Automatic hooking device for hoisting concrete pipe pile mould

A technology of concrete pipe piles and hook devices, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of long driving operation time and low personal safety factor, reduce operating time, improve production efficiency, and reduce driving waiting the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The automatic hook device for concrete pipe pile mold lifting of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

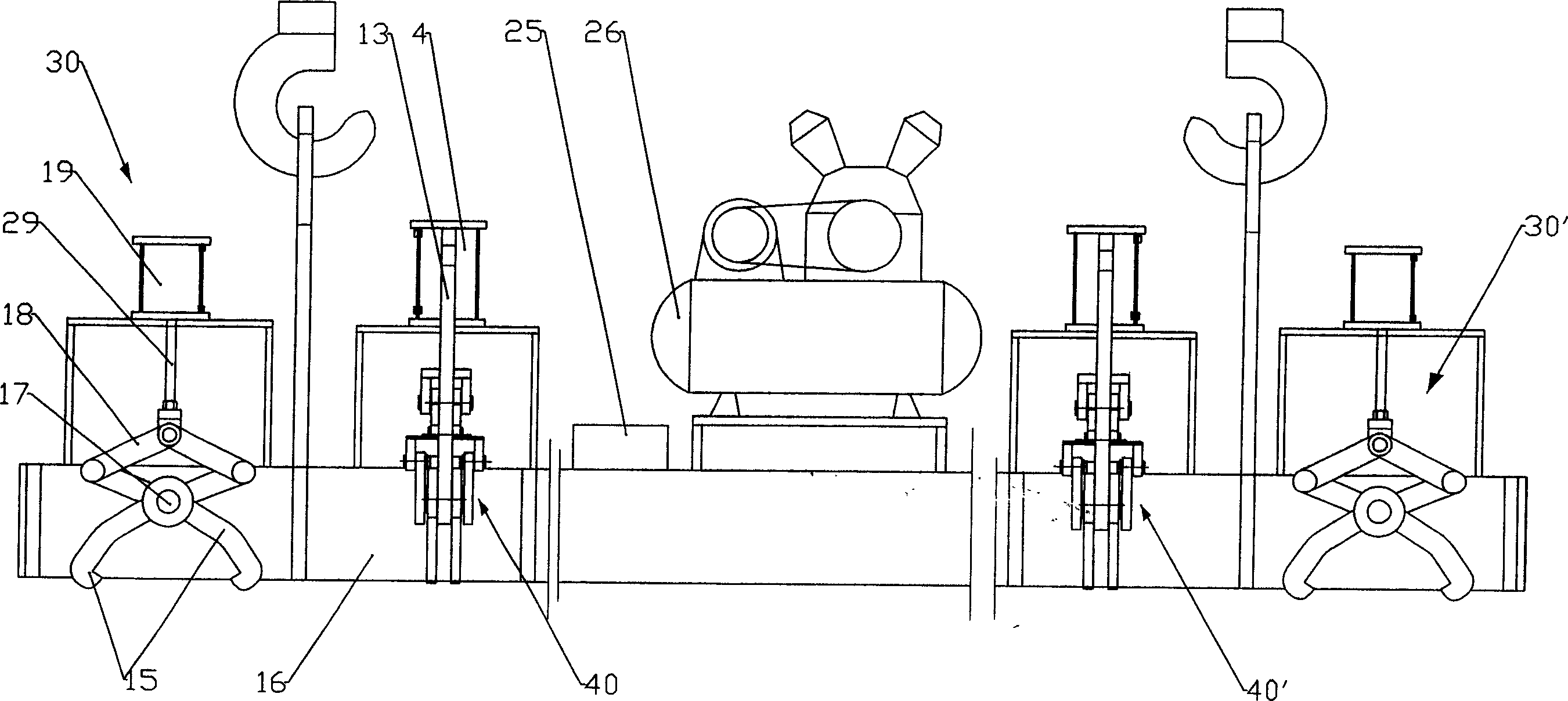

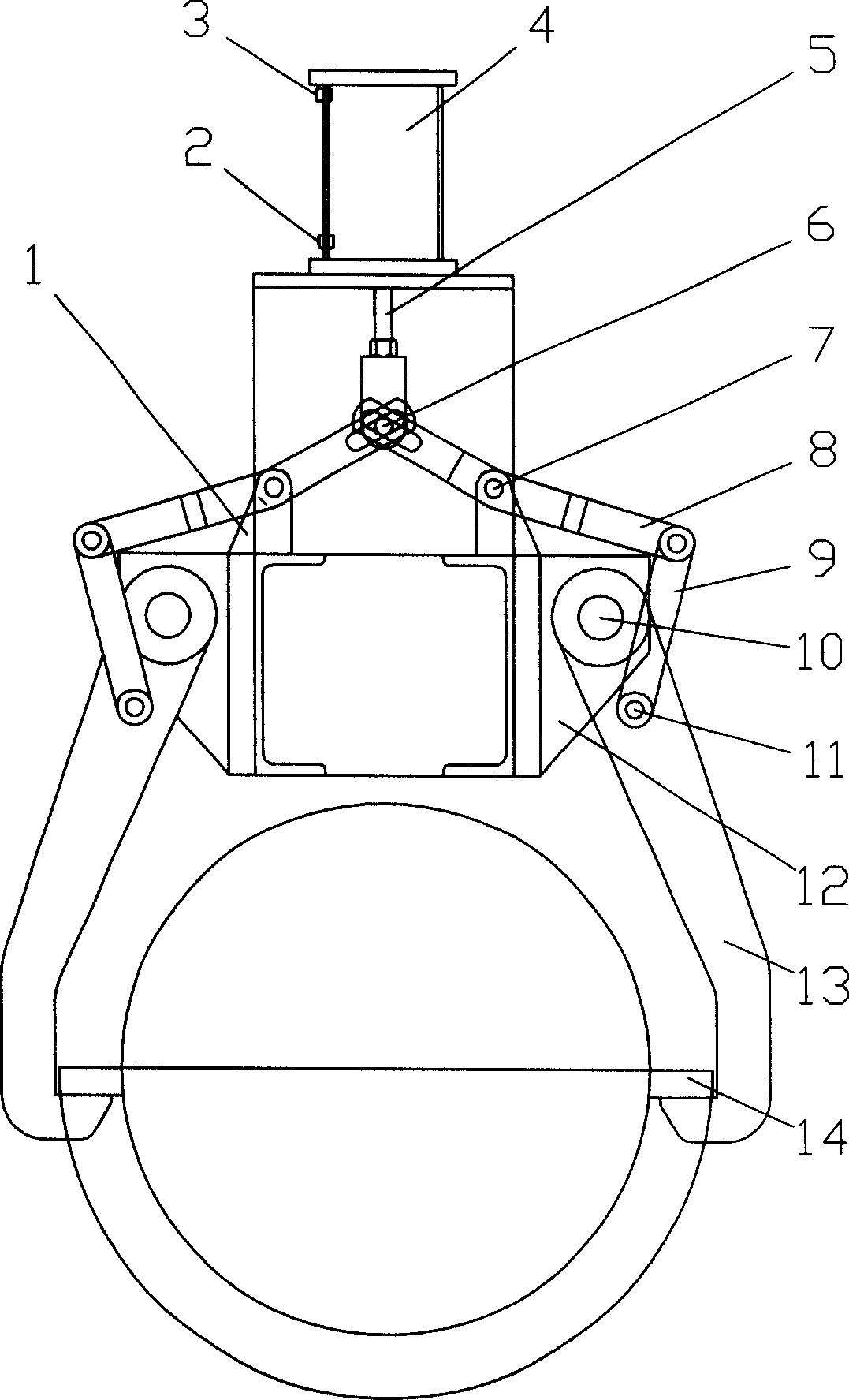

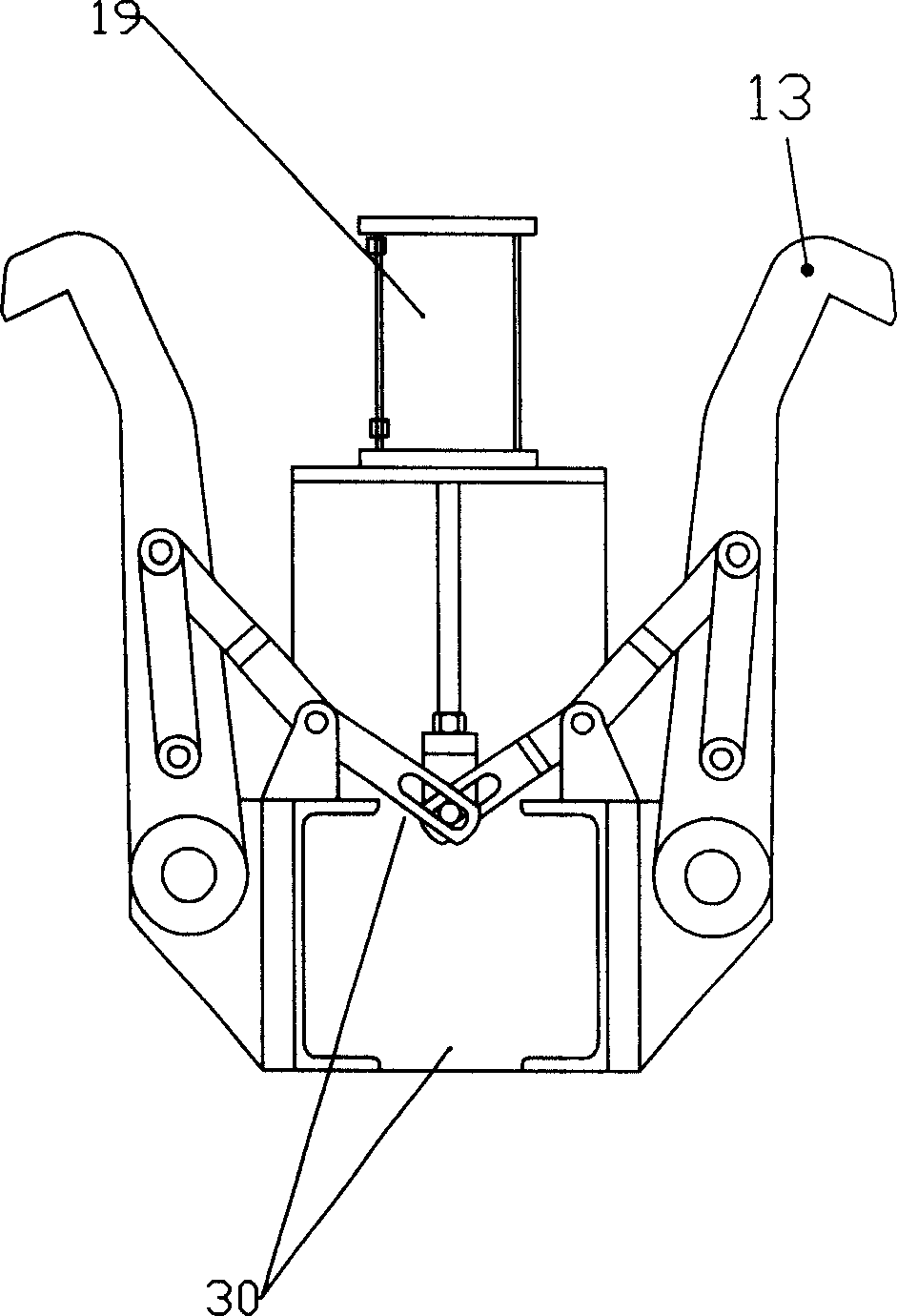

[0019] Such as figure 1 and Figure 4 As shown, the automatic hooking device for hanging concrete pipe pile molds includes a crossbeam 16, and two groups of base mold hooks 40, And two groups of mold cover hooks 30, To form an automatic hooking device, each group of hooking devices is composed of a pair of opening and closing claws and an actuator.

[0020] The actuator includes cylinders 4, 19 and an air compressor 26 that drives the cylinders. The electromagnetic control valve assembly 25 is installed on the air path between the air compressor and the cylinders to control the actions of each cylinder, so as to control the opening and closing of the claws of the automatic hooking device. combine. The lifting of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap