Process for the production of dinitrotoluene

一种硝酸、硝化芳族的技术,应用在硝基化合物制备、有机化学等方向,能够解决无法实现等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

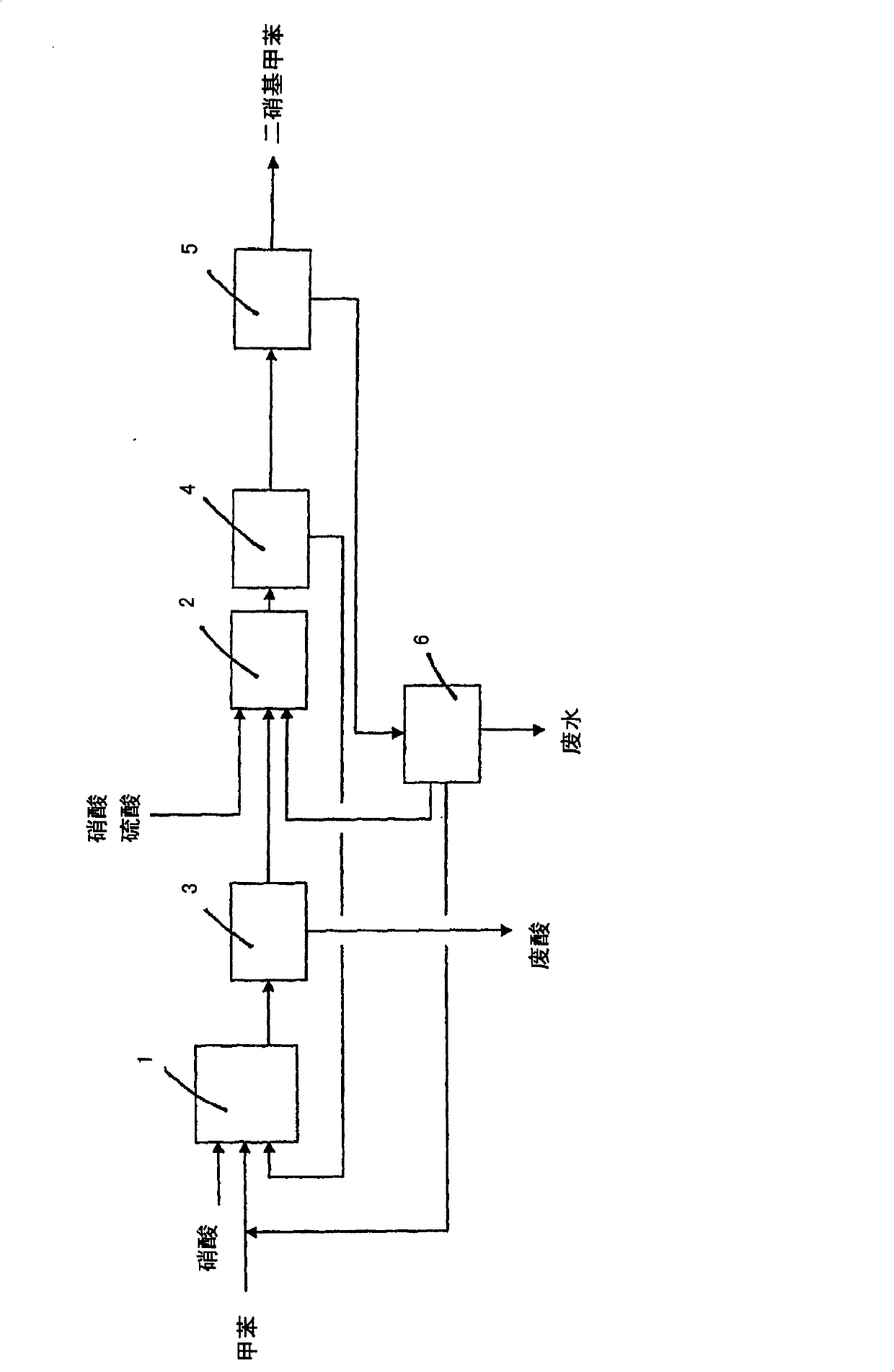

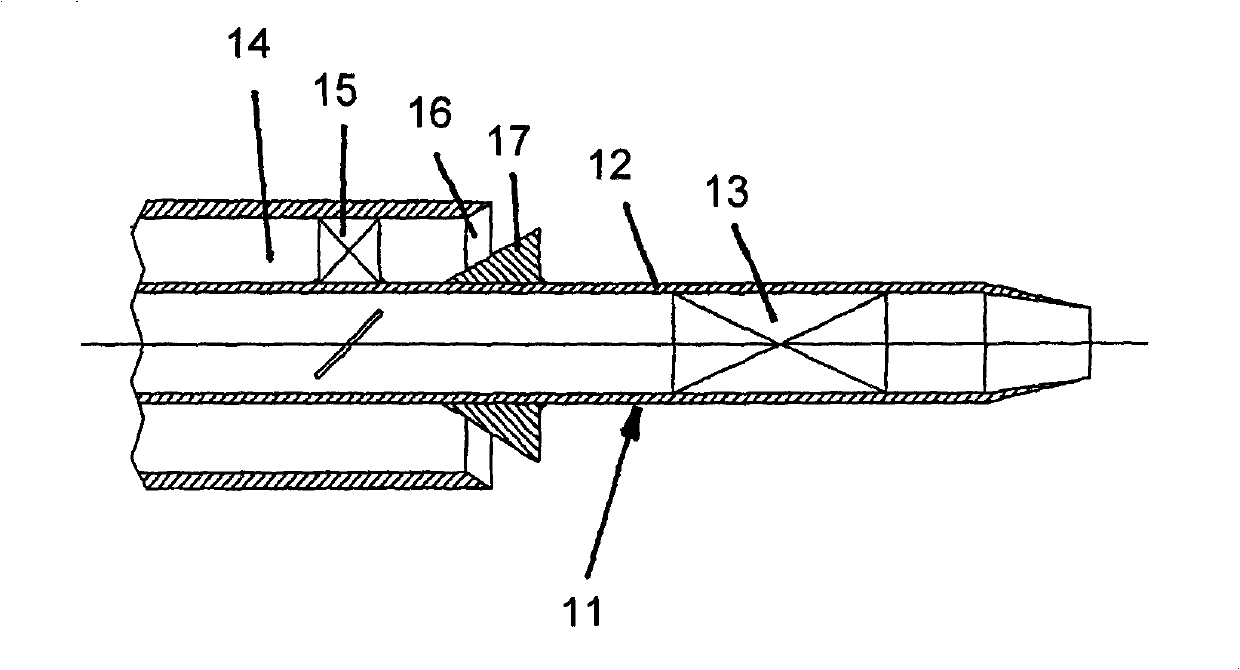

[0028] Toluene is carried out the reaction that nitration generates dinitrotoluene is carried out in an experiment workshop according to the present invention, and wherein flow process is shown in figure 2 middle. A mixture of 9.4% by weight nitric acid, 71.5% by weight sulfuric acid and 19.1% by weight water was used as nitrating acid. A flow of 5000 kg / h of toluene was mixed with 36616 kg / h of premixed nitrating acid in figure 1 Mix in the mixing nozzle shown. The average flow velocity of toluene in the tubular reactor of the mixing nozzle was 5 m / s. The average flow velocity of nitrifying acid in the annular gap of the mixing nozzle is 2.2 m / s. Nitrification was carried out in reactor 1 with a cooling water temperature of about 35°C and in reactor 2 with a cooling water temperature of 65°C. A mixing nozzle is used in Reactor 1.

[0029] In comparative examples (ie, examples not representative of the present invention), nitrating acid and toluene were fed into the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com