Micro contact-element and making method

A manufacturing method and micro-contact technology, which can be used in contact manufacturing, contact components, semiconductor/solid-state device manufacturing, etc., and can solve problems such as bending of silicon substrates, increased failure rate, and poor process qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable a further understanding and recognition of the features and objectives of the present invention, the following preferred embodiments are enumerated and described below with accompanying drawings.

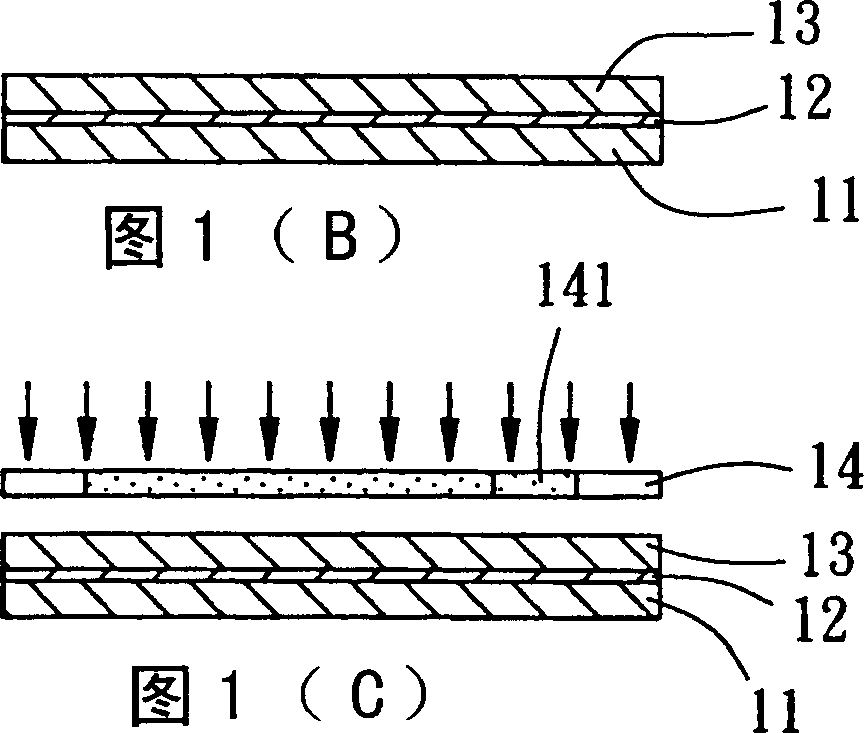

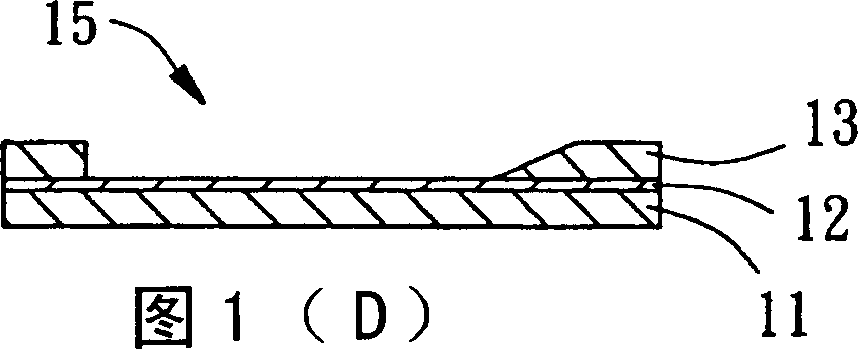

[0025] Please refer to Fig. 1 (A) to Fig. 1 (H), which is a manufacturing method of a micro-contact element provided by the first preferred embodiment of the present invention, wherein the micro-contact element manufactured by the following manufacturing method is an example of a probe , whose steps include:

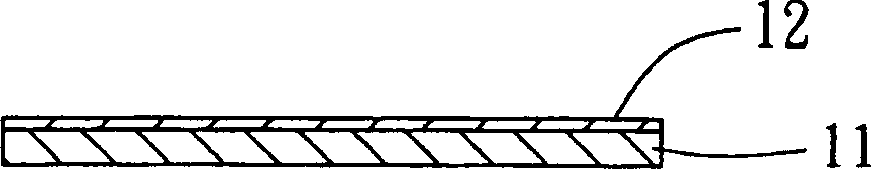

[0026] a) As shown in FIG. 1(A): Laying and forming a conductive film 12 on a substrate 11 with a non-conductive surface.

[0027] Wherein, the material of the substrate 11 can be a semiconductor material, a metal plate coated with a non-conductive material, a polymer material, a ceramic material, a composite material, etc., such as a silicon substrate. The conductive film 12 can be a metal with good adhesion, such as titanium metal; the conductive f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com