Appearance checking device and method

A visual inspection device, one-sided technology, applied in the direction of measuring device, image enhancement, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

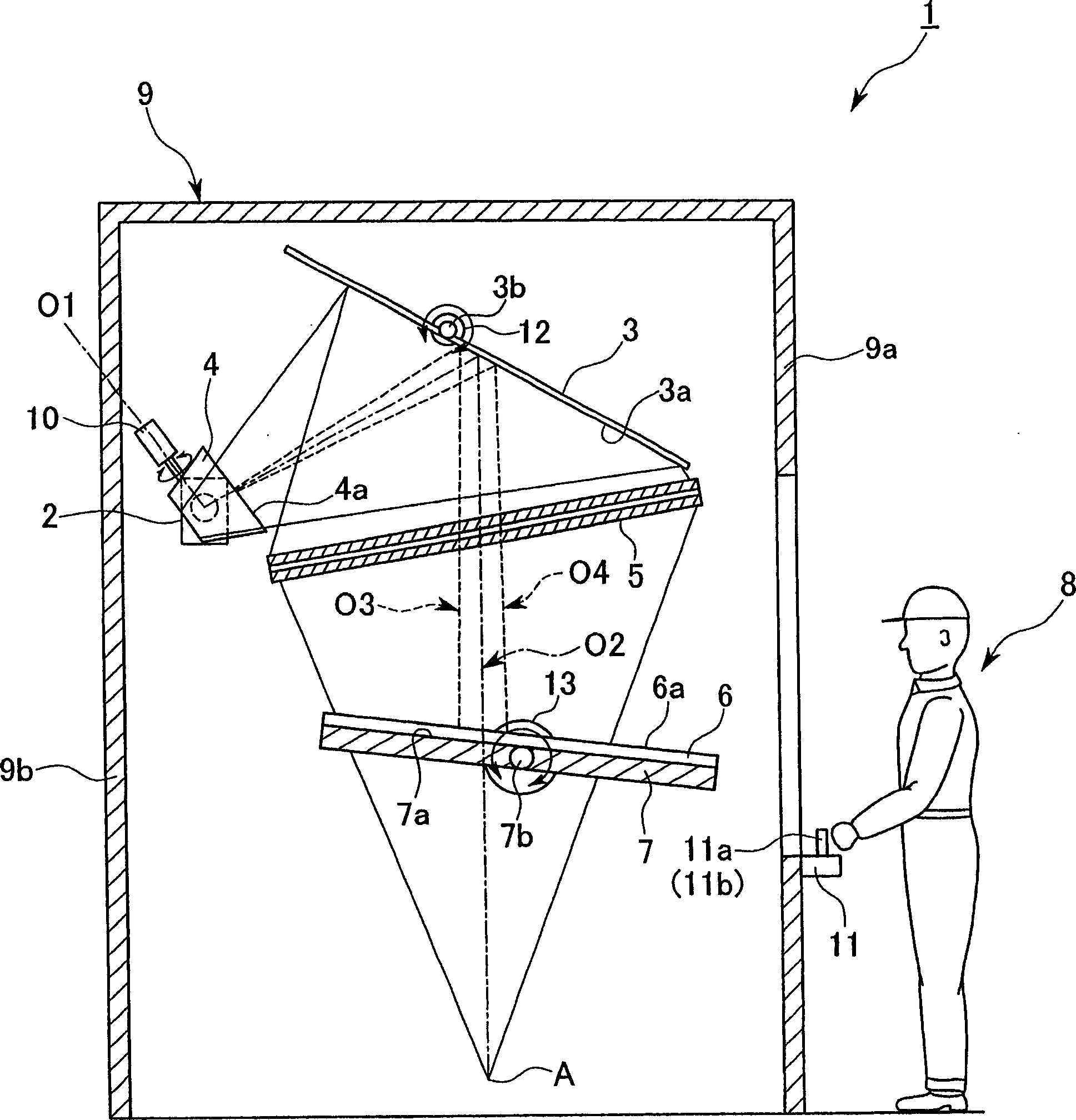

[0014] Below, refer to figure 1 The visual inspection device and visual inspection method according to the first embodiment of the present invention will be described.

[0015] The first embodiment of the present invention provides such figure 1 Shown, for example, is used for the appearance inspection apparatus 1 of the inspection of liquid crystal glass substrate, and this appearance inspection apparatus 1 is made up of the following parts for example: the light source 2 of metal halide lamp etc.; The light emitted by the light source 2 is deflected to the second reflector 3 side; the second reflector 3 (optical element), which deflects the light deflected by the first reflector 4 to the converging lens 5 side; the converging lens 5 (optical element), It condenses the light deflected by the second mirror 3 to irradiate the whole or part of the wide inspection area of the surface 6a of the substrate 6; the substrate holder 7 is arranged under the converging lens 5, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com