High tightness slide window

A high-sealing, sliding window technology, which is applied in the direction of sealing devices and wing leaf arrangement, can solve the problems of dust ingress, inconvenience, poor sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

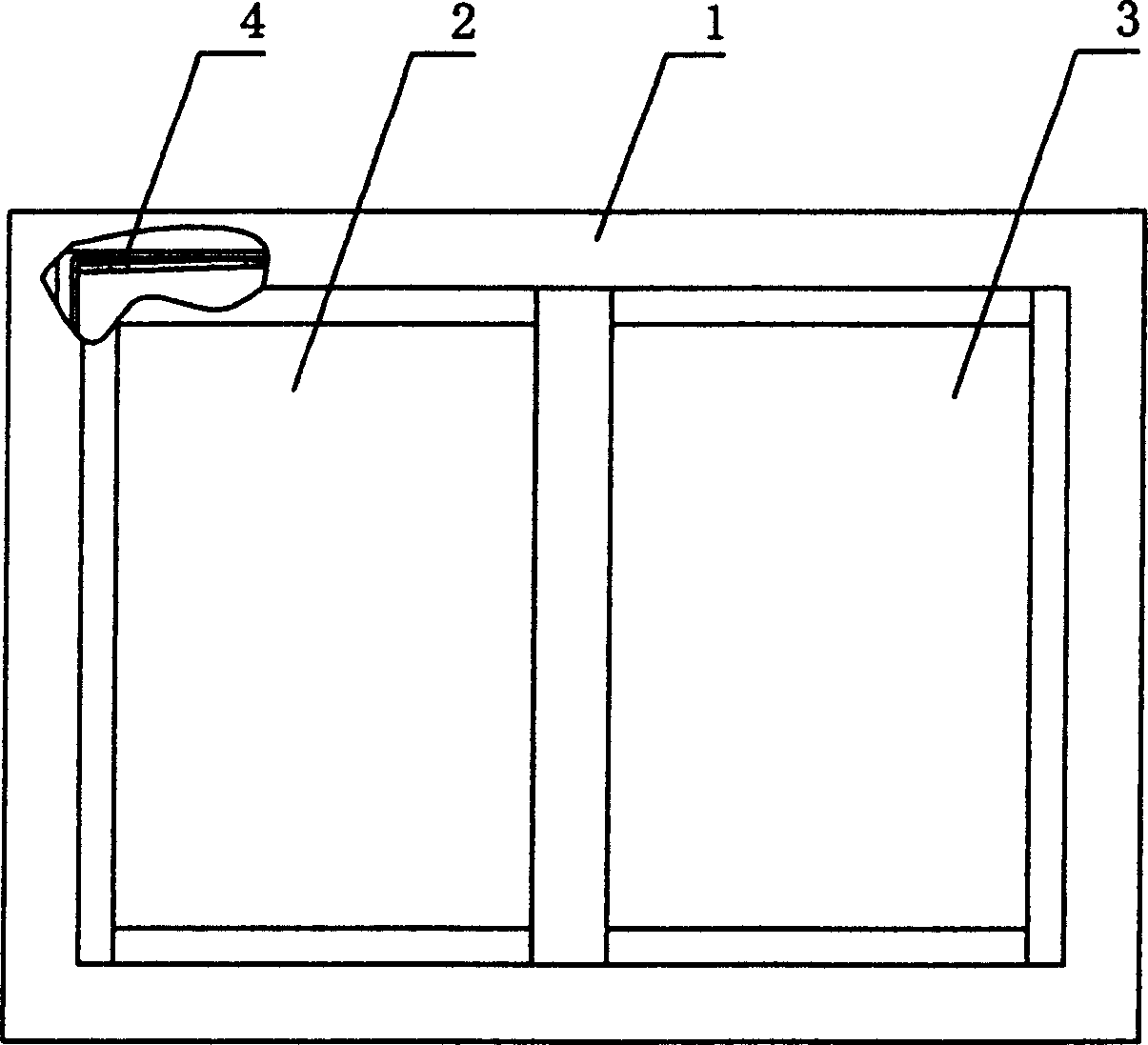

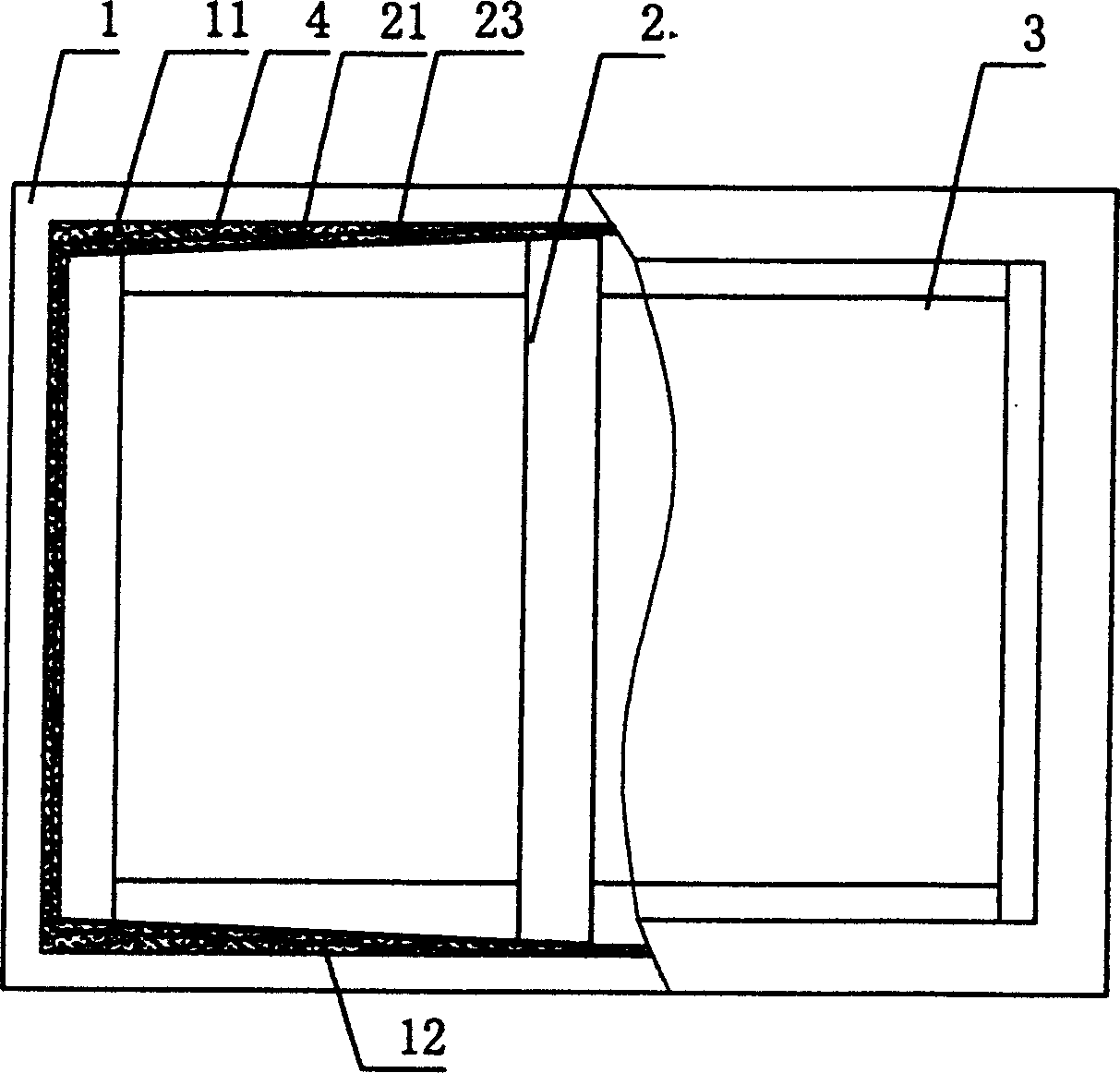

[0015] refer to figure 1 , a kind of high sealing performance sliding window of the present invention is: comprise the window frame 1 that is used to fix the whole form, be provided with chute 12 on sash 1, be provided with the movable window of closing and opening window in chute 12 2, and the fixed window 3, the movable window 2 has a rear end close to the fixed window 3 side and a front end away from the side when the window is closed, in order to strengthen the sealing performance of the window, a fixed sealing strip 11 is provided in the chute 12, for To further enhance the sealing performance of the window, a sealing device 4 capable of sealing under the condition of reducing the push-pull resistance when the movable window 2 is opened and closed is provided between the sliding groove 12 and the movable window 2 .

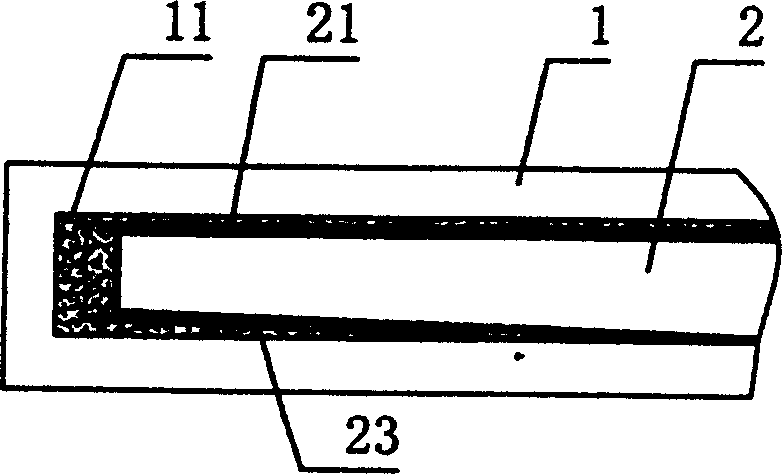

[0016] The sealing device 4 can be as figure 2 As shown in , the upper end surface and the lower end surface of the movable window 2 located in the chute 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com