Laser level device and operating method thereof

A technology of a leveling device and an operating method, applied in the field of laser leveling devices with intermittent power supply mode, can solve the problems of application, unstable operation, power consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

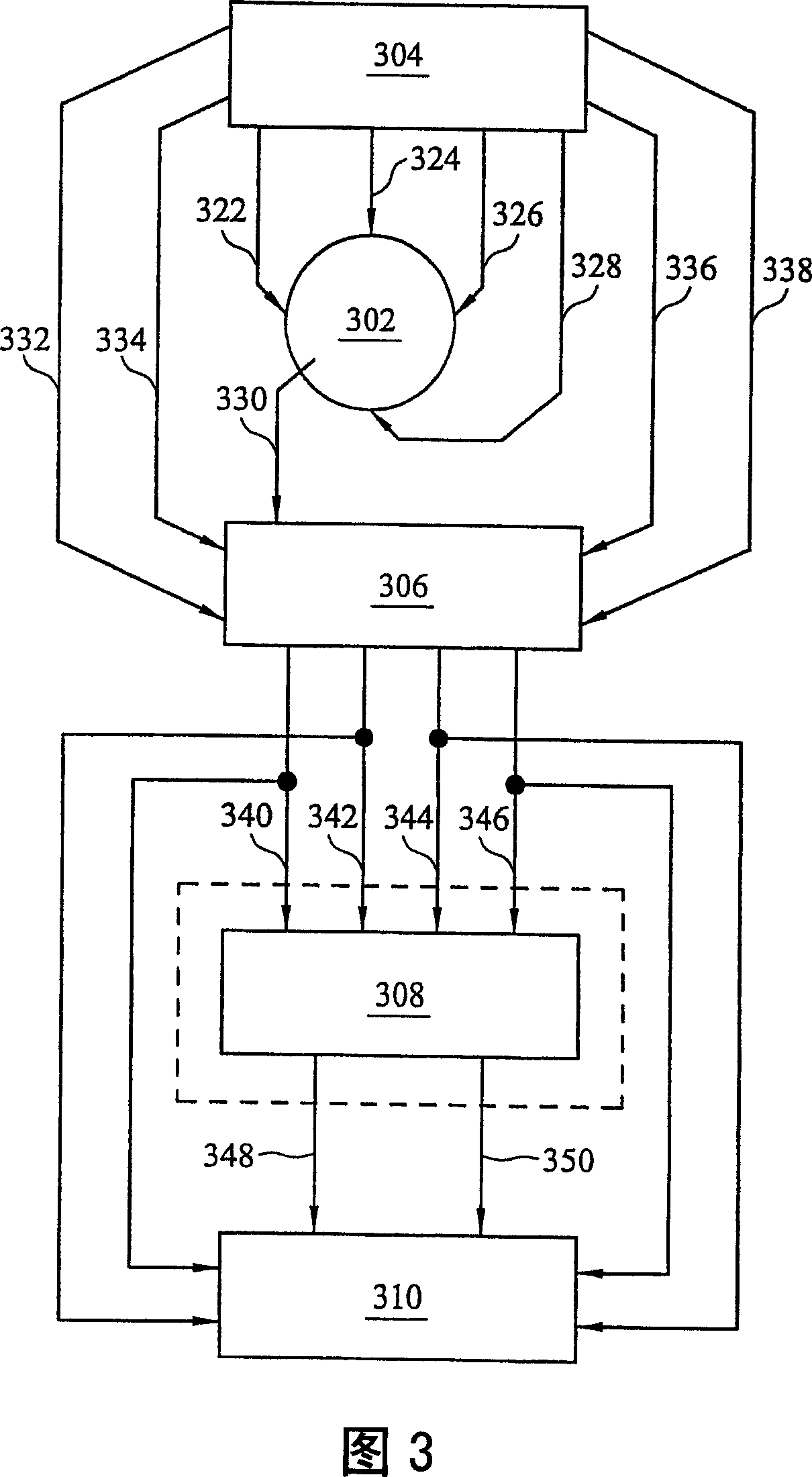

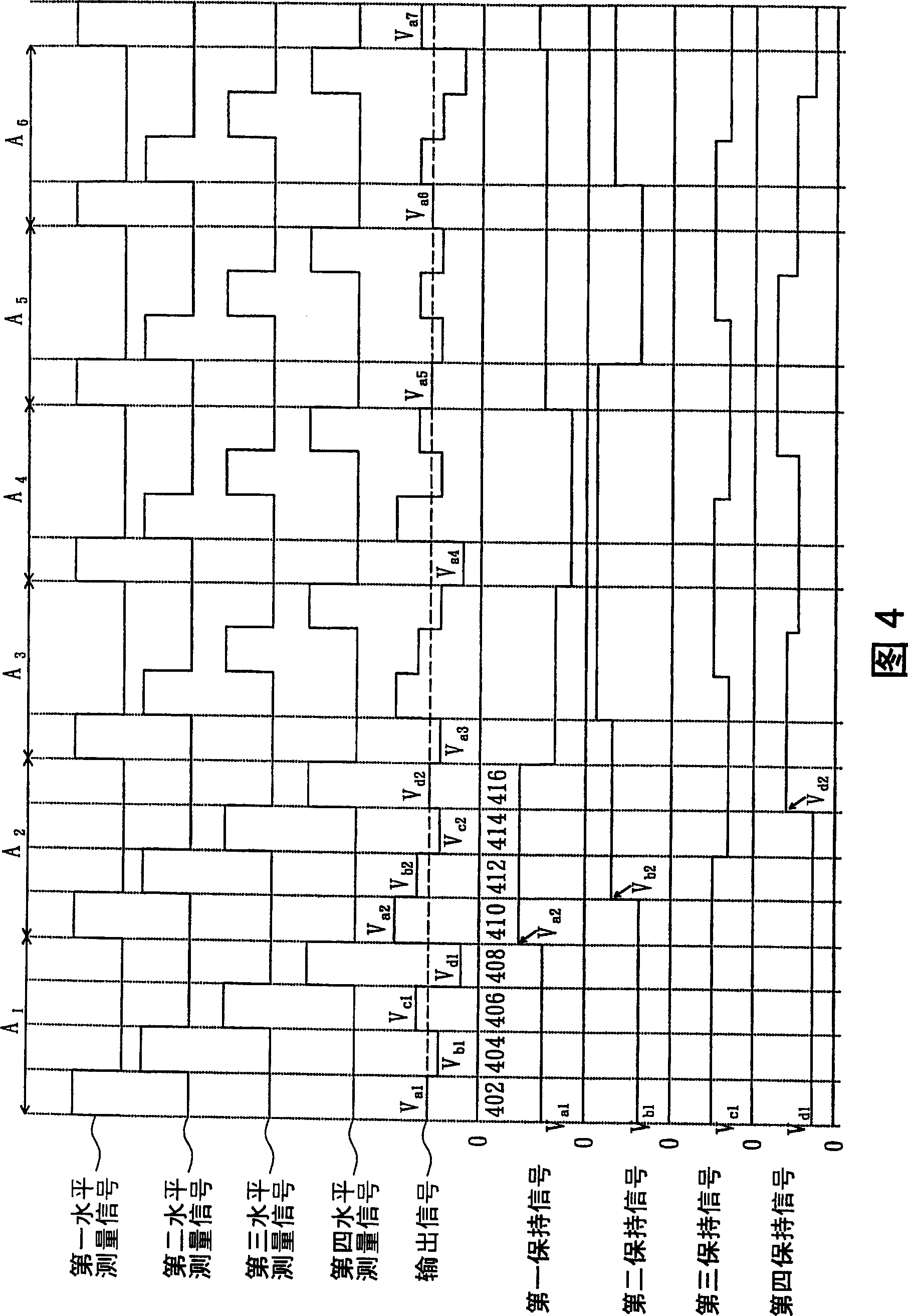

[0056] The invention discloses a laser leveling device and method, which are suitable for laser leveling instruments and angle measuring instruments. By intermittently supplying power to the inclination sensor of the leveling device, the working stability of the leveling device can be increased, and the purpose of power saving can be achieved. On the other hand, by intermittently supplying power to the inclination sensor and the motor, the inclination angle of the horizontal device can be locked for further use by the user. In order to make the narration of the present invention more detailed and complete, refer to the following description and cooperate Figure 3 to Figure 6a and Figure 6b icon of the .

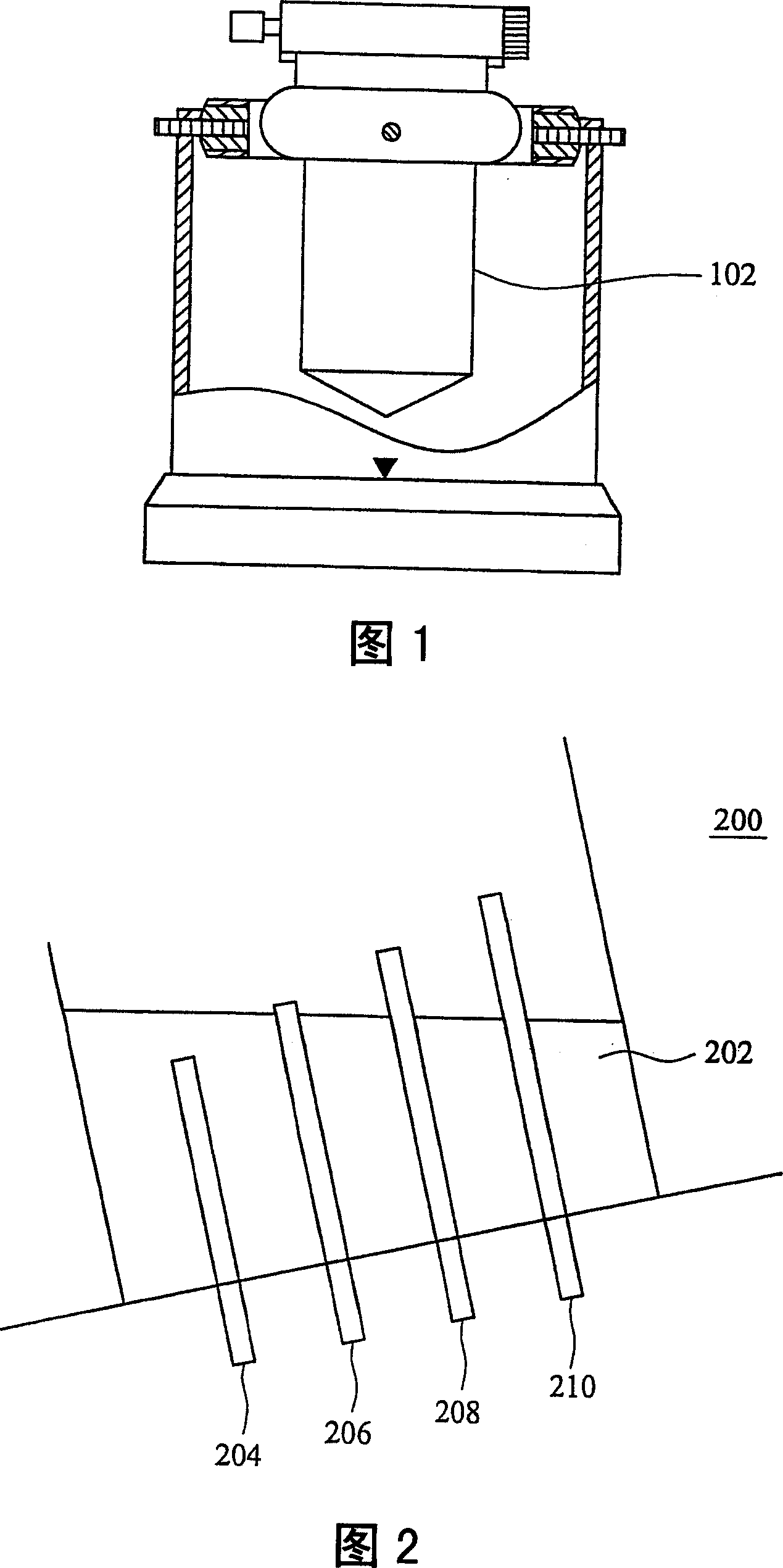

[0057] The laser leveling device of the present invention is composed of three parts: a casing group, an electrical appliance group and a body group. The housing group consists of the housing and the operator panel. The electrical unit is mainly composed of a level adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com