Long-distance continuous lining pipe and short metal pipe composite device and preparation method

A composite device and metal pipe technology, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, mechanical equipment, etc., can solve problems such as deviation and inconvenience in construction, and achieve the effects of improving operating efficiency, overcoming long-distance traction, and tight docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

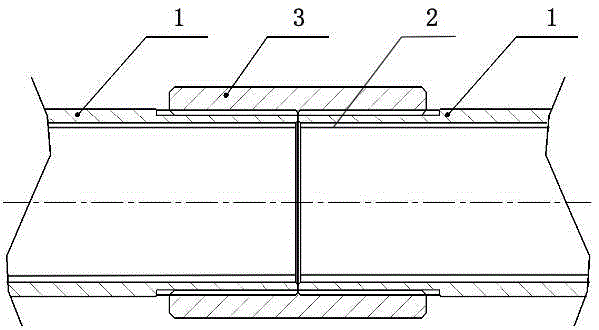

[0020] A long-distance continuous lining pipe and short metal pipe composite device comprises a plurality of short metal pipes 1 in the outer layer and a lining pipe 2 in the inner layer, and the plurality of short metal pipes 1 are connected end to end. Also includes a collar 3, the collar 3 has a female thread inside, and the two ends of the short metal pipe 1 have male threads respectively, and the ends of two adjacent short metal pipes 1 are screwed into the collar 3 and passed through the male thread It is engaged with the female thread of the coupling 3, and the end faces of the two short metal pipes 1 are tightly butted. The original welding is replaced by threaded connection, which greatly improves the construction accuracy and prevents the deviation of the welding joint, which will cause the inner liner to be easily stuck or scratched.

[0021] The sum of the lengths of the male threads at both ends of the short metal pipe 1 is 10%-15% greater than the length of the f...

Embodiment 2

[0024] A method for preparing a long-distance continuous lining pipe and a short metal pipe composite device, the method comprising the following steps:

[0025] (1) Screw the end of the first short metal pipe into the coupling;

[0026] (2) Connect the lining pipe with a traction tool and pass through the first short metal pipe;

[0027] (3) Pass the pulling tool through the second short metal pipe;

[0028] (4) Screw the second short metal pipe into the coupling that has been connected to the first short metal pipe until the ends of the two short metal pipes are tightly connected;

[0029] (5) Pull the lining pipe through the second short metal pipe with a pulling tool, and so on.

[0030] The following is an example of HDPE (high-density polyethylene) long-distance continuous lining pipe and short metal pipe.

[0031] HDPE (high-density polyethylene) has an outer diameter of 60mm, an inner diameter of 50mm, and a single length of 500m. The short metal pipe is made of 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com