Synthetic-resin window sectional materials with multiple-color and three-dimensional surface figure and producing apparatus thereof

A technology of synthetic resin and production equipment, which is applied in the field of synthetic resin window profiles and production equipment with multi-color and three-dimensional grain surfaces, which can solve problems such as erosion, uneven gloss, deformation of window profiles, etc., to prolong service life and improve durability Sexuality, the effect of improving the aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

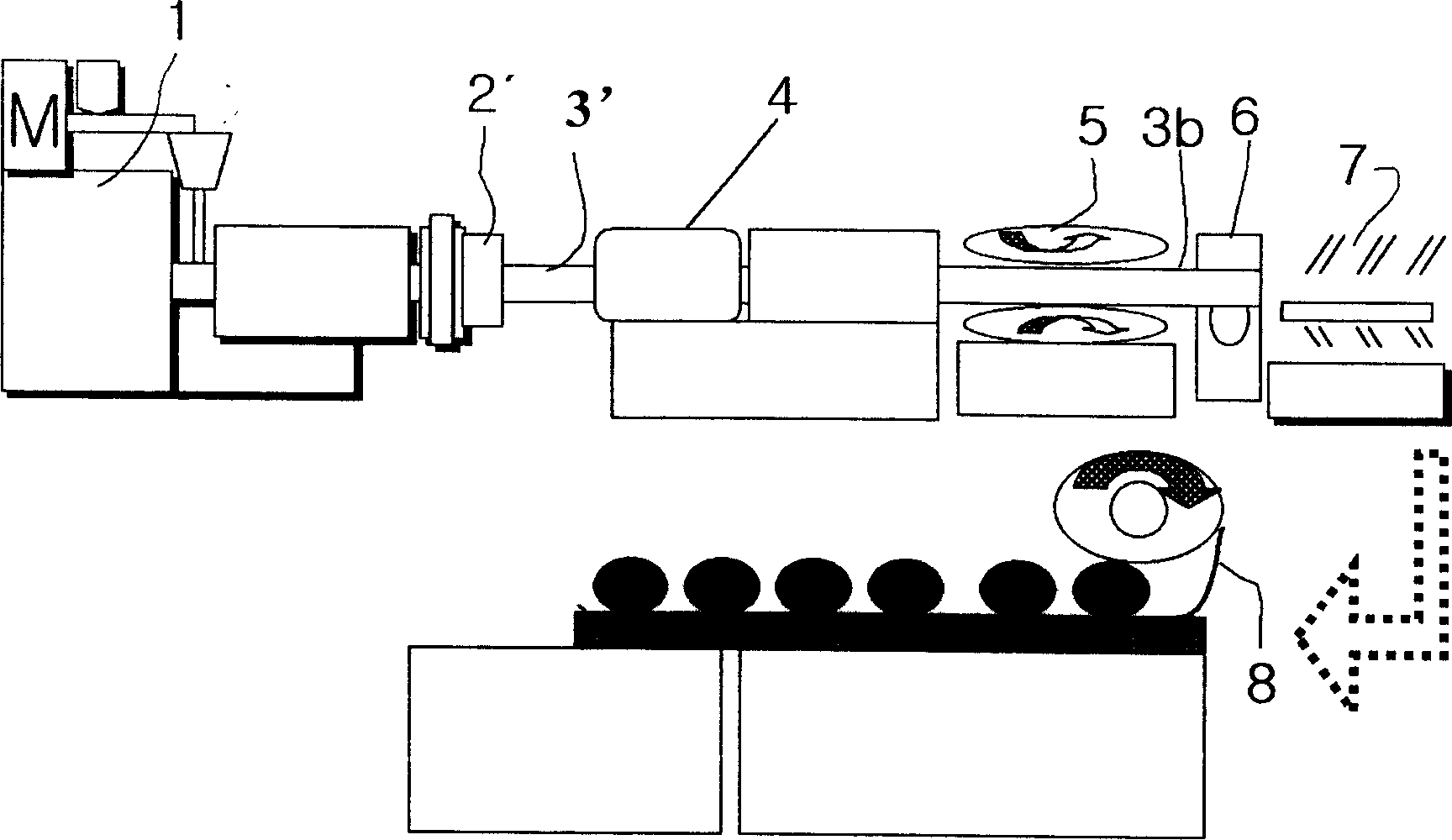

[0034] like Figure 4 As shown, the synthetic resin window profiles production equipment provided by the present invention mainly includes an extruder 1 capable of melting and extruding resin raw materials; extruding the resin extruded by the extruder 1 into a A mold 2 for extruding resin 3 with a certain shape; a vacuum cooling device 4 capable of cooling and shaping the extruded resin 3 with a certain shape extruded from the mold 2; connected with the mold 2, capable of melting resin materials of other materials And extruded to provide the auxiliary extruder 9 of the mold 2;

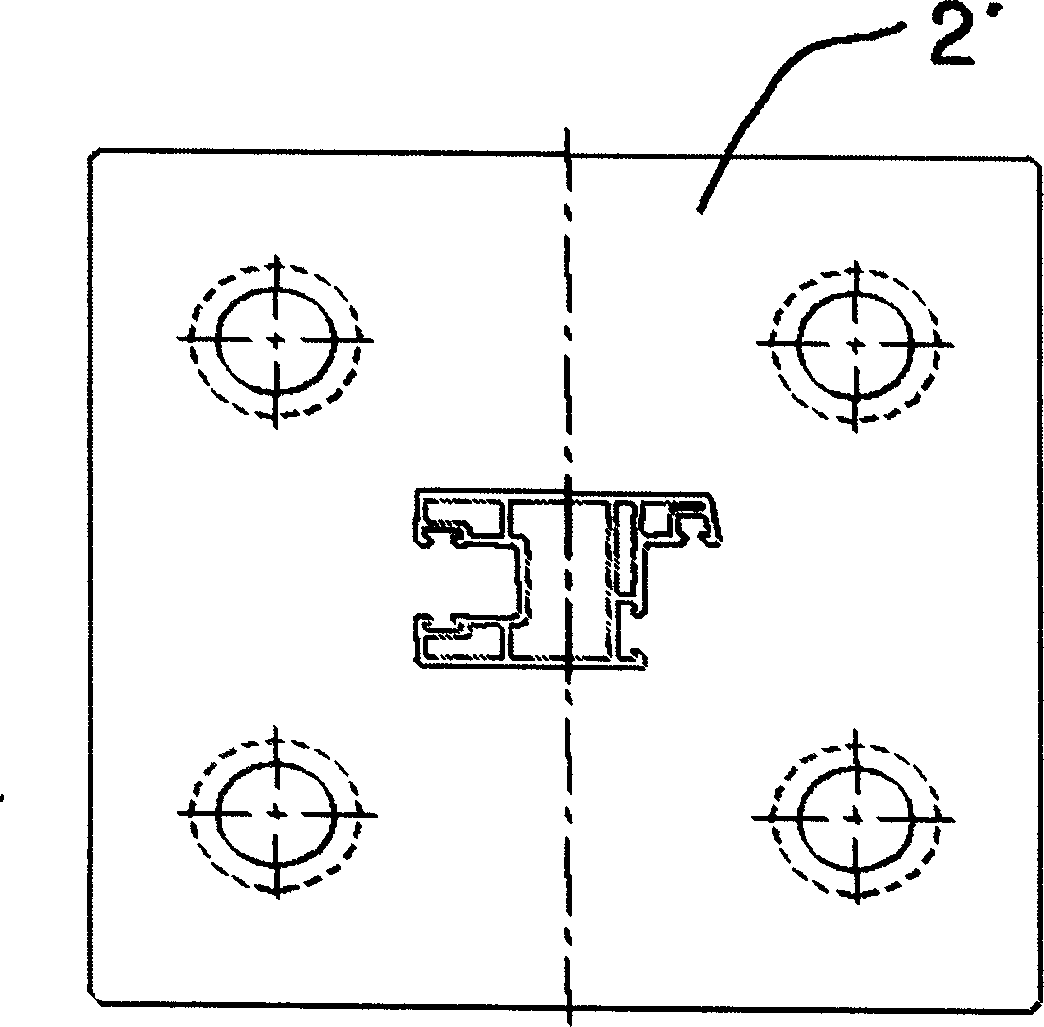

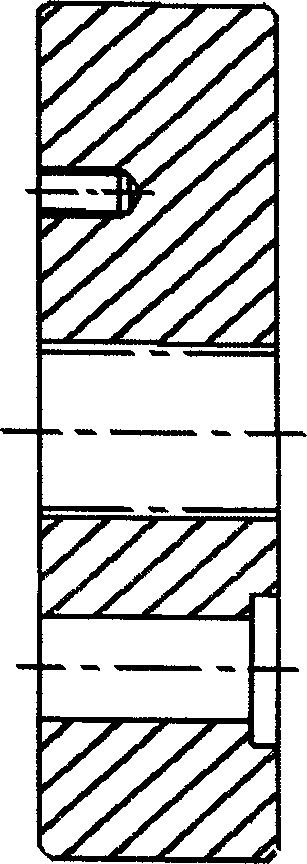

[0035] like Figure 5 As shown, the mold 2 is provided with a molten resin inflow channel 12 capable of allowing the resin melted by the auxiliary extruder 9 to flow into its interior, and the resin melted by the auxiliary extruder 9 can be evenly distributed in the secondary extruder 1 and the dispersed flow channel 13 on the surface of the extruded resin 3 extruded by the mold 2, the resin flowing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com