Cell automatic deviation rectifying and closing system and cell automatic deviation rectifying and closing method

An automatic deviation correction and cell technology, which is applied to circuits, electrical components, primary batteries, etc., can solve the problems of high labor intensity, low yield, and poor consistency of cell products, and achieve the goal of improving quality and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

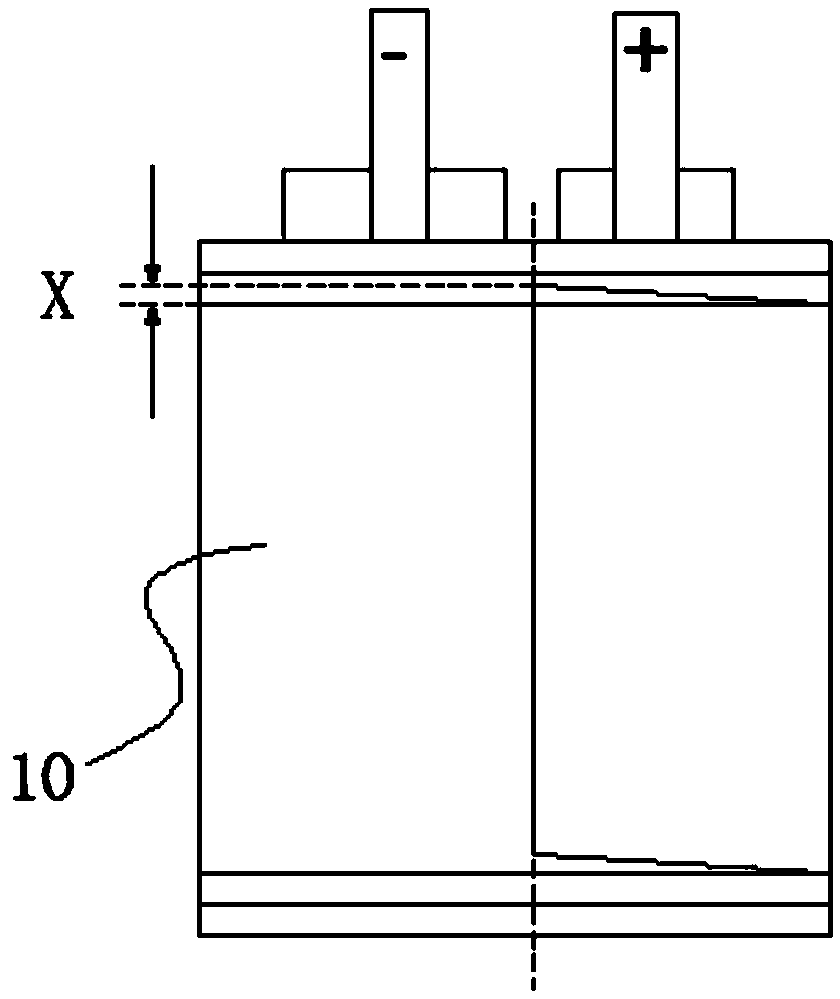

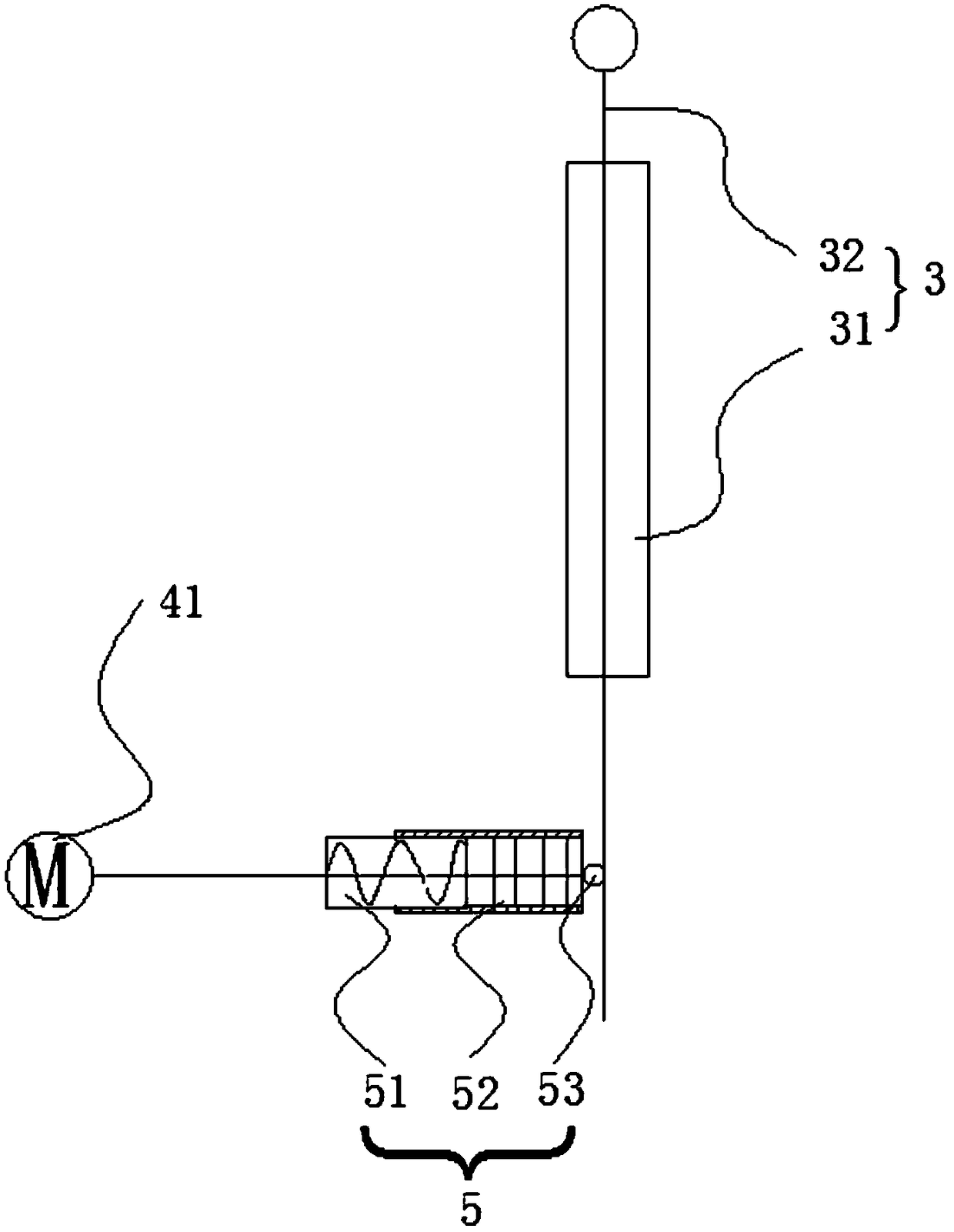

[0049] see figure 1 - Figure 5 , this embodiment 1 provides an automatic correction and finishing system for battery cells, which is used to correct the misalignment of the ending part of the battery cells, including an image collector 1, a controller 2, a roller 3, a driving member 4 and a transmission mechanism 5 , the image collector 1 is electrically connected to the controller 2 , and the controller 2 is electrically connected to the driving member 4 .

[0050] Wherein, the image collector 1 is used to collect the characteristic image of the battery cell, and transmit the collected characteristic image of the battery cell to the controller 2; the controller 2 is used to The misalignment adjustment value of the ending part of the cell is obtained, a control instruction is generated according to the misalignment adjustment value, and the driving member 4 is controlled to drive the transmission mechanism 5 to operate according to the control instruction.

[0051] The end ...

Embodiment 2

[0089] see figure 1 - Figure 5 , the second embodiment provides a method for automatically correcting the end of the cell, which is used to correct the misalignment of the end part of the cell, including the following steps:

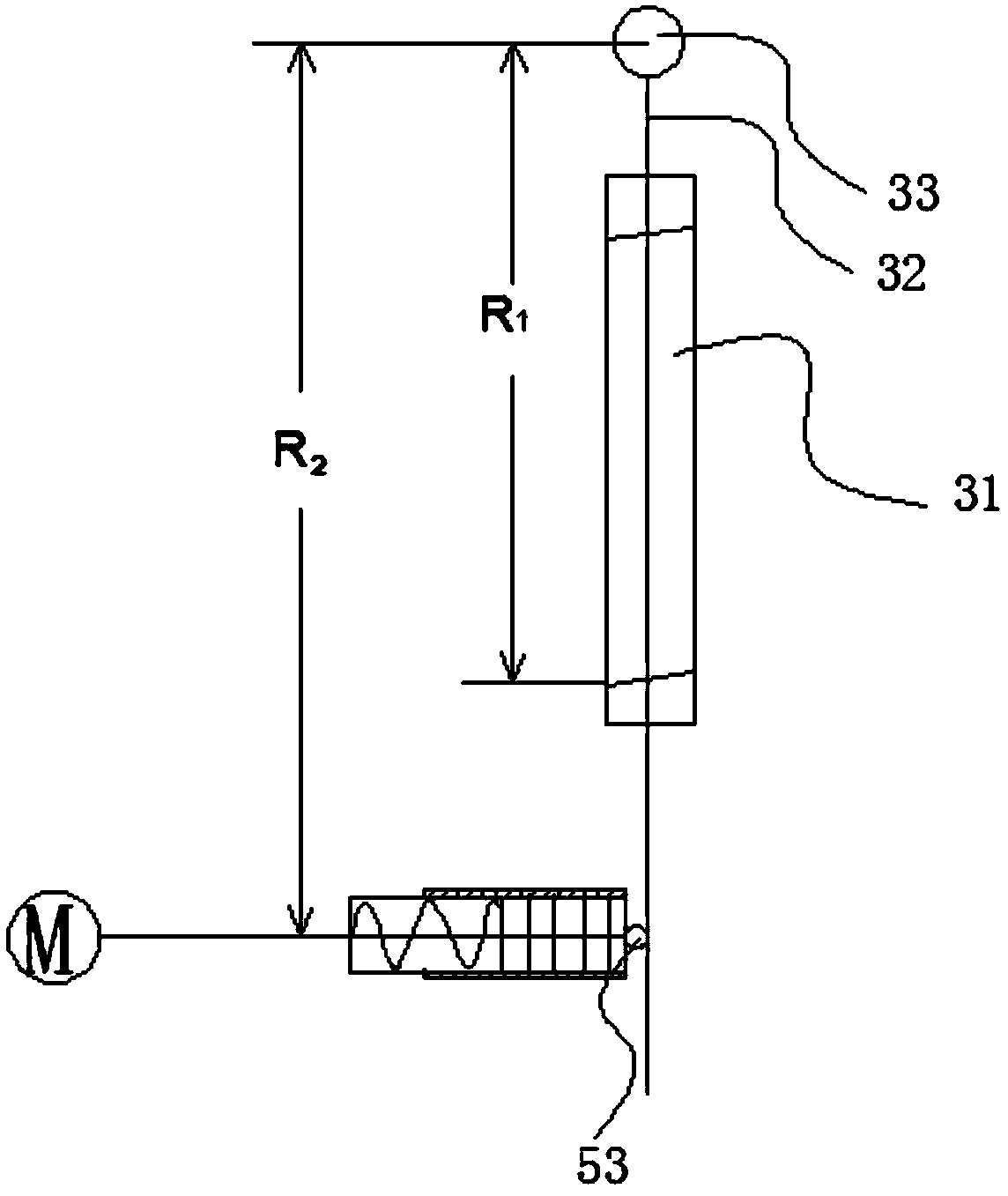

[0090] Provide an automatic cell correction and finishing system arranged in a winding machine, including an image collector 1, a controller 2, a roller 3, a driving member 4 and a transmission mechanism 5, the image collector 1 and the controller 2 Electrically connected, and the controller 2 is electrically connected to the drive member 4; the end of the transmission mechanism 5 is connected to one end of the roller 3, and the other end of the roller 3 is connected to the winding machine Rotate and connect at the fulcrum 33;

[0091] The image collector 1 collects a plurality of cell characteristic images, and transmits the collected plurality of cell characteristic images to the controller 2;

[0092] The controller 2 obtains the misalignment adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com