Robot controlling device

A control device, robot technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of movement speed change, contact and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

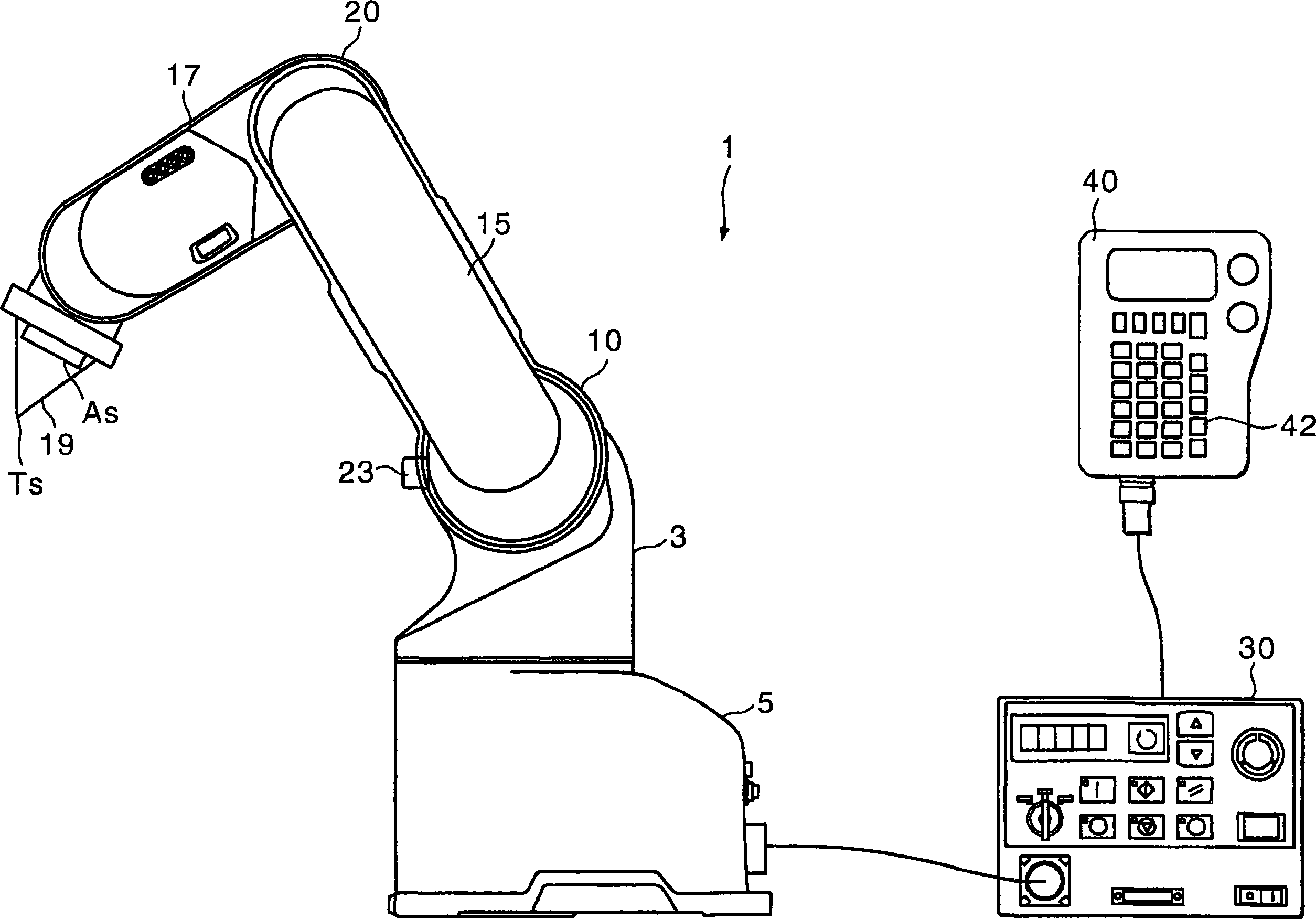

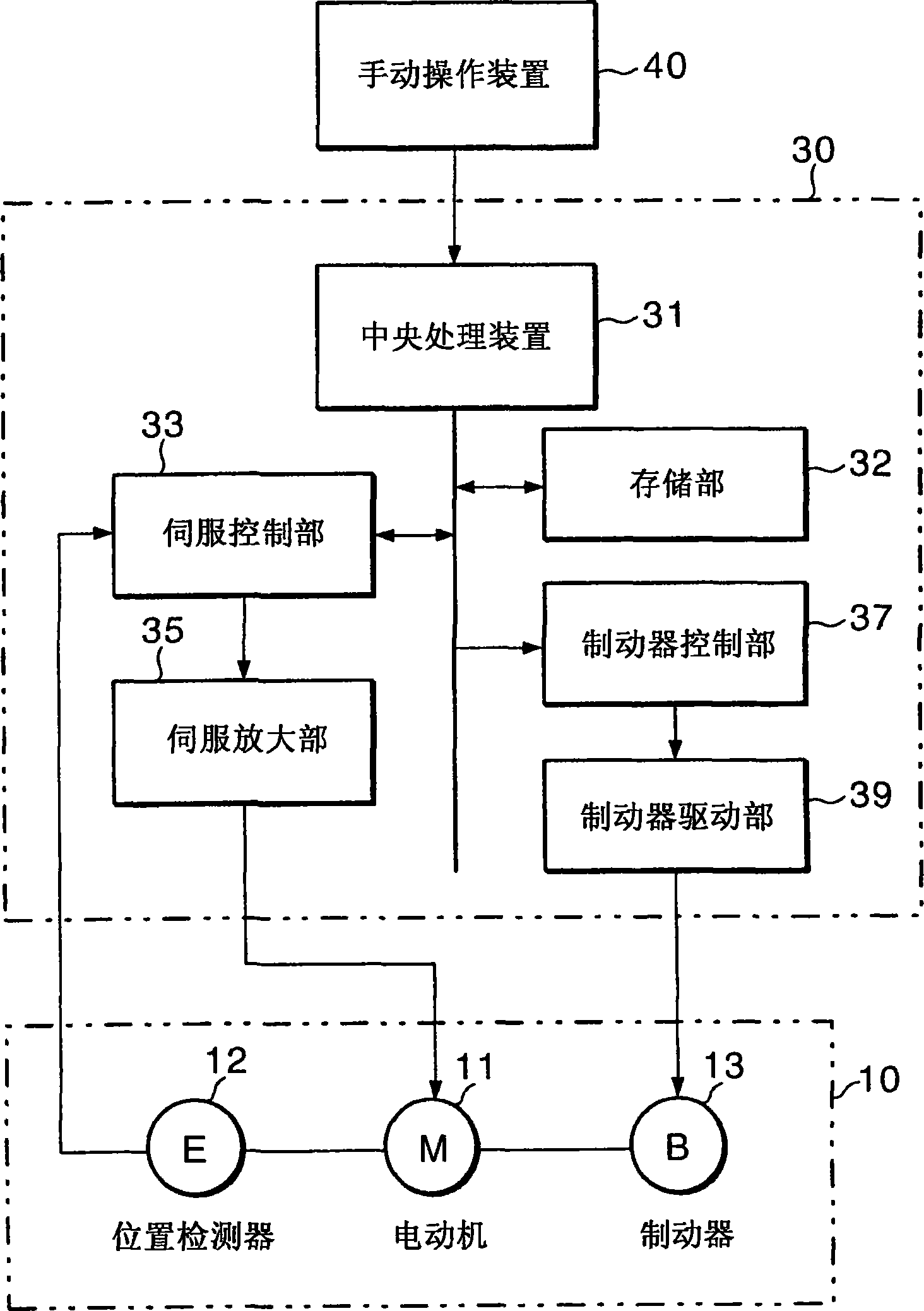

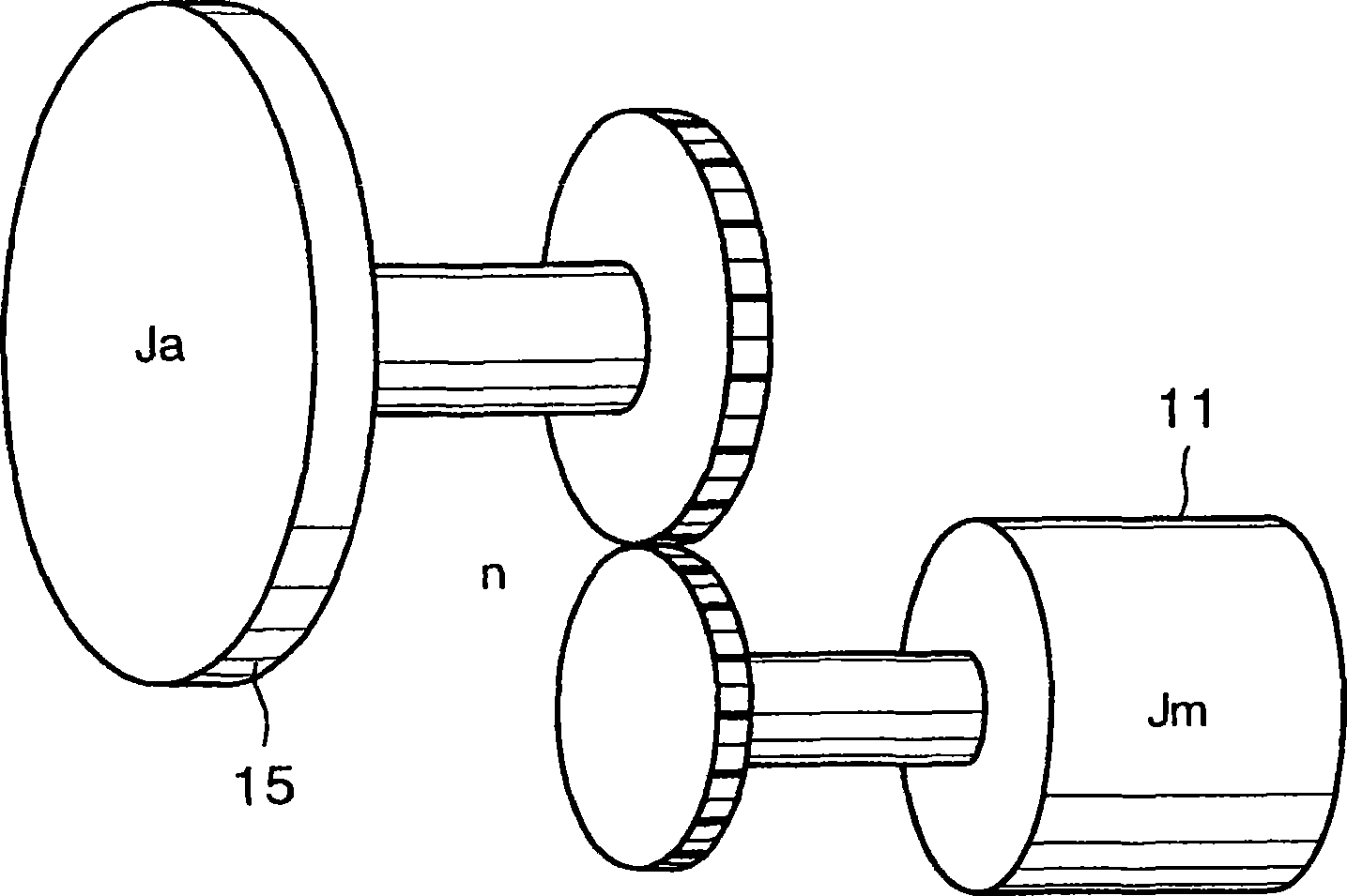

[0032] according to Figure 1 to Figure 4 One embodiment of the present invention will be described. figure 1 is an overall configuration diagram of a robot system representing an embodiment, figure 2 yes means figure 1 A block diagram of the electrical system of the robotic system is shown, image 3 is a model diagram of a joint consisting of an arm and a motor, Figure 4 is the correspondence between the load torque and the angle of the arm.

[0033] exist figure 1 Among them, the robot system 1 has: a control device 30 that has a servo control unit 33 that controls the robot 3, and has a teaching function as a position recognition unit for teaching the end Ts (working point) of the robot 3; The operation device 40 executes the operation of the robot 3 and also has a release operation switch 43 as a command unit for turning the servo control unit 33 on and off.

[0034] The robot 3 has: a main body 5, which is set upright; a first arm 15, which is connected to the mai...

Embodiment 2

[0062] In the above-mentioned embodiment, the duty cycle of switching on and off of the brake 13 is changed according to the angle difference between the arm 15 and the stopper 17. The following description also considers the speed of the arm 15 to make the switching on and off of the brake 13 Example of duty cycle variation.

[0063] Formula (3) above is reformulated as follows.

[0064] ω=dθ / dt=[(TL-Tb) / J 0 〕t

[0065] Integrating both sides of this formula becomes the following formula.

[0066] θ=(TL-Tb)t 2 / (2J 0 )+B……(7)

[0067] Since θ=0 at t=0, the integral constant B=0.

[0068] θ=(TL-Tb)t 2 / (2J 0 ) ……(8)

[0069] In the above formula (8), assuming that the load torque TL is a constant value regardless of the angle difference, when the arm 15 exceeds the maximum rotation speed ωmax, the deceleration of the arm 15 is made constant by the restraint brake 13 . Because the deceleration is constant, the deceleration time is proportional to the angle differen...

Embodiment 3

[0076] The first embodiment described above is provided with a stopper 23 that limits the rotation of the arm 15. In this embodiment, in the robot 3 that can contact the main body 5 and the end As of the second arm 17 as the work point, the arm 17 is prevented from being rotated. The control of the stopper 13 in which the end As is in contact with the main body 5 will be described.

[0077] The robot system of the present embodiment and figure 1 The same as shown, including the second joint part 20 and constituted as follows Figure 9 electrical system shown. Figure 9 in, with figure 2 The same reference numerals denote the same parts, and explanations thereof are omitted. exist figure 1 and Figure 9 Among them, the robot 3 has two joints 10, 20, the first joint 10 is driven by the first motor 11, and the second joint 20 has: the second motor 111, which drives the arm 17; the second position as the second position detection unit A detector 112 detects the rotational p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com