Valve

A valve and valve body technology, used in sliding valves, valve devices, engine components, etc., can solve the problems that the performance parameters are difficult to meet the needs of industrial engineering, the design of the operating mechanism is complex, and the manufacturing cost is high. Fast, easy to process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

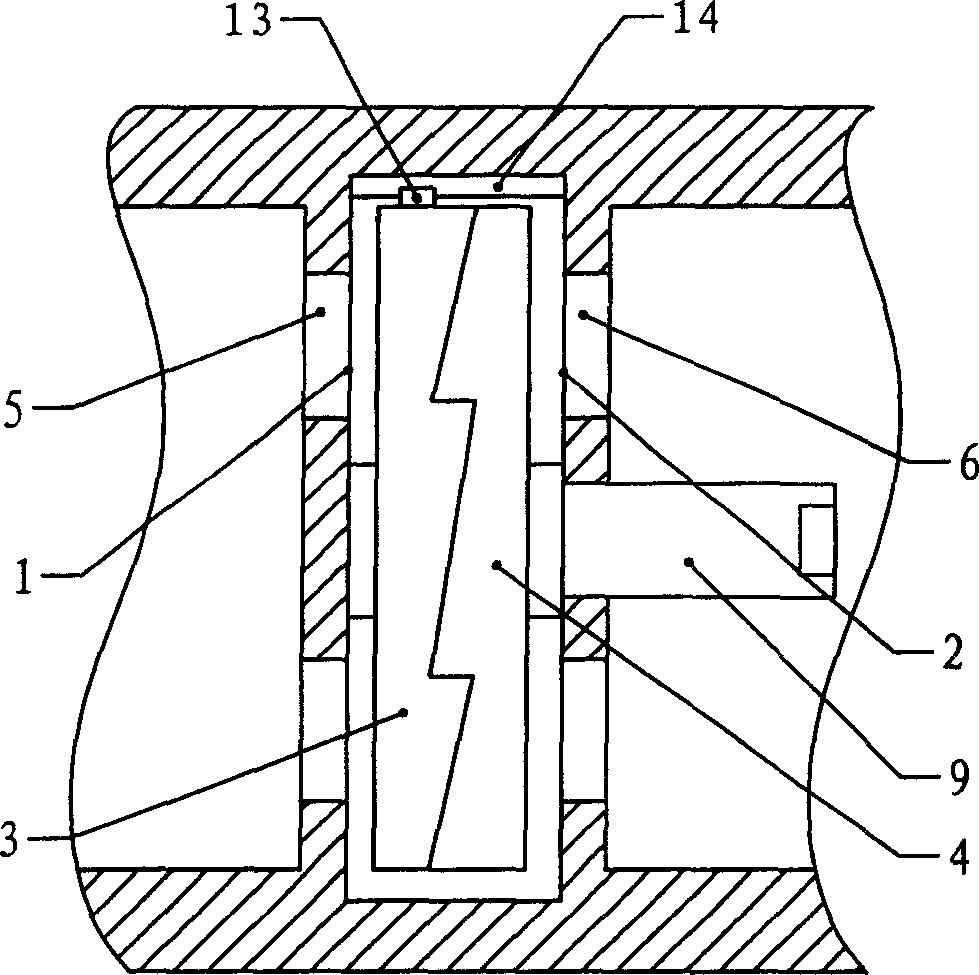

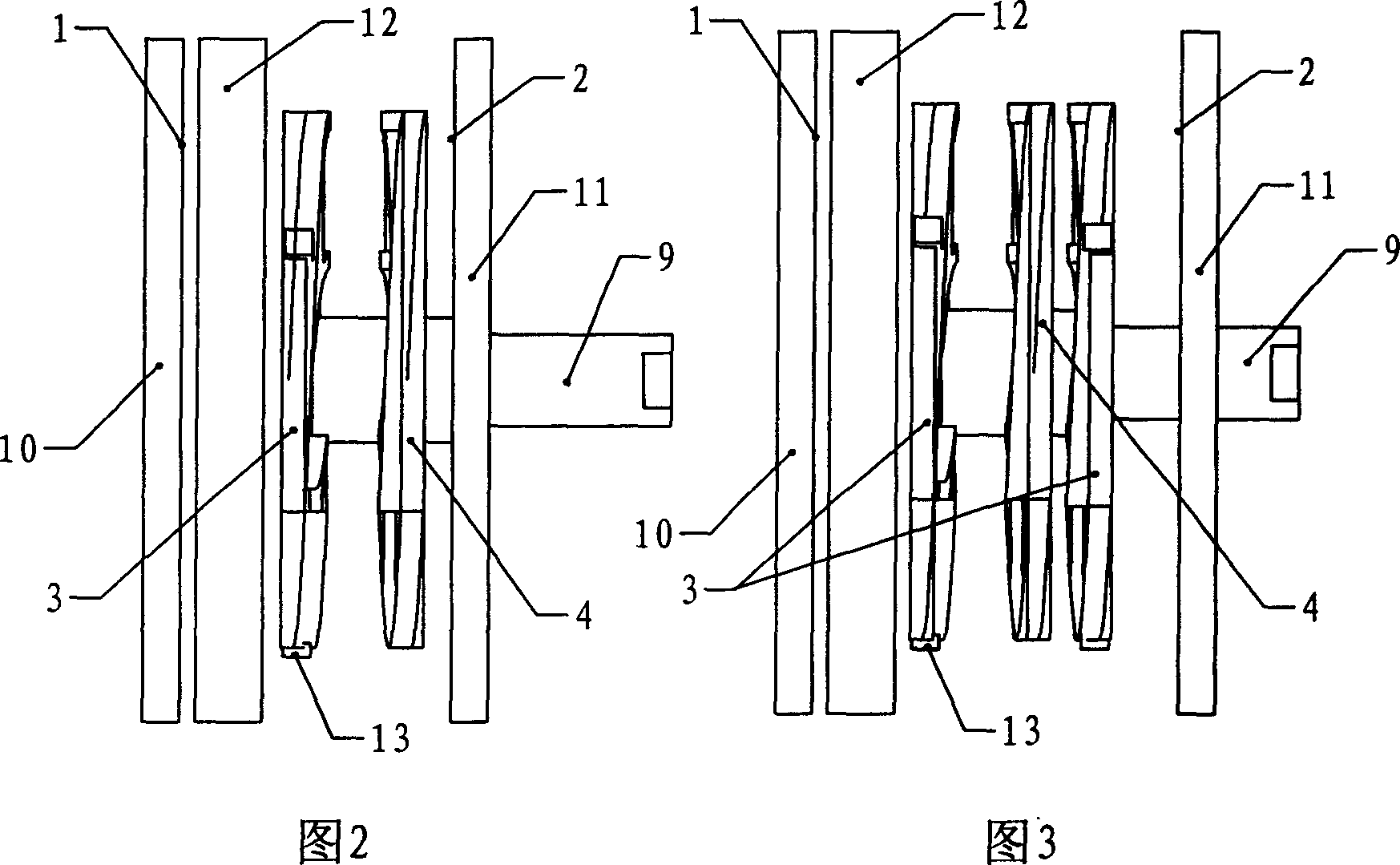

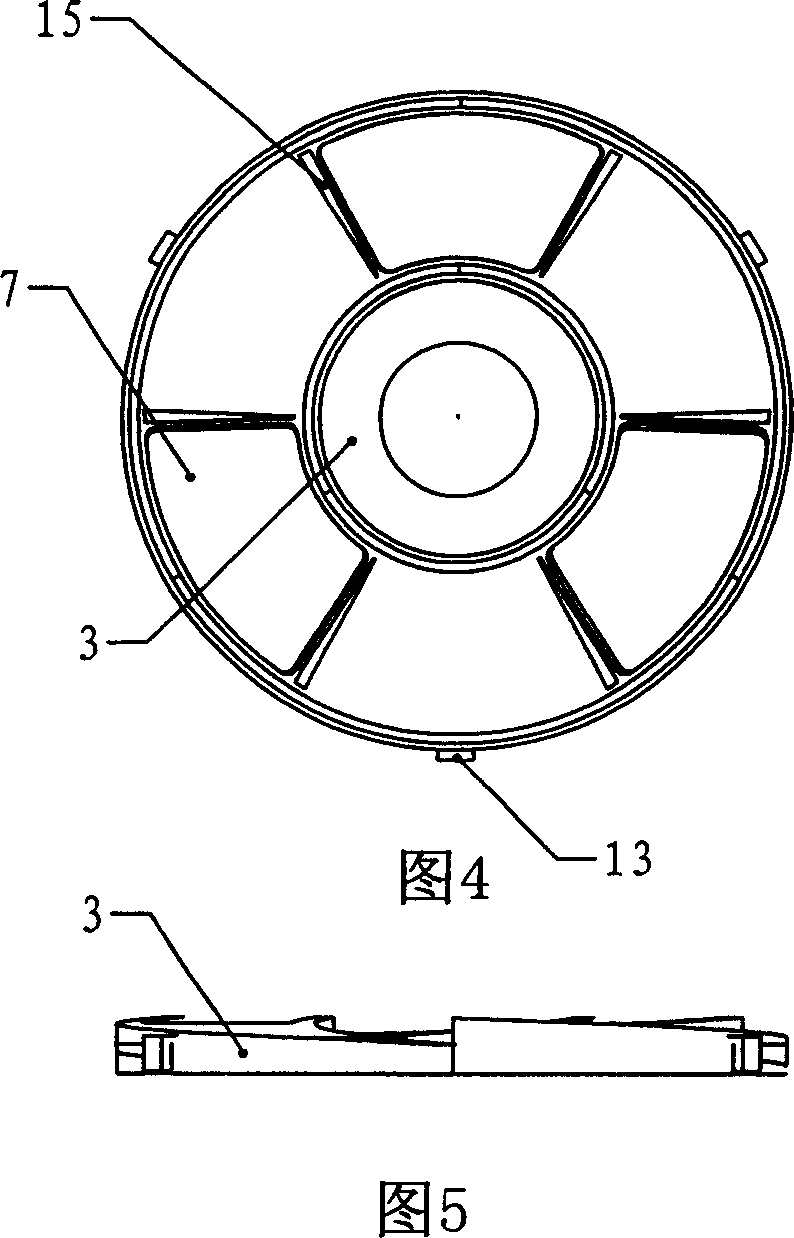

[0038] Embodiment 1: as shown in Fig. 2, 4~ Figure 11 As shown, the valve of the present invention includes a valve body provided with a sealing cavity. The lower pressing plate 10, the supporting ring 12 and the upper pressing plate 11 are sequentially stacked and connected with the valve body as a whole. The hollow part inside the supporting ring 12 forms a sealing cavity. The upper sealing surface 1 is arranged on the lower pressing plate 10, the lower sealing surface 2 is arranged on the upper pressing plate 11, and the inlet and outlet of the flow channel connecting the sealing cavity are respectively arranged on the lower sealing surface 1 and the upper sealing surface of the lower pressing plate 10 and the upper pressing plate 11 2 on. The sealing unit formed by the semi-moving plate 3 and the moving plate 4 arranged opposite to the lower sealing surface 1 and the upper sealing surface 2 is stacked coaxially in the sealing chamber, and the contact surface between the s...

Embodiment 2

[0039] Embodiment 2: as shown in Figure 3~ Figure 11 As shown, the valve of the present invention includes a valve body provided with a sealing cavity. The lower pressing plate 10, the supporting ring 12 and the upper pressing plate 11 are sequentially stacked and connected with the valve body as a whole. The hollow part inside the supporting ring 12 forms a sealing cavity. The upper sealing surface 1 is arranged on the lower pressing plate 10, the lower sealing surface 2 is arranged on the upper pressing plate 11, and the inlet and outlet of the flow channel connecting the sealing cavity are respectively arranged on the lower sealing surface 1 and the upper sealing surface of the lower pressing plate 10 and the upper pressing plate 11 2 on. In the sealing chamber, there are two semi-moving plates 3 and one moving plate 4 stacked in sequence on the lower sealing surface 1 and the upper sealing surface 2 to form a sealing unit, and the two semi-moving plates 3 are stacked on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com