Sewing machine

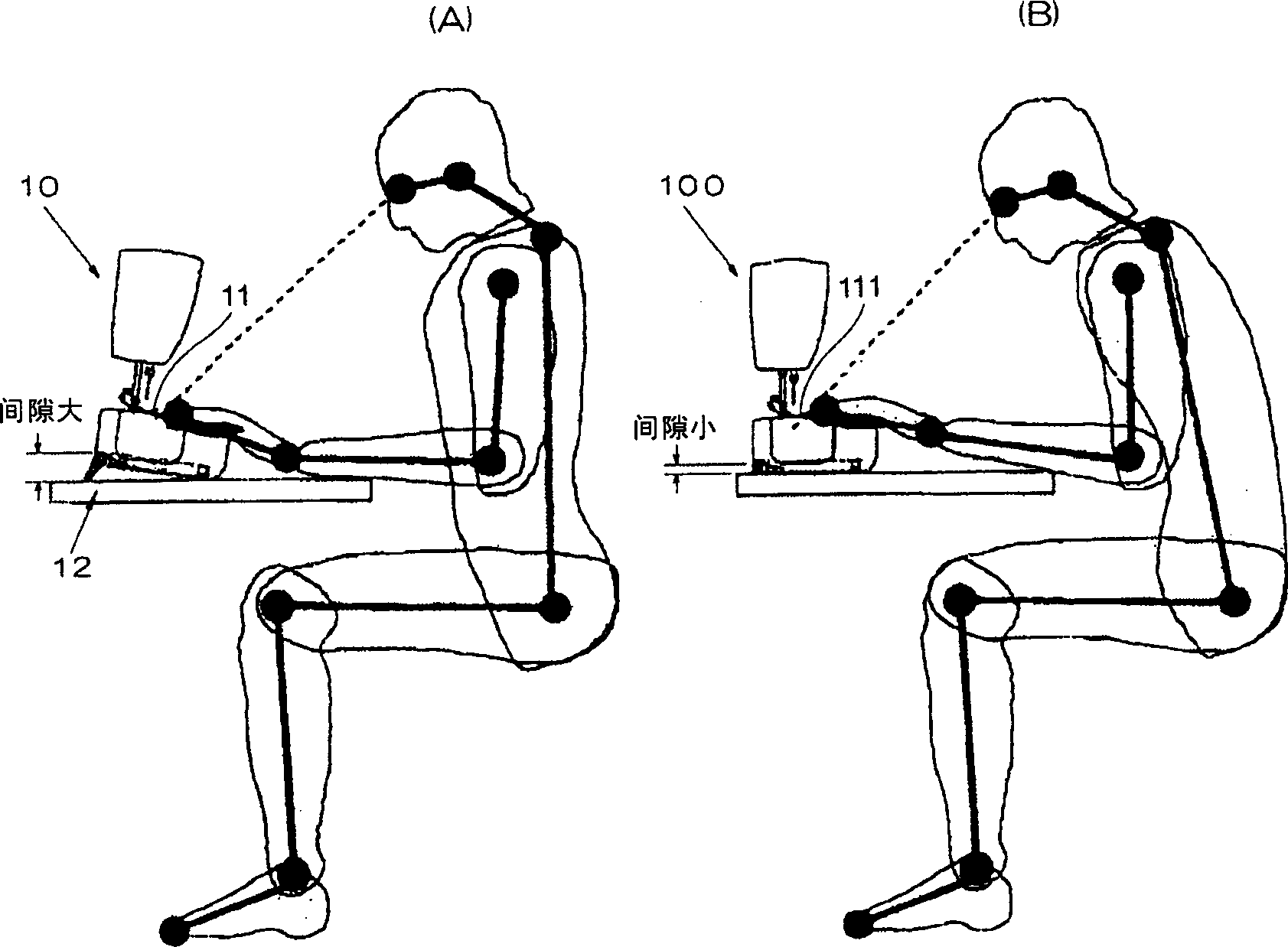

A sewing machine and storage position technology, which is applied in the field of sewing machines, can solve problems such as unstable positioning parts, difficulty in pulling out positioning parts, and not improving sewing posture, so as to achieve the effect of reducing work efficiency and easy sewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0038] An embodiment of the present invention will be described below with reference to the drawings.

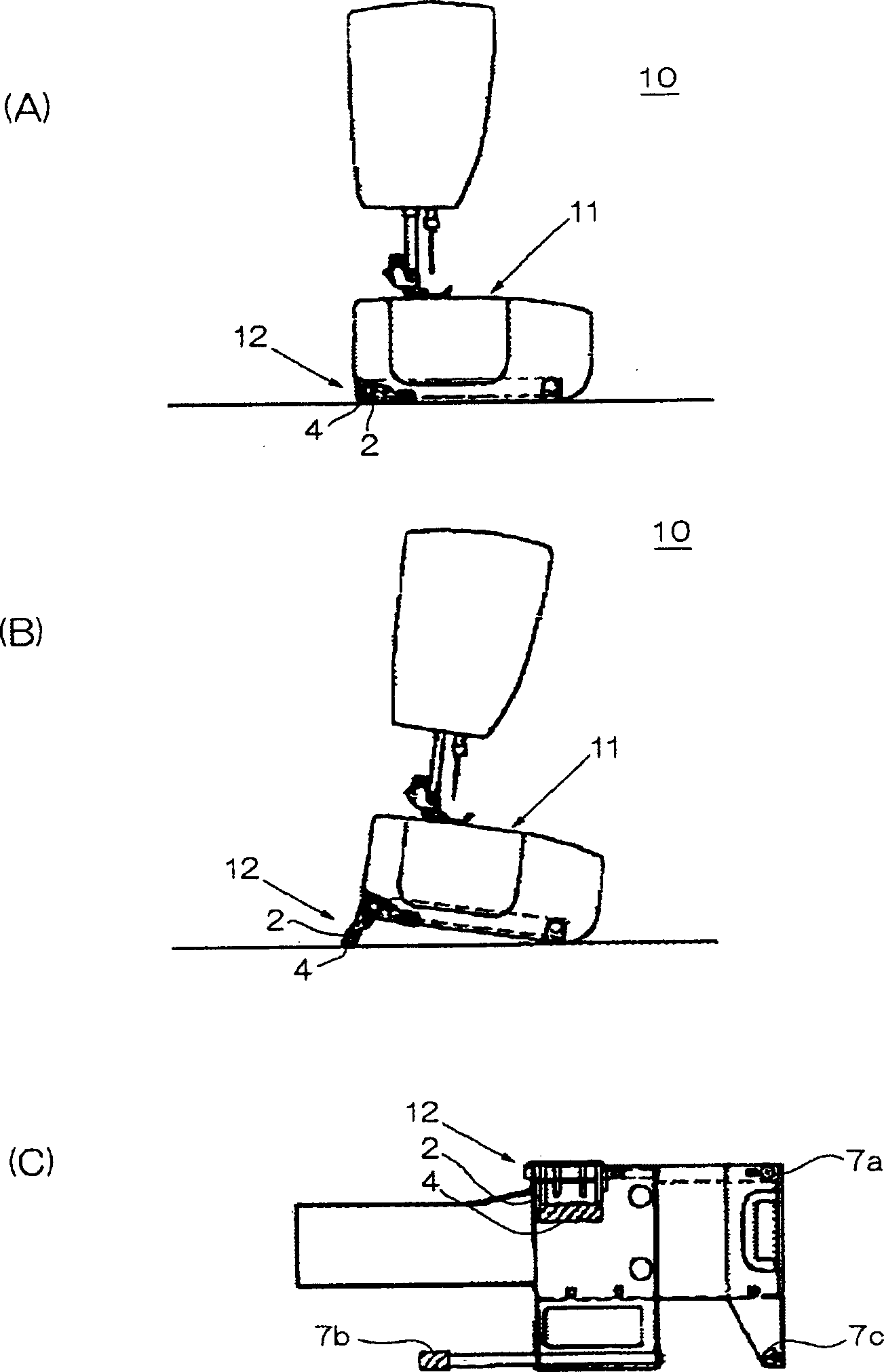

[0039] figure 2 (A)- figure 2 (C) is a schematic diagram illustrating the appearance of the sewing machine related to the first embodiment of the present invention, respectively figure 2 (A) shows that the bottom surface of the sewing machine is horizontal. figure 2 (B) shows that the bottom surface of the sewing machine is inclined when the arm is free. figure 2 (C) means figure 2 (A) The bottom surface of the sewing machine.

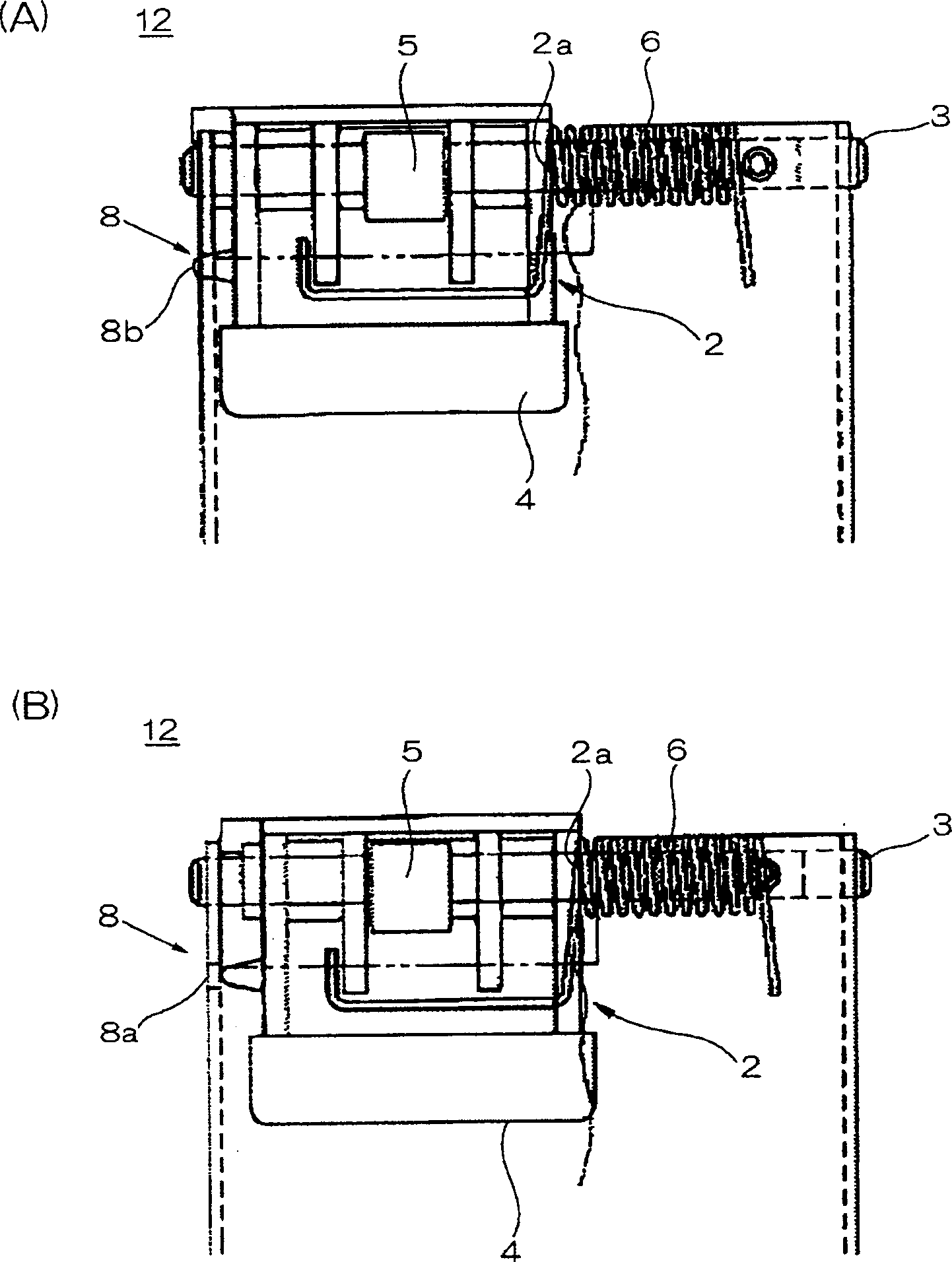

[0040] image 3 (A) for figure 2 (C) Enlarged view of key parts, image 3 (B) for image 3 (A) Action diagram.

[0041] Figure 4 (A) for image 3 (A) side view, Figure 4 (B) for image 3 (B) Side view.

[0042] refer to figure 2 (A)- figure 2 (C) As can be seen, on the sewing machine bottom of the sewing machine 10 related to the first embodiment of the present invention, a mechanism 12 capable of tilting the sewing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com