Mill stand for rolling rod-like or tubular rolling stock

A technology for rolling mill racks and rolled pieces, which is applied to metal rolling racks, metal rolling mill stands, metal rolling, etc., and can solve problems such as excessive installation and adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

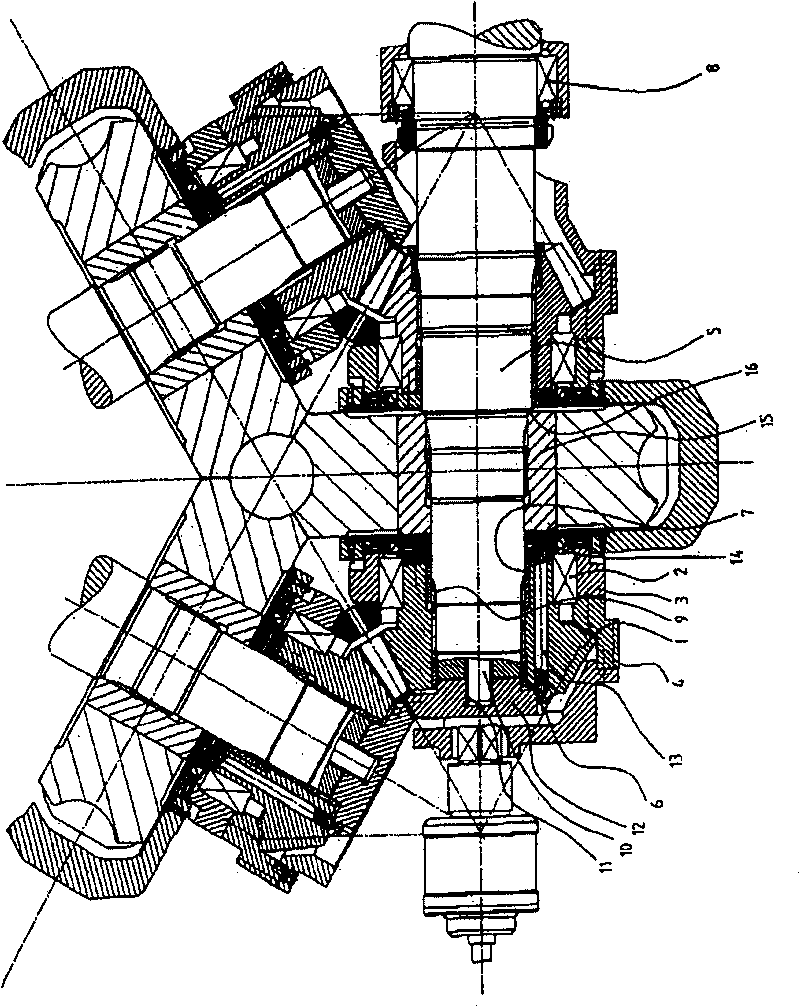

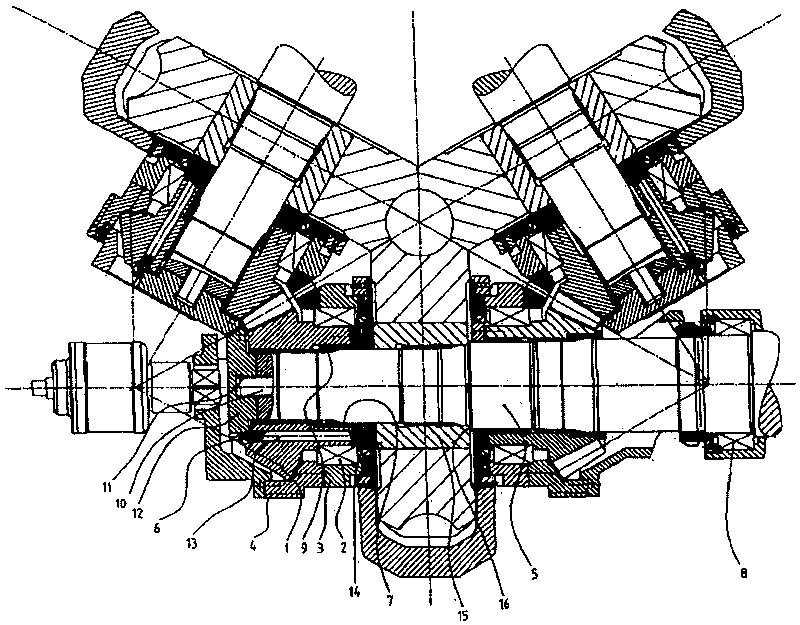

[0020] As can be seen from the drawing, the bevel gear 1 is supported in the eccentric bushing 3 by means of a rolling bearing 2, and the bevel gear rotates the eccentric bushing 3 each time via the trapezoidal thread 4 arranged on the outside on the eccentric bushing 3 in a known manner. Cover 3 when just moved axially. Accordingly, the bevel gear moves axially on the roll shaft 5 , which is supported radially in the bevel gear via sleeves 6 , 7 and is held fixed in its axial position by an axial bearing 8 . The torque is positively transmitted from the roll shaft 5 to the bevel gear via the involute toothing 9 . The tension rod force F is transmitted from the tension rod 10 via the thread 11 to the cover 12 and from there as pressure via a plurality of pressure screws 13 spaced at equal intervals on the circumference to the compression ring 14 . The compression ring 14 transmits the tension force to the roll hub 15 and thus presses the roll hub against the shaft shoulder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com