Plastic pipe with thin wall

A technology of plastic thin-walled and thin-walled tubes, which is applied in the direction of formwork/formwork/working frame, building components, and on-site preparation of building components, which can solve the problems of small occupied space, high cost, and large number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

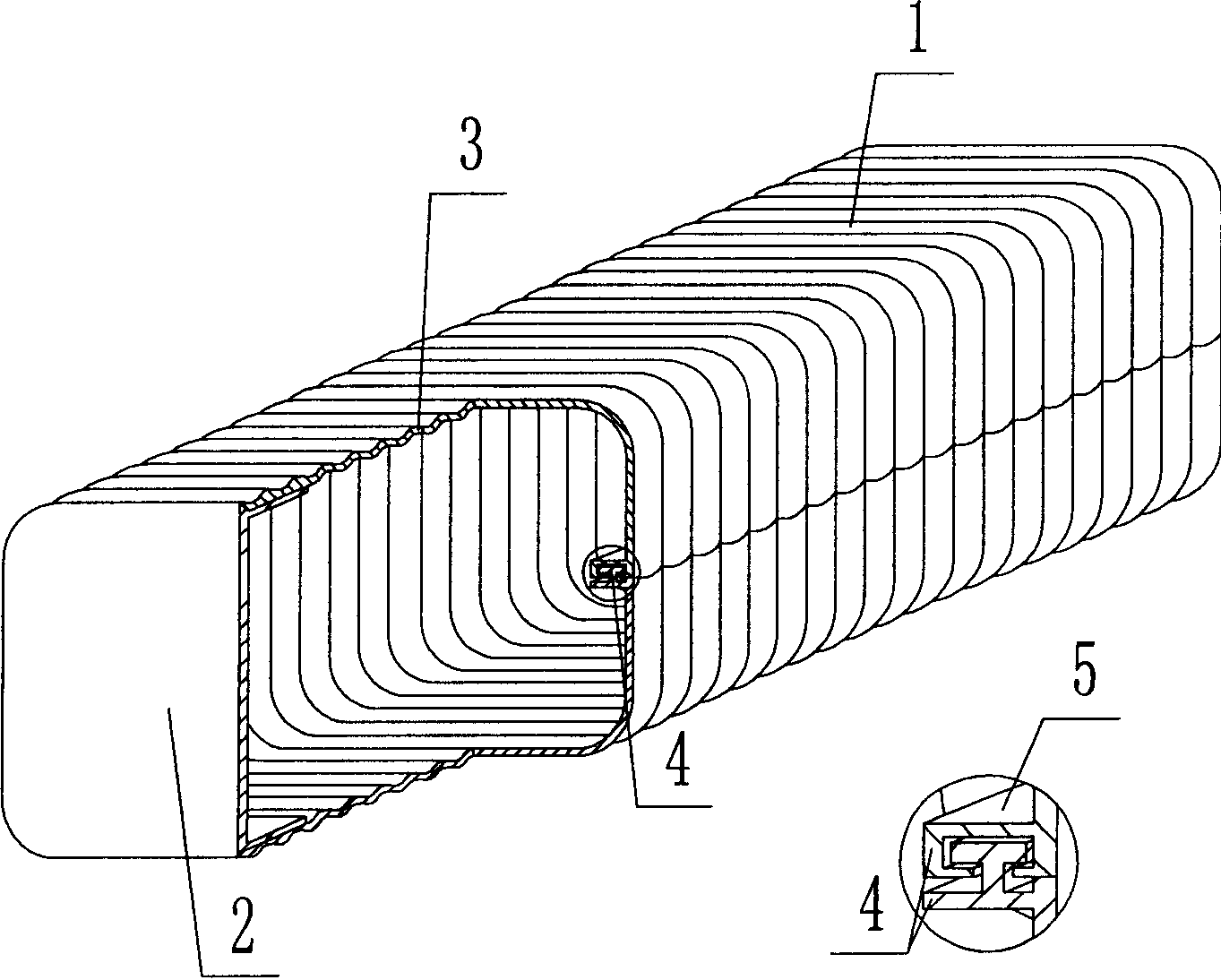

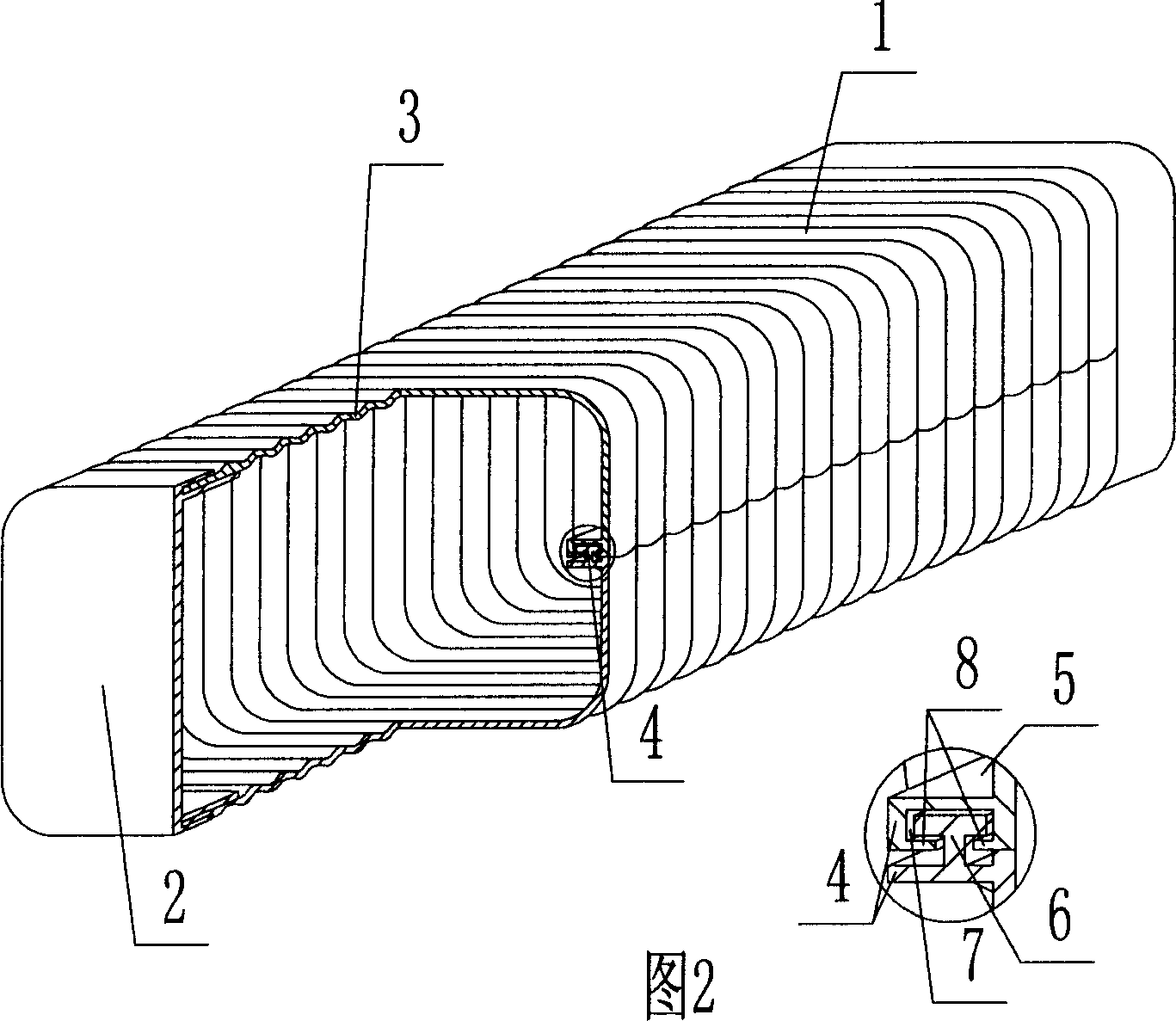

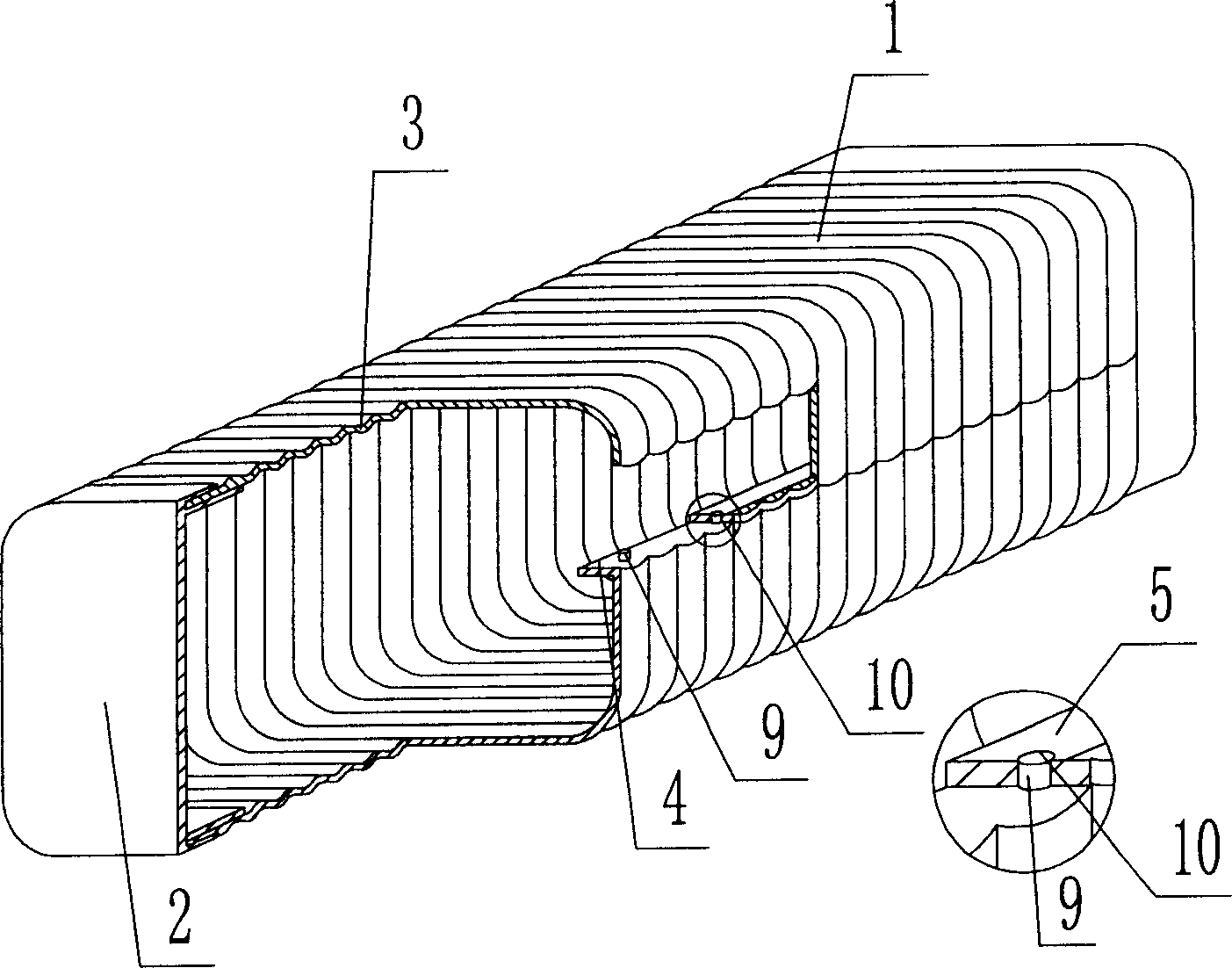

[0059] As shown in the accompanying drawings, the present invention includes an annular thin-walled pipe body 1 and a sealing plate 2, and the sealing plate 2 closes the pipe end of the annular thin-walled pipe body 1 to form a closed hollow thin-walled pipe, which is characterized in that the annular thin-walled pipe body The wall pipe body 1 is formed by rolling a plate 3 into a circular splicing, and the splicing parts are connected to each other by a connecting piece 4 to form a longitudinal splicing strip 5. The outer wall of the thin-wall pipe body 1 is a corrugated wall. In each drawing, 1 is an annular thin-walled pipe body, 2 is a sealing plate, 3 is a plate, 4 is a connector, and 5 is a splicing strip. In the following drawings, those with the same number have the same description. like figure 1 As shown, it includes an annular thin-walled pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap