Organic electroluminescence type display apparatus

A display device and luminescent technology, applied in the direction of electroluminescent light source, electric light source, measuring device, etc., can solve the problems of high light reflectivity, unobtainable, difficult metal, etc., achieve high reflection efficiency and improve injection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

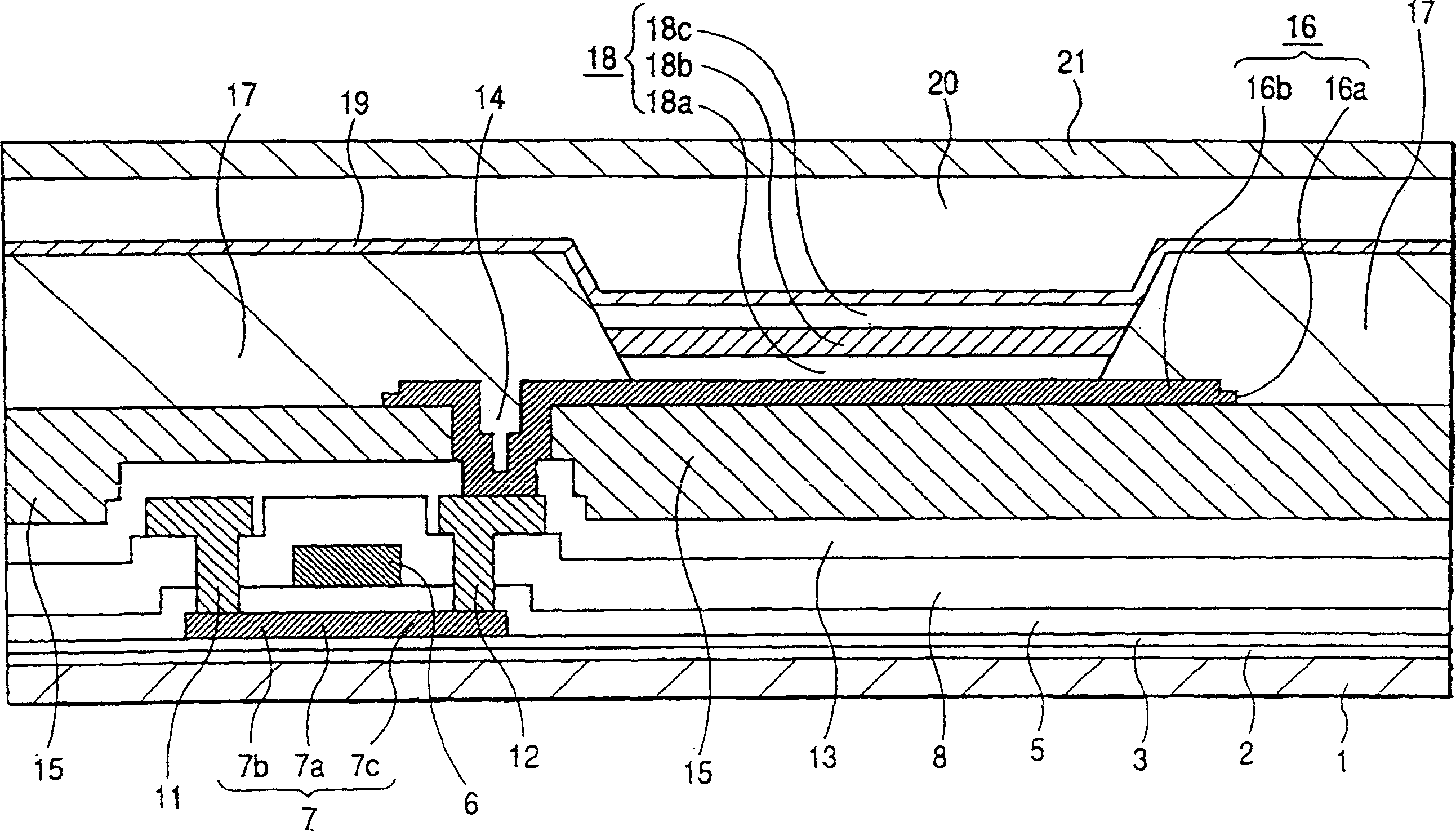

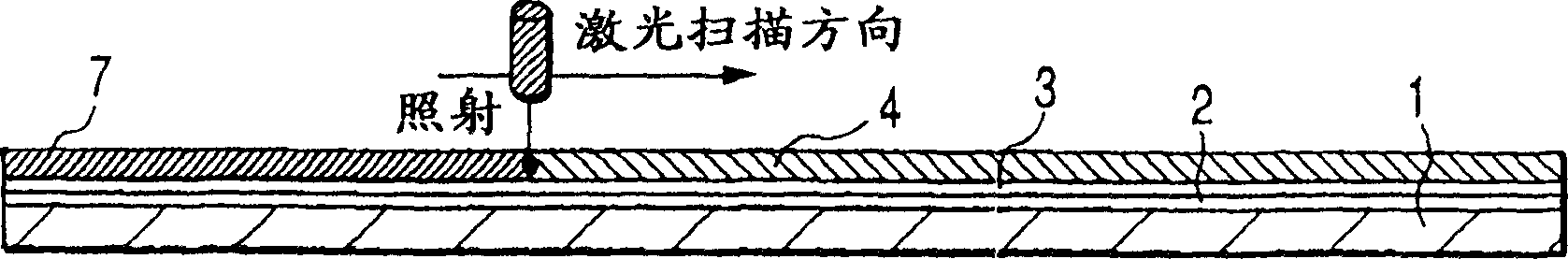

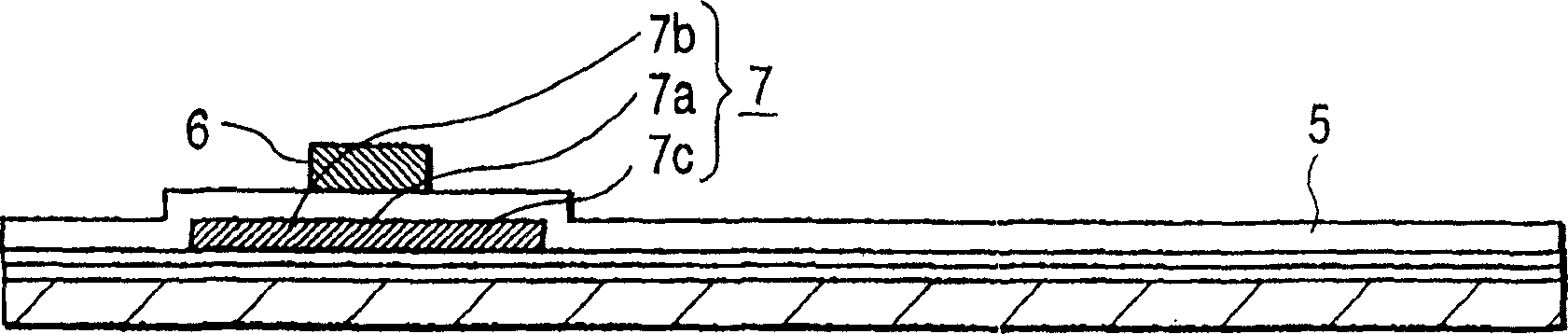

[0032] figure 1 It is a cross-sectional view showing a TFT substrate constituting the organic electroluminescent display device according to Example 1 of the present invention and a pixel portion of an organic EL element formed on top of the TFT substrate. figure 1 Among them, the transparent insulating film formed on the insulating substrate 1, that is, the SiN film 2, SiO 2 On the film 3, a polysilicon film 7 including a channel region 7a, a source region 7b, and a drain region 7c is provided. covered SiO 2 film 3 or polysilicon film 7 to form a gate insulating film 5, and a gate electrode 6 is formed on its top layer, made of SiO 2 The first interlayer insulating film 8 composed of etc. The source electrode 11 and the drain electrode 12 are on the first interlayer insulating film 8 and are respectively connected to the source region 7b and the drain region 7c through the contact holes 9 and 10, forming a thin film transistor based on the above structure. Also, the top l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com