Production of self-cleaning glass

A self-cleaning and glass technology, applied in the field of self-cleaning glass preparation, can solve the problems of pollution, danger, waste of water resources, etc., and achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0027] 1. Clean the float glass substrate with a self-made surfactant washing solution, rinse it with deionized water, dry it, and set it aside;

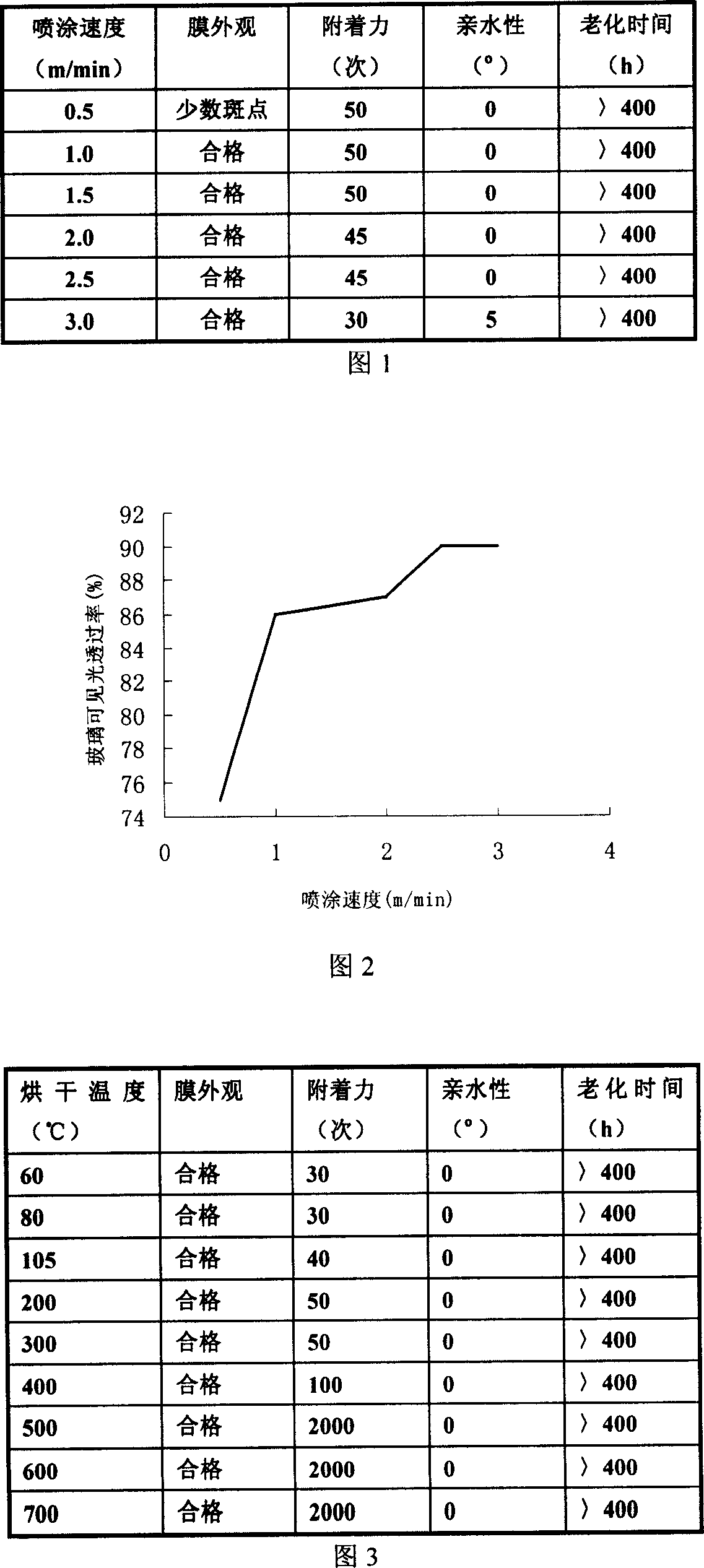

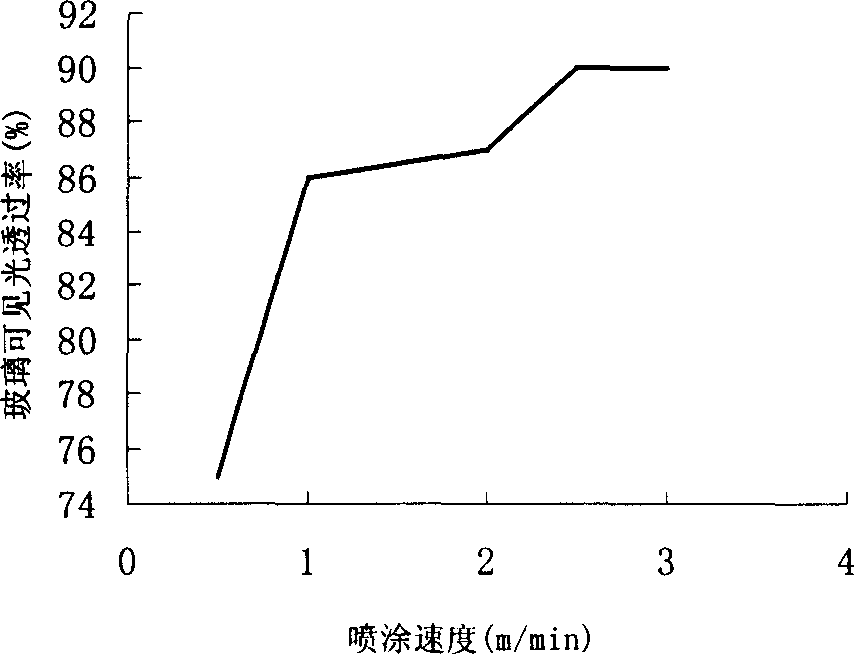

[0028] Second, the prepared TiO 2 The composite sol is poured into the sprayer, and the spraying speed is controlled to be 1.0m / min to spray TiO on the moving glass substrate at a speed of 1.5m / min. 2 Composite sol;

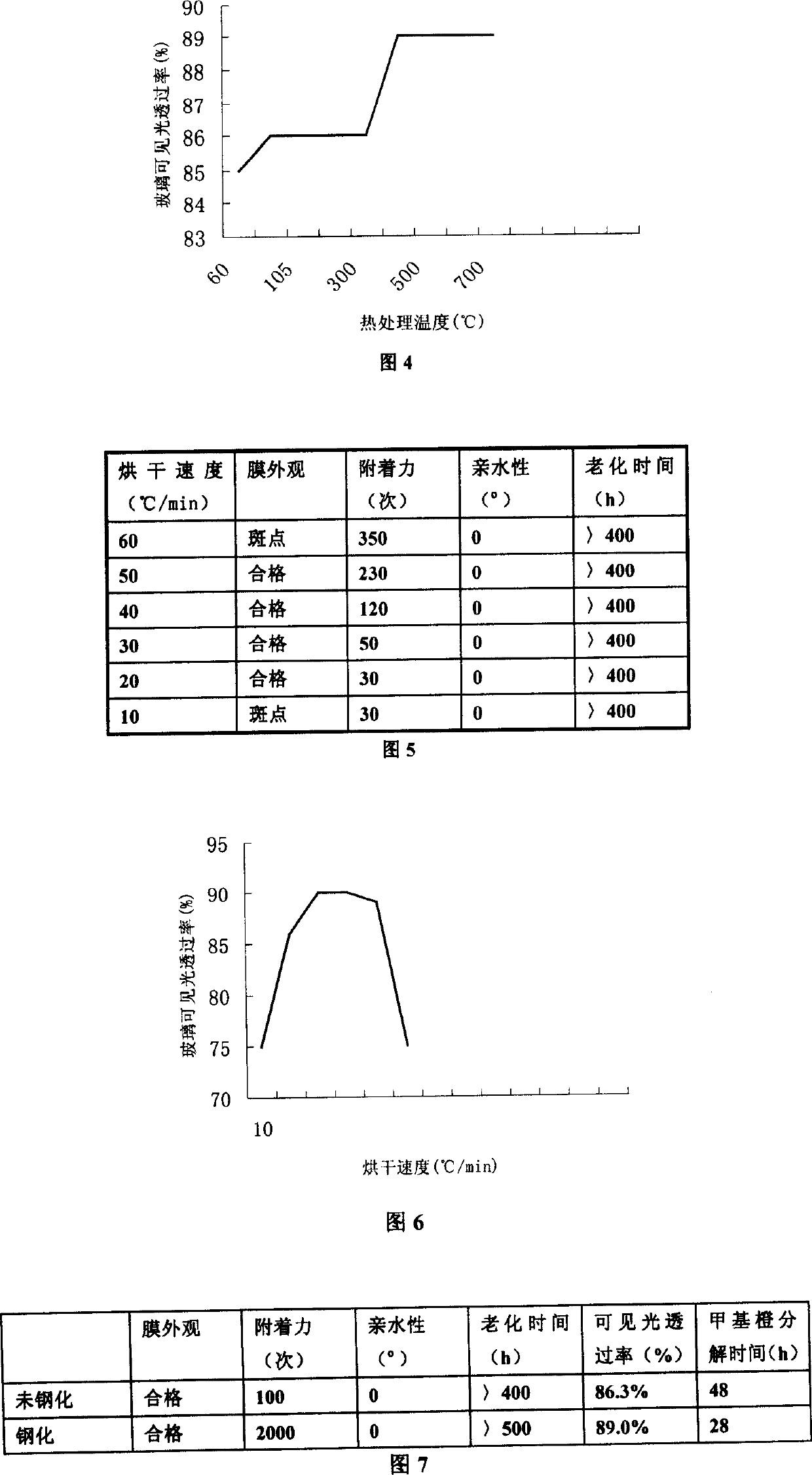

[0029] Three, will be sprayed with TiO 2 The glass substrate of the composite sol is dried at a temperature of 105°C to form TiO 2 Self-cleaning film, the TiO in the film layer 2 The particle diameter is about 30nm, the film thickness is 53nm, with nano TiO 2 characteristic;

[0030] 4. After aging at 300°C for 10 minutes, TiO-coated 2 The self-cleaning glass of the self-cleaning film has good hydrophilicity, and the water contact angle of the glass surface is θ=0°; the transparency is good, and the visible light transmittance is 85.3%. Under the irradiation of visible light, the time for methyl orange to decompo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com