Oxide catalyst for dehydrogenating ethyl benzene to prepare styrene

An ethylbenzene dehydrogenation and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbons, etc., can solve the problem of poor stability, low styrene selectivity, and catalyst side effects Problems such as more toluene production, to achieve the effect of less by-product toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

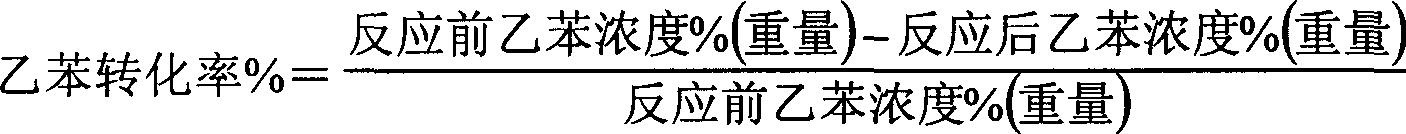

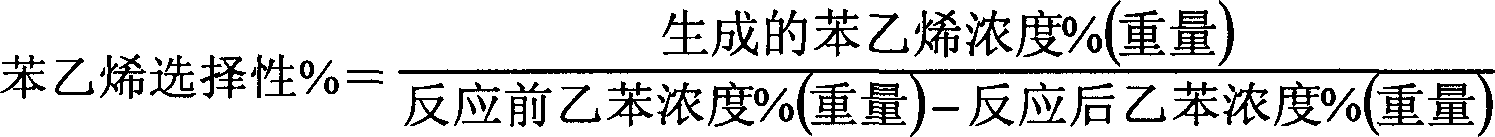

Image

Examples

Embodiment 1

[0028]

[0029] composition

[0030]

[0031] composition

[0032] catalyst

[0033]

[0034] Reaction time

[0035] The above examples illustrate that in the Fe-K-Ce-Mo system, zirconium, tin, and at least one oxide combination selected from calcium, manganese, and tungsten are added, and a pore-forming agent and a binder are added to form a desiccant. The hydrogen catalyst has the outstanding advantages of less by-product toluene, high styrene selectivity and good stability, which is beneficial to the factory to increase the output of styrene and increase economic benefits. It is a new type of dehydrogenation catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com