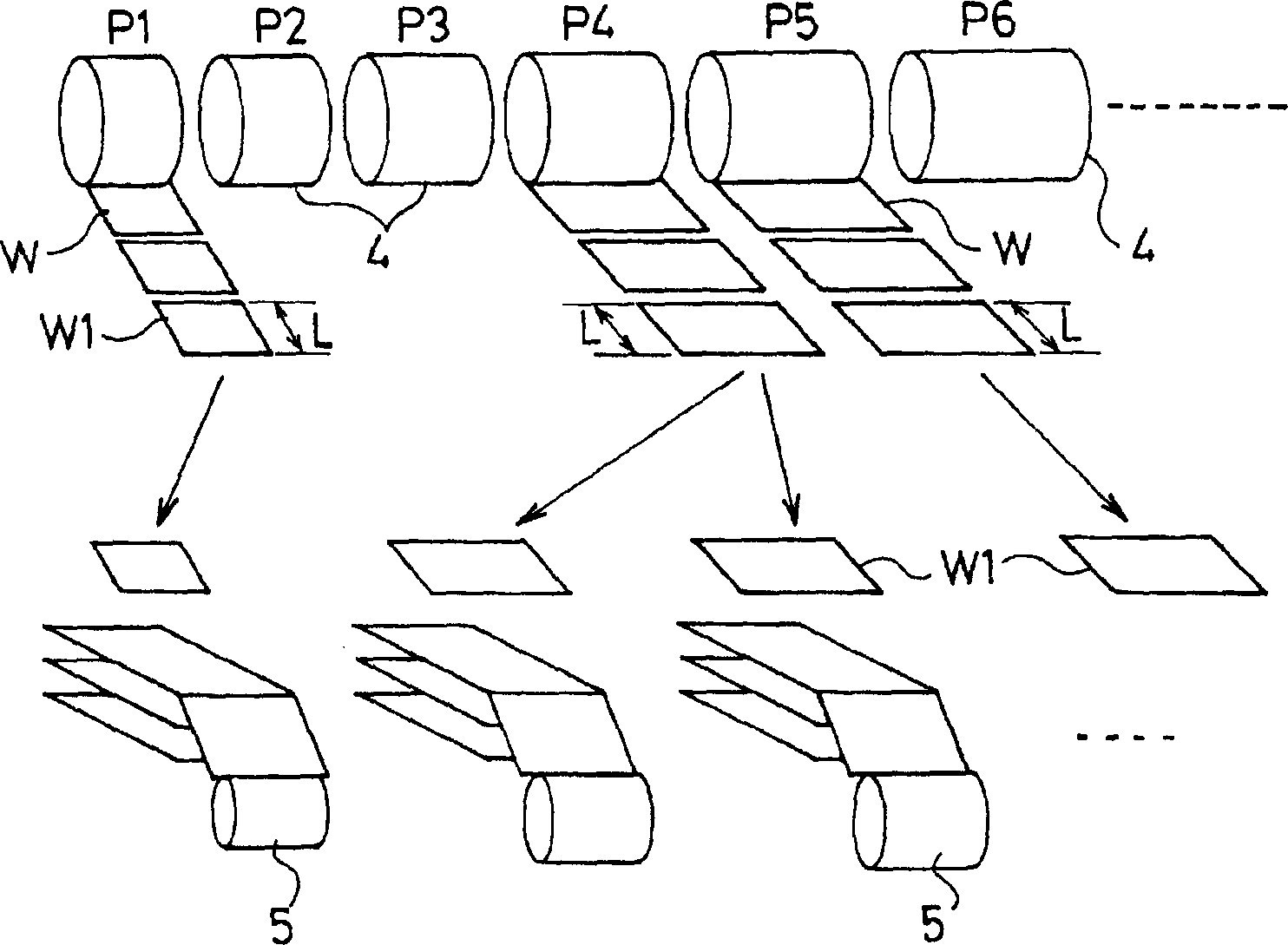

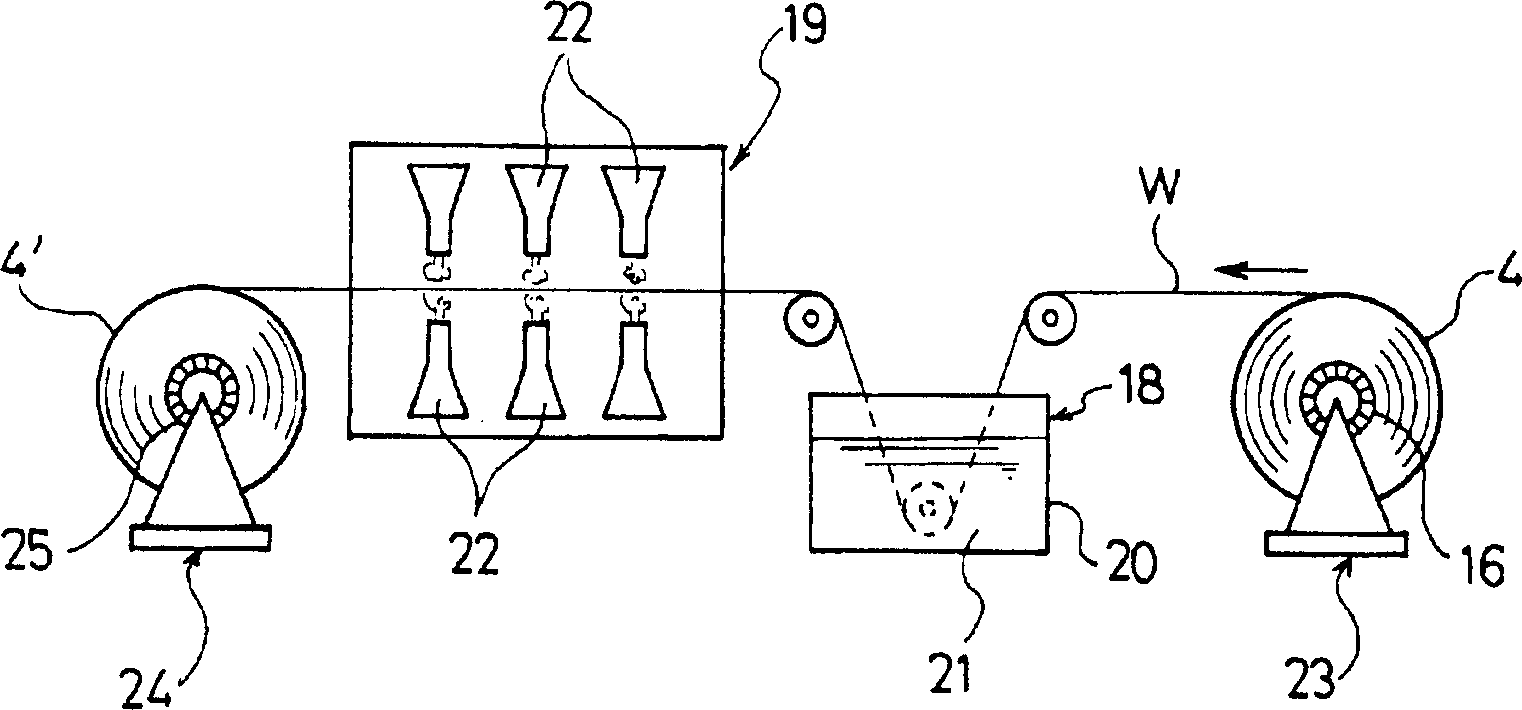

[0018] exist figure 1 , 2 Among them, 1 is a uniaxial extruder, 2 is a circular die installed on the extrusion port of the uniaxial extruder 1, 3 is a ventilator for air cooling the cylindrical film W extruded from the circular die 2, and 4 Reference numeral 5 denotes a roll body formed by winding a cylindrical film W into a roll, 5 denotes a building drum (tire molding machine), and W1 denotes a tire component. The tire component W1 is composed of a thermoplastic resin elastic material in which a rubber component is dispersed in a thermoplastic resin component, and is particularly suitably used as an inner liner arranged on the inner surface of a pneumatic tire.

[0019] The method of supplying tire components of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com