Floor drain

A floor drain and flange installation technology, which is applied to indoor sanitary pipeline installations, waterway systems, drainage structures, etc., can solve the problems of heavy tight connections, difficult and impossible floor drains, etc., and achieve a good airtight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

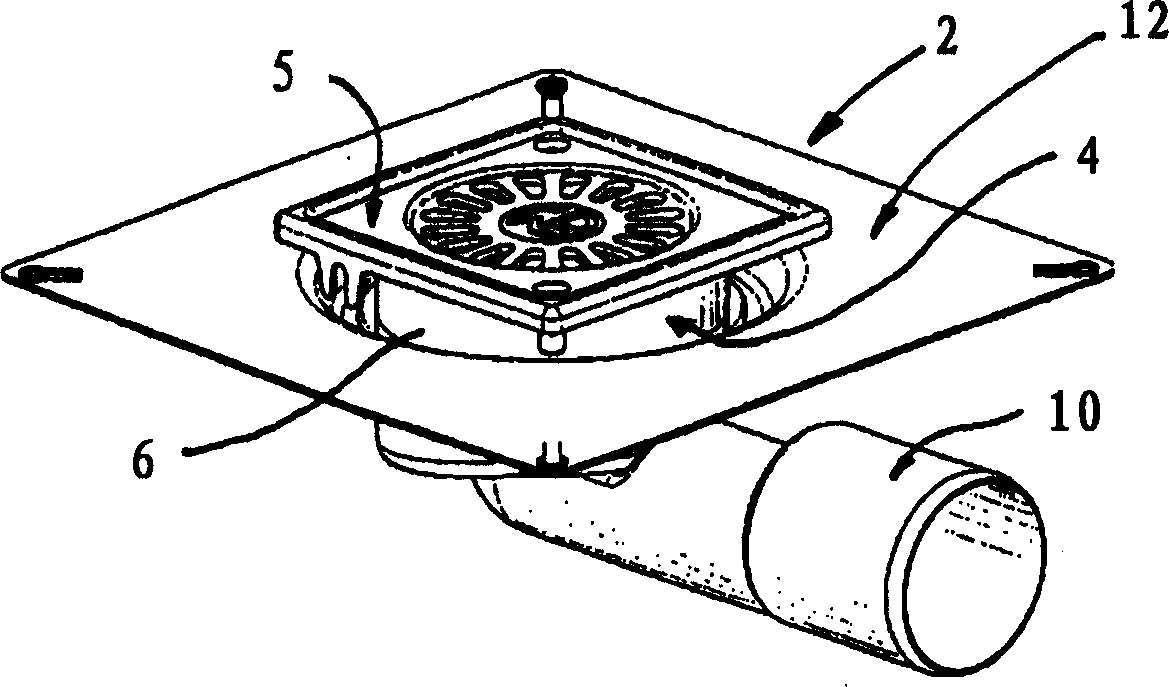

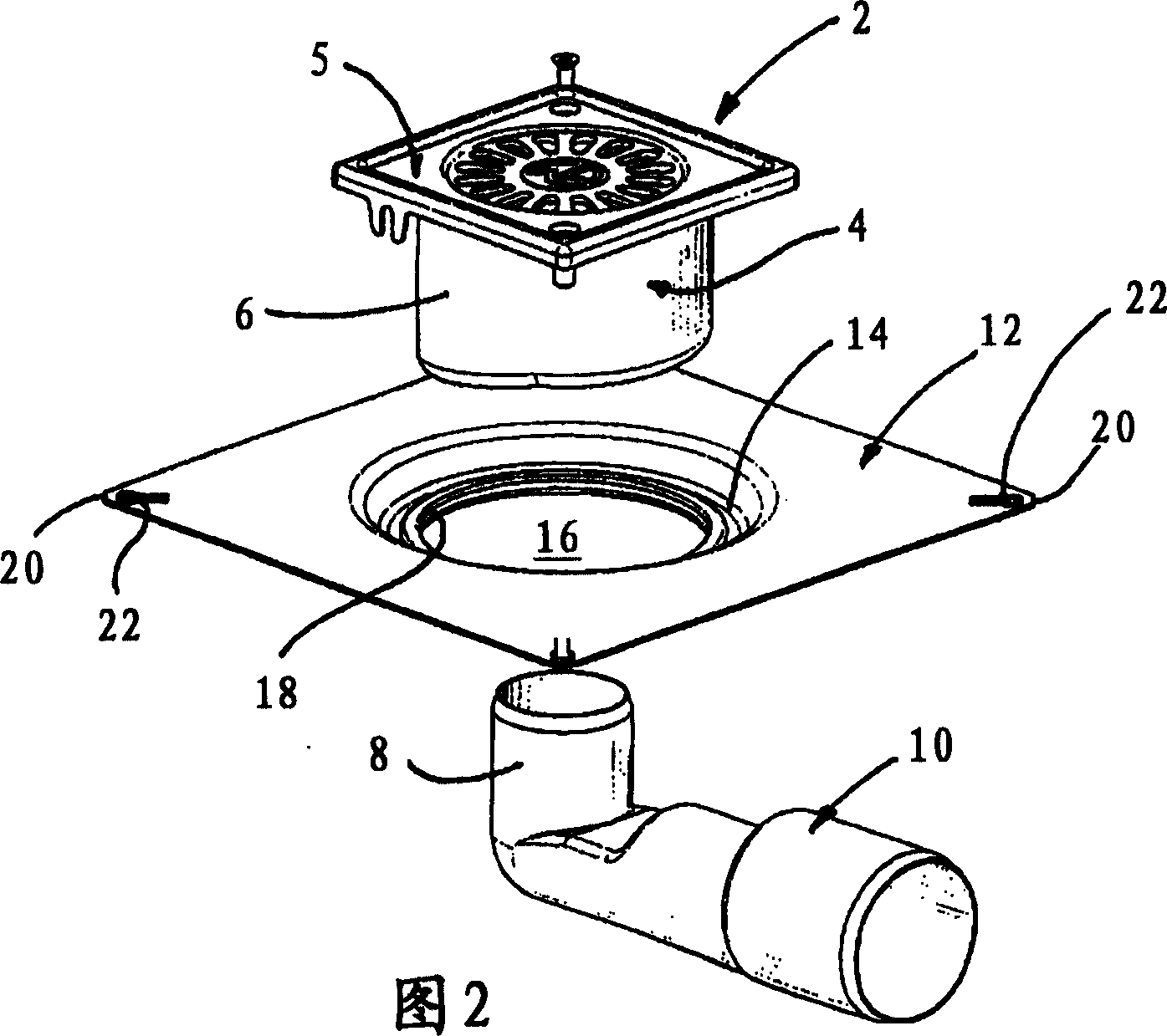

[0022] exist figure 1 The floor drain 2 shown at - 2 comprises a drain cover 4 with a cylindrical outer side 6 . The drain cover 4 can comprise a water reservoir, not shown, with a centrally located lower drain hole, into which the vertical connection part 8 of the elbow connection pipe 10 can be fitted by means of a suitable filling tool. The floor drain 2 is provided with a square drainage grid 5 at the top.

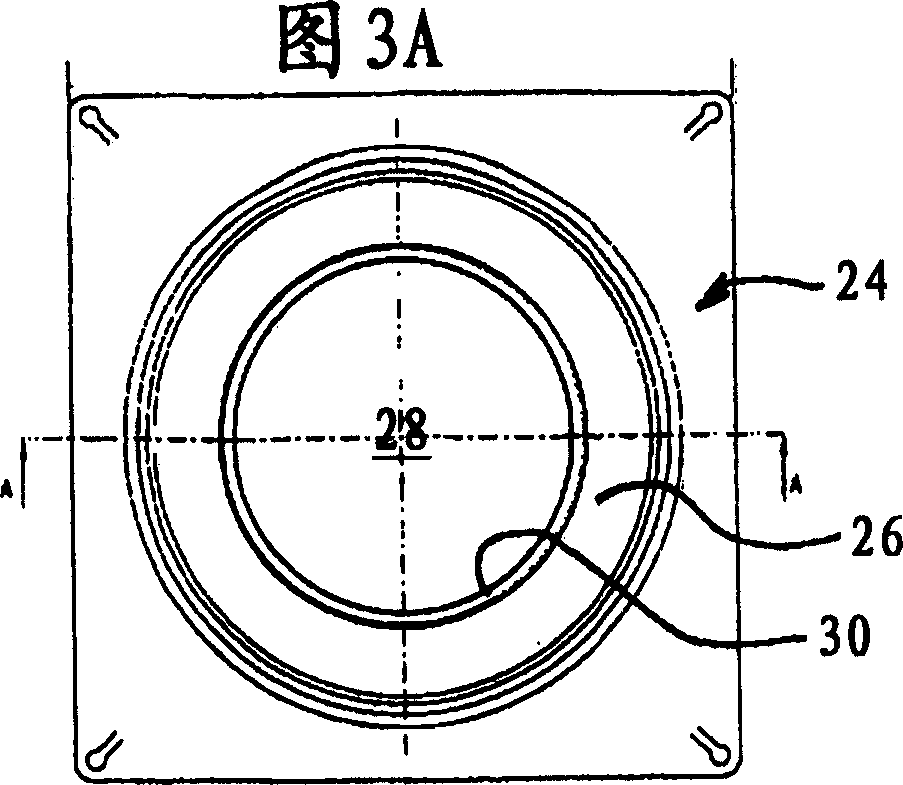

[0023] In addition, the floor drain 2 also includes a mounting flange 12 which has a connection hole 16 with a circular filling tool 18 at the centrally bent tab portion 14, so that the loosened mounting flange 12 can be mounted on the drain cover 4 in a watertight manner. On the predetermined height outside cylindrical outer 6. Alternatively, it is also possible to use a circular filling tool which is fixed in the connecting hole 16 by vulcanization.

[0024] As clearly shown in FIG. 2, the mounting flange 12 is mounted on the cylindrical outer side 6 of the drain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com