Foamer dispenser

A sprayer and foaming agent technology, which can be used in spray devices, household containers, dressing containers, etc., can solve problems such as uneven foam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in more detail through the drawings of preferred embodiments below.

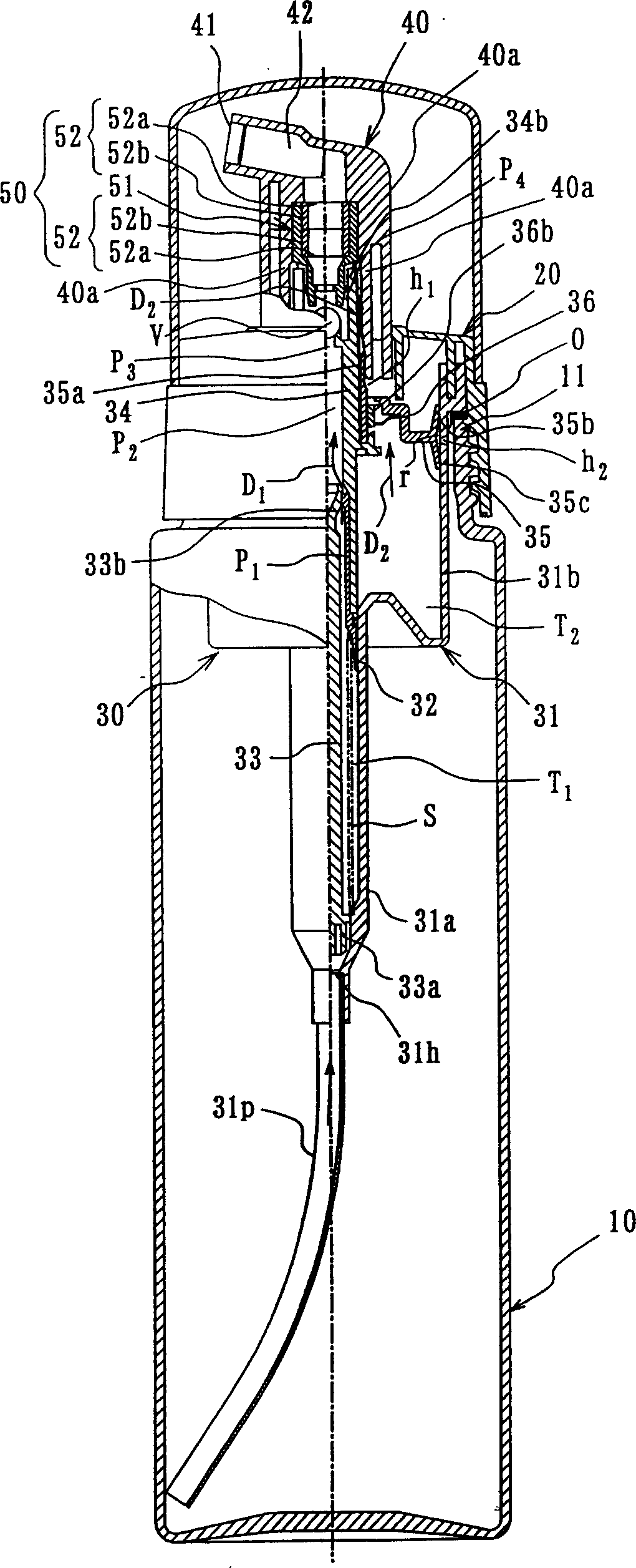

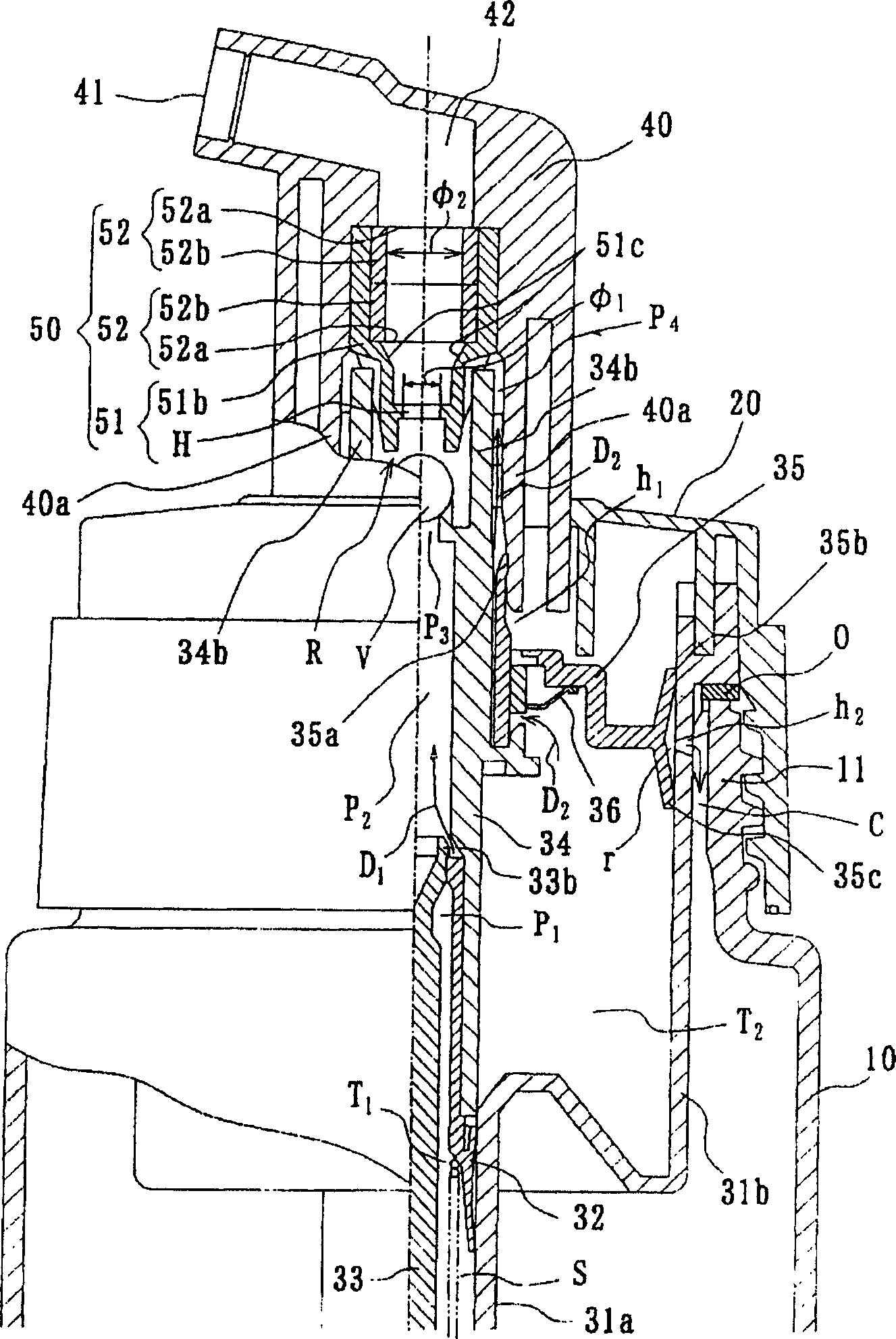

[0044] Such as figure 1 As shown, the support cap 20 can be fixed on the mouth and neck portion 11 of the bottle-shaped container 10 filled with liquid content through threads, and can be disassembled at any time. A dual pressure pump 30 is installed in the support cap 20 to draw, pressurize and pressure-feed the content in the container 10 and the outside air respectively.

[0045] The pressure pump 30 has a cylinder 31 that fits with the undercut of the support cap 20 and hangs below the support cap 20, and consists of a small diameter cylindrical part 31a and a large diameter cylindrical part connected in series with the small diameter cylindrical part 31b composition. The small-diameter cylindrical portion 31a includes an introduction port 31h to which a pipe 31p for sucking up the contents inside the container 10 is connected.

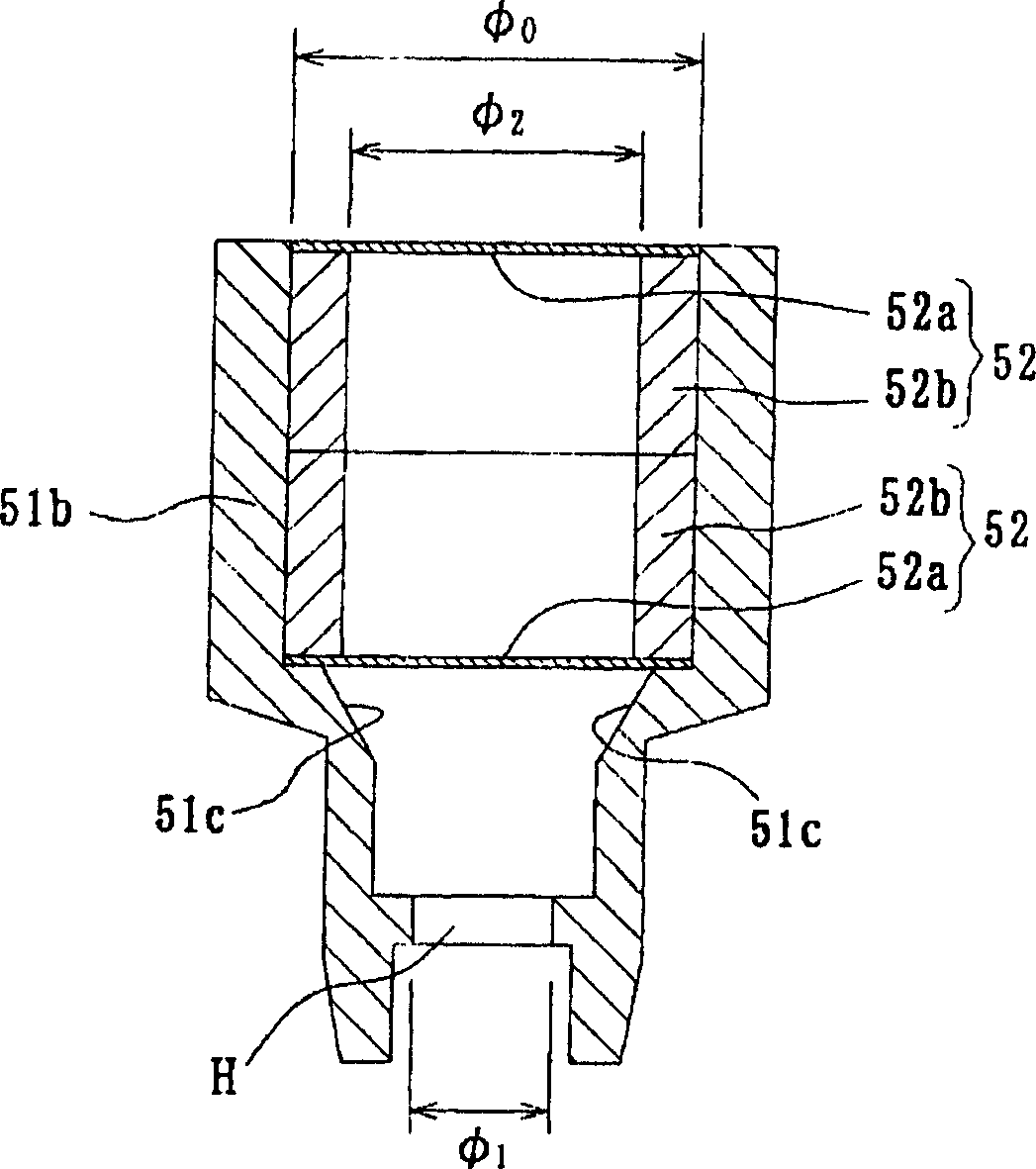

[0046] The small-diameter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com