Self repairing tyre for motorcycle

A self-repairing technology for motorcycles, applied to tire parts, vehicle parts, transportation and packaging, etc., can solve problems such as inability to self-repair tires, unsatisfactory anti-puncture performance, and inconvenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

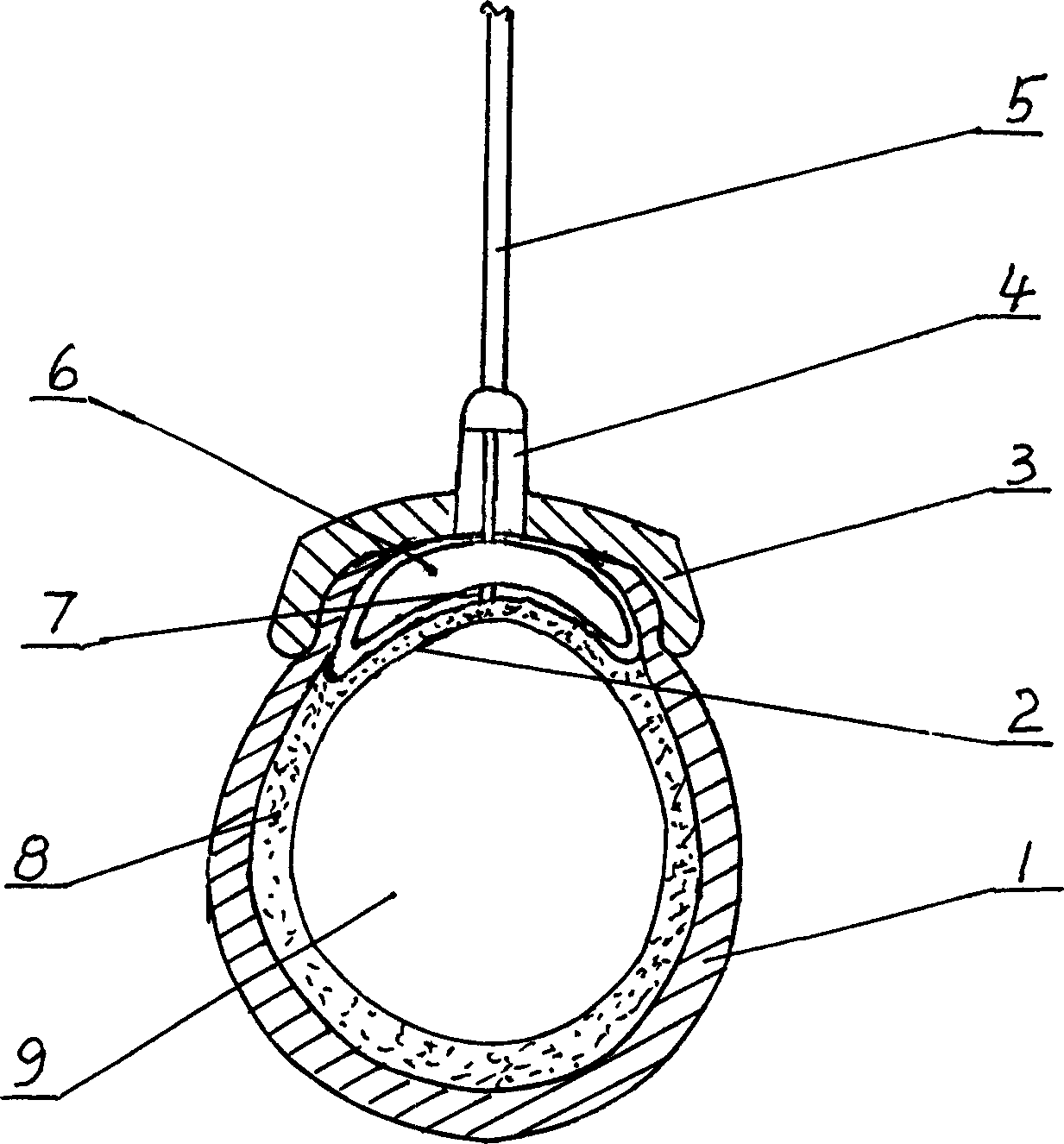

[0006] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

[0007] A kind of motorcycle self-repairing tire, see attached figure 1 , it consists of a rubber tire 1 embedded on the motorcycle hub steel 3, and an auxiliary inner tire 2 is arranged in the tire 1 close to the steel ring 3, covering the inner surface of the steel ring 3 and the joint between the tire 1 and the steel ring 3, Auxiliary inner tube 2 has inflation nozzle 4 to stretch out outside steel ring 3, and ventilating hole 7 is arranged to communicate with inner tube 2 inner chamber 6 and the tire inner cavity 8 formed by cover tire 1 and steel ring 3, and one layer of self-contained layer is covered on tire inner cavity 8 peripheral walls. Tire sealant 8, mark 5 among the figure is the wheel hub steel wire on the steel ring.

[0008] Self-sealing tire liquid is the self-sealing tire liquid of existing market purchase. Or adopt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com