Method for increasing permalloy thin film magnetic resistance change rate

A technology of permalloy and magnetoresistance, which is applied in the field of preparation of functional material thin films, can solve the problems of adverse effects on the magnetic properties of permalloy thin films, increase the difficulty of thin film preparation, increase the thickness of magnetic dead layers, etc., so as to improve anisotropic magnetic properties. Effect of resistance change rate, device performance improvement, and magnetoresistance change rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

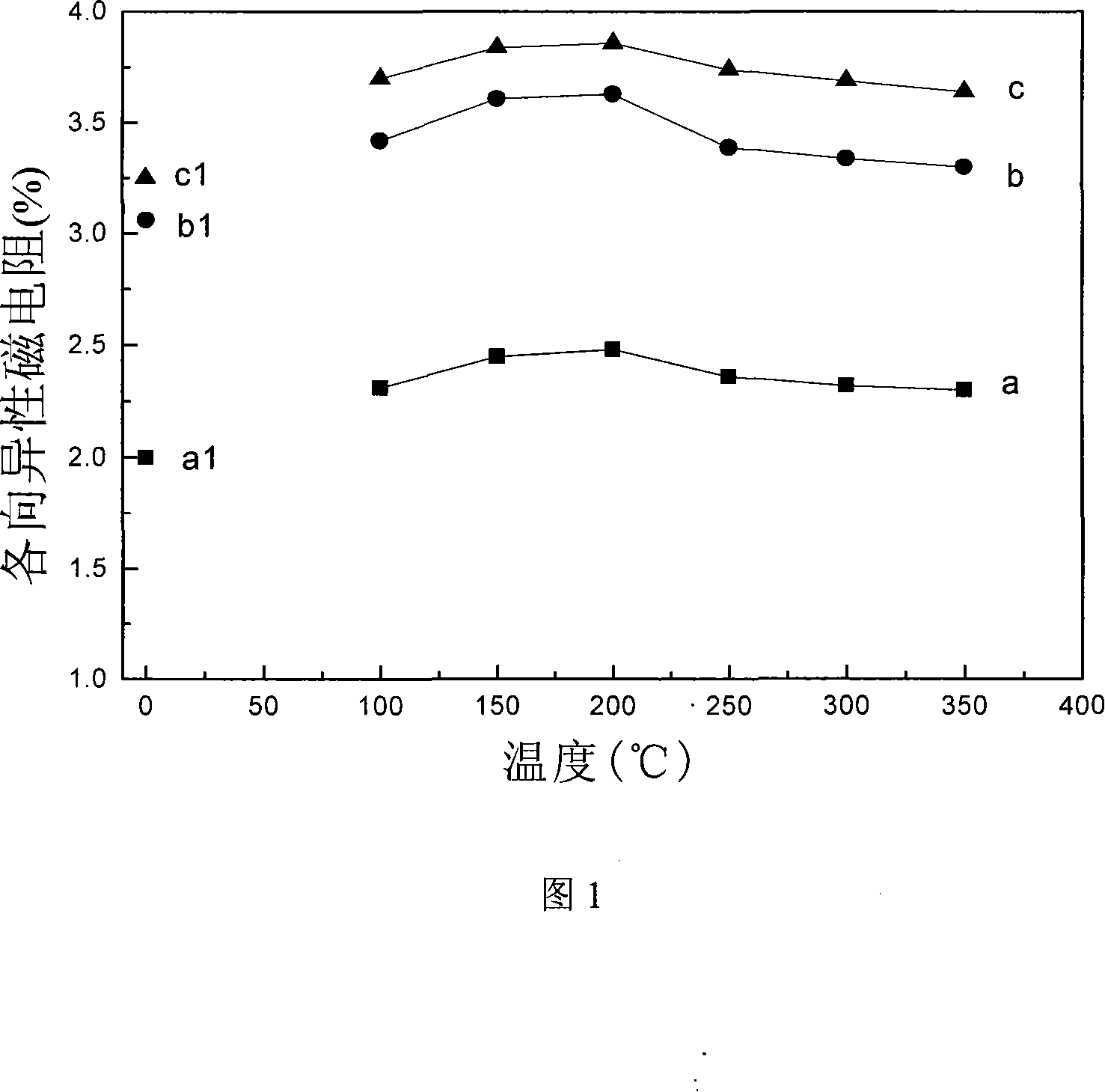

[0007] As shown in Figure 1, the sputtering process condition of the curve (a) is: the background vacuum degree of the sputtering chamber is 1×10 -5 Pa, the gas pressure of argon (99.99% pure) during sputtering is 0.2Pa. During the sputtering process, a magnetic field parallel to the film surface is applied on the surface of the substrate, the magnitude is 150Oe, and the substrate rotates at a rate of 20r / min; 100 Ȧ) / NOL (10 Ȧ) / Ta (20 Ȧ); when the cobalt-iron CoFe nano oxide layer was prepared, the oxygen pressure was 0.1Pa, and the oxidation time was 10 minutes; the background vacuum was 1×10 during annealing -4 Pa, the magnetic field applied parallel to the easy axis of the film is 150Oe, and the annealing time is 60 minutes.

[0008] The sputtering process condition of curve (b) is: the background vacuum of the sputtering chamber is 3×10 -5 Pa, the gas pressure of argon (99.99% pure) during sputtering is 0.3Pa. During the sputtering process, a magnetic field parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com