Roll core and electrode body manufacturing method using same

A manufacturing method and electrode body technology, applied in secondary battery manufacturing, winding/folding electrodes, battery electrodes, etc., can solve the problems of electrode body quality degradation, separator tearing, and core cost increase, and achieve the purpose of suppressing damage , prevent slipping, and prevent quality reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

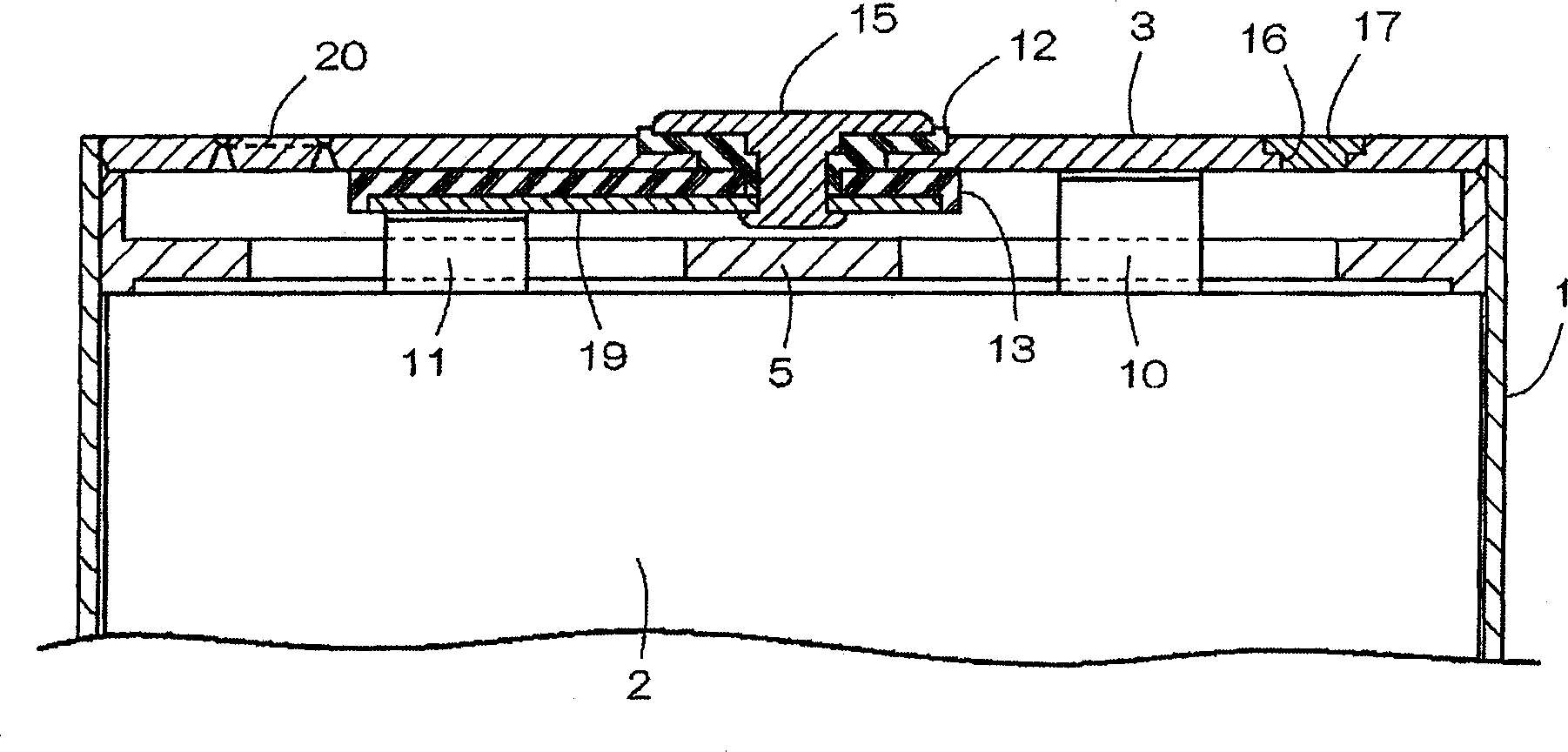

[0027] exist image 3 and Figure 4 Among them, the thin and sealed rectangular battery of the present invention comprises: a bottomed square battery case 1 with long left and right lateral openings; an electrode body 2 and a non-aqueous electrolyte contained in the battery case 1; the opening of the battery case 1 is blocked The upper left-right laterally long cover 3 and the plastic insulator 5 disposed inside the cover 3 are provided. The battery case 1 is a clad material made of nickel and aluminum, which is deep-drawn to form a thin case that is long in the vertical direction. The left and right width of the battery case 1 is 34 mm, the vertical height is 50 mm, and the front and rear thickness is 3.8 mm.

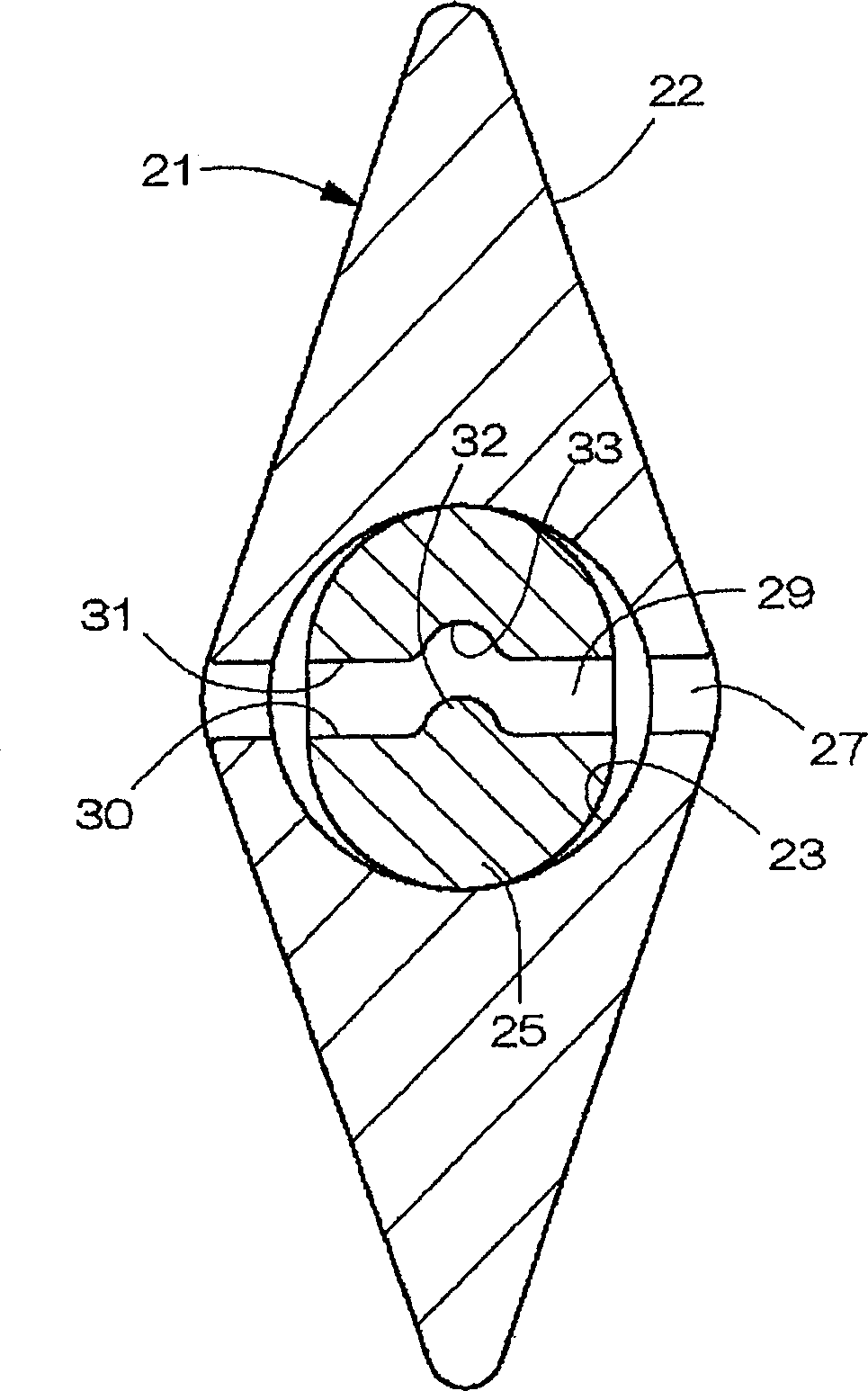

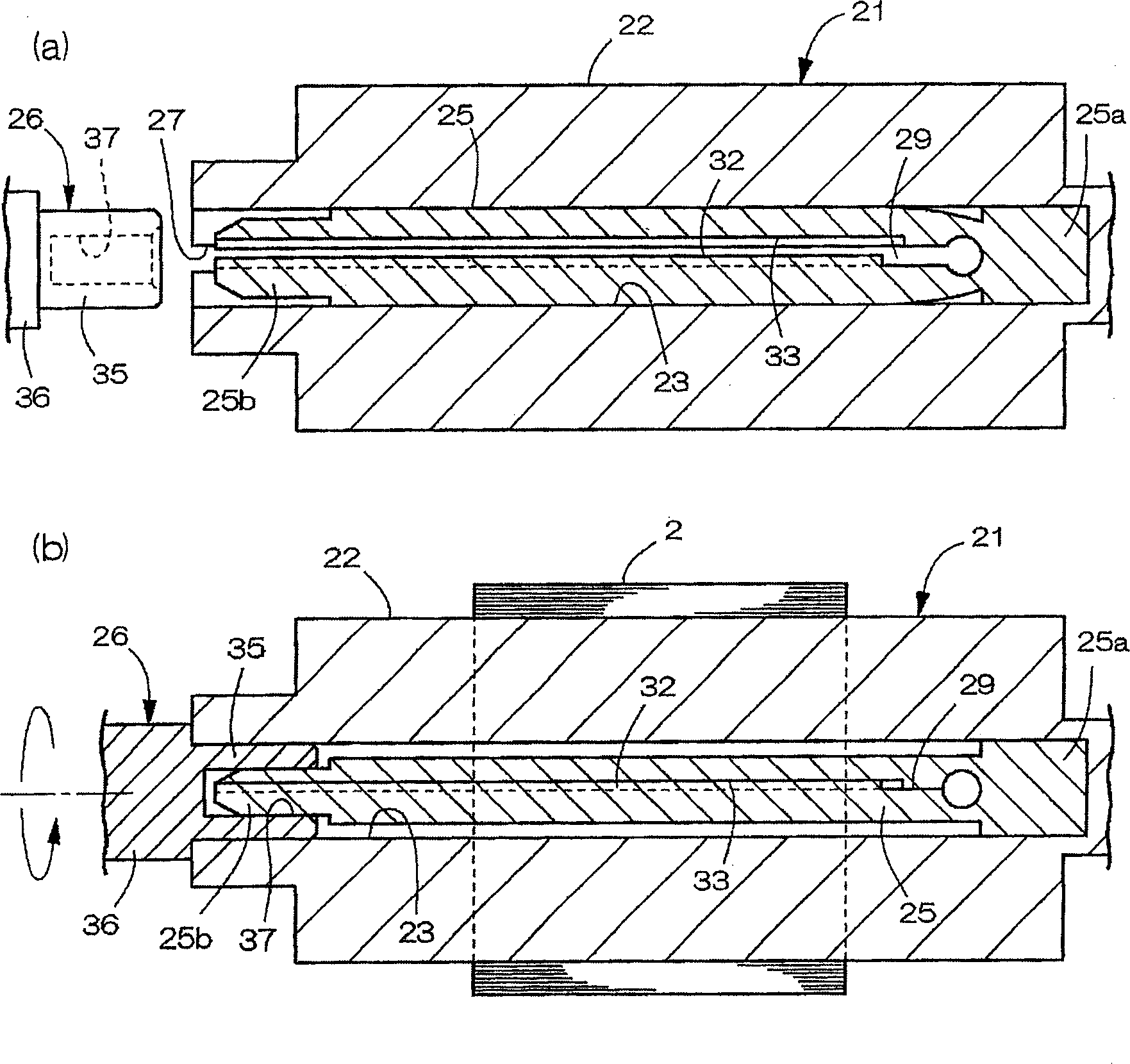

[0028] The electrode body 2 is formed by spirally winding a strip-shaped separator 9 made of a microporous polyethylene film (polyethylene film) between the strip-shaped positive electrode 6 and the strip-shaped negative electrode 7 . After winding, the electrode bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com