Preparation method of magneto-resistor film for improving accuracy of electronic compass

An electronic compass and magnetoresistance technology, which is applied in the field of preparation of magnetic multilayer films, achieves the effects of improving precision, improving sensitivity, and facilitating preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

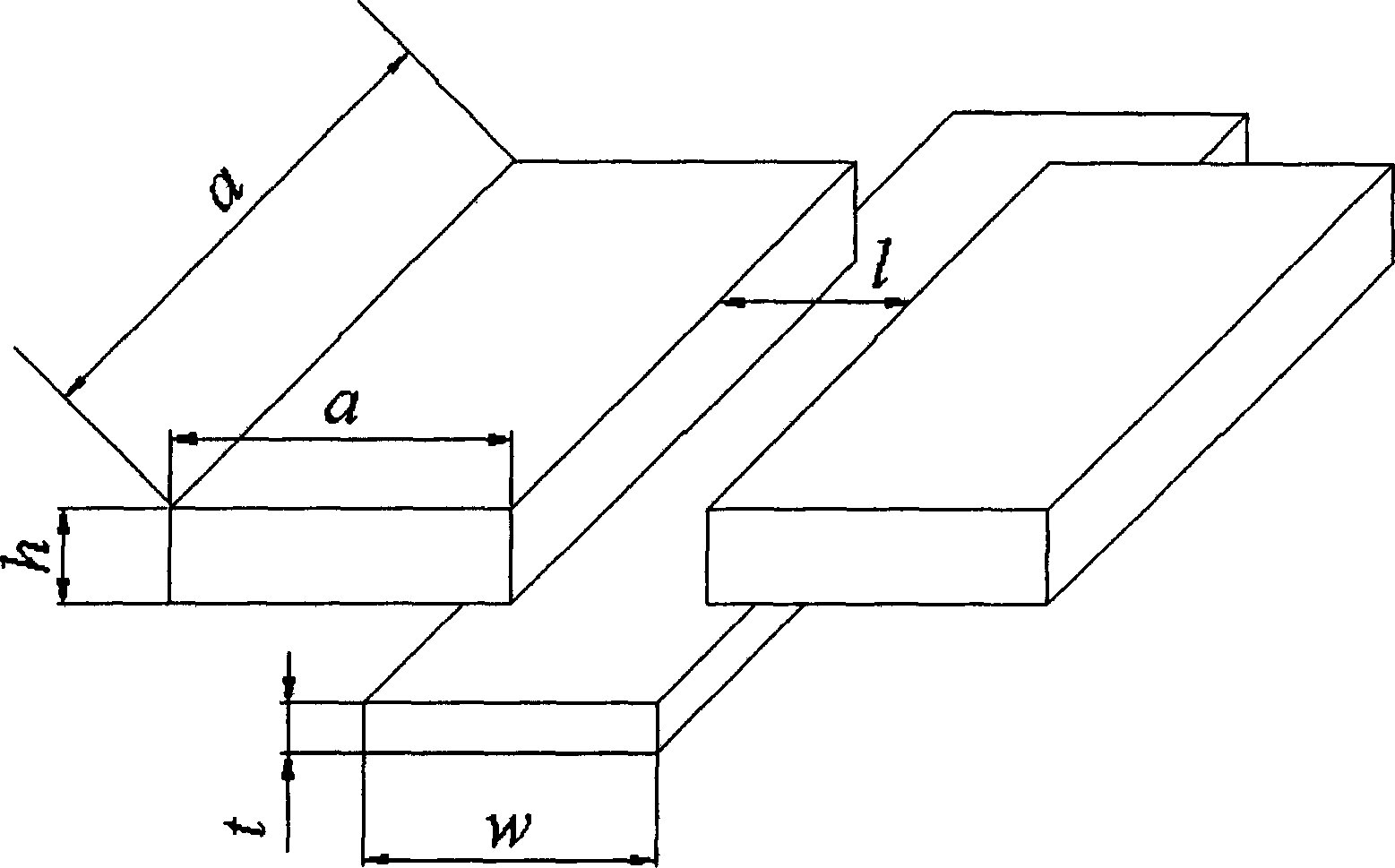

Image

Examples

Embodiment 1

[0012] Example 1: Preparation of a magnetic multilayer film in a magnetron sputtering apparatus. First, the single crystal Si (001) substrate was ultrasonically cleaned with organic chemical solvent and deionized water, and then mounted on the sample base of the sputtering chamber. The substrate is cooled by circulating water, and a magnetic field of 150-250 Oe is applied parallel to the direction of the substrate. Sputtering chamber background vacuum 3×10 -5 Pa, under the condition of argon gas (purity of 99.99%) pressure of 0.5 Pa during sputtering (Ni 0.81 Fe 0.19 ) 54 Cr 36 (50) / Ni 0.81 Fe 0.19 (300) / Ta(6); Then, the thin film is processed into a magnetoresistive sensor element with a line width of 30 microns through a general semiconductor processing technology. Combined with the semiconductor processing technology, the thickness of 8 microns Ni is deposited on both sides of the component parallel to the strip-shaped component. 0.81 Fe 0.19 film. Ni deposited 0.81 Fe 0.19 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap