Static material stirrer

A static and material technology, applied in fluid mixers, chemical instruments and methods, dissolution, etc., can solve problems such as poor mixing effect and poor mixing effect, and achieve low design and manufacturing costs, stable manufacturing, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

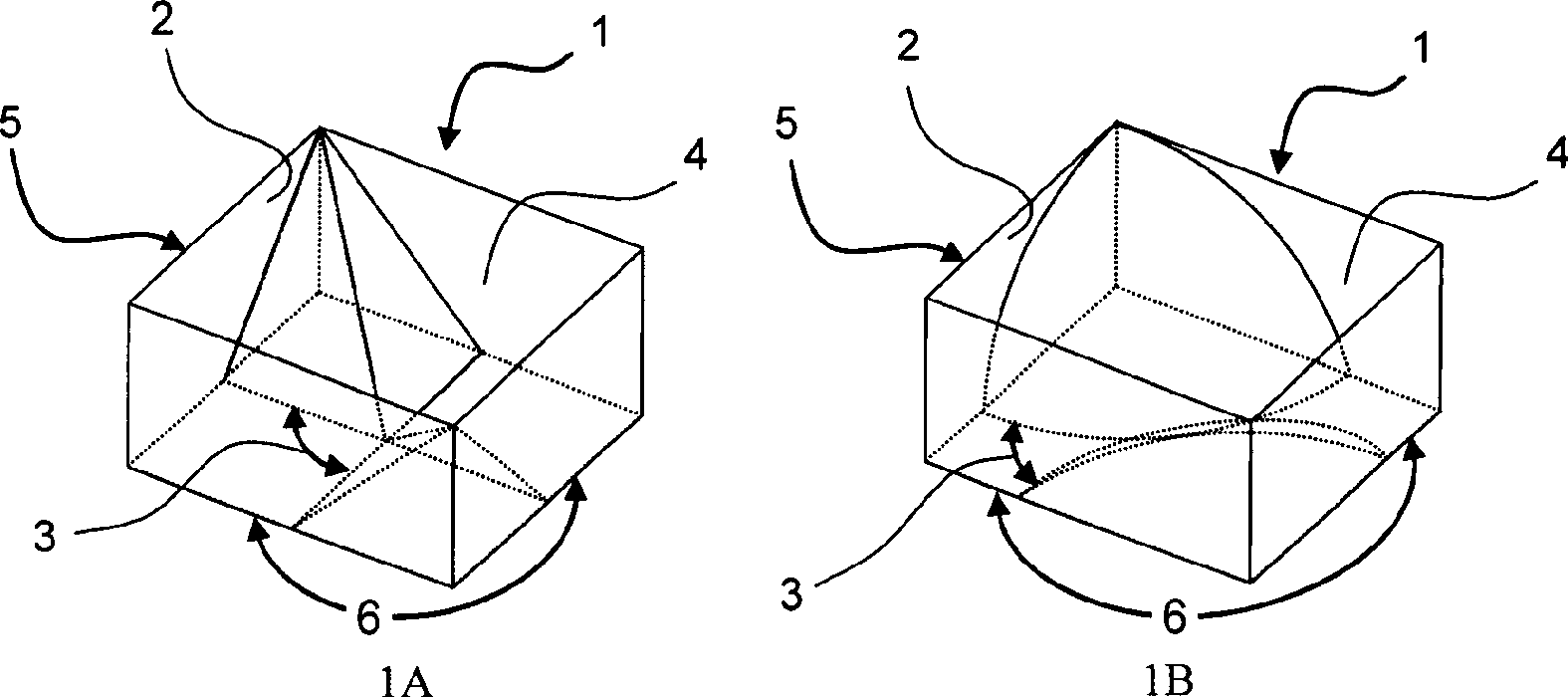

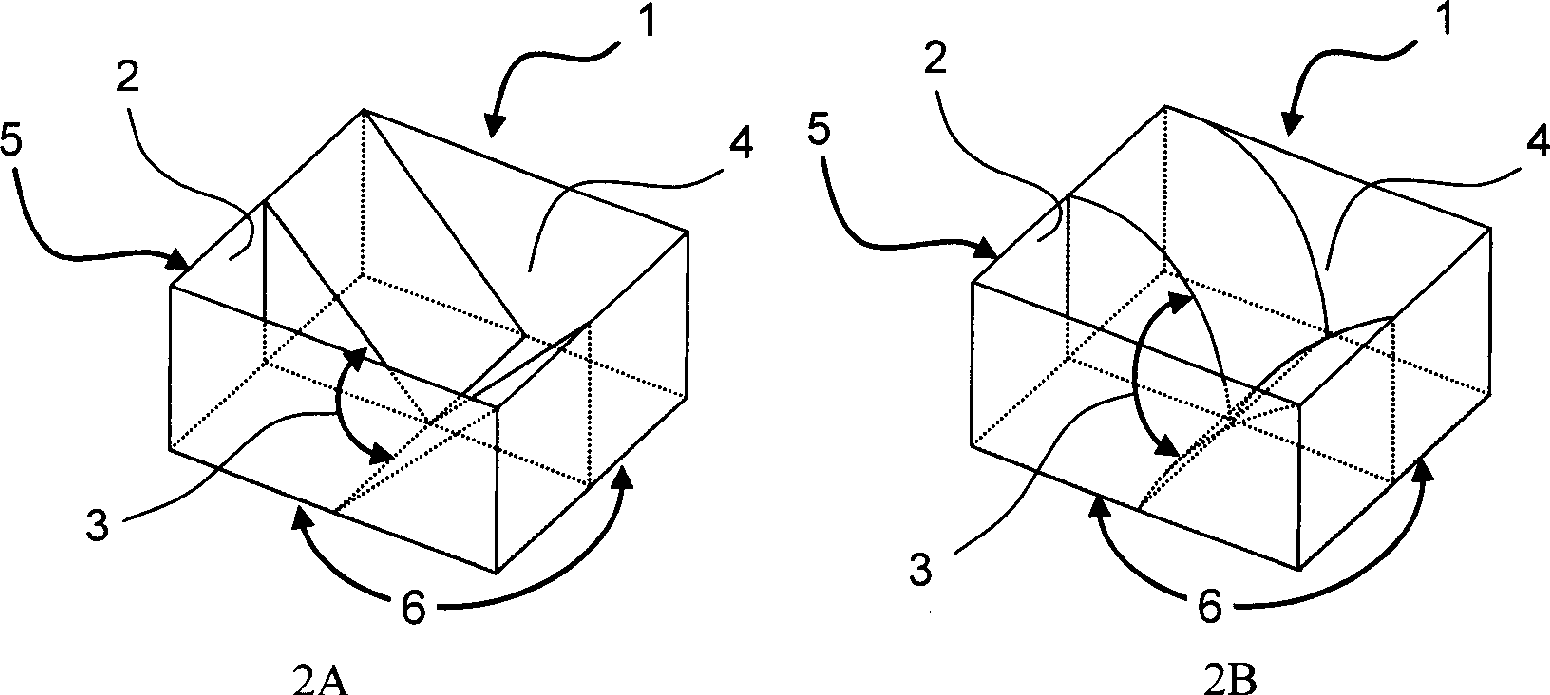

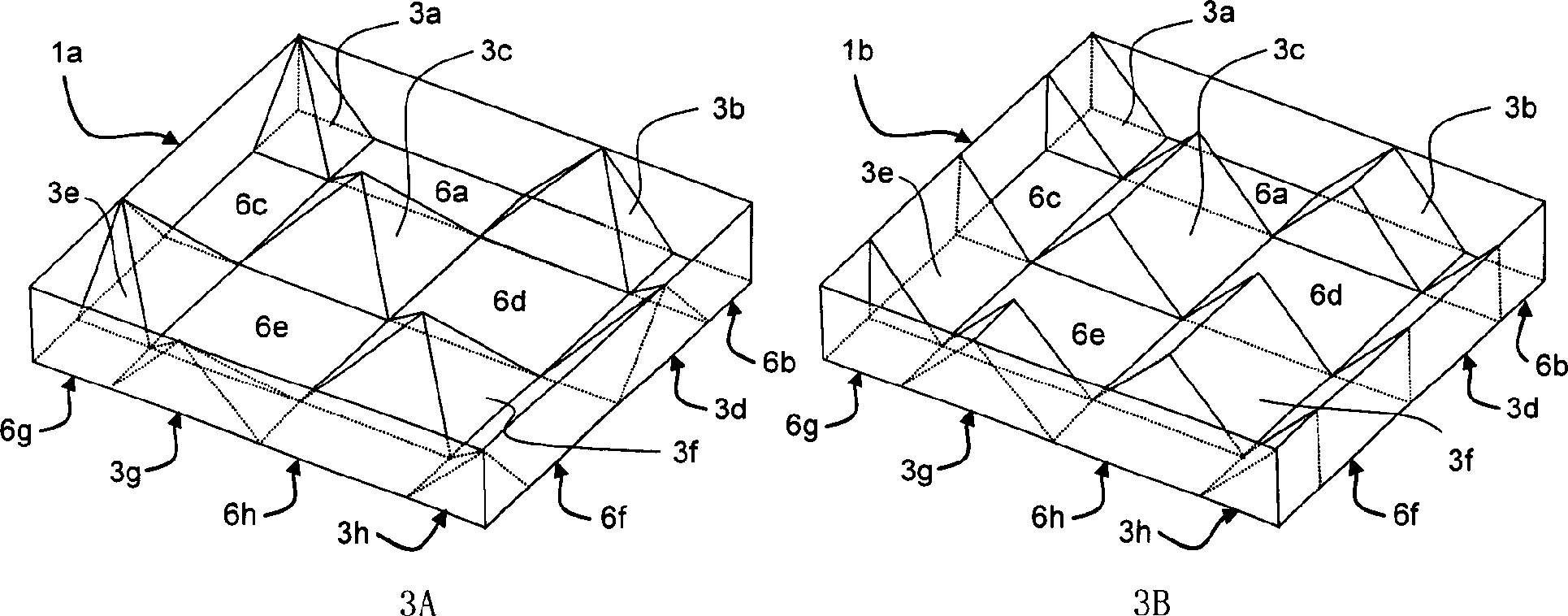

[0022] The mixing structure of the present invention includes a cylindrical outer wall with a circular or polygonal cross section, an inlet of the mixing structure, a mountain-shaped protrusion, a space surrounded by the outer wall and the mountain-shaped protrusion wall, and a discharge port. Each mixing structure is composed of two or more mountain-shaped protruding parts and outlets. The mountain-shaped protruding parts and outlets are arranged alternately along the longitudinal and transverse directions, and the quantity is determined according to the material characteristics of the mixed materials. The mountain-shaped protruding part is a geometric body composed of planes and / or curved surfaces, and the shapes include quadrangular pyramid, triangular prism, hemispherical and semicylindrical. The angle, height and shape of the side walls of the mountain-shaped protrusions are selected according to the properties of the materials to be mixed.

[0023] The mixing structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com