Bearing platform type track slab

A track slab and desktop technology, applied in the field of track slabs, can solve the problems of increased damage to the gravel track bed, poor track smoothness, and increased maintenance workload, and achieve the effects of saving raw materials, increasing distance, and ensuring insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

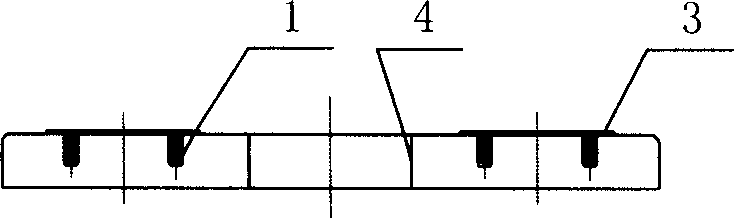

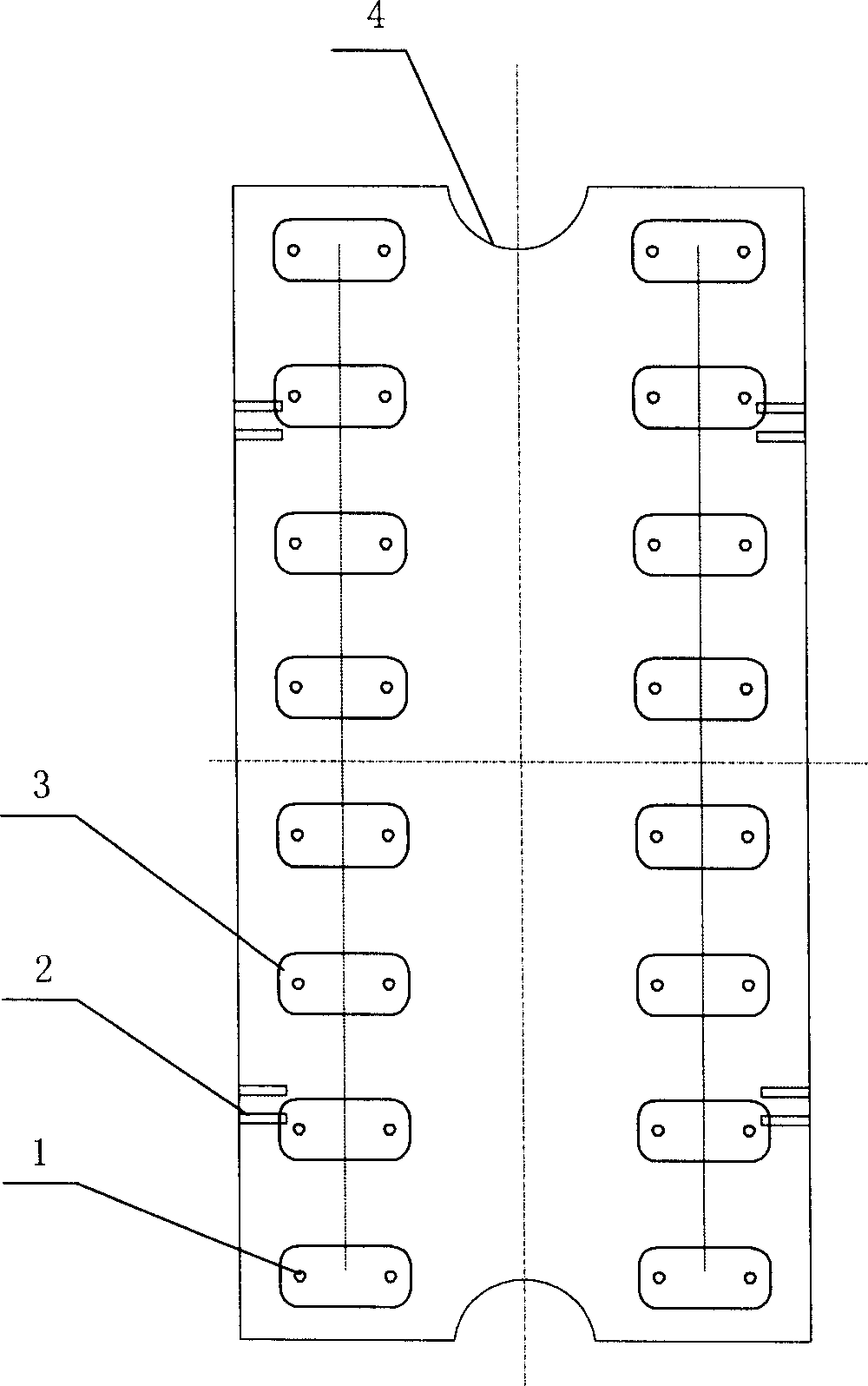

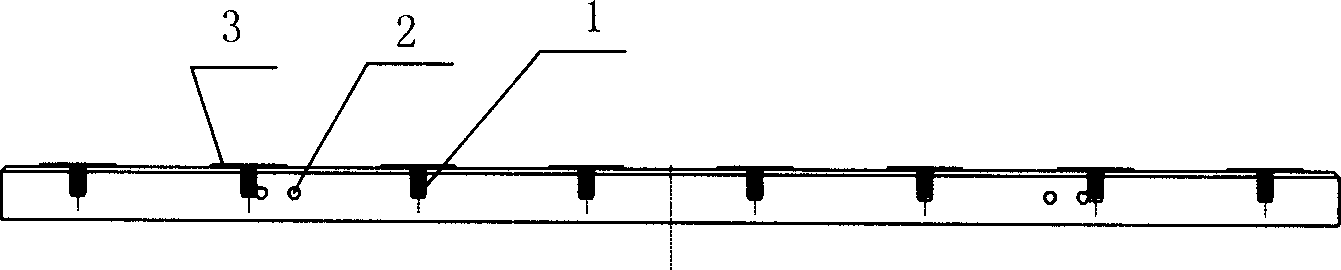

[0022] Such as figure 1 , figure 2 , image 3 As shown, a bearing platform track slab is mainly formed by pouring concrete and built-in steel bars. The middle part of the longitudinal two ends of the track slab is provided with a semicircular notch 4, which is used to cooperate with the convex block on the base to overcome The reaction force caused by the disturbance of the loaded plate under the action of the wheel load; the bearing part of the track plate is symmetrically distributed with caps 3, which increases the distance between the rail and the internal steel bars of the track plate, which is more conducive to the relationship between the rail and the track plate The insulating bolt sleeves 1 embedded in the bearing platform 3 are symmetrically distributed in order to be insulated from the bolts on which the rail is installed; the built-in steel bar nodes of the track slab are insulating nodes, that is, the steel bar nodes inside the track slab are insulated The stee...

Embodiment 2

[0025] Such as Figure 4 , Figure 5 , Figure 6 As shown, a platform-type track slab is mainly formed by pouring concrete and built-in steel bars. There are holes 5 in the height direction of the middle of the track slab, which can save raw materials and reduce the manufacturing cost of the track slab; the middle of the longitudinal two ends of the track slab A semicircular notch 4 is provided, and caps 3 are symmetrically distributed on the rail bearing part of the track slab, and pre-buried insulating bolt sleeves 1 are symmetrically distributed in the caps 3, and the built-in reinforcement nodes of the track slab are insulating nodes, that is, the track The steel bar nodes inside the slab are insulated. The steel bars inside the track slab are cross-bound by vertical and horizontal steel bars. The horizontal steel bars are ordinary steel bars, generally hot-rolled ribbed steel bars. According to the regulations of Rib Reinforcement, the longitudinal reinforcement is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com