Substrate transferring apparatus

A substrate transfer equipment and substrate technology, applied in lighting and heating equipment, conveyors, conveyor objects, etc., can solve the problems of increased manufacturing costs, complex structure of substrate transfer equipment, and difficult management of conduits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

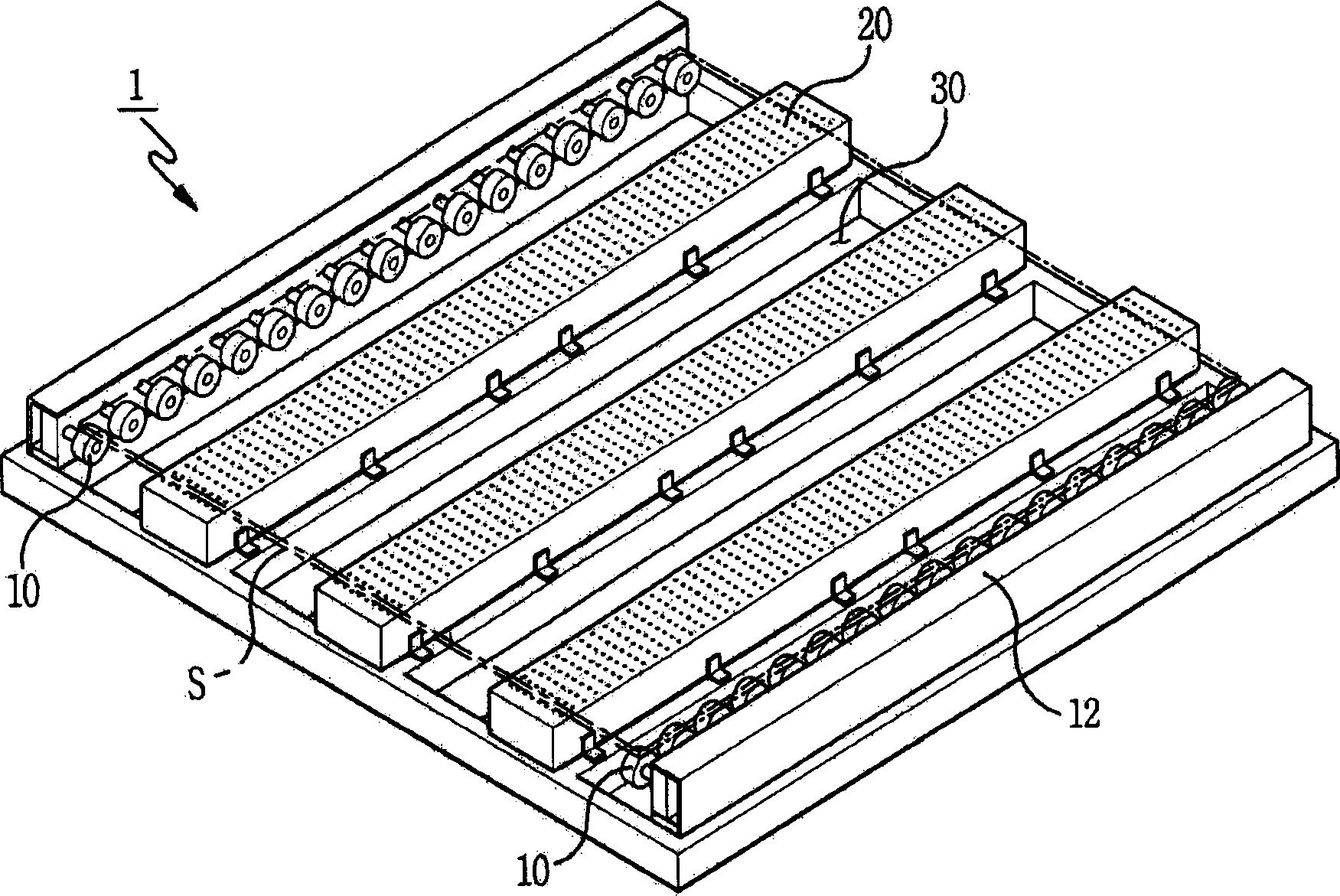

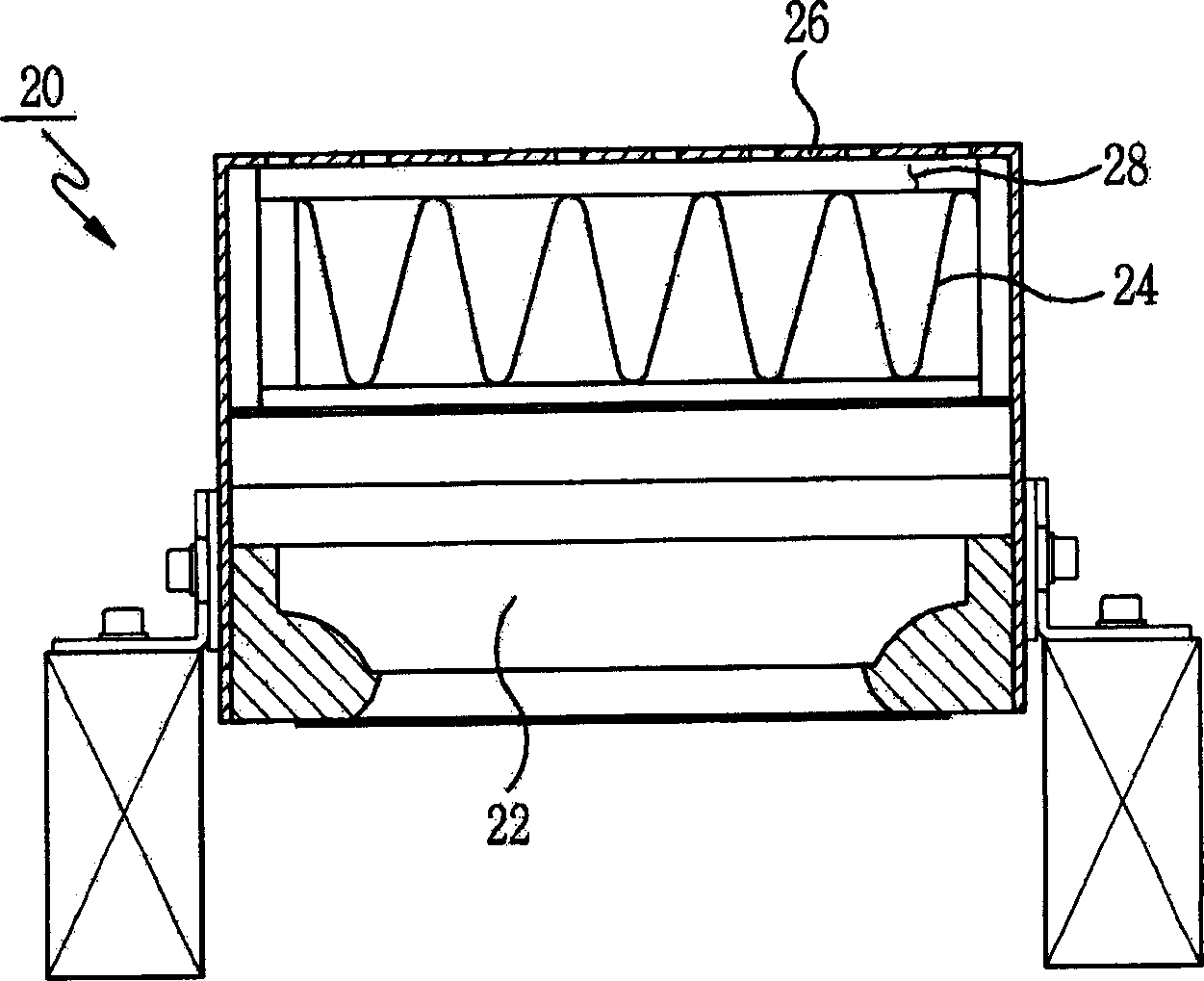

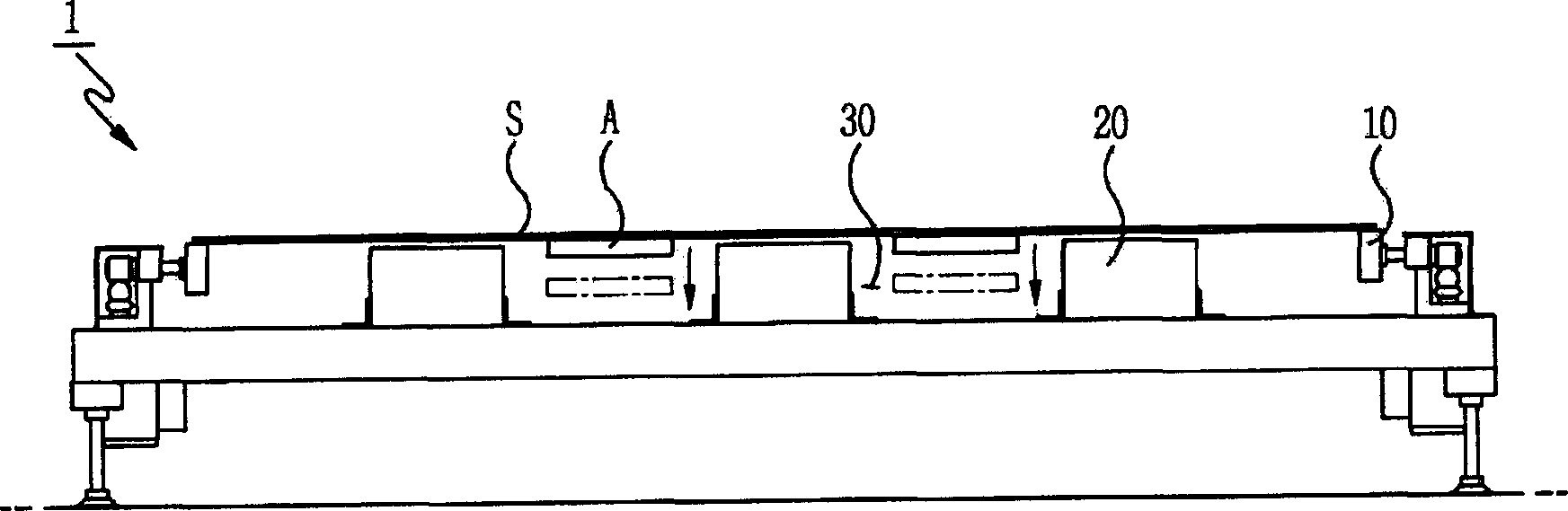

[0021] Such as figure 1 As shown, the substrate transfer apparatus 1 according to the first embodiment includes a pair of transfer roller devices 10 , a plurality of air injection modules 20 , and a plurality of substrate loading and unloading channels 30 .

[0022] The pair of transfer roller devices 10 are in direct contact with both ends of the substrate S, and rotate to transfer the substrate S in a horizontal direction. In order for the substrate to be conveyed by the pair of conveying roller assemblies 10 with a very narrow portion on both sides of the substrate in contact with the pair of conveying roller assemblies 10, the conveying roller assemblies 10 are spaced apart as far as possible in the horizontal direction. . At this time, the transport roller device 10 is rotated by an isolated driving unit (not shown). Here, the driving unit is separated from the pair of transfer roller devices 10 in order to prevent particles that may be generated during the rotation of ...

Embodiment approach 2

[0035] Such as Figure 6 As shown, the substrate transfer apparatus 100 according to the second embodiment includes a substrate moving part 110 and a plurality of air injection modules 120 . According to the second embodiment, the substrate is transferred in an inclined state instead of a horizontal state to reduce the footprint of the substrate transfer apparatus 100 . Here, the substrate is conveyed obliquely at a predetermined angle instead of being conveyed upright, thereby ensuring higher stability when conveying the substrate. When the substrate is transferred obliquely at a predetermined angle, the substrate is supported by the plurality of air injection modules 120 at one side thereof. This allows the substrate to be stably transferred without dropping, and reduces the space occupied by the substrate transfer apparatus 100 in the clean room.

[0036] The substrate moving part 110 is used to move the substrate in the horizontal direction while maintaining the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com