Contact with strong connecting-disconnecting function

A technology of contact and capacity, which is applied in the direction of electric switches, contact materials, high-voltage air circuit breakers, etc., can solve the problem of unsatisfactory electrical indicators such as cut-off value, voltage shock resistance, and breaking times, shortening the life of vacuum interrupters, and affecting Contact life and other issues to achieve the effect of improving welding resistance and breaking capacity, reducing current density and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described, wherein:

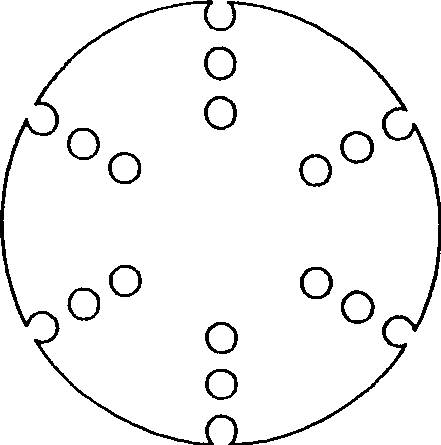

[0025] in the attached figure 1 In the first embodiment shown, the series of circular holes are uniform radial holes. It can be seen from the accompanying drawing that the series of circular holes are equal in size and uniformly distributed radially. The radial holes shown in the accompanying drawing are divided into six rows, each row of three circular holes, They are equal in size and distributed radially. Of course, the number of rows can be more or less; the number of holes in each row can also be appropriately changed; it can be changed reasonably according to design requirements.

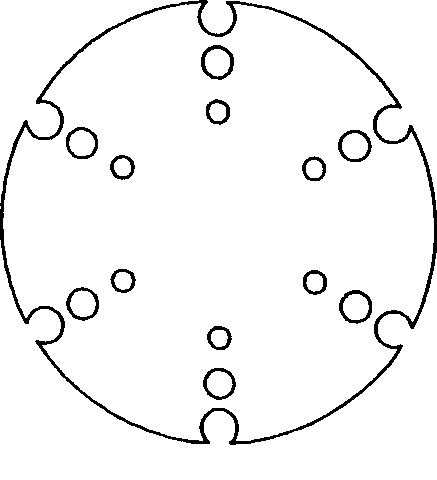

[0026] in the attached figure 2 In the second embodiment shown, the series of circular holes are tapered radial holes. It can be seen from the accompanying drawing that the sizes of the series of circular holes are not equal, and although they are also uniformly dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com