Optical glass material for moulding

An optical glass and molding technology, applied in the field of optical glass materials for molding, can solve the problems of excellent surface quality, high roughness and high adhesion of carbon film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

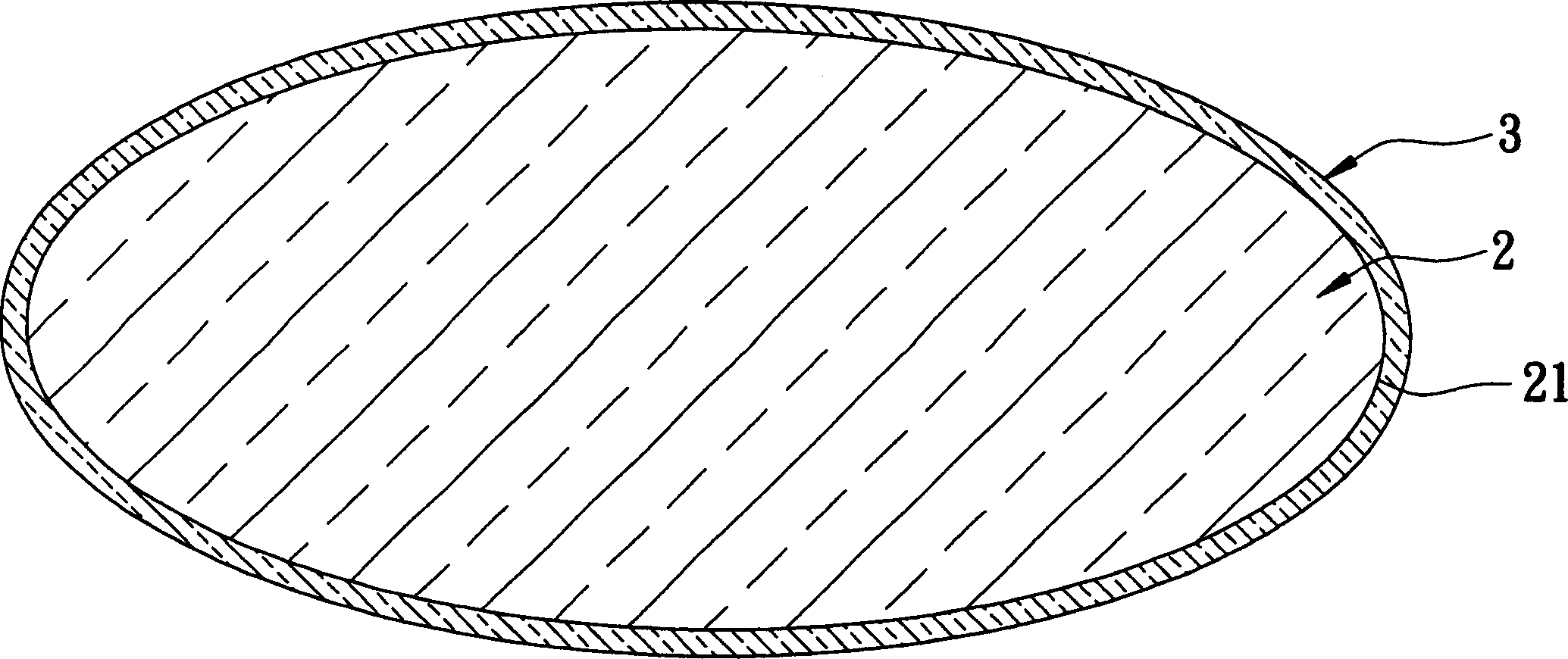

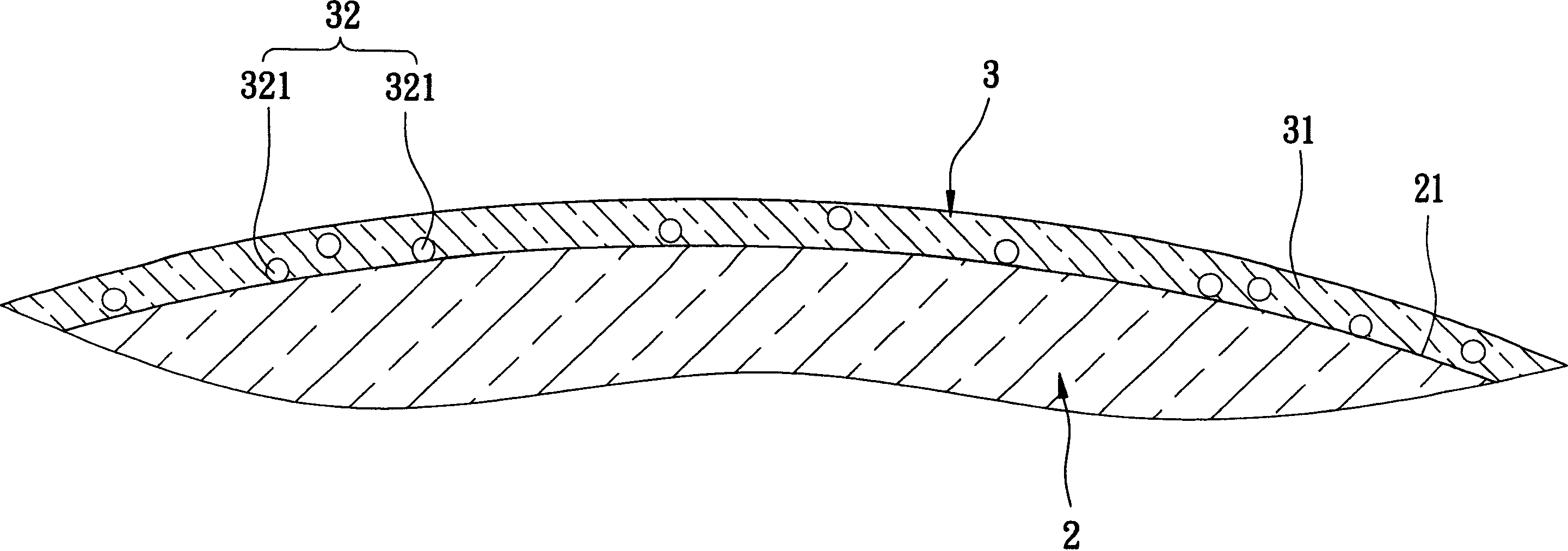

[0028]In a specific embodiment of the optical glass material for molding of the present invention, the matrix layer 31 of the protective film 3 is a matrix layer of amorphous carbon, and the diffusion unit 32 is composed of a component containing silicon and carbon, containing silicon and Oxygen components, and components containing silicon, carbon and oxygen are made. Therefore, in this specific embodiment, the nanoparticles 321 are composed of three kinds of nanoparticles: nanoparticles containing silicon and carbon (Si-C), nanoparticles containing oxygen and silicon (Si-O), and nanoparticles containing silicon , carbon and oxygen (Si-C-O) nanoparticles.

[0029] In this specific embodiment, the model produced by Nisho OHARA is L-LBAL35 and T g The glass raw material with a temperature of 527° C. is used as the glass body 2 . The manufacturing method of the optical glass material for molding in this specific embodiment of the present invention is briefly described below. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap