Dual-feeding mixed excitation axial magnetic field magento motor

A hybrid excitation and axial magnetic field technology, applied in electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of small constant power speed regulation range, difficult magnetic field weakening control, and unadjustable magnetic field, etc. Wide range of amplitude variation, improved reliability, and easy cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

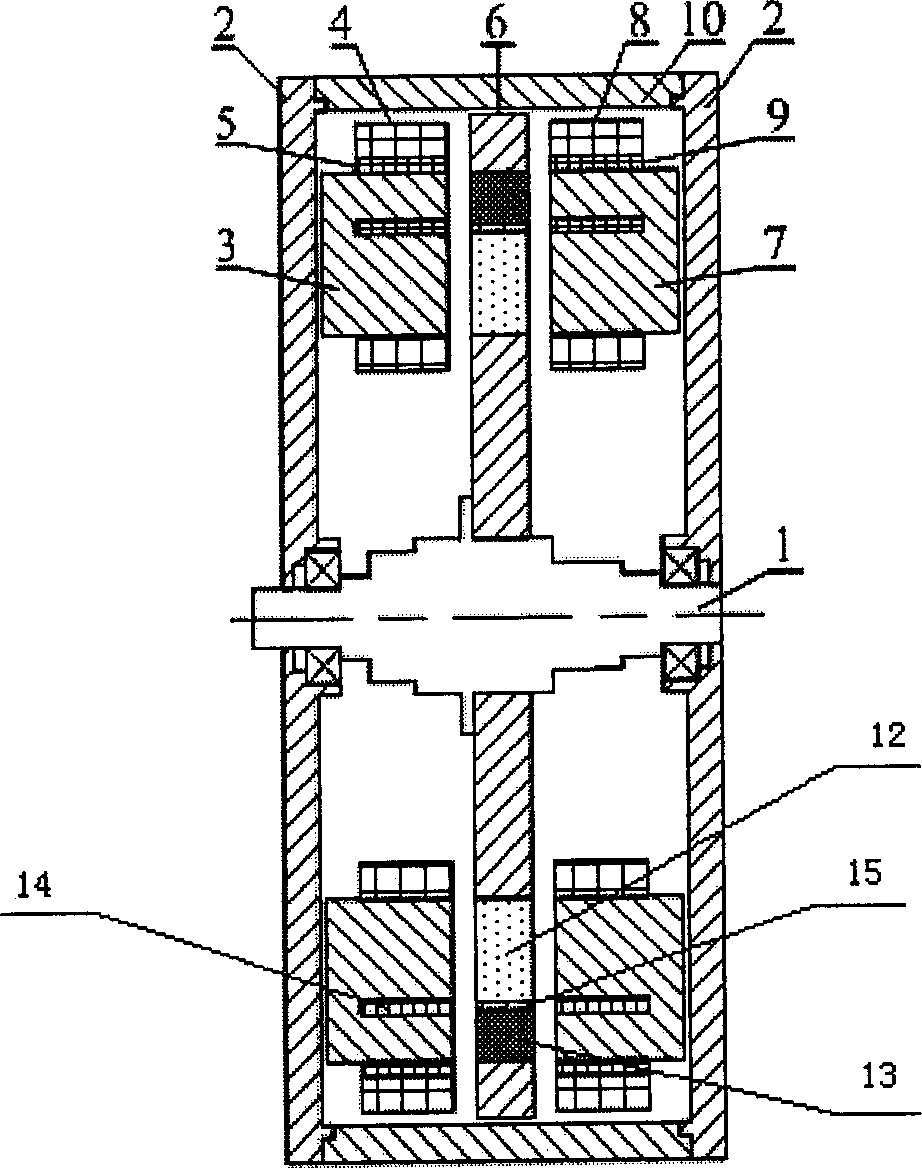

[0021] The specific implementation of the double-fed hybrid excitation axial field permanent magnet motor will be further described in detail in conjunction with the accompanying drawings:

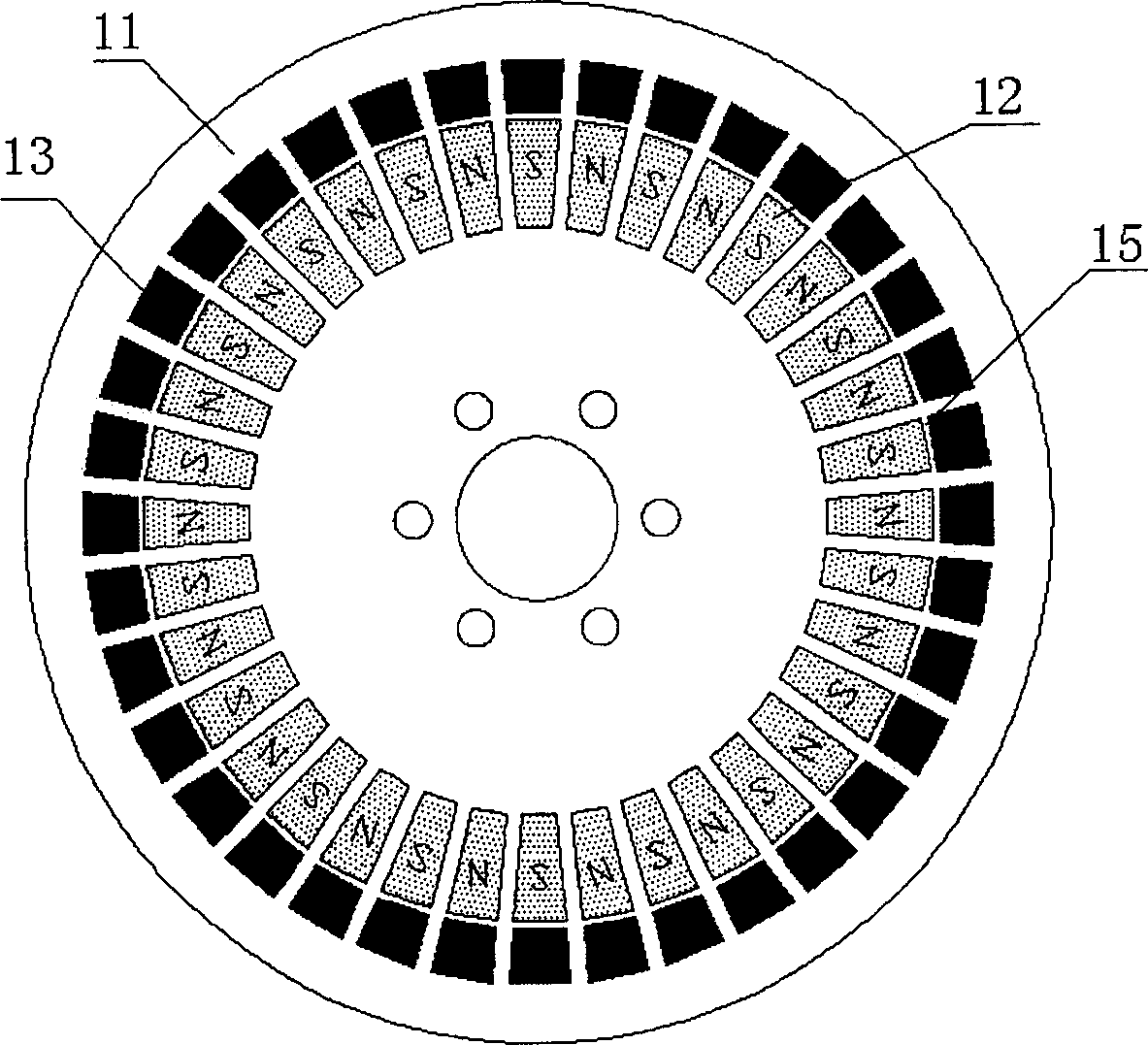

[0022] 1. The stainless steel frame 11 of the rotor is dug with a plurality of trapezoidal holes to form inner and outer circles of holes. The inner circle holes are staggered to insert permanent magnets 12 with opposite polarities, and the outer circle holes are embedded with iron core poles 13. The iron core poles 13 and The number of permanent magnet poles 12 is equal to the number of motor poles, and the stainless steel between the inner and outer circles of holes is a magnetic isolation area 15 to reduce the magnetic flux leakage between the permanent magnet 12 and the iron core pole 13, specifically as figure 2 shown.

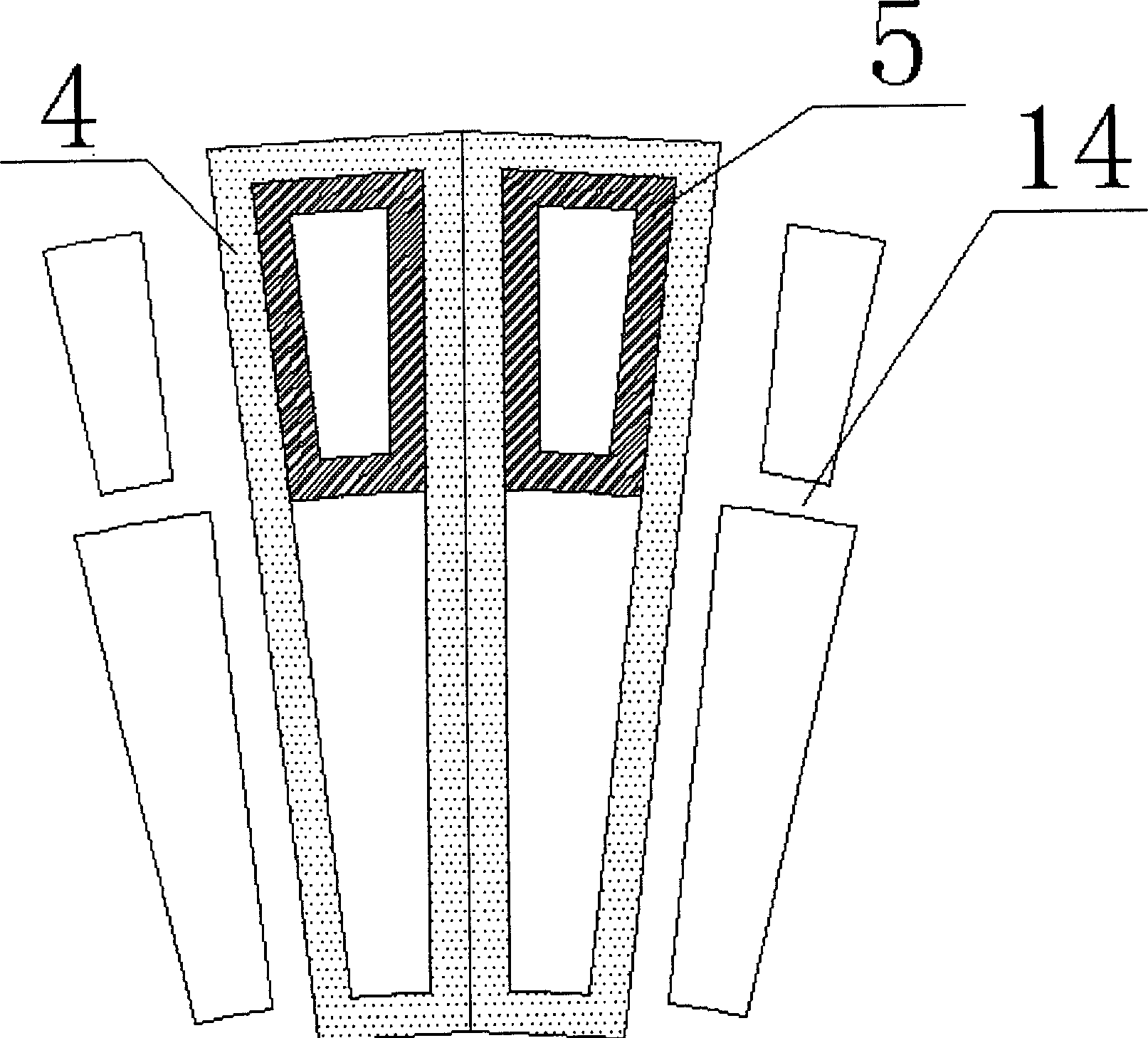

[0023] 2. The left and right stators 3 and 7 have an auxiliary slot 14 at the position corresponding to the magnetic isolation area 15 of the rotor. The radial width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com