Sewing machine

A sewing machine and needle technology, applied to sewing machine components, sewing equipment, program-controlled sewing machines, etc., can solve the problems of materials that cannot change the amplitude of up and down movements, cannot fully cope with thickness, and cannot fully cope with shrinkage, etc., to achieve Improve the effect of correspondence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

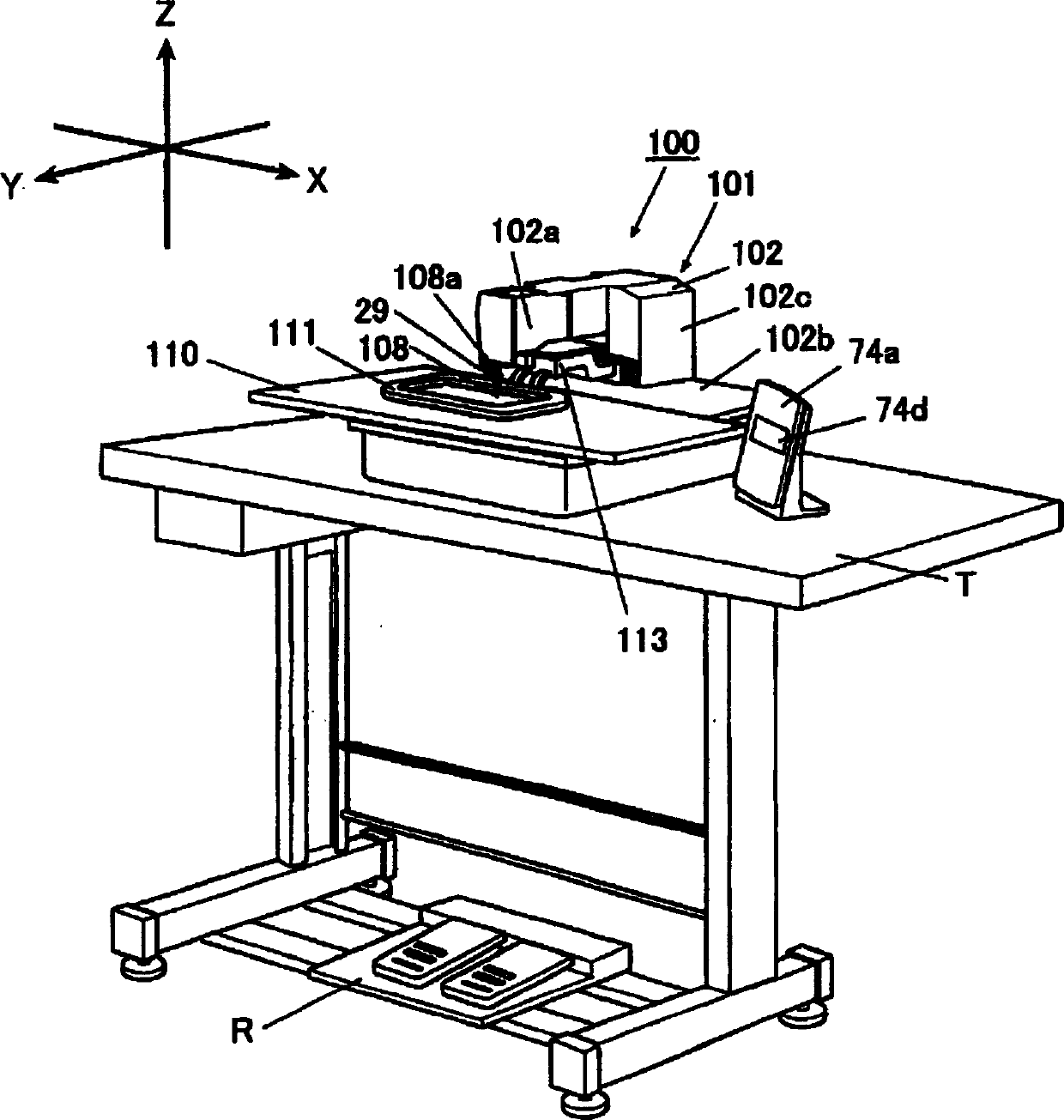

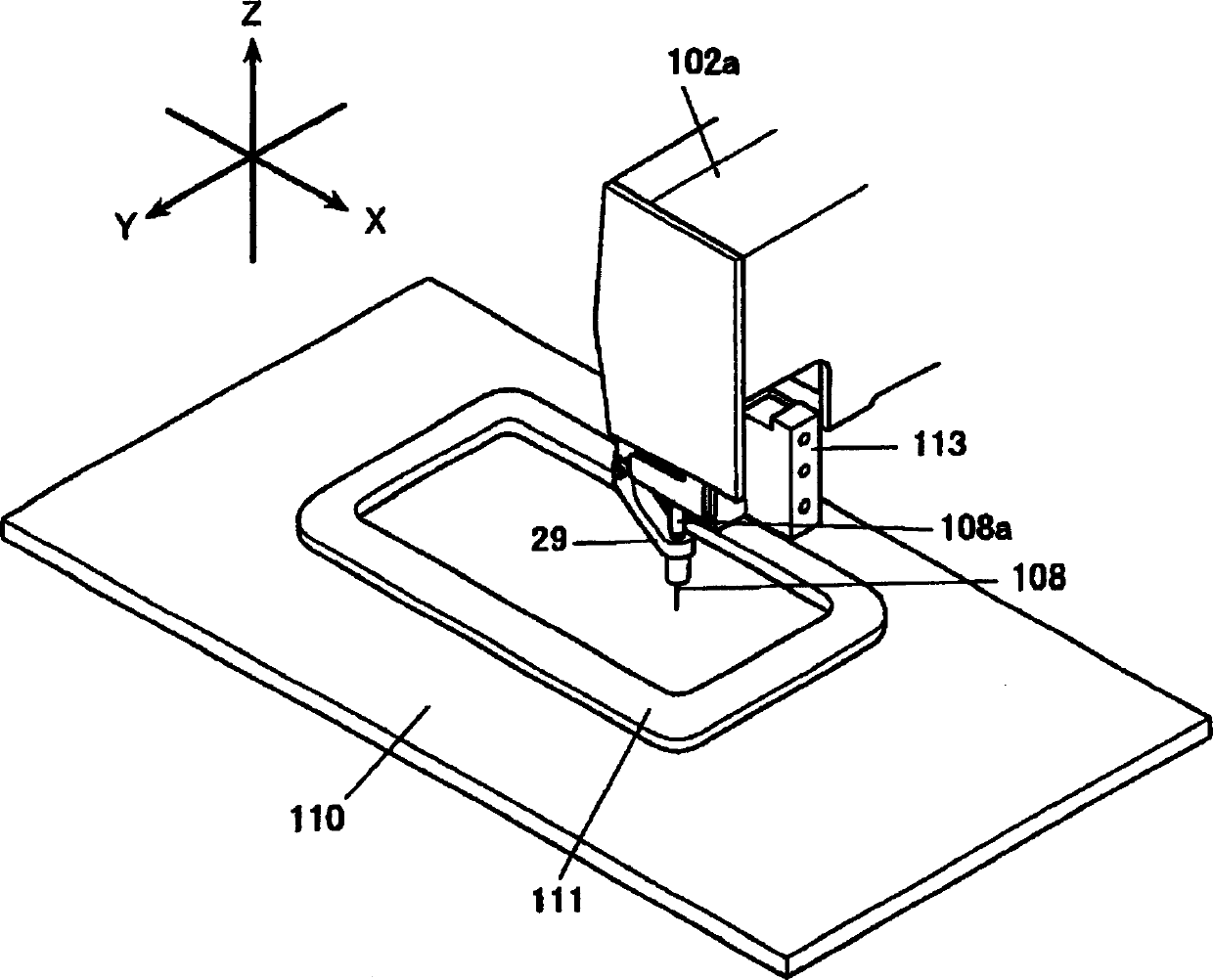

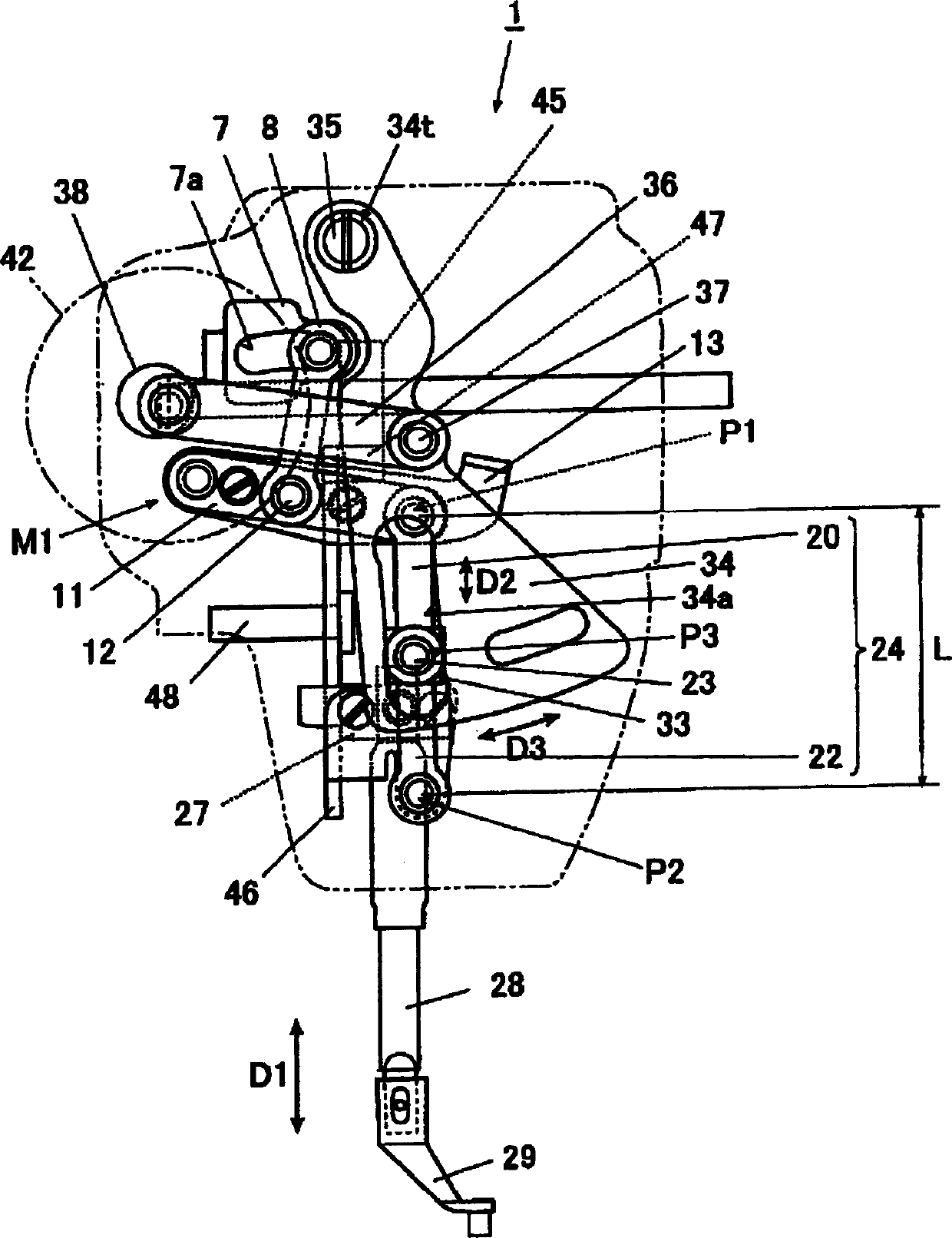

[0049] (The overall structure of the electronic cycle sewing machine)

[0050] Embodiments of the present invention will be described based on FIGS. 1 to 22 .

[0051] In this embodiment, an electronic cycle sewing machine will be described as an example of the sewing machine. An electronic cycle sewing machine is a sewing machine that has a holding frame that is used as a cloth holding portion for holding the cloth of the sewn object to be sewn. The stitches of the specified sewing data (stitch pattern).

[0052]Here, the direction in which the machine needle 108 described later moves up and down is defined as the Z-axis direction (up-and-down direction), and one direction perpendicular thereto is defined as the X-axis direction (left-right direction). The direction perpendicular to the two directions of defines the Y-axis direction (front-rear direction).

[0053] Electronic cycle sewing machine 100 (hereinafter referred to as sewing machine 100), as shown in FIG. Pedal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com