Novel fire-retardant core

A flame arresting technology, applied in fire rescue, pipeline system, mechanical equipment, etc., can solve the problems of high cost, failure to prevent explosion, complex structure of composite flame arrester, etc., achieve low cost, improve safety, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

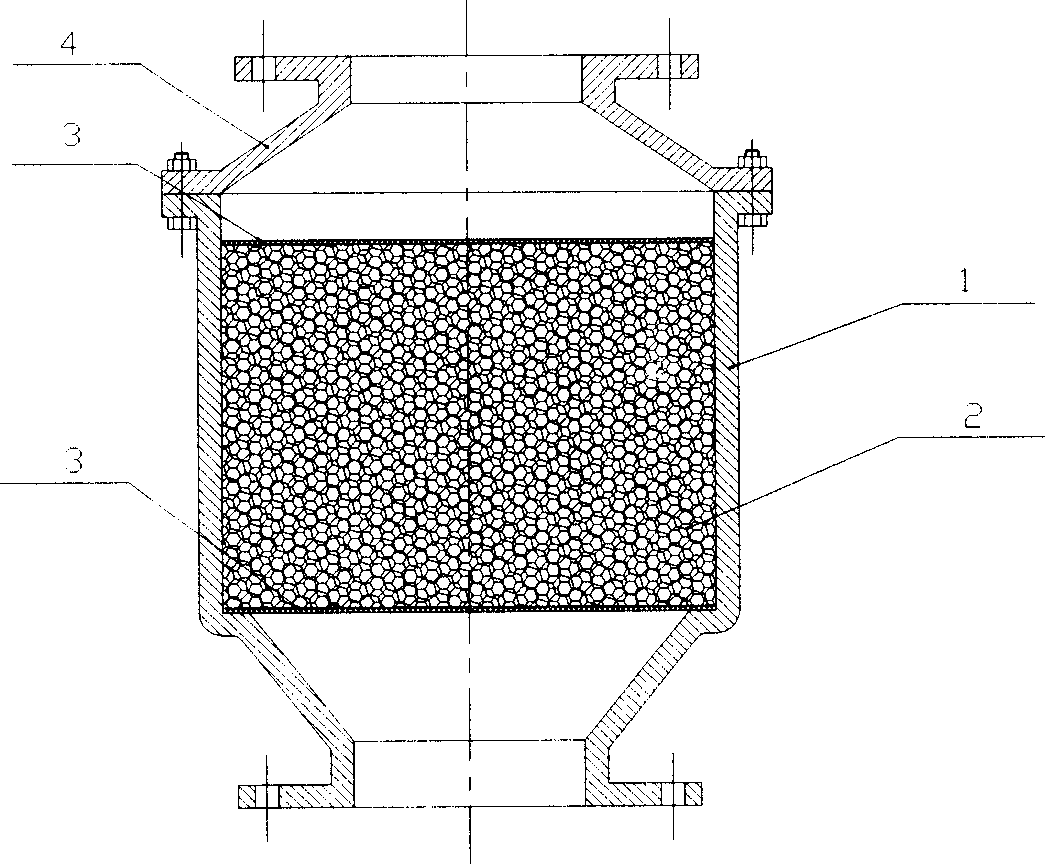

[0009] Accompanying drawing is the embodiment that the present invention is used for the vent pipe of petroleum storage tank.

[0010] In the figure, the flame arrester is composed of a shell 1, a fire arresting core 2, a wire mesh 3 for fixing the fire arresting core and an upper cover 4. The lower end of the shell 1 is connected with the vent pipe of the oil storage tank through the flange, and the upper shell 4 is connected with the breather valve of the oil tank.

[0011] The fire retardant core 2 adopts a structure with a certain thickness and elasticity, which is formed by spirally forming a ribbon metal material and then wound, has a good space flow channel, and the size of the flow channel can decrease with the increase of the pressure. Use the constantly changing, small and uneven space flow channels and the good heat dissipation of metal materials to block the flame propagation; at the same time, use the excellent elastic deformation capacity of the structure to slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com