Drum type washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve problems such as difficult outflow of lint, water leakage, troublesome installation of lint-collecting filter, etc., and achieve the effect of easy cleaning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

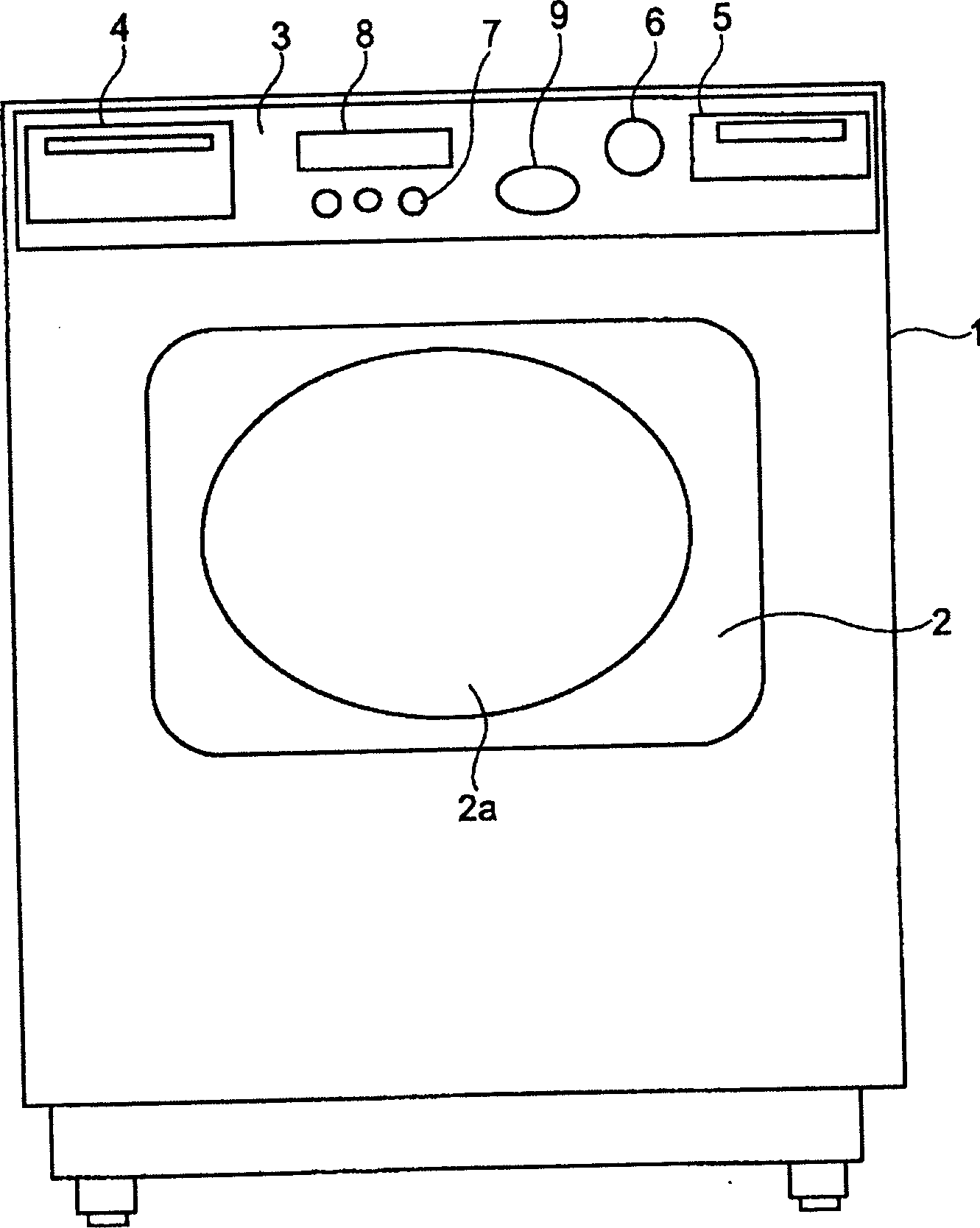

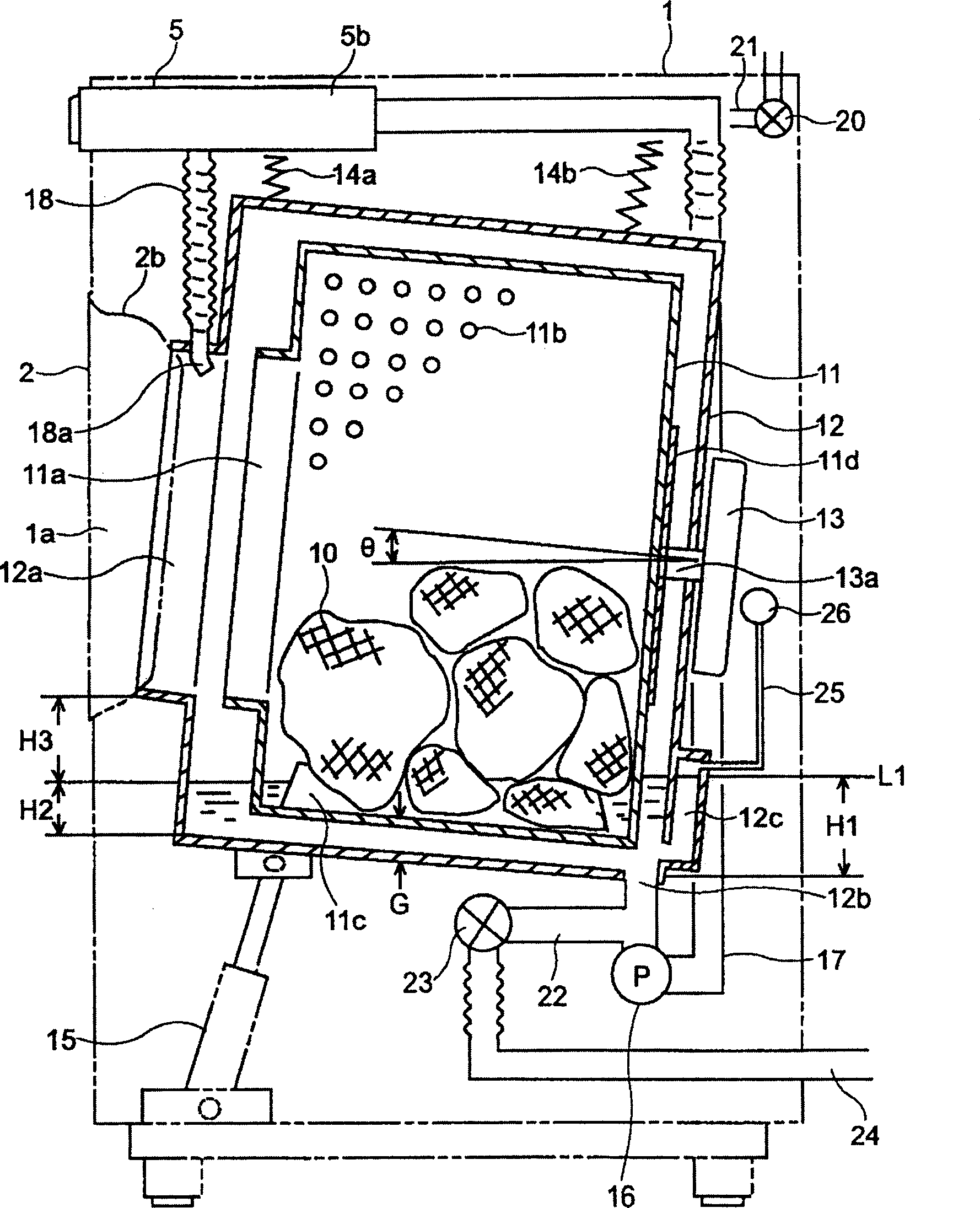

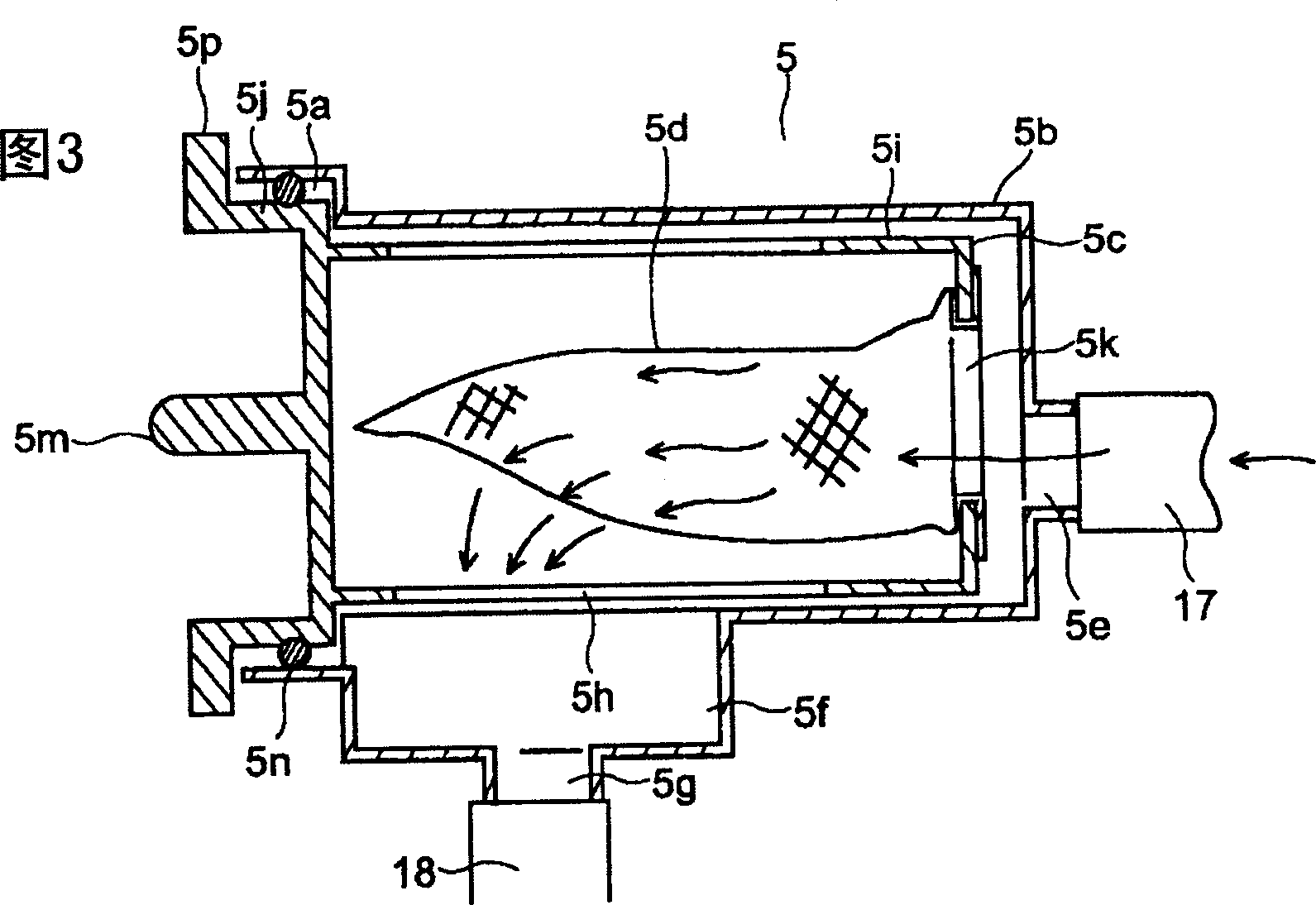

[0025] Embodiment 1 of the present invention will be described with reference to the drawings.

[0026] figure 1 It is the front view of the front-loading-type washing machine of Example 1, figure 2 It is a longitudinal sectional side view of its internal mechanism, FIG. 3 is a longitudinal sectional side view of the thread end catcher mechanism, and FIG. 4 is a plan view showing the installation structure of the thread end catcher mechanism to the outer frame without the top plate, Figure 5 It is an exploded perspective view showing the attachment structure of the thread capture mechanism to the outer frame.

[0027] The outer frame 1 of the drum-type washing machine of Embodiment 1 is in the shape of a box, and the clothing loading and unloading window 1a formed at a position slightly higher than the center of the front central part can be covered by the clothing loading and unloading cover 2 with a transparent window 2a. It is constructed so that it can be opened and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com